Non-metal-doped de-nitration catalyst and preparation method thereof

A denitration catalyst and non-metal technology, applied in the field of denitration catalysts, can solve the problems of general engineering application prospects, poor water resistance of the catalyst, and the catalyst reaction temperature window has not been expanded, and achieves increased catalytic activity, good engineering application prospects, and widened The effect of the reaction temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

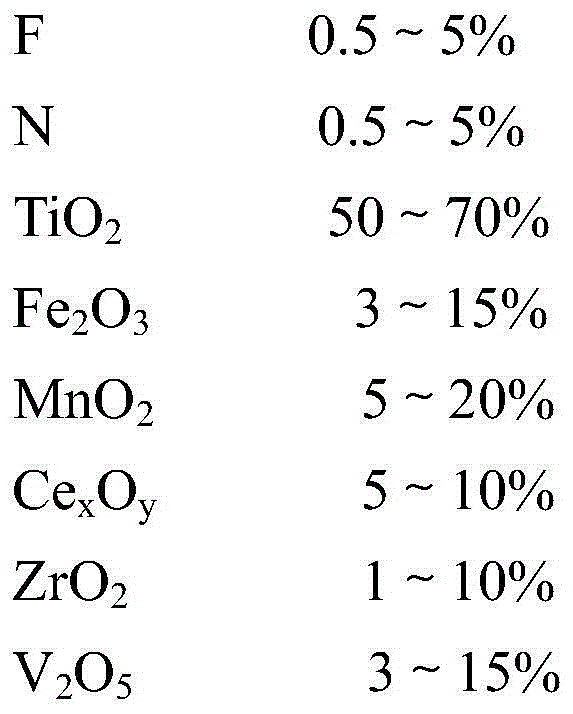

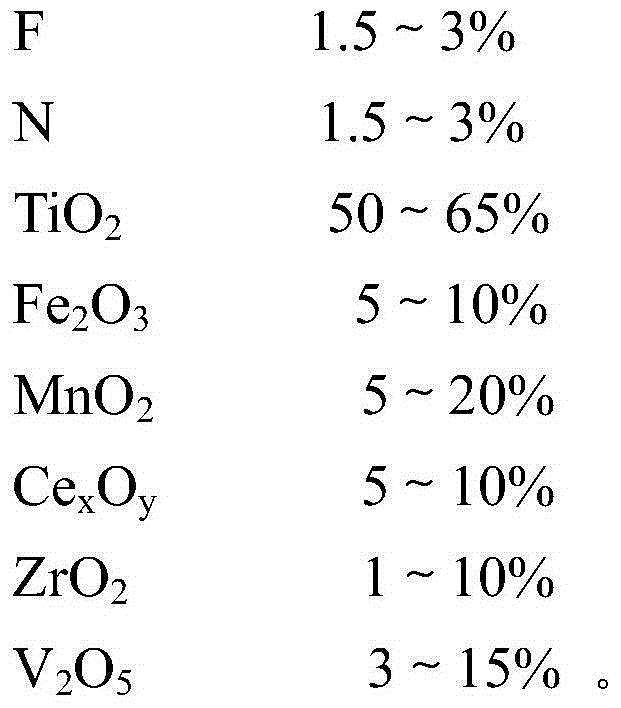

Method used

Image

Examples

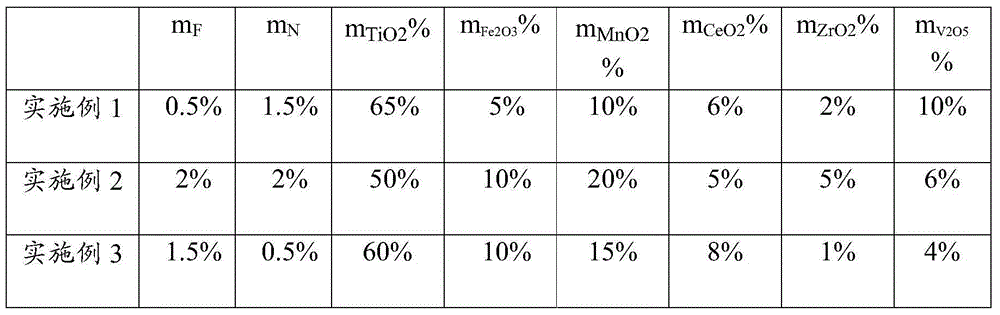

Embodiment 1

[0043] Preparation of non-metal doped denitrification catalyst

[0044] (1) Dry mixing: Take 10g NH 4 F, 32gCO(NH 2 ) 2 , 650gTiO 2 Powder, 28gFeC 2 o 4 2H 2 O, 282gMn(CH 3 COO) 2 4H 2 O, 151gCe(NO 3 ) 3 ·6H 2 O, 70gZr(NO 3 ) 4 ·5H 2 O, 32gNH 4 VO 3 , 120g glass fiber, 64g carboxymethyl cellulose, 50g stearic acid, put the above various solids together in a dry powder mixer and mix them for 15 minutes;

[0045] (2) Kneading: 130ml of water and 100ml of glycerin are added to the above mixture, and the kneading process is started for 30 minutes;

[0046] (3) Mud refining: pass the kneaded plastic material through a sieve plate or into a vacuum mud refining machine to remove excess water and gas in the material;

[0047] (4) Extrusion molding: the dense and uniform mud section obtained after mud refining enters the extruder, and is extruded by a honeycomb steel mold to obtain a catalyst green body;

[0048] (5) Drying and roasting: Dry at 60°C for 10 hours, hea...

Embodiment 2

[0050] Preparation of non-metal doped denitrification catalyst

[0051] (1) Dry mixing: take 41gNH 4 F, 43gCO(NH 2 ) 2 , 500gTiO 2 Powder, 56gFeC 2 o 4 2H 2 O, 564gMn(CH 3 COO) 2 4H 2 O, 126gCe(NO 3 ) 3 ·6H 2 O, 174gZr(NO 3 ) 4 ·5H 2 O, 19gNH 4 VO 3 , 150g glass fiber, 64g sodium carboxymethyl cellulose, 60g stearic acid; various solids are placed together in a dry powder mixer and mixed for 15 minutes;

[0052] (2) Kneading: Add 120ml of water and 120ml of glycerin to the above mixture, and start the kneading process for 20 minutes;

[0053] (3) Mud refining: pass the kneaded plastic material through a sieve plate or into a vacuum mud refining machine to remove excess water and gas in the material;

[0054] (4) Extrusion molding: the dense and uniform mud section obtained after mud refining enters the extruder, and is extruded by a honeycomb steel mold to obtain a catalyst green body;

[0055] (5) Drying and roasting: drying at 70°C for 8 hours, then heatin...

Embodiment 3

[0057] Preparation of non-metal doped denitrification catalyst

[0058] (1) Dry mixing: take 31gNH 4 F, 11gCO(NH 2 ) 2 , 600gTiO 2 Powder, 56gFeC 2 o 4 2H 2 O, 422gMn(CH 3 COO) 2 4H 2 O, 202gCe(NO 3 ) 3 ·6H 2 O, 35gZr(NO 3 ) 4 ·5H 2 O, 13gNH 4 VO 3 , 120g glass fiber, 64g sodium carboxymethylcellulose and 50g stearic acid. Mix all kinds of solids together in a dry powder mixer for 15 minutes;

[0059] (2) Kneading: Add 120ml of water and 128ml of glycerin to the above mixture, and start the kneading process for 30 minutes;

[0060] (3) Mud refining: pass the kneaded plastic material through a sieve plate or into a vacuum mud refining machine to remove excess water and gas in the material;

[0061] (4) Extrusion molding: the dense and uniform mud section obtained after mud refining enters the extruder, and is extruded by a honeycomb steel mold to obtain a catalyst green body;

[0062] (5) Drying and roasting: drying at 70°C for 8 hours, then heating up to 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com