Patents

Literature

65results about How to "Good catalytic activity at low temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Honeycomb metal wire net carrier catalyst for catalytically reducing nitrogen oxide and preparing method thereof

InactiveCN101015800AHigh activityGood dispersionDispersed particle separationCatalyst activation/preparationCeriumHoneycomb like

The invention relates to a honeycomb metal network carrier catalyst for catalyzing and reducing nitrogen oxide, and relative preparation, used in vehicle tail gas purification technique. The invention comprises metal carrier and catalyst, characterized in that the catalyst is load-type catalyst, the catalyst carrier is honeycomb metal network carrier carrying gamma-Al2O3 coat, referring coat mass, the content of TiO2 is 14.0-20.0wt% and the content of CeZrO is 3.0-6.0wt%, and referring to catalyst mass, the content of active component palladium is 0.1-1.0wt%, and the preparation comprises that preparing TiO2 gel, preparing TiO2 coat at the face of carrier, loading cerium zirconium oxide on carrier, leading in catalyst active component palladium. The invention has the advantages that the invention can improve mass transfer and heat transfer in catalyst, the catalyst has higher catalysis activity in low-temperature oxygen-abundant condition, wide active temperature window, simple preparation and low cost.

Owner:DALIAN UNIV OF TECH

Rare-earth modified sulfur-resisting low-temperature SCR catalyst and preparing method thereof

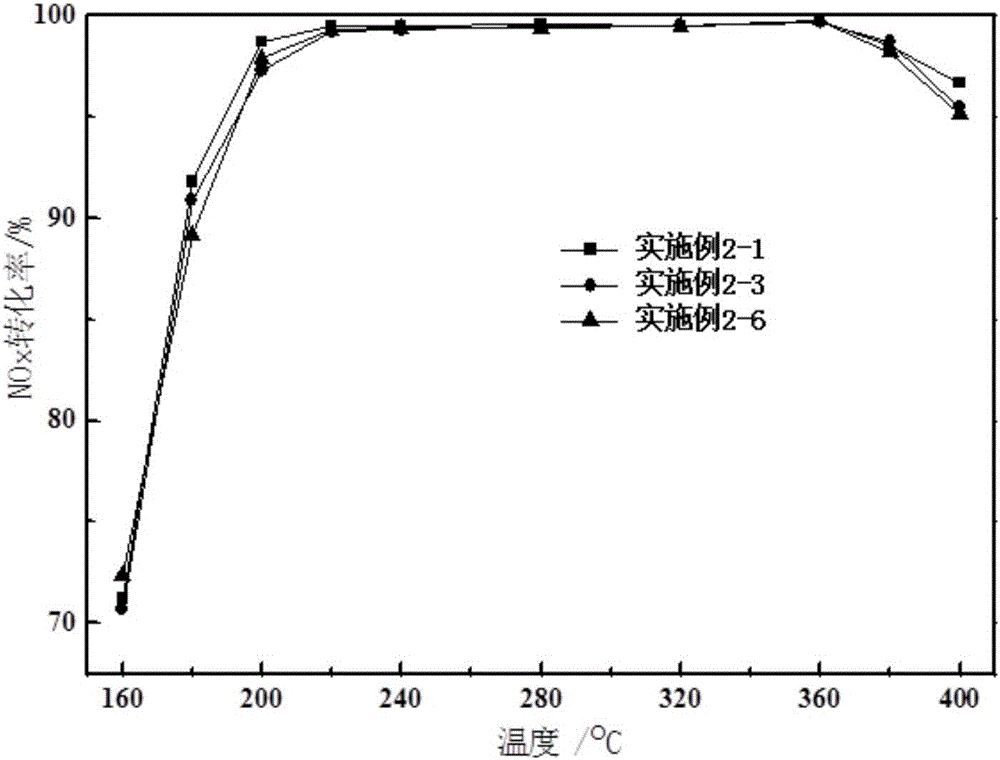

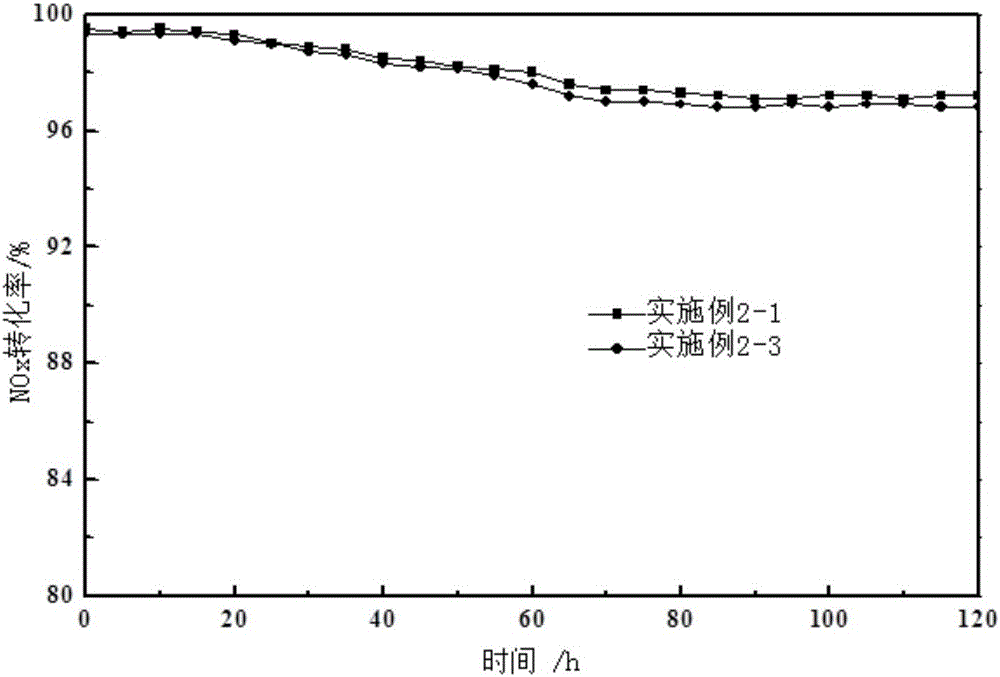

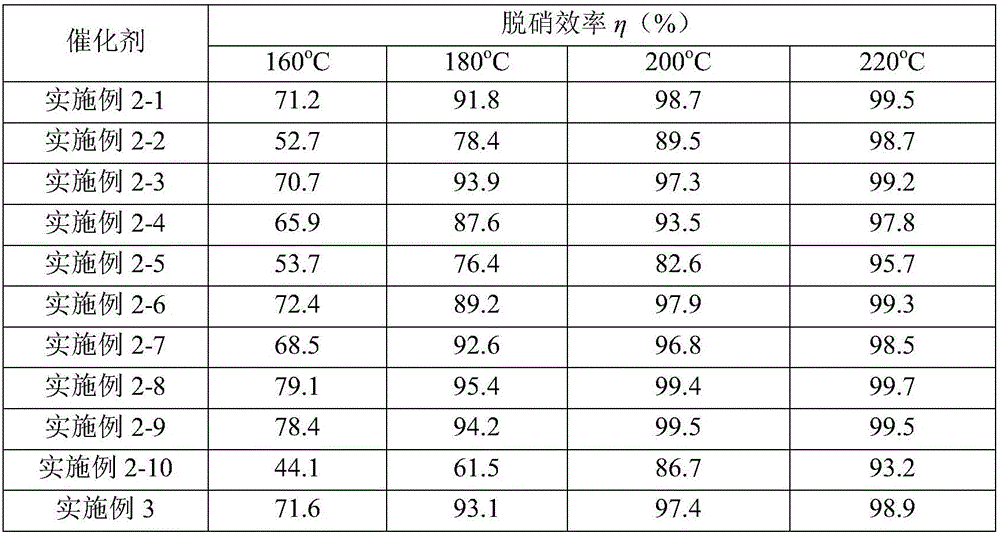

ActiveCN105817220AHigh low temperature activityHigh catalytic activityNitrous oxide captureGas treatmentRare earthUltimate tensile strength

The invention relates to a rare-earth modified sulfur-resisting low-temperature SCR catalyst and a preparing method thereof. The catalyst is composed of a carrier, an activity component and a performance additive component. The preparing method of the catalyst comprises the step one of catalyst powder preparation and the step two of pug treatment and formation. A certain amount of rare earth oxide is doped, acid site strength of the surface of the catalyst is improved, the number is increased, low-temperature activity of the catalyst is improved, a temperature window is broadened, the NOx removing rate of the catalyst within the range of 170-400 DEG C is kept to be 95% or above, and the application field of the denitration technology is broadened; meanwhile, production raw materials of the catalyst are easy to obtain, the preparing process is simple, and industrial production and market popularization can be achieved easily.

Owner:展宗城

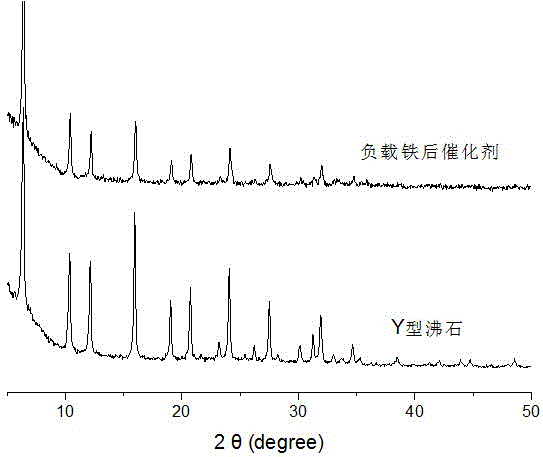

Regenerable heterogeneous Fenton catalyst, and preparation method and application thereof

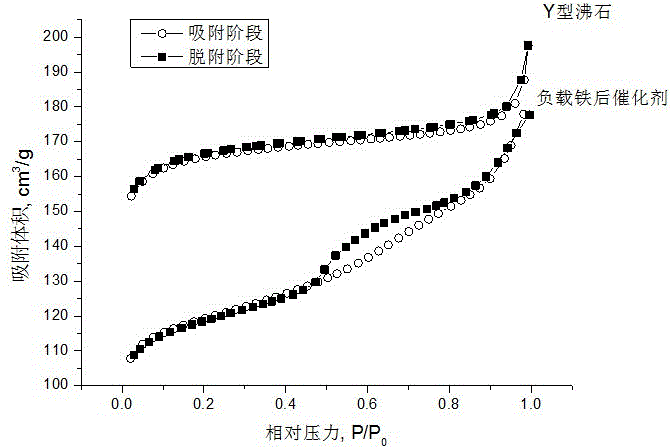

ActiveCN105478155AImprove stabilityGood regeneration performanceMolecular sieve catalystsWater treatment compoundsPhenolPollution

The invention specifically relates to a regenerable heterogeneous Fenton catalyst, and a preparation method and application thereof, which belongs to the technical field of industrial catalysts. The catalyst provided by the invention uses commercial zeolite as a carrier and is prepared through the following steps: surface modification of the carrier with a high polymer; loading of an active component Fe or Co; and roasting so as to form an iron or cobalt compound-valence oxide on the surface of zeolite. The catalyst shows high-efficiency degradability to industrial intractable organic waste water containing phenols, dyes or the like, and the degradation rate of organic matters in waste water is up to more than 90% at room temperature (less than 30 DEG C) under an almost neutral condition (wherein a pH value is in a range of 6 to 8); and the catalyst has good regeneration performance. According to the method, the heterogeneous Fenton catalyst is used for oxidation removal of organic matters like phenols and dyes in waste water, so cost is low and no secondary pollution is produced; and a process for treating waste water with the Fenton catalyst is a promising organic waste water treatment process.

Owner:FUDAN UNIV

Catalyst used for preparing glycol from hydrogenation of oxalates and preparation method thereof

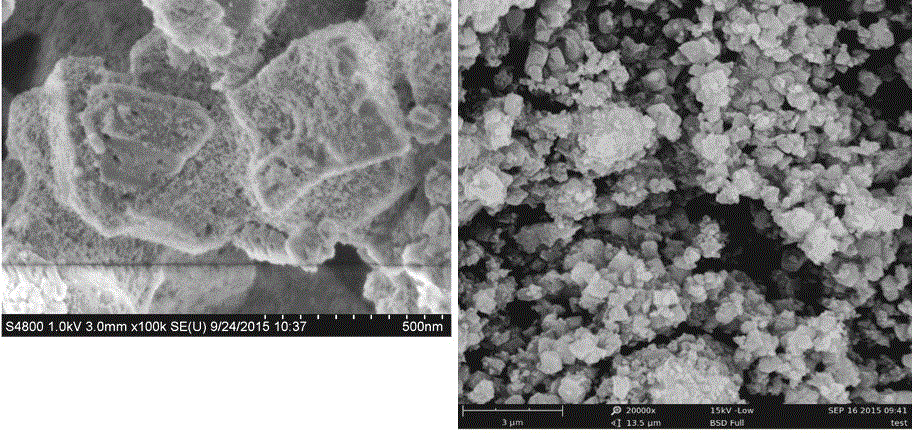

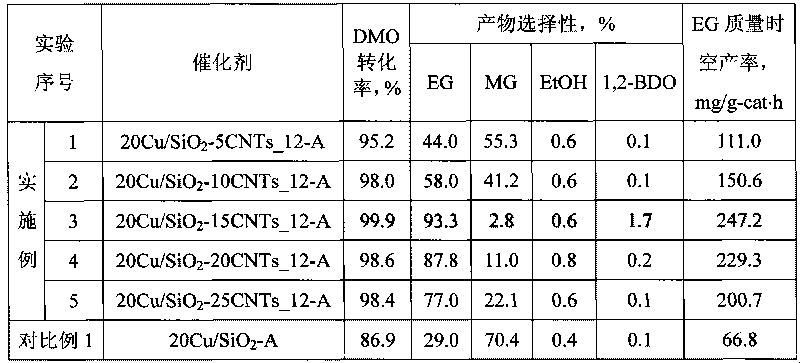

InactiveCN101757915AImprove performanceSimple preparation processOrganic compound preparationHydroxy compound preparationAdditive ingredientCarbon nanotube

The invention relates to a catalyst used for preparing glycol from hydrogenation of oxalates and a preparation method thereof. The invention is characterized in that carbon nano tubes are added in hydrogenation of oxalates catalyst for preparing efficient carbon nano tube glycol copper-silicon based catalyst with promoting effect for hydrogenation of oxalates, which has environmentally friendly features, high activity and high selectivity. The catalyst contains copper, silicon dioxide and carbon nano tubes. The chemical formula of the catalyst is xCu / SiO2-yCNTs, wherein x% indicates that the mass percent of copper in the catalyst is x%, y% indicates that the mass percent of the carbon nano tubes in the catalyst is y%, and CNTs indicates multi-wall carbon nano tubes. The catalyst contains the ingredients in mass percent: 5-60 of Cu, 0.5-30 of CNTs and balance of SiO2. The catalyst is prepared in a method of coprecipitation, and is obtained after oven-drying, furnacing and reduction.

Owner:XIAMEN UNIV

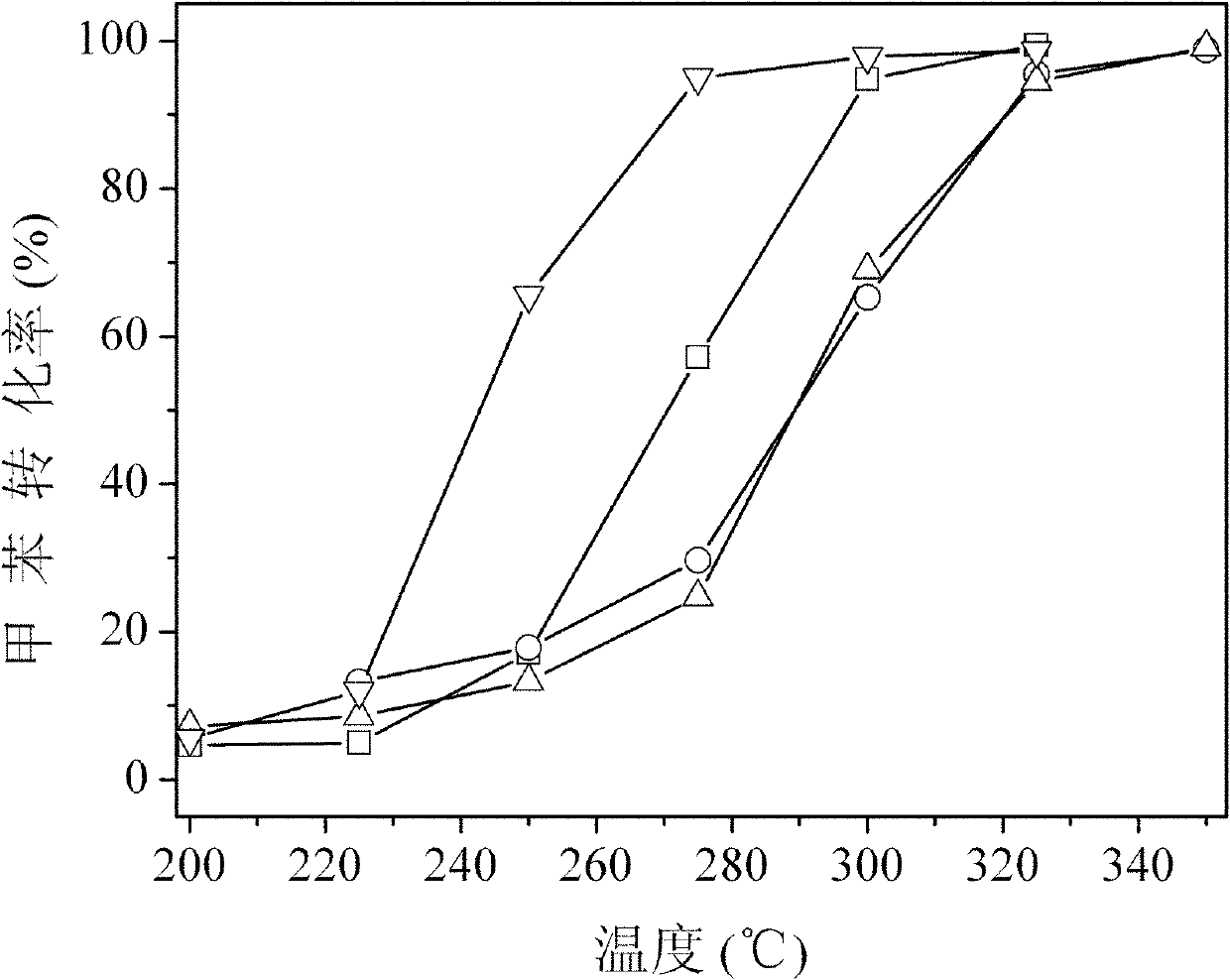

Sliver-based bimetallic catalyst for catalyzing oxidation of volatile organic contaminant, preparation method and application thereof

InactiveCN101992105AStable structureUnique synergyDispersed particle separationCatalyst activation/preparationSynthesis methodsCatalytic oxidation

The invention claims a sliver-based bimetallic catalyst, a preparation method and application thereof, wherein the catalyst takes mesoporous molecular sieves such as SBA-15, MCM-41 or MCM-48 and etc. and oxides such as aluminium oxide, silicon oxide and cerium oxide and the like as carriers; the active ingredient of the catalyst is sliver, the second ingredient is M which is any one of transition metal selected from the group consisting of Cu, Co, Ce and Mn and etc. The synthetic method of the catalyst is characterized in that the operation is simple and easy, the synergistic effects of selected different transition metals selected to the sliver type are different, taking copper as an example, when Ag: Cu is more than 1: 2 but not more than 2: 1, the catalyst presents an obvious synergistic effect between metals, and the catalytic oxidation reactivity of volatile organic contaminant (VOC) is obviously improved. Simultaneously, the sliver-based bimetallic catalyst provided by the invention has the advantages that the price of transition metal which is used is low by comparing with platinum, palladium and gold and etc., the resource of the transition metal is rich, the catalyst is suitable for mass production and industrial application and the application value and the application prospect are good.

Owner:DALIAN UNIV OF TECH

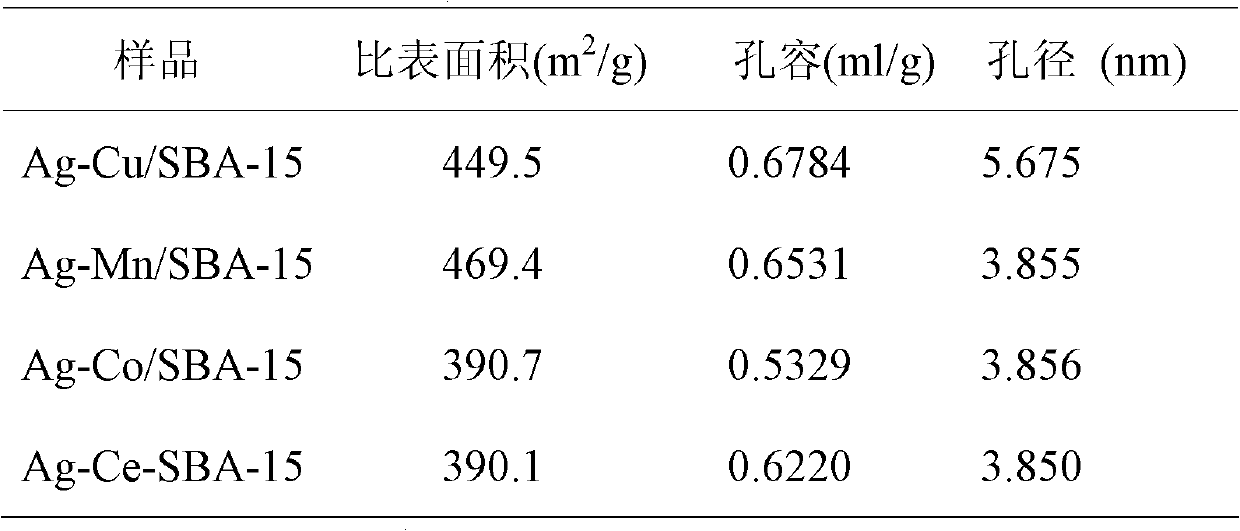

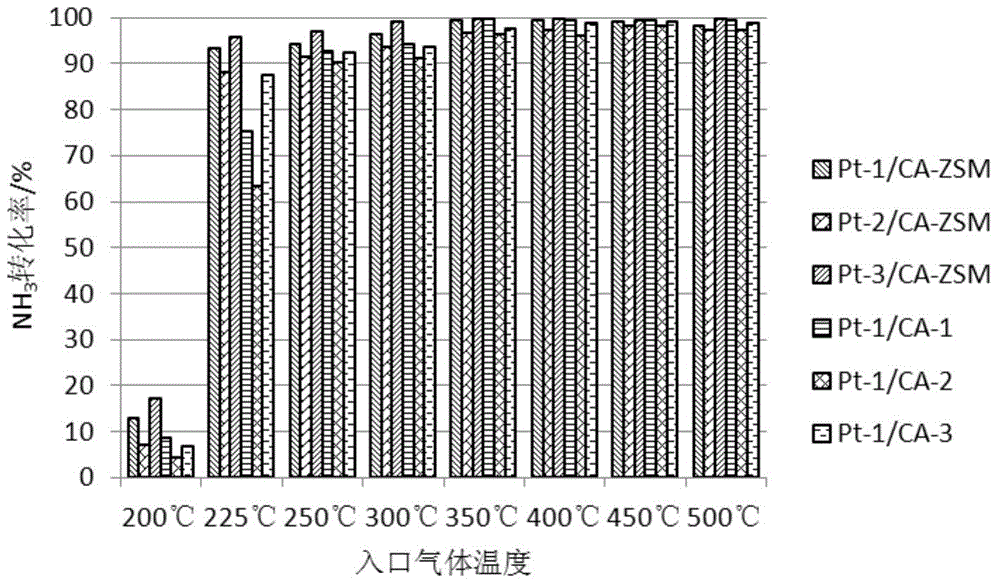

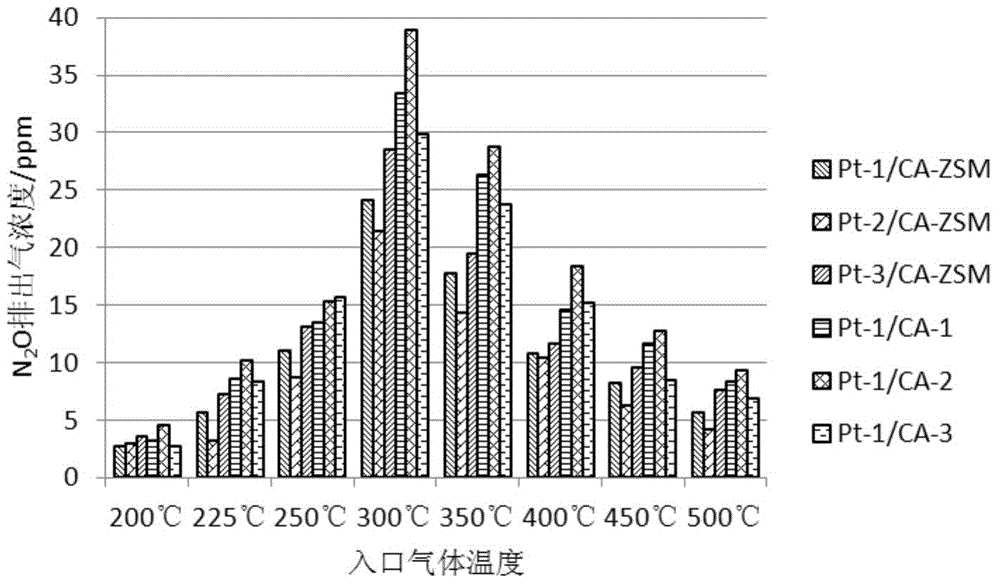

Platinum/cerium aluminum-molecular sieve catalyst for catalytic oxidation of ammonia gas and preparation method thereof

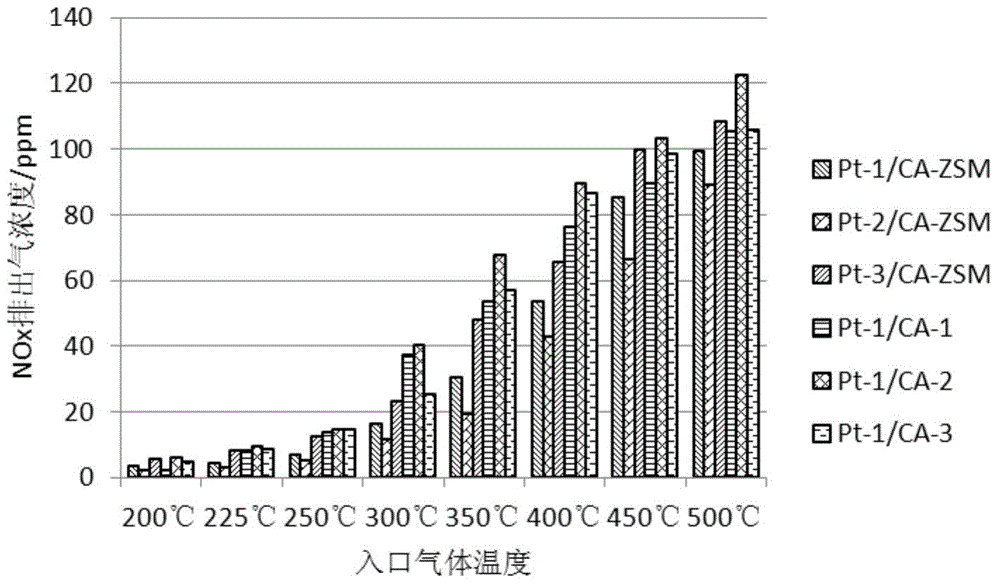

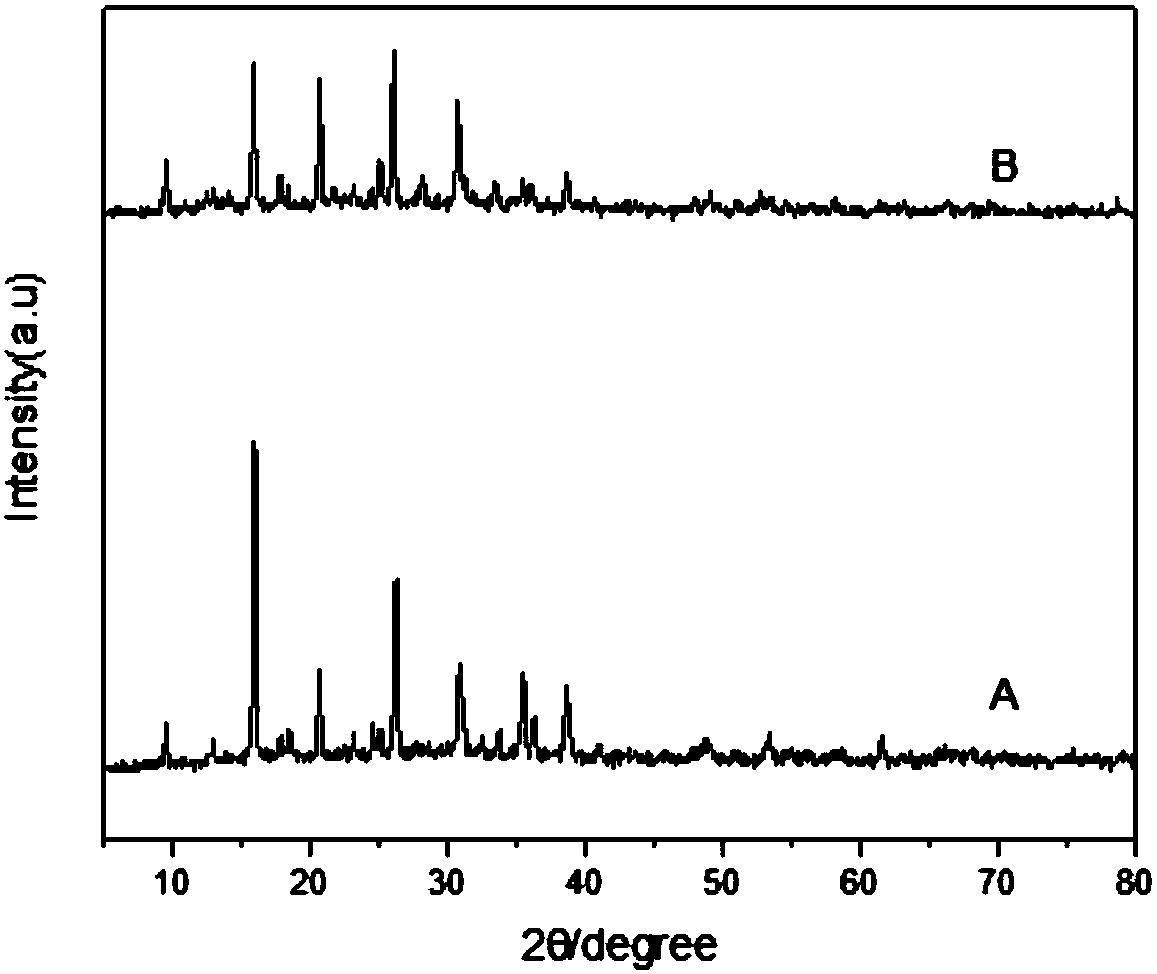

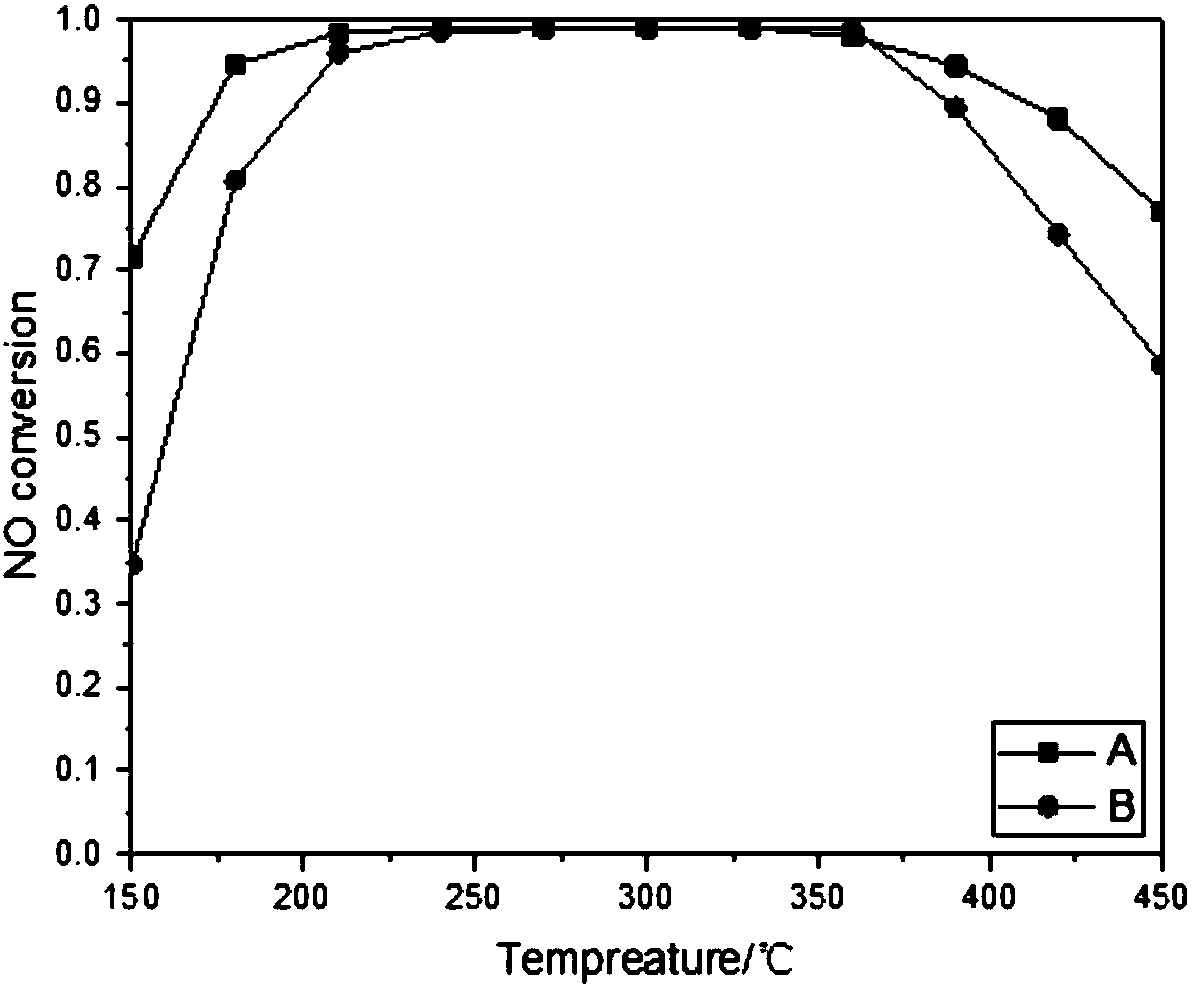

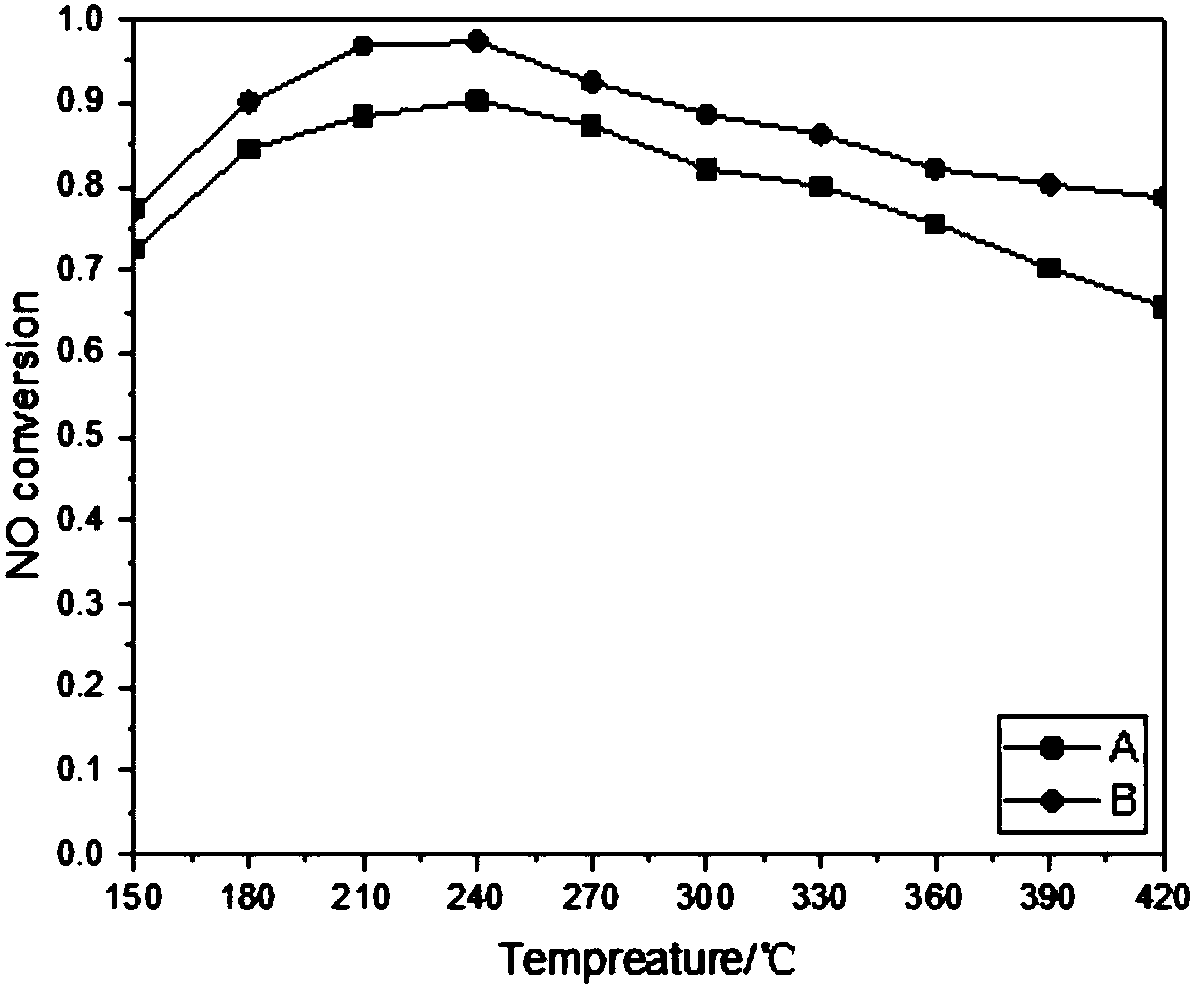

ActiveCN104888845ASuppress generationGood catalytic activity at low temperatureNitrous oxide captureMolecular sieve catalystsCatalytic oxidationCerium

The invention provides a platinum / cerium aluminum-molecular sieve catalyst for catalytic oxidation of an ammonia gas. Cordierite ceramic is utilized as a carrier for the platinum / cerium aluminum-molecular sieve catalyst, the surface of the carrier is coated with a catalyst layer, and the catalytic active site of the catalyst layer consists of a noble metal platinum, a cerium-aluminum composite oxide and a neodymium-modified molecular sieve; the mass ratio of the cerium-aluminum composite oxide to the neodymium-modified molecular sieve to the noble metal platinum is (20-80):(20-80):(0.01-0.1), and the mass ratio of cerium oxide and aluminum oxide in the cerium-aluminum composite oxide is (1-3):(1-5); the mass ratio of neodymium oxide and a molecular sieve in the neodymium-modified molecular sieve is (1-10):(90-100). The platinum / cerium aluminum-molecular sieve catalyst is also capable of achieving wide low-temperature activity window, good catalytic activity and high selectivity even at a high space velocity (SV), and is capable of effectively restraining generation of secondary pollutants of N2O, NO and NO2. The invention further provides a preparation method of the platinum / cerium aluminum-molecular sieve catalyst.

Owner:SINOCAT ENVIRONMENTAL TECH

Preparation method of Cu-Ce-La-SSZ-13 molecular sieve catalyst

ActiveCN108128784AThe synthesis steps are simpleActive ingredients increasedMolecular sieve catalystsDispersed particle separationSulfurActive component

The invention discloses a preparation method of a Cu-Ce-La-SSZ-13 molecular sieve catalyst. The method is characterized in that a molecular sieve structure guide agent is formed jointly through addingCe(NO)3.6H2O and La(NO)3.6H2O after preliminary complexation of Cu<2+> and tetraethylene pentamine, and a Cu-Ce-La-SSZ-13 molecular sieve is synthesized through one step. The preparation method disclosed by the invention is simple; lanthanum as a third active component is introduced, so that the stability of the lanthanum in the molecular sieve and the oxidation capacity of the molecular sieve are improved. The Cu-Ce-La-SSZ-13 molecular sieve prepared by the preparation method disclosed by the invention has excellent low-temperature catalytic activity, the SCR activity reaches above 90 percent at a temperature of 180 DEG C, and meanwhile, the water resistance and the sulfur resistance are improved.

Owner:NANJING UNIV OF SCI & TECH

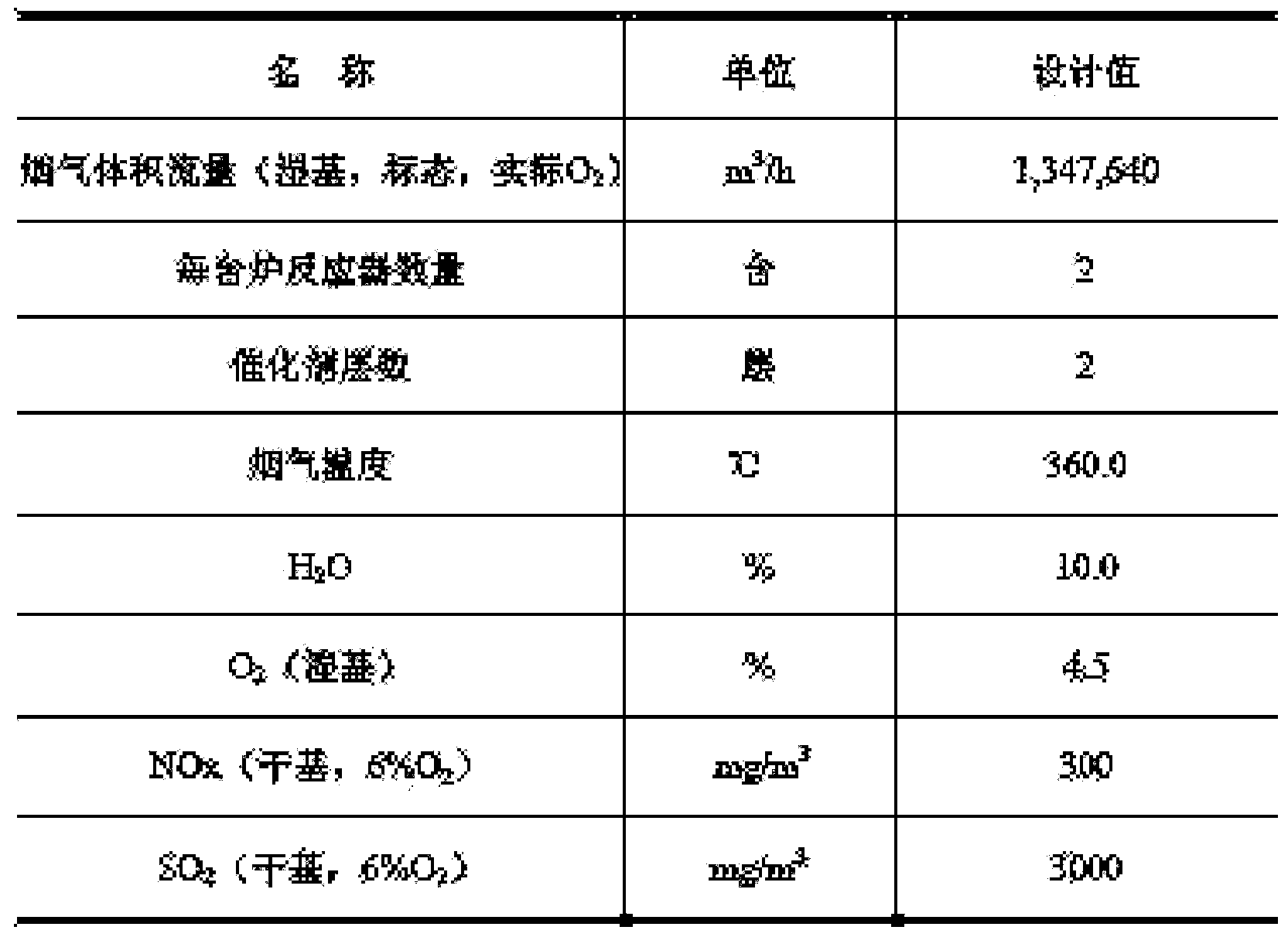

Method for removing NOx in sintering flue gas through low-temperature SCR (Selective Catalytic Reduction) catalyst

InactiveCN105561781ASolve the purchaseSolve a series of problems such as transportation and warehousingGas treatmentDispersed particle separationWater vaporSorbent

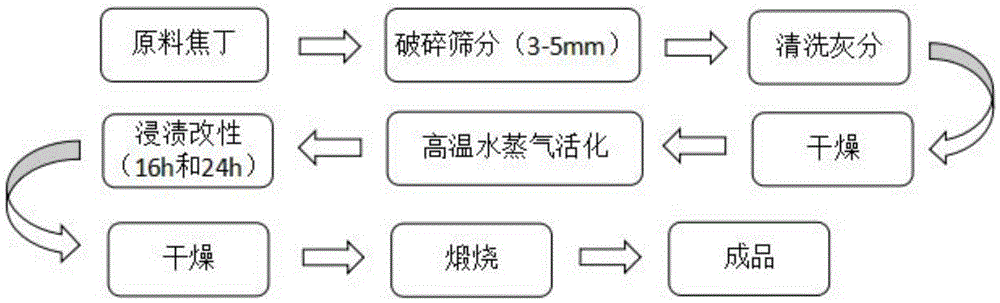

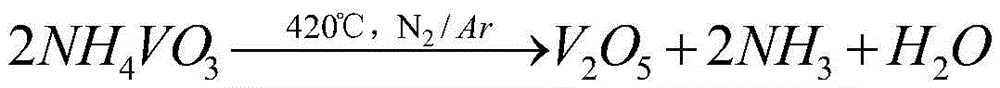

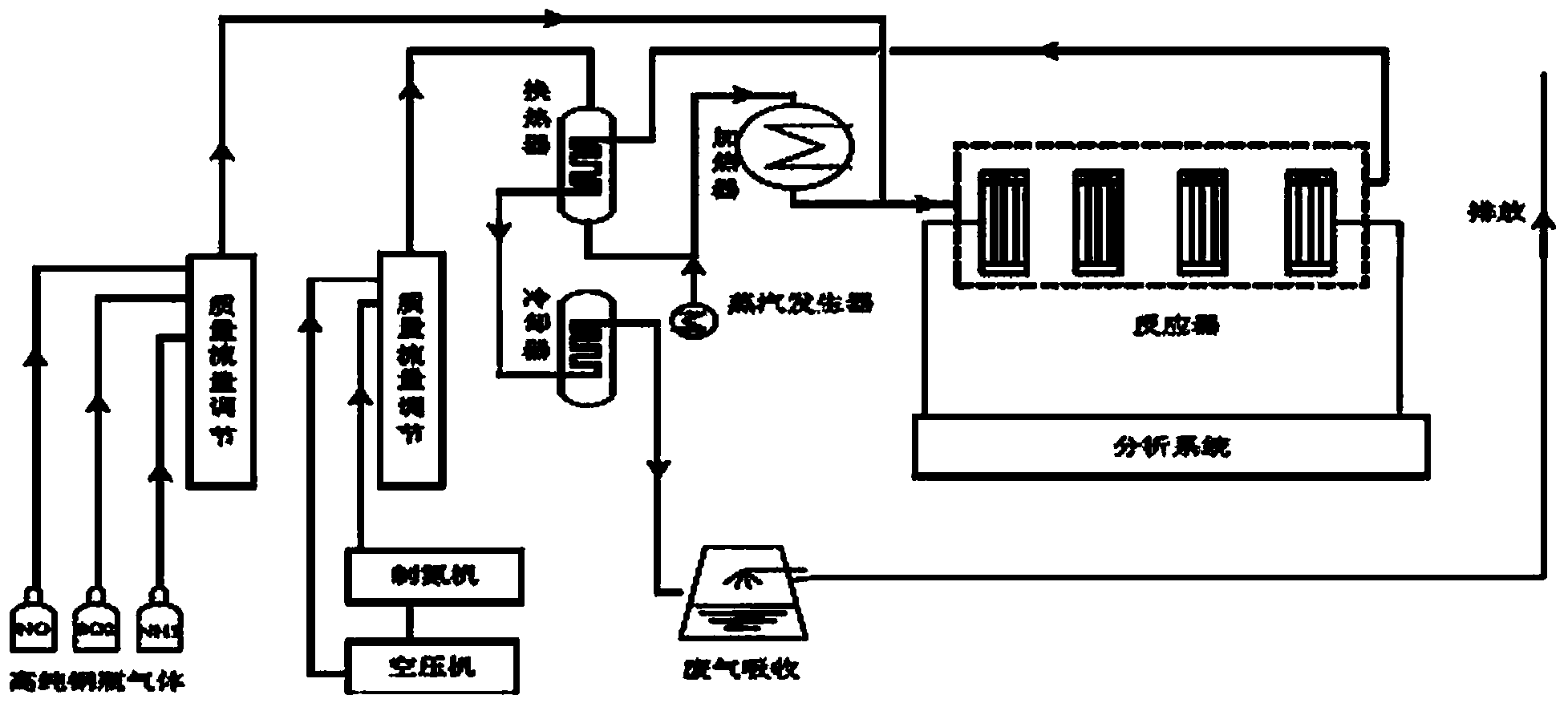

The invention discloses a method for removing NOx in sintering flue gas through a low-temperature SCR (Selective Catalytic Reduction) catalyst based on a metallurgy coke nut adsorbent. The method comprises the following steps: (1) smashing and sieving defective coke to obtain metallurgy coke nut; (2) cleaning the metallurgy coke nut with clear water, draining, and placing the drained metallurgy coke nut into a drying oven of which the temperature is 120 DEG C to perform constant-temperature drying for 2 hours; (3) performing high-temperature water vapor activation on the dried metallurgy coke nut; (4) selecting V2O5 to serve as an active component of the low-temperature SCR catalyst, selecting an ammonium metavanadate solution to serve as a precursor of V2O5, and soaking the metallurgy coke nut into a solution of which the V2O5 concentration is 6 percent and a solution of which the V2O5 concentration is 10 percent respectively for 16 hours through a soaking process to obtain a metallurgy coke nut low-temperature SCR de-nitration catalyst; (5) taking out a sample, placing the sample into an air blast drying box to dry for 3 hours, then placing the sample into a resistance furnace, and calcining in a nitrogen atmosphere at the temperature of 600 DEG C for 2 hours in order that the ammonium metavanadate is fully decomposed to obtain a V2O5-loaded modified metallurgy coke nut catalyst.

Owner:CHONGQING UNIV

SCR (Selective Catalytic Reduction) catalyst and preparation method thereof

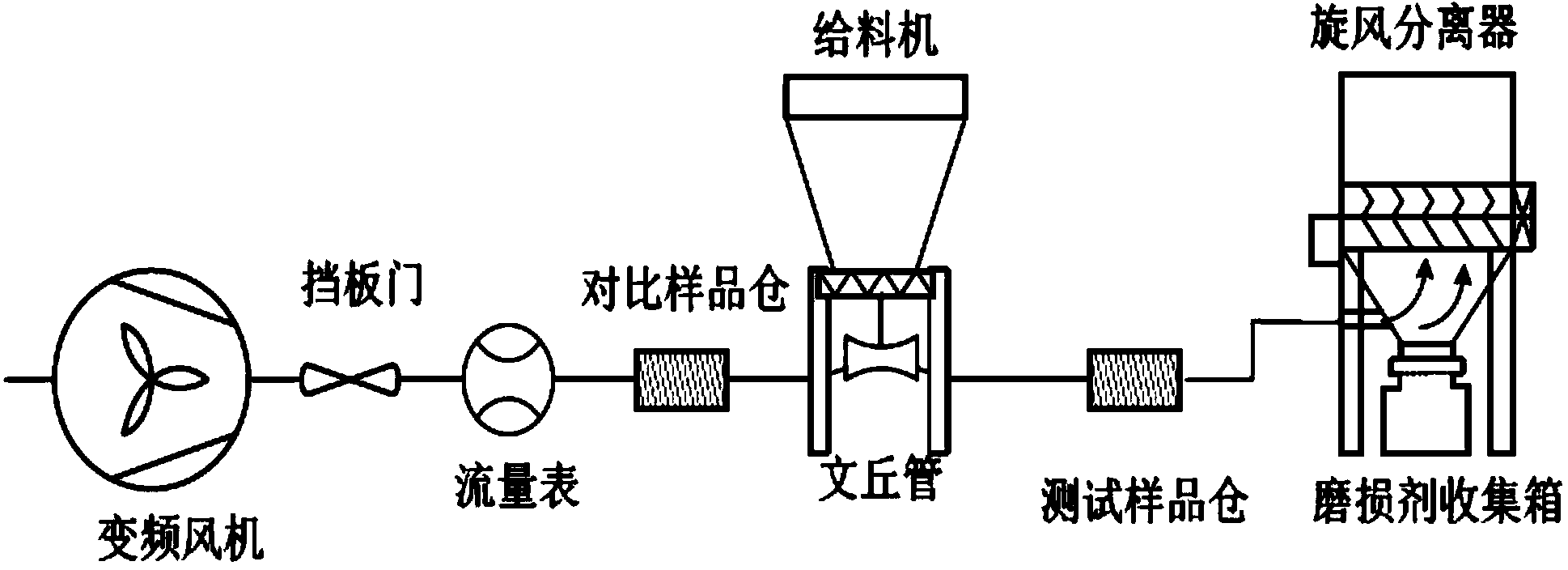

InactiveCN104226300AGood catalytic activity at low temperatureGood wear resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberGlass fiber

The invention provides an SCR (Selective Catalytic Reduction) catalyst which is prepared from the following raw materials in parts by weight: 85-95 parts of TiO2, 3-5 parts of WO3, 1-3 parts of V2O5, 5-8 parts of glass fibers, 5-10 parts of ammonia water, 8 parts of CMC, 50 parts of ionized water and 6 parts of RP-CHOP functional fibers. The catalyst provided by the invention has the characteristics of high low-temperature activity and high denitration efficiency and also has excellent compressive property and wear resistance. The invention also provides a method for preparing the catalyst.

Owner:江苏宇达环保科技股份有限公司

Catalyst for catalytic cleaning of lean-burn engine tail gas and its preparing process

InactiveCN101015801AGood dispersionHigh activityCatalyst carriersDispersed particle separationCeriumOxygen

The invention relates to a catalyst for catalyzing and purifying tail gas of engine, and relative preparation, used in vehicle tail gas purification technique. The invention comprises that carrier and catalyst active component, characterized in that the catalyst uses gamma-Al2O3 as carrier, adhered with mixed oxide coat of titania and cerium zirconium, the invention loads active component palladium via immerge method, referring the carrier mass, the content of TiO2 is 14.0-20.0wt% and the content of CeZrO is 3.0-6.0wt%, referring to catalyst mass, the content of active component palladium is 0.1-1.0wt%. And the preparation comprises that preparing titania gel, preparing titania coat on the face of Al2O3, preparing cerium zirconium gel, loading cerium zirconium oxide on the carrier adhered with titania coat, and leading in active component palladium. The invention has the advantages that under over-oxygen condition, in low-temperature, the invention has strong activity for removing nitrogen oxide, with simple production.

Owner:DALIAN UNIV OF TECH

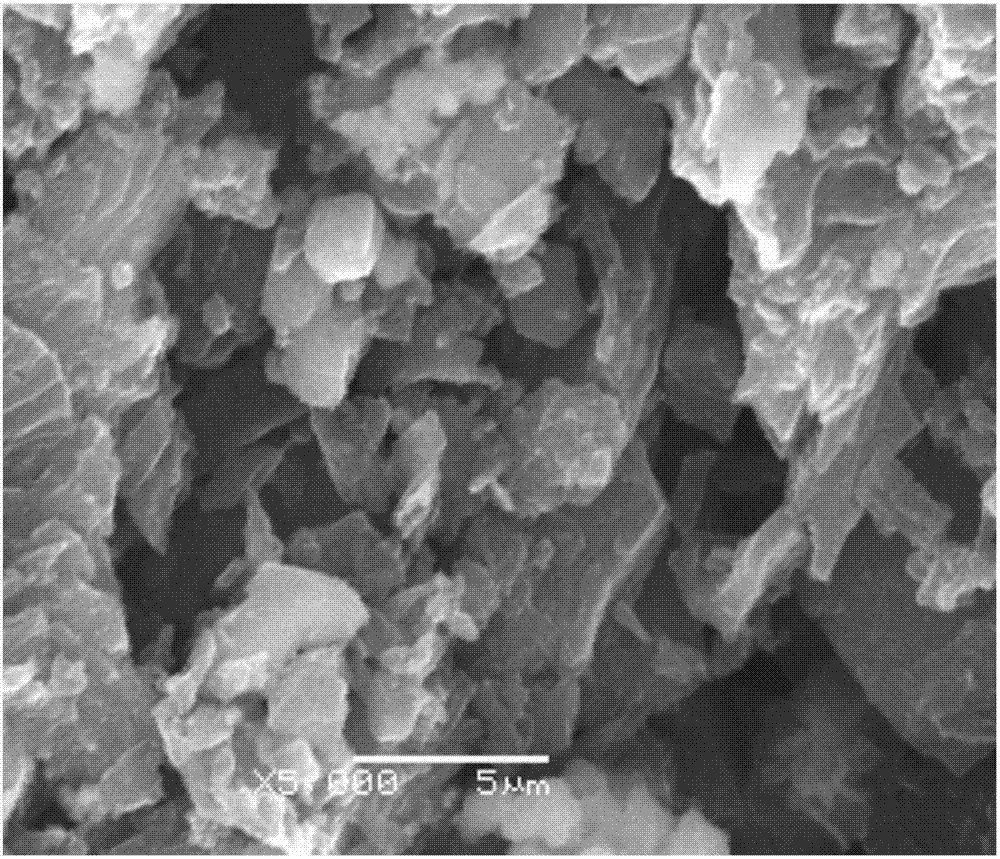

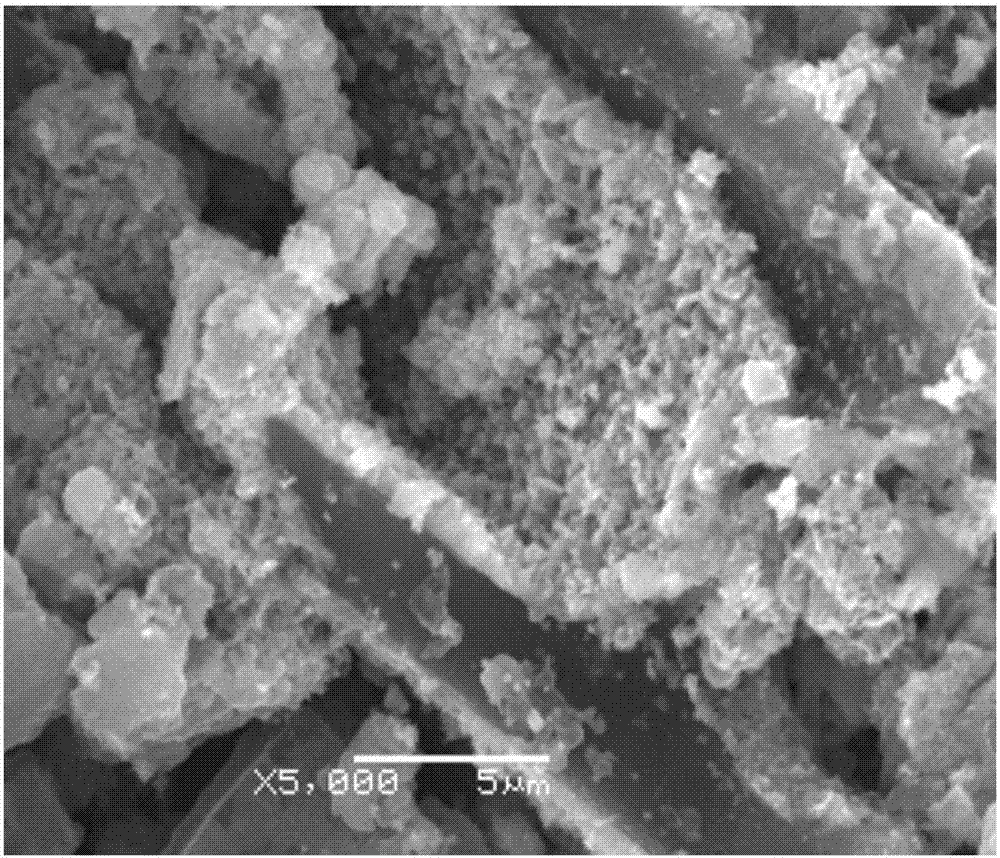

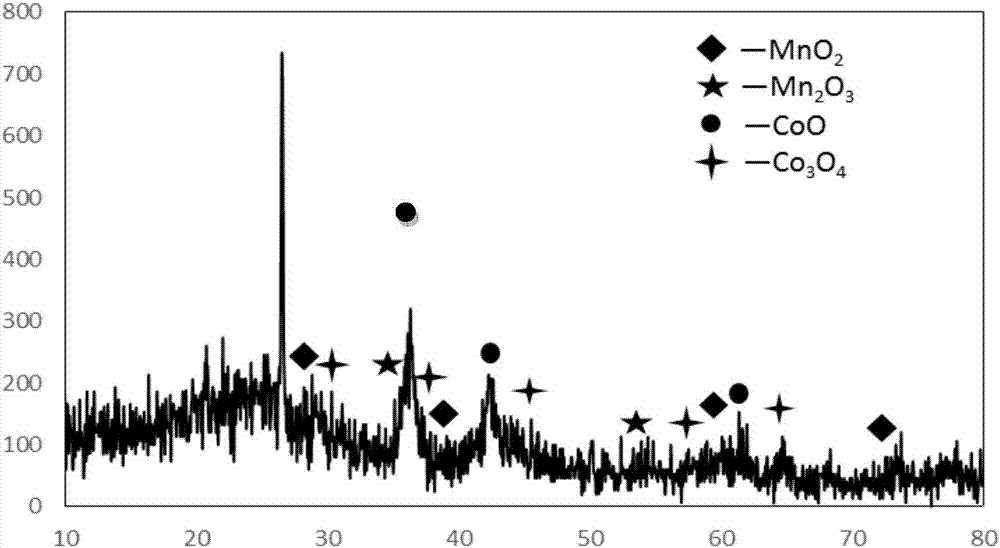

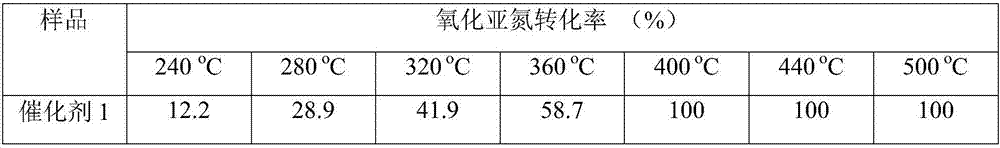

Method for preparing SCO denitration catalyst by virtue of plasma method

InactiveCN107008338AImprove denitrification efficiencyGood catalytic activity at low temperatureGas treatmentDispersed particle separationNitrateManganese

The invention discloses a method for preparing an SCO denitration catalyst by virtue of a plasma method. The method comprises the following steps: (1) sieving brown coal particles by virtue of a sieve, and roasting the brown coal particles in a tubular furnace, so as to obtain pyrolysis coke; (2) dipping the pyrolysis coke into a manganese nitrate solution by virtue of an equivalent-volume impregnation method, so as to obtain pyrolysis coke dipped with manganese nitrate; (3) dipping the pyrolysis coke dipped with manganese nitrate into a cobalt nitrate solution by virtue of the equivalent-volume impregnation method, so as to obtain pyrolysis coke dipped with manganese nitrate and cobalt nitrate; and (4) frying the pyrolysis coke dipped with manganese nitrate and cobalt nitrate by virtue of an electric furnace, putting the pyrolysis coke into a plasma reaction kettle, and carrying out low-temperature plasma roasting, so as to obtain the SCO denitration catalyst. By improving existing preparation methods of denitration catalysts, the catalyst is subjected to pyrolysis coke surface modification by utilizing a plasma method and changing background gas, so that the ratio of a surface pore structure of the catalyst is increased, and the catalytic performance of the SCO denitration catalyst is improved.

Owner:XIAN UNIV OF SCI & TECH

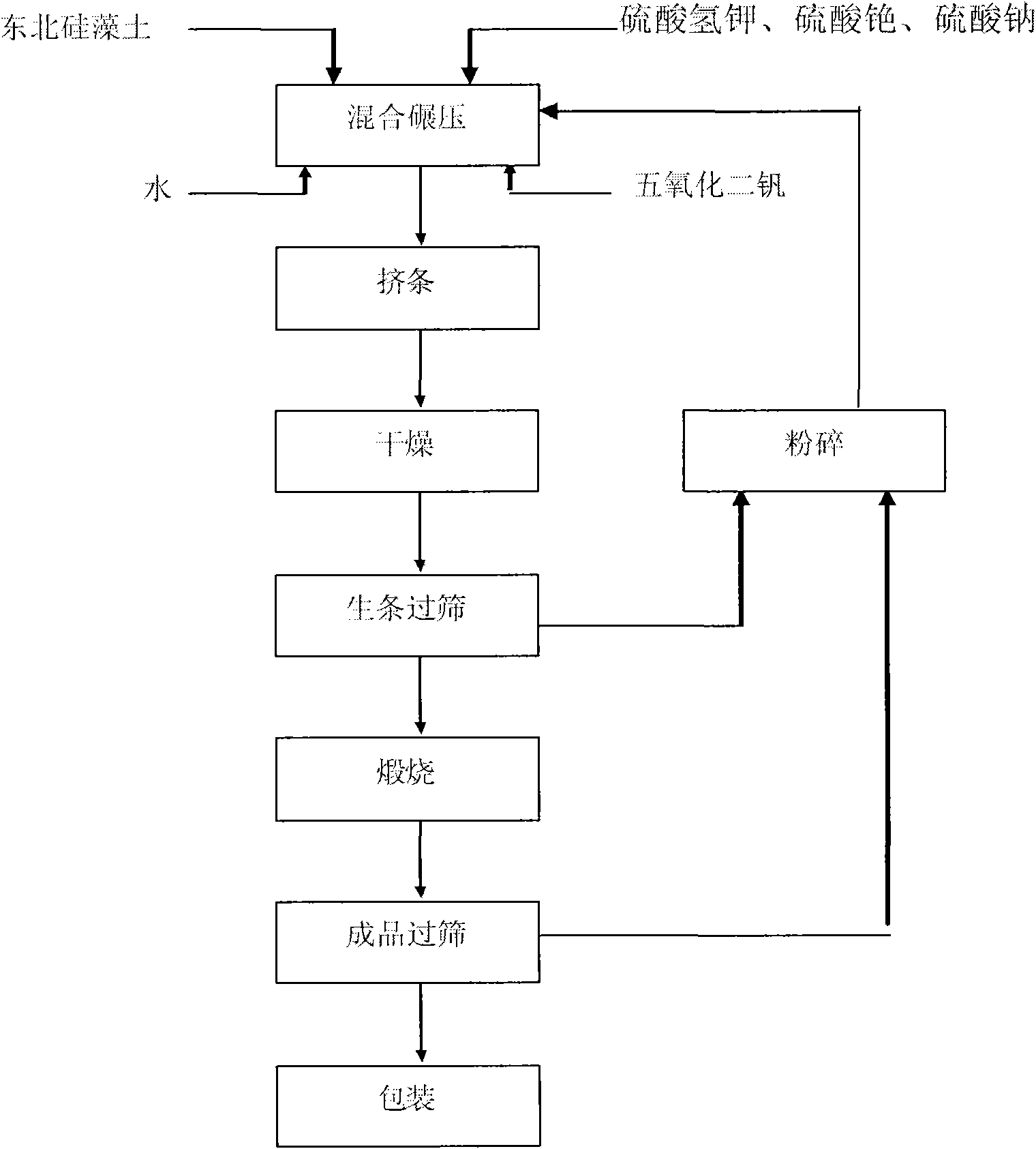

Low-temperature type vanadium catalyst for catalyzing SO2 oxidizing reaction

ActiveCN101850261AGood catalytic activity at low temperatureMeet industry needsPhysical/chemical process catalystsSulfur compoundsSulfateCesium sulfate

The invention provides a low-temperature type vanadium catalyst for catalyzing SO2 oxidizing reaction, which comprises kieselguhr, vanadium pentoxide, potassic sulfate, sodium-contained sulfate and cesium sulfate. The catalyst has excellent catalytic activity. The invention also provides a preparation method of the vanadium catalyst for catalyzing the SO2 oxidizing reaction. The method directly adopts a mixed milling method to prepare the vanadium catalyst without acid treatment or a vanadium oxidizing process or a neutralization process, and thereby, not only is the production flow shortened but also acidic waste water can not be generated. The catalyst has environmental friendliness.

Owner:吉林省临江天元催化剂有限公司

Denitration catalyst, and preparation method and application thereof

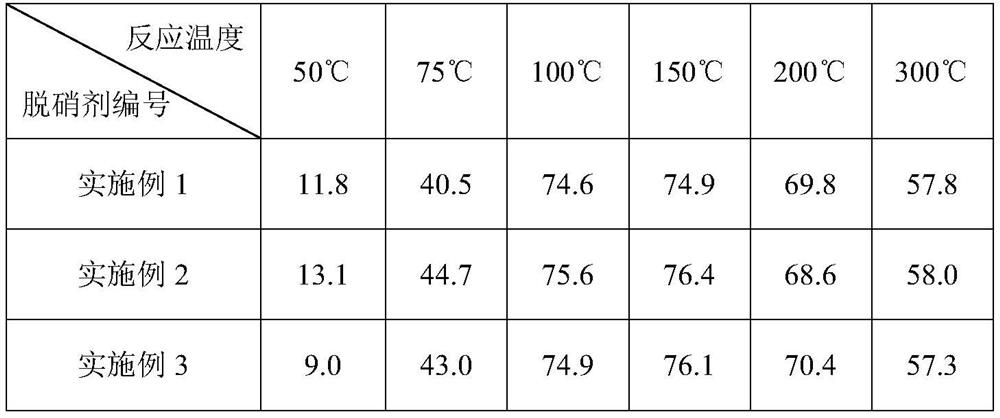

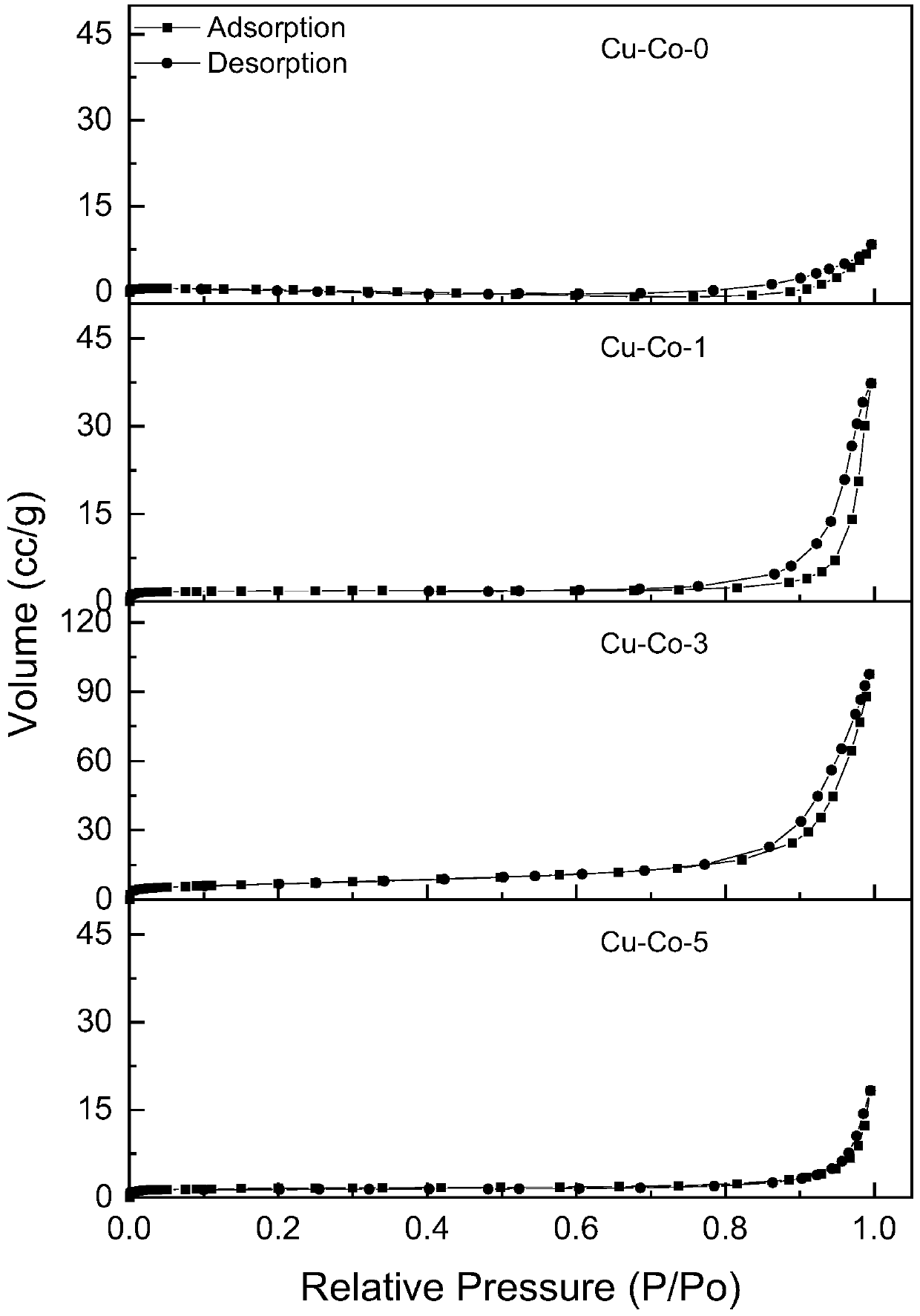

ActiveCN111804306AThe surface is rich in oxygenLarge specific surface areaNitrous oxide captureGas treatmentPtru catalystReaction temperature

The invention discloses a denitration catalyst, and a preparation method and application thereof, and relates to the technical field of denitration catalysts. The denitration catalyst is a low-temperature SCR denitration catalyst taking red mud as a main raw material. The denitration catalyst is prepared through roasting 45-80 parts of red mud, 10-40 parts of fly ash, 3-25 parts of perovskite typecomposite metal oxide and 0.5-5 parts of pore-enlarging agent. The reaction temperature required by the denitration catalyst is relatively low, and the denitration catalyst has good low-temperature catalytic activity. Besides, the denitration catalyst is large in specific surface area, developed in void structure and good in sulfur resistance, and the production cost of the denitration catalyst is reduced under the condition that the red mud is effectively recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite metal oxide catalyst for low temperature denitration and preparation method thereof

InactiveCN105457624AReduce cloggingReduce riskGas treatmentHeterogenous catalyst chemical elementsActive ingredientMetal

The present invention relates to a composite metal oxide catalyst for low temperature denitration, and belongs to the technical field of industrial denitration. The composite metal oxide catalyst for low temperature denitration is characterized by comprising active ingredients containing MoO3, CeO2 and V2O5, and a carrier of TiO2. The active ingredients and the carrier are proportioned according to the following weight ratio: 3-10 parts of MoO3, 1-5 parts of CeO2, 1-5 parts of V2O5, and 100 parts of TiO2. Through the above technical scheme, the active ingredients of MoO3, CeO2 and V2O5 are supported by TiO2 to form a MoO3-CeO2-V2O5 / TiO2 composite metal oxide catalyst for low temperature denitration. The molybdenum-based catalyst has good low-temperature catalytic activity; and CeO2 as an active auxiliary agent not only effectively suppresses SO2 from converting to SO3 to reduce the risk of catalyst clogging and poisoning, but also broadens the active window of the catalyst, so as to reach significant beneficial effects. The invention also relates to a preparation method of the catalyst. The method reaches a stable denitration efficiency of above 90%, and has excellent denitration effect.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

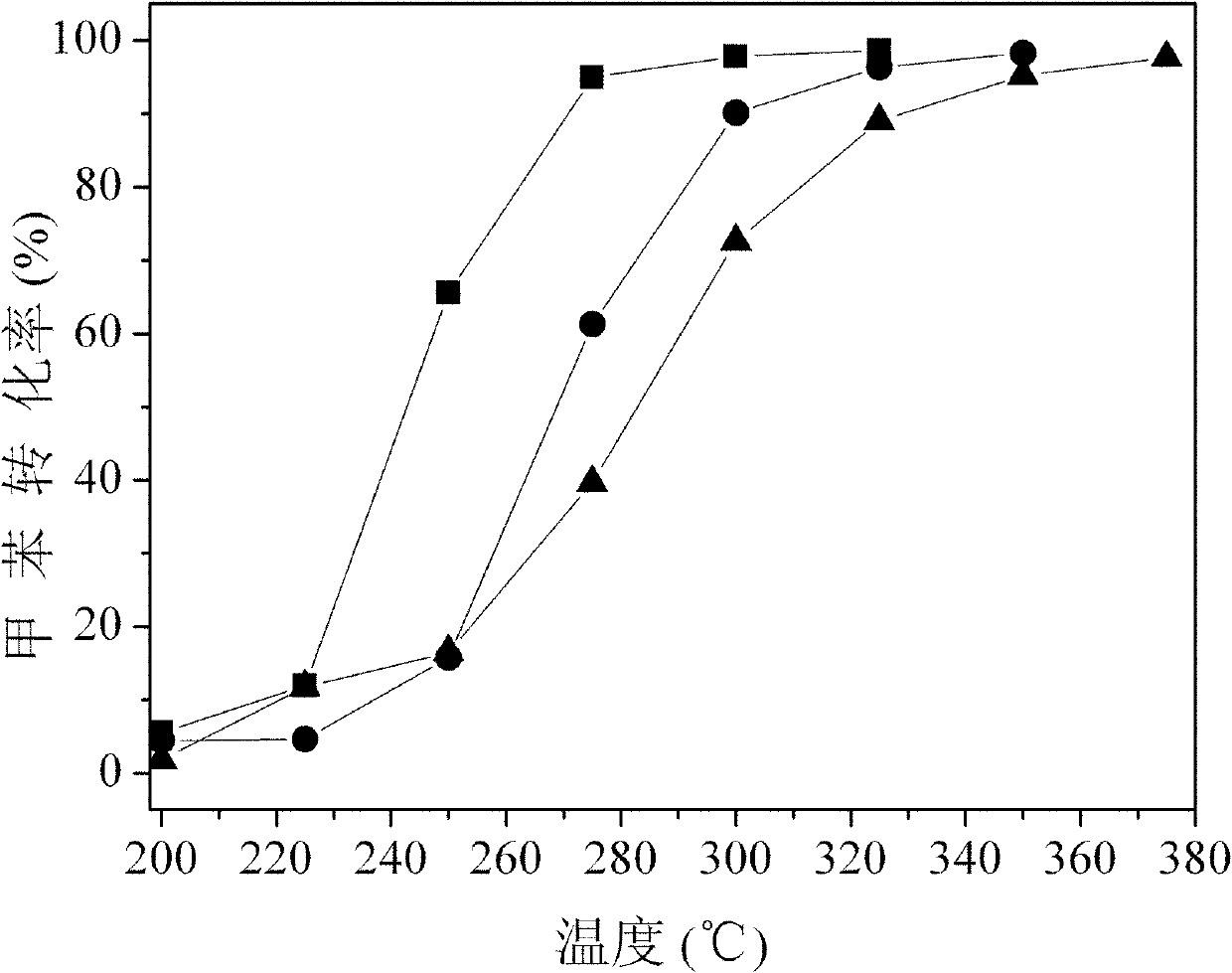

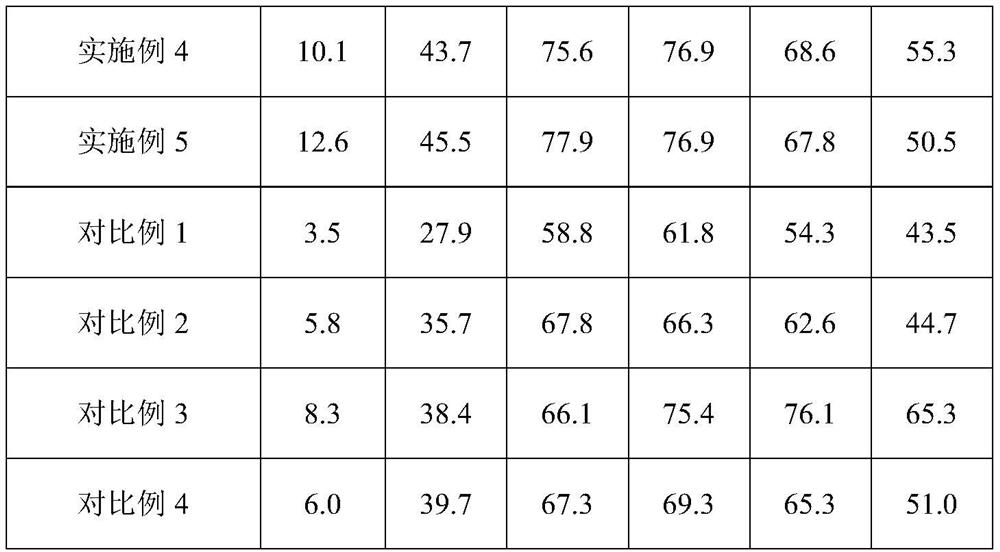

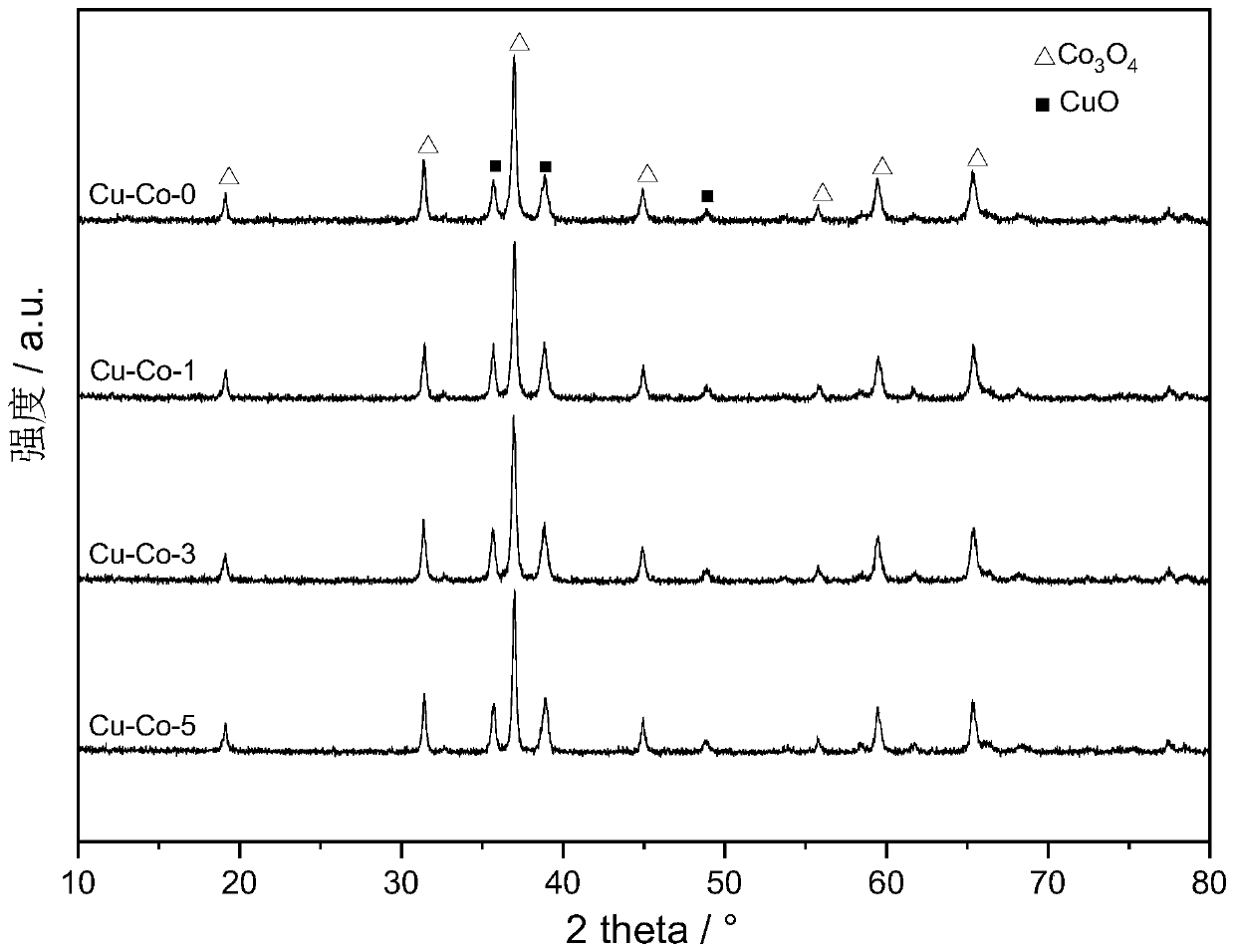

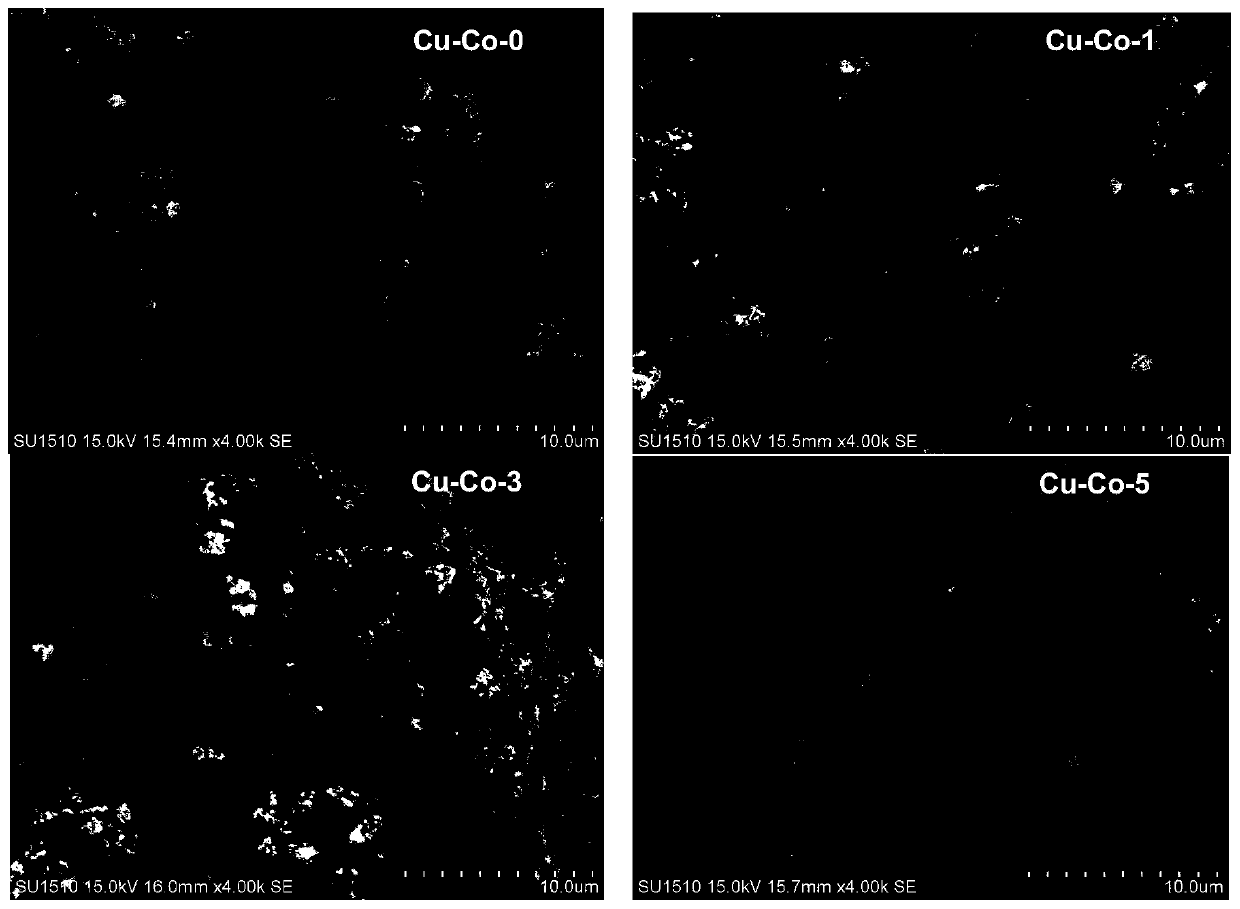

Preparation method and application of copper-cobalt composite oxide catalyst

InactiveCN110975870ALow costGood catalytic combustion activity of toluene volatile organic compoundsGas treatmentDispersed particle separationOXALIC ACID DIHYDRATEVolatile organic compound

The invention discloses a preparation method and application of a copper-cobalt composite oxide catalyst, belonging to the technical field of preparation of composite catalysts. The preparation methodcomprises the following steps: mixing and grinding a copper salt, a cobalt salt and a complexing agent to form a dry material; and roasting the dry material under the roasting condition that a temperature is raised to 300-550 DEG C at a heating rate of 10 DEG C / min, then performing roasting for 1-2 hours at a constant temperature of 300-550 DEG C, and taking out the dry material after the temperature drops to a normal temperature after roasting is finished so as to obtain the catalyst, wherein a molar ratio of the copper salt to the cobalt salt to the complexing agent is 1: 2: (0-5), and thecomplexing agent is oxalic acid. The copper-cobalt composite oxide catalyst prepared by the method disclosed by the invention shows good activity in catalytic combustion of toluene volatile organic compounds at low temperature. According to the method, the copper-cobalt composite oxide catalyst is prepared through a grinding method, so preparation process is simple, conditions are mild and are easy to control, safety and environmental protection are achieved, repeatability is good, and great industrial application value is achieved.

Owner:CHONGQING TECH & BUSINESS UNIV

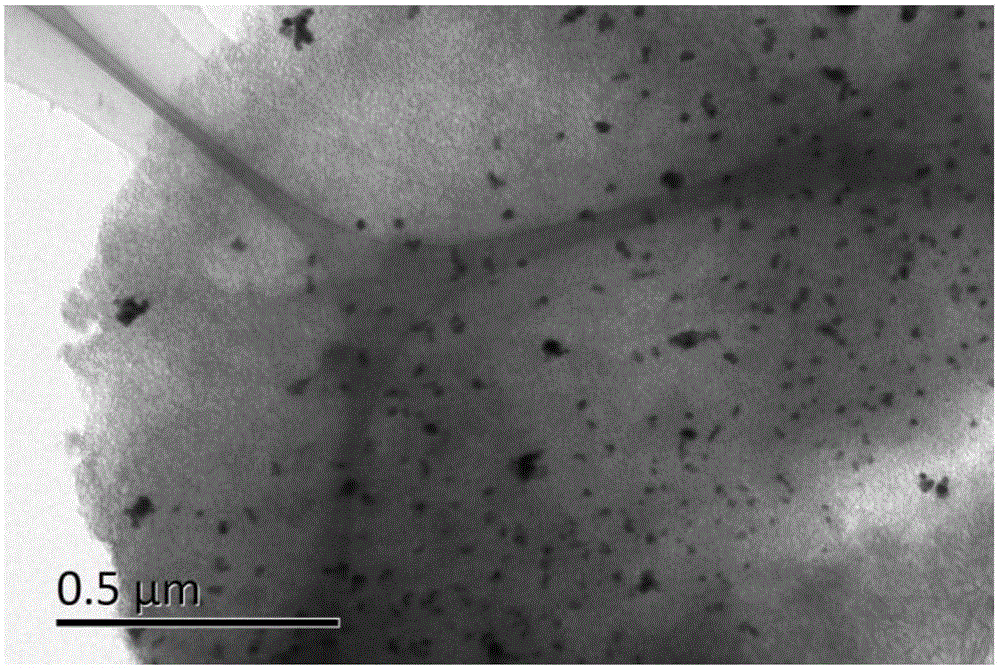

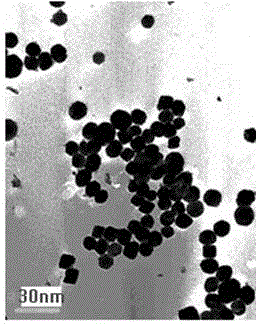

Preparation method for Au-Ce/AlTiOx applied to NO+CO reaction and application thereof

InactiveCN105833867AGood channel structureEasy to operateGas treatmentDispersed particle separationDeposition precipitationFlue gas

The invention provides a preparation method for Au-Ce / AlTiOx applied to NO+CO reaction and belongs to the technical field of a catalytic material and a nanometer material. The preparation method comprises the following steps: preparing a titanium-aluminum oxide carrier of the catalyst according to a triblock copolymer template method; taking chloroauric acid as a gold precursor; loading the gold on the carrier through a deposition precipitation process; highly dispersing nanometer gold grains on the carrier; and introducing Ce by utilizing an impregnation method, thereby acquiring the Au-Ce / AlTiOx catalyst. The preparation method provided by the invention is simple; the reaction condition is easily controlled; the equipment requirement is low; the prepared Au-Ce / AlTiOx material grain has a diameter of 10nm and a specific surface area of 370m<2> / g; and the reaction test conditions are as follows: 500ppm NO, 500ppm CO and He serve as balancing gases, the total flow of flue gas is 300ml / min, and the denitration catalytic efficiency at 300 DEG C reaches 100%.

Owner:DALIAN UNIV OF TECH

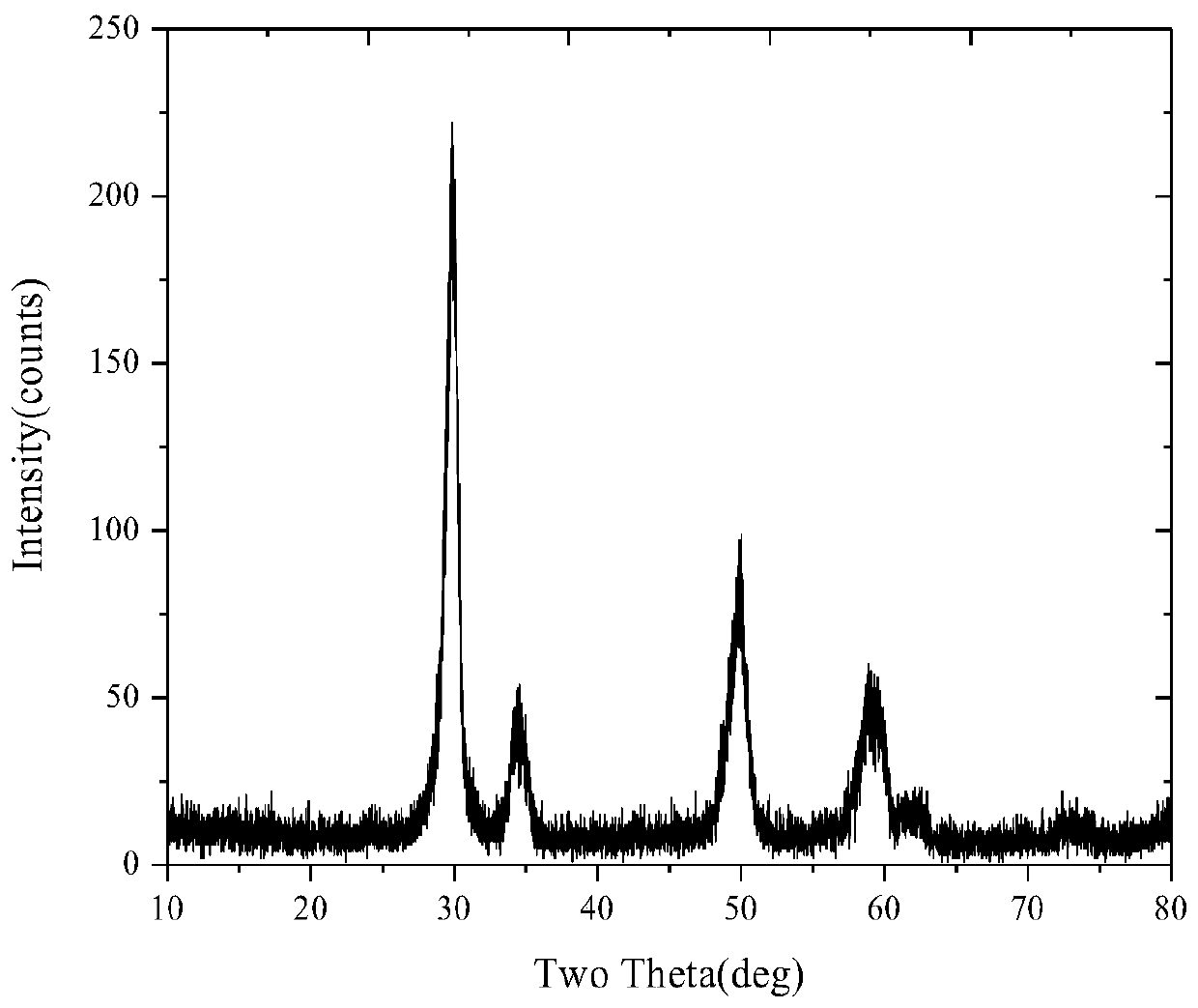

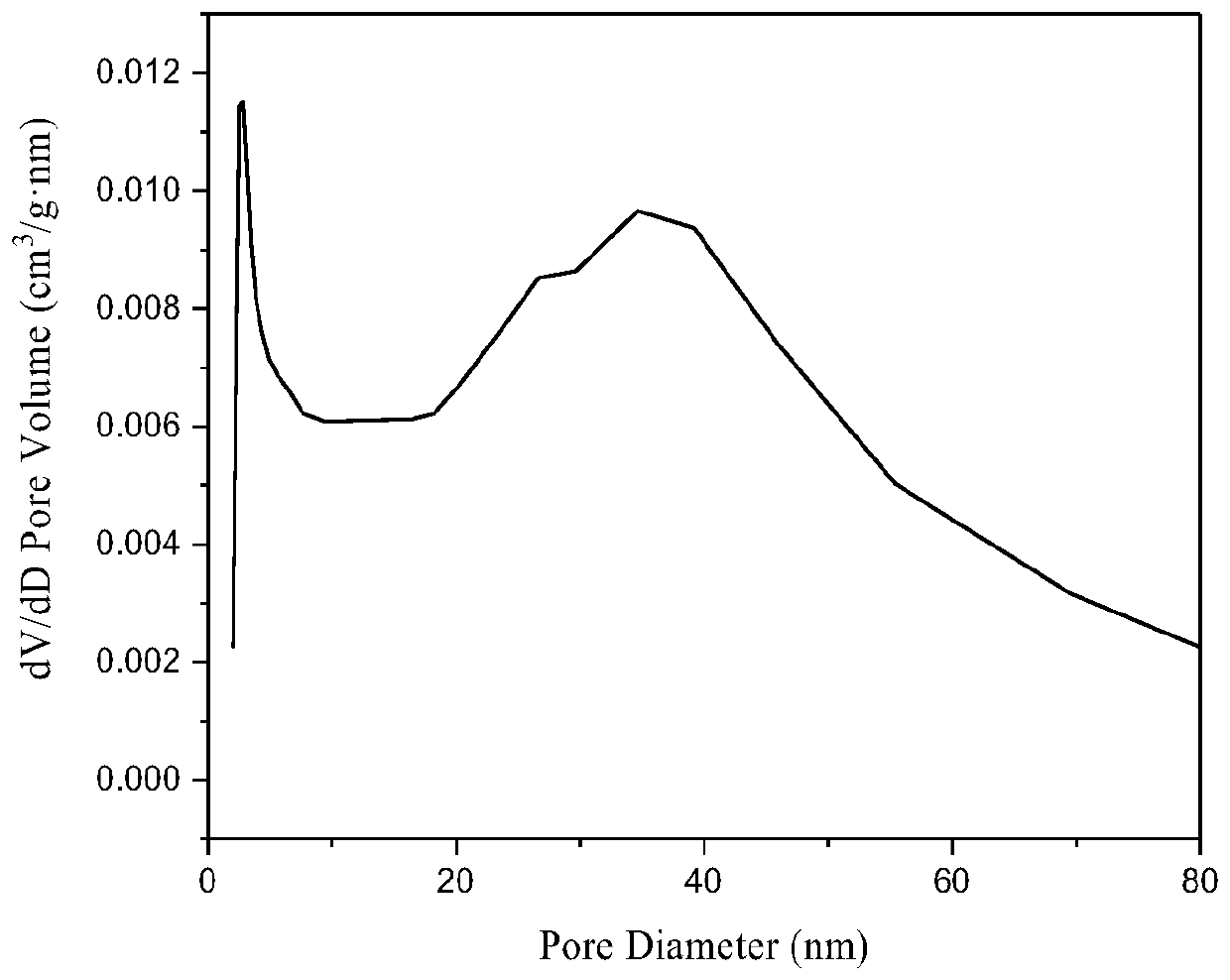

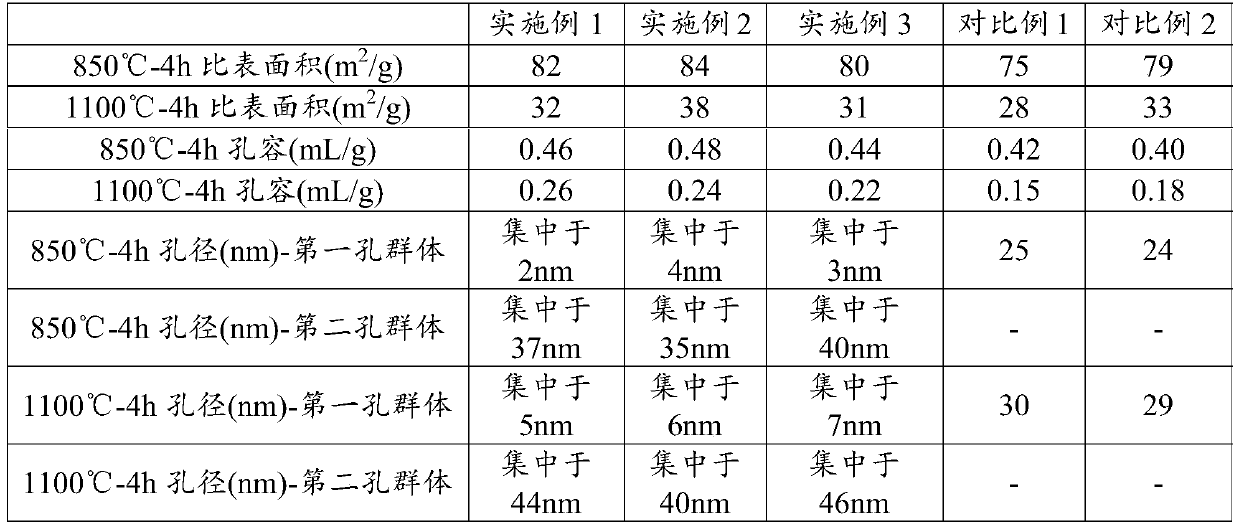

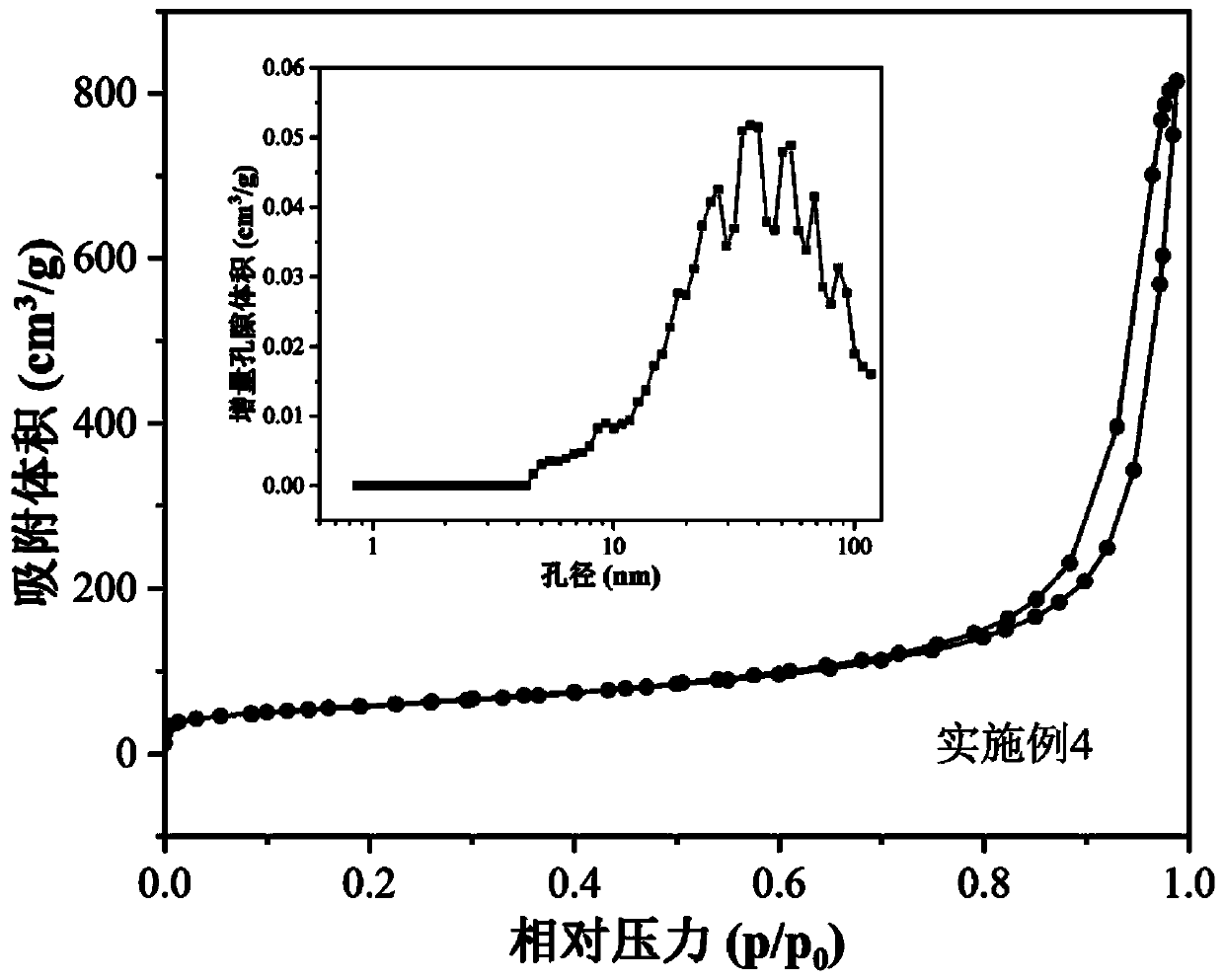

Cerium-zirconium composite oxide and preparation method thereof

ActiveCN110385120AUniform distribution of dopingLarge specific surface areaHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsRare earthCerium

The invention provides a cerium-zirconium composite oxide, comprising cerium oxide, zirconium oxide and the oxide of at least one rare earth metal element except cerium. After the cerium-zirconium composite oxide is subjected to heat treatment at 850 DEG C for 4 to 8 h, the cerium-zirconium composite oxide has pore sizes in the form of dual pore group distribution, wherein the diameters of a firstpore group are concentrated in a range of 2 to 10 nm, and the diameter of a second pore group is concentrated in a range of 15 to 80 nm. The cerium-zirconium composite oxide provided by the inventionhas remarkable low-temperature catalytic activity and can be used for catalyzing hydrocarbons, carbon oxides and / or nitrogen oxides in mobile-source exhaust gas. The invention also provides a preparation method for the cerium-zirconium composite oxide. The preparation method can prepare the cerium-zirconium composite oxide which is more uniform in lattice doping distribution and free of phase separation, and is of great significance to study on cerium-zirconium composite oxide-containing cleaning agents for treatment of mobile-source exhaust gas.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

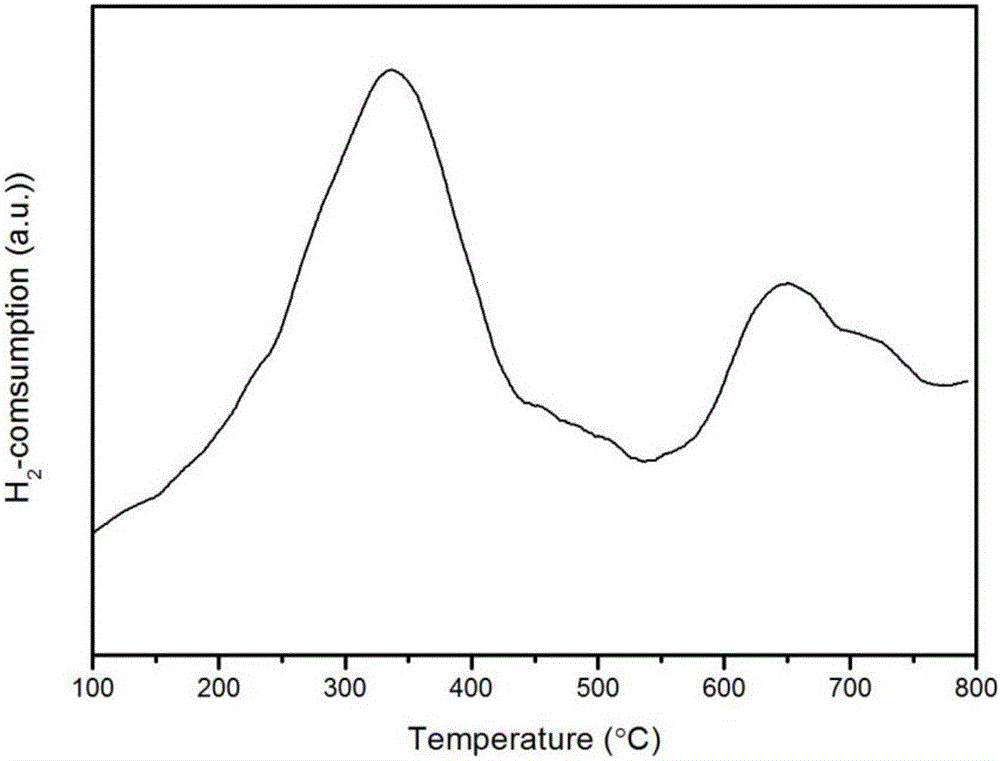

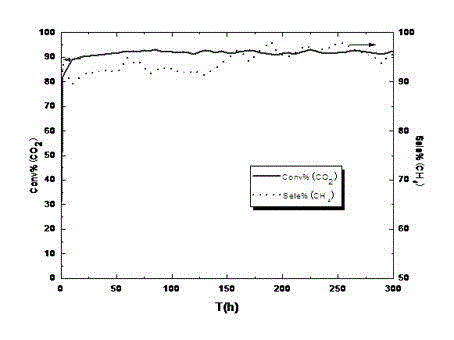

Liquid-phase CO2 methanation catalyst, preparation method and application of catalyst

ActiveCN102716766ACatalytic activity regulationStable separationHydrocarbon from carbon oxidesOrganic-compounds/hydrides/coordination-complexes catalystsPlatinumPtru catalyst

The invention relates to a liquid-phase CO2 methanation catalyst, a preparation method and application of the catalyst. The liquid-phase CO2 methanation catalyst comprises amphipathic ionic liquid and metal active components dispersed in the amphipathic ionic liquid in the state of stable colloid, the grain sizes of the metal active components range from 0.5nm to 20nm, the spherical metal active components include a first metal active component and a second metal active component, the first metal active component includes nickel, the second metal active component includes one or mixture of more than one of lanthanum, cerium, molybdenum, ruthenium, ytterbium, rhodium, palladium, platinum, potassium and magnesium, and the molar ratio of the first metal active component to the second metal active component is 10:0.1-2. The metal active components in the liquid-phase CO2 methanation catalyst are small in grain size, narrow in distribution, wide in application prospect, easy to separate and recyclable, CO2 methanation of low-temperature liquid phase can be realized at the temperature of 100-200 DEG C, the liquid-phase CO2 methanation catalyst has excellent low-temperature catalytic activity, methane selectivity and heat stability, and the preparation method is simple and practicable, low in cost and easy in popularization.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

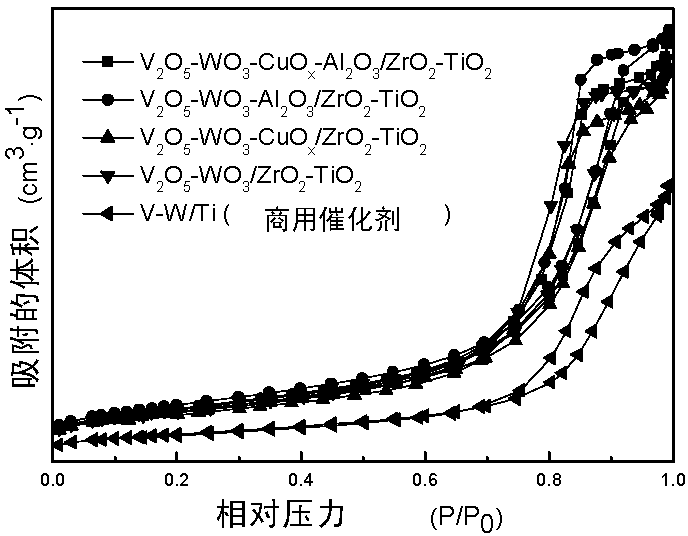

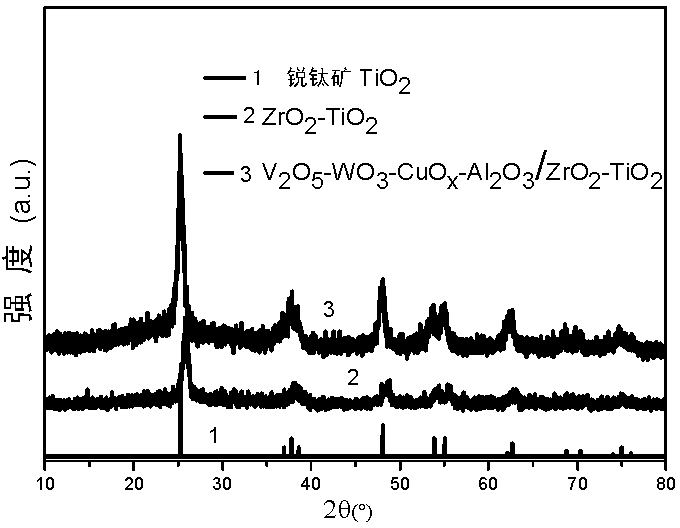

Mesoporous composite oxide catalyst for purifying tail gases and preparation method thereof

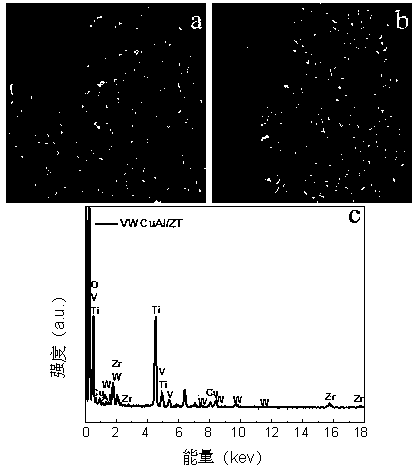

InactiveCN104324728AGood catalytic activity at low temperatureImprove conversion efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPhysical chemistryComposite oxide

The invention relates to a mesoporous composite oxide catalyst for purifying tail gases and a preparation method thereof. The composition chemical formula of the mesoporous composite oxide catalyst is V2O5- WO3-CuOx-Al2O3 / ZrO2-TiO2, wherein the ratio of the mass of V to the mass sum of ZrO2 and TiO2 is not larger than 10%, the ratio of the mass of W to the mass sum of ZrO2 and TiO2 is not larger than 20%, the ratio of the mass of Cu to the mass sum of ZrO2 and TiO2 is not larger than 10%, the ratio of the mass of Al to the mass sum of ZrO2 and TiO2 is not larger than 5%, and the value range of x is that x is not smaller than 0 and is not larger than 1.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Low-temperature coke oven flue gas desulfurizing and denitrifying process

InactiveCN106334443AGood catalytic activity at low temperatureImprove high temperature resistanceOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationManganeseCerium

The invention discloses a low-temperature coke oven flue gas desulfurizing and denitrifying process. The low-temperature coke oven flue gas desulfurizing and denitrifying process comprises the following steps: firstly, preparing an SCR catalyst, wherein the catalyst is obtained by preparing clay, polymethyl methacrylate and sodium silicate into a carrier and then loading metal oxides of manganese and cerium, and the catalyst has good catalytic activity at low temperature and a large adsorption rate; then in a desulfurizing and denitrifying step, dedusting coke oven flue gas first and then injecting the coke oven flue gas into a desulfurizing adsorption zone for desulfurizing, wherein a desulfurized product is adsorbed by the SCR catalyst, and the catalyst can be recycled after desulfurization regeneration and activation treatment; injecting the dedusted and desulfurized coke oven flue gas into an SCR reaction zone, injecting cyanuric acid and ammonia gas into the SCR reaction zone in a mixing manner, contacting with the coke oven flue gas and the SCR catalyst, denitrifying, and discharging the desulfurized and denitrified flue gas after the catalyst is recycled. The low-temperature coke oven flue gas desulfurizing and denitrifying process has high desulfurizing and denitrifying efficiency and high SCR catalyst adsorbing rate, and can be recycled, so that the cost is reduced.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

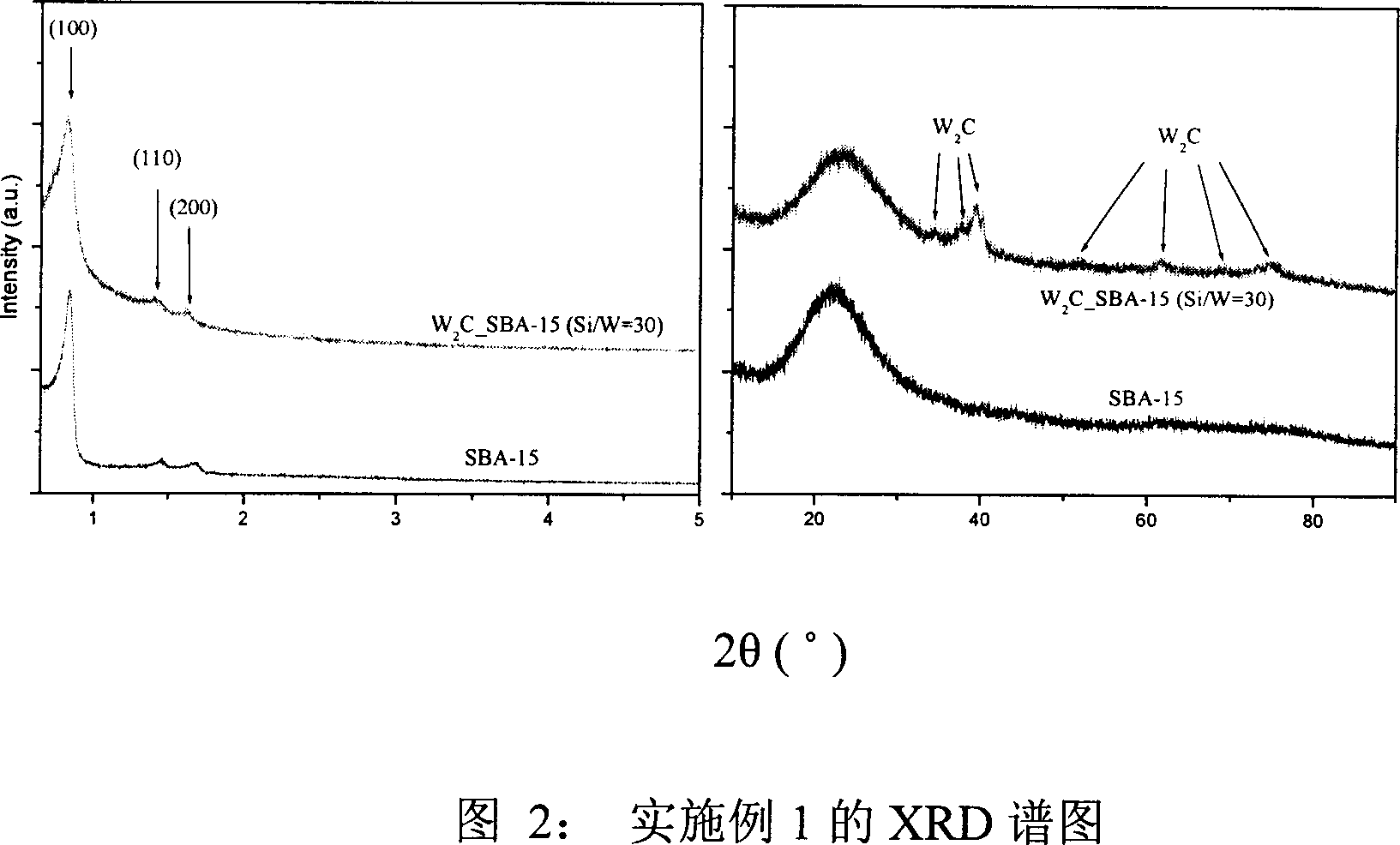

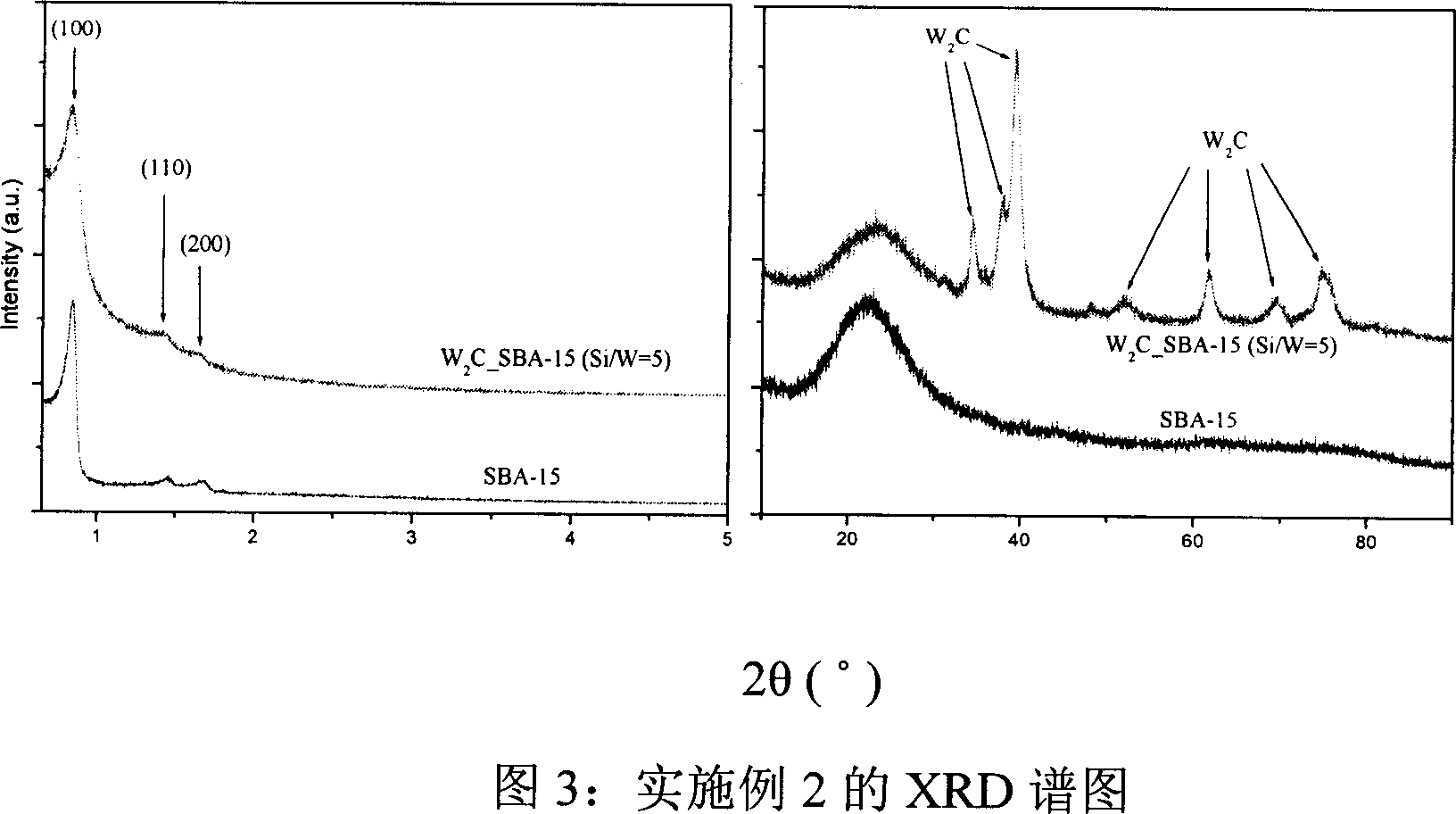

Porous molecular sieve catalyst for assembling tungsten carbide and its preparation

InactiveCN1895778AImprove performanceImprove stabilityMolecular sieve catalystsMolecular sieveActive component

A meso-porous molecular sieve catalyst with tungsten carbide features that the tungsten carbide particles are assembled in the pores of meso-porous molecular sieve, resulting in high isolation and dispersion of active component particles and in turn high stability and activity.

Owner:BEIJING UNIV OF CHEM TECH

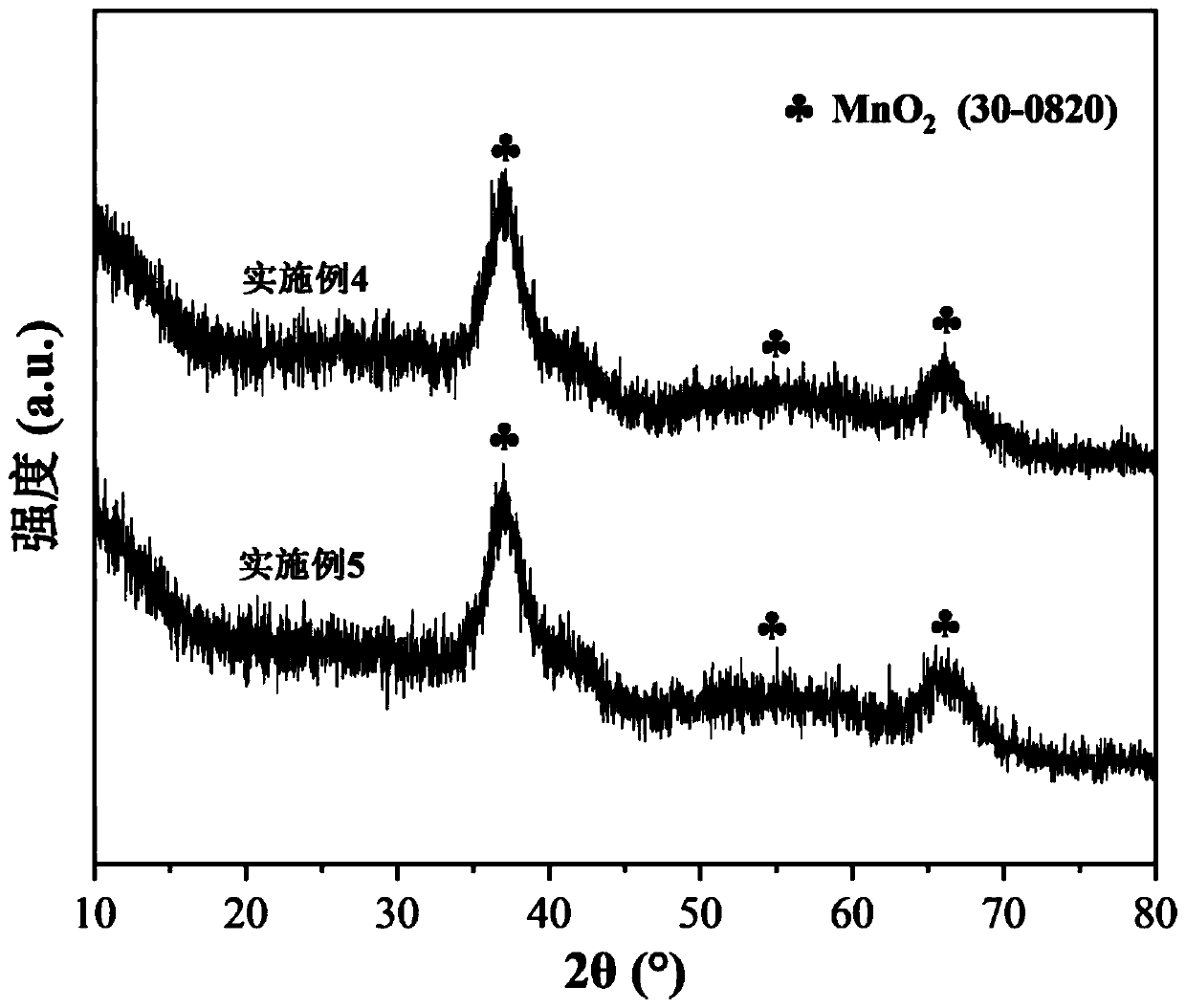

Double metal cobalt-based catalyst and preparation method and application

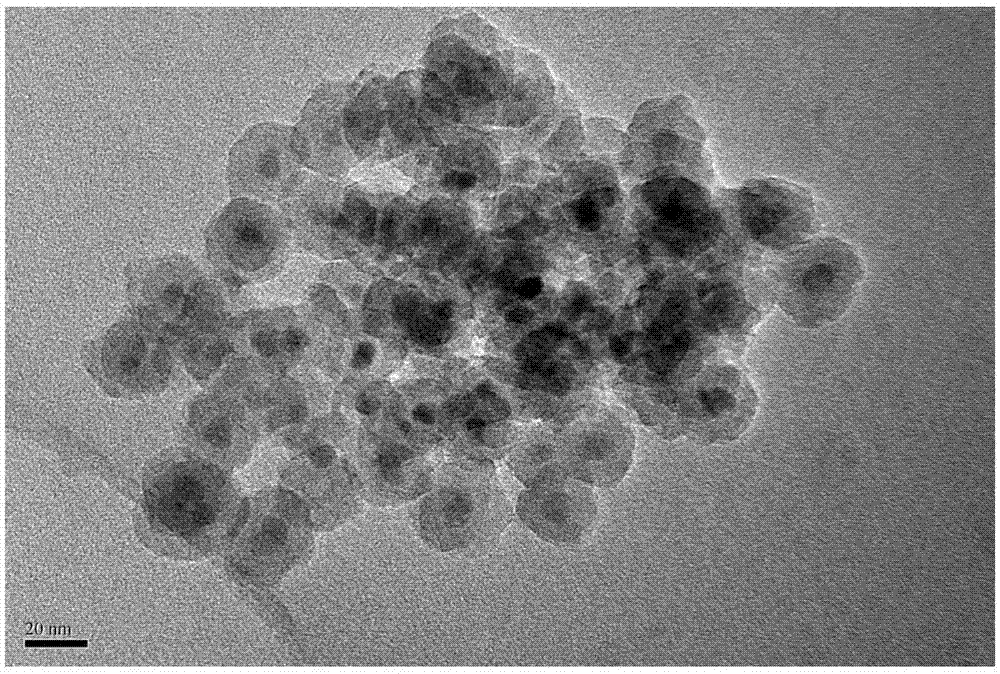

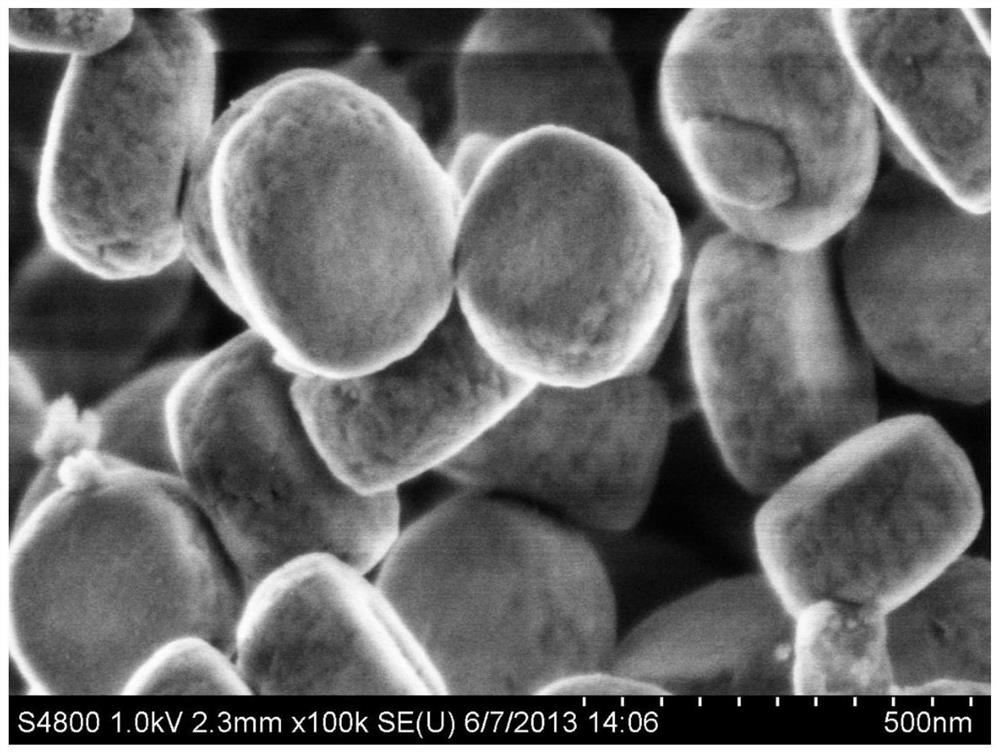

ActiveCN106984318AHigh catalytic activityLow conversion temperatureNitrous oxide captureMaterial nanotechnologyMetal oxide nanoparticlesActive component

The invention discloses a double metal cobalt-based catalyst, which comprises an active oxide kernel and a porous inert oxide shell layer, wherein the component of the active oxide kernel is one of a main active component Co3O4 and an auxiliary active component Cu oxide or Fe oxide; the porous inert oxide shell layer comprises a component SiO2-NxOy, wherein NxOy is one of ZrO2 or CeO2; and the weight percent of the main active component Co3O4 is 10-40wt%; the weigh percent of the auxiliary active component sis 1-5wt%, the weight percent of the NxOy is 1-3wt% and the balance is SiO2. The double metal cobalt-based catalyst has the advantages that the high-temperature stability and the hydrothermal stability of active metal oxide nanoparticles are improved, the activity of the catalyst is improved and the service life of the catalyst is prolonged.

Owner:SHANXI UNIV

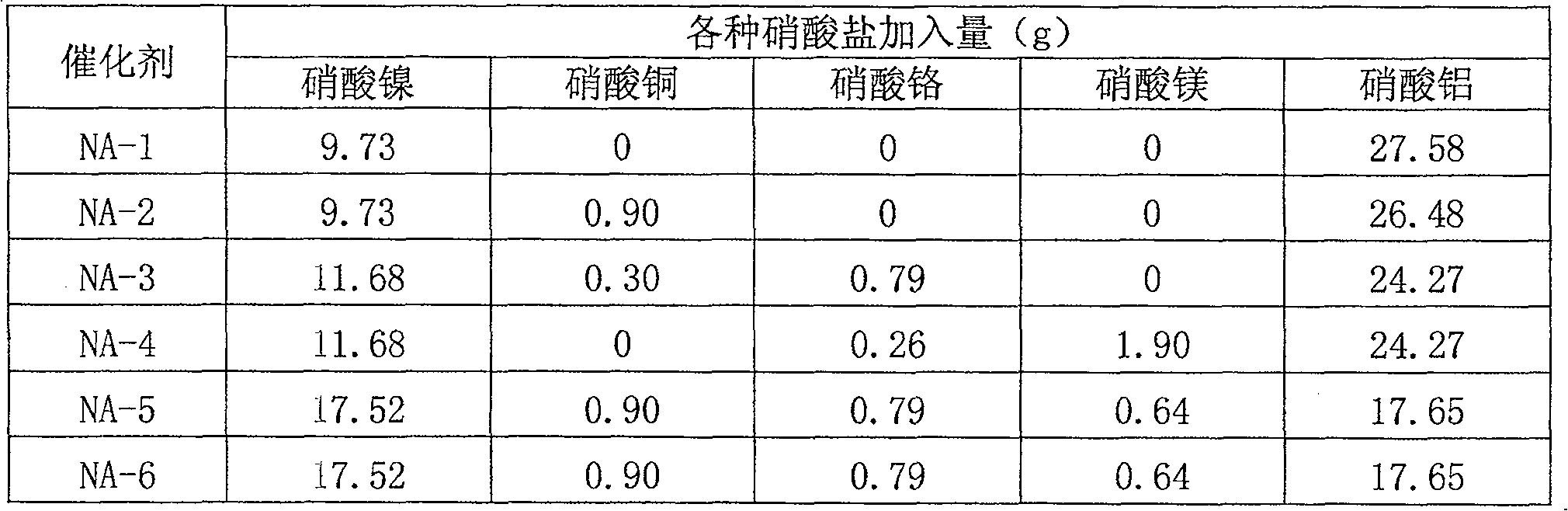

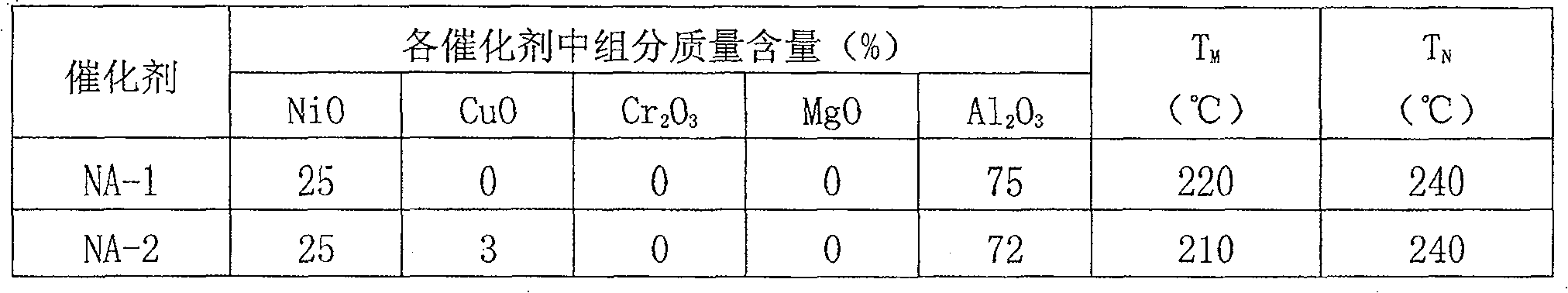

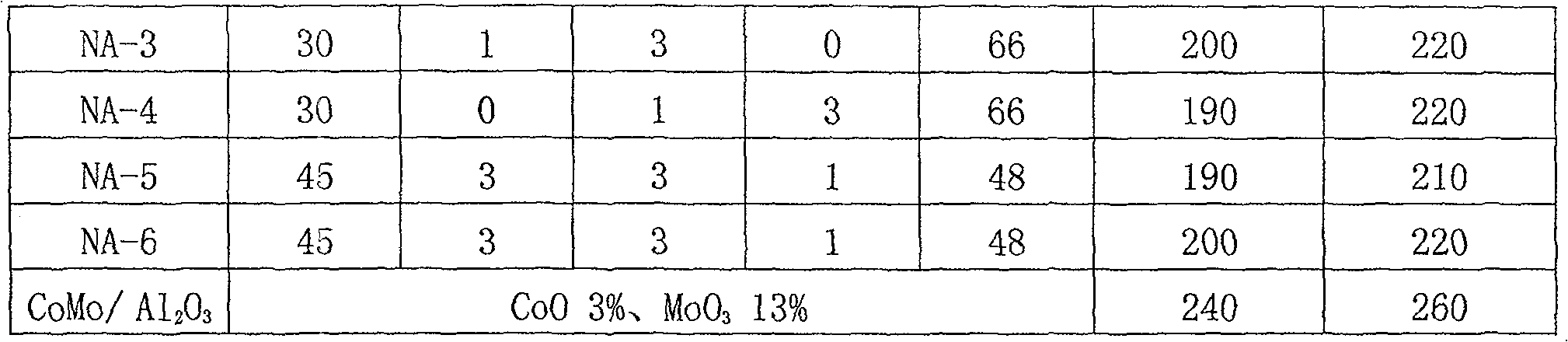

Nickel base crouse vent gas hydrogenation catalysts and coprecipitation manufacturing method

InactiveCN101108349ALow costExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentCoprecipitation

The invention relates to a hydrogenation catalyst for the tail gas of Crouse sulphur recycle device and the preparation method. A nickel pyridyl Crouse tail gas hydrogenation catalyst is characterized in that: the catalyst is mainly composed of an active component, an assistance active component and alumina three components, the quality per centage of each component is: the main active component is 20.1 to 60 per cent, the assistance active component 0 to 10 per cent, the alumina 40 to 79.9 per cent, the sum of the three components is 100 per cent; wherein, the main active component is nickel oxide, the assistance active component is one of chrome oxide, aerugo and iron oxide or a mixture of one or two in above three substances, when being a mixture of one or two in above three substances, the mixture ratio among the oxide is random. The invention has the characters of good low temperature catalyzing activity and low cost.

Owner:WUHAN UNIV OF TECH

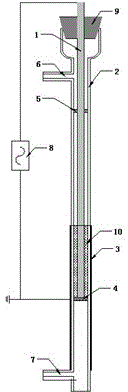

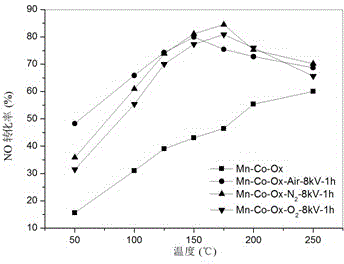

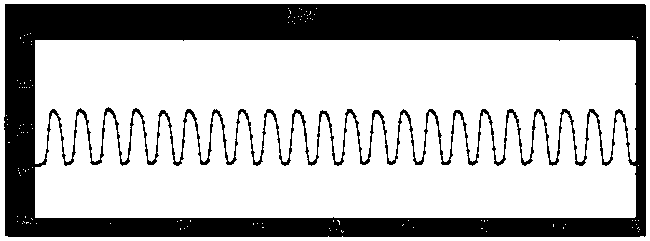

Method for catalytically oxidizing NO by dielectric barrier discharge plasma modified catalyst

InactiveCN102908896BEasy to observeGood catalytic activity at low temperatureDispersed particle separationCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses a method for catalytically oxidizing NO by a dielectric barrier discharge plasma modified catalyst. The method comprises the steps of filling a catalyst into a dielectric barrier discharge plasma reactor to be modified; and placing the modified catalyst into a glass pipe type fixed bed reactor and introducing mixed gas to catalytically oxidize the NO into NO2. The modified catalyst has higher low-temperature catalytic activity and the NO catalytic oxidization efficiency can reach 75-85% at maximum; the cylindrical dielectric barrier discharge plasma reactor is adopted so as to be convenient for observing modification conditions of the catalyst; the actual operation is simple and the modification condition is easy to control; the energy consumption is lower; the modification time is shorter; the product NO2 can be absorbed by an alkali solution to obtain a byproduct and can be recycled; and the method is convenient for actual production and application and has a higher industrial application value.

Owner:KUNMING UNIV OF SCI & TECH

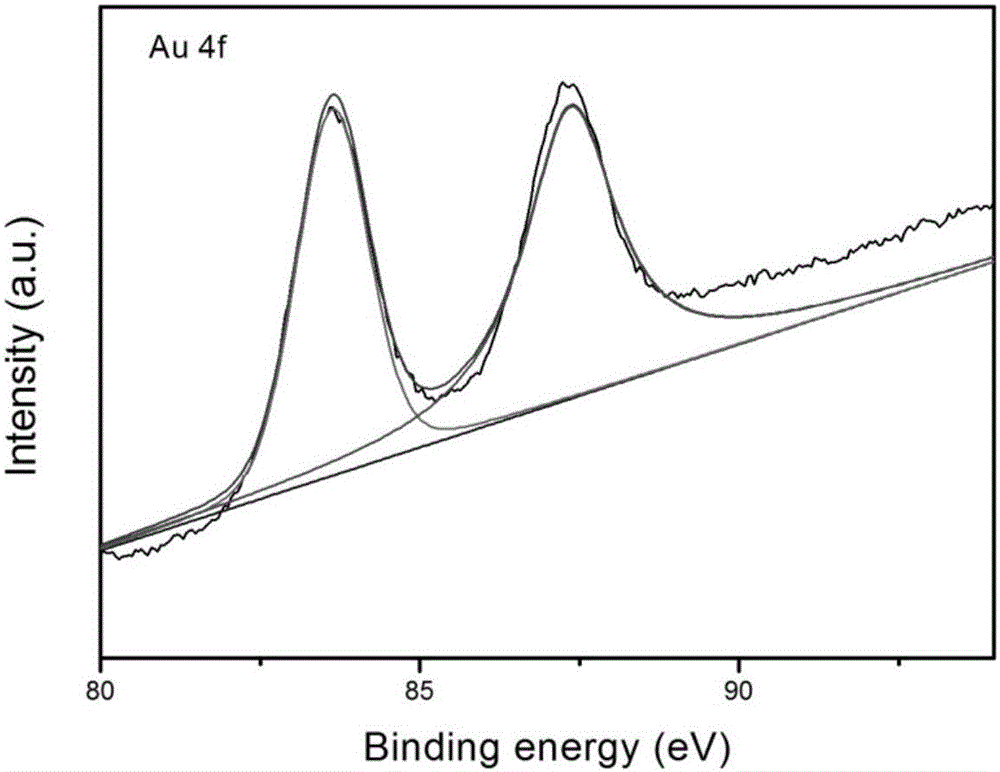

Monoatomic gold catalyst and preparation method and application thereof

InactiveCN110433826AEasy to prepareLow costOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsStyrene oxideReduction treatment

The invention particularly relates to a method for preparing a monoatomic gold catalyst. The method for preparing the monoatomic gold catalyst comprises the following steps that a magnesium cobalt aluminum layered composite hydroxide containing a gold anion is prepared in situ by a coprecipitation method, and then the active component gold is uniformly dispersed between nanosheet layers of the magnesium cobalt aluminum layered composite hydroxide and the surfaces in the form of atomic scale after hydrogen reduction treatment to prepare the monoatomic gold catalyst. The method for preparing themonoatomic gold catalyst is simple and environmentally friendly, and has low cost and industrial application value, the monoatomic gold catalyst is used for epoxidation of styrene to prepare phenyloxirane, and has the characteristics of high activity, high selectivity and reusability.

Owner:北京氦舶科技有限责任公司

Novel ceramic catalytic electrode and preparation method thereof

PendingCN111505083ACatalytic strongIncrease the number of three-phase interfacesMaterial analysis by electric/magnetic meansLiquid/solution decomposition chemical coatingSingle electrodePorous ceramics

The invention discloses a novel ceramic catalytic electrode and a preparation method thereof. The novel ceramic catalytic electrode comprises a catalytic electrode ceramic matrix and precious metals arranged in the catalytic electrode ceramic matrix and on the surface of the catalytic electrode ceramic matrix, the catalytic electrode ceramic matrix is porous ceramic with tiny three-dimensional pore channels in the interior and on the surface, and the precious metals are distributed in the porous ceramic in a three-dimensional net shape. One purpose of the invention is to provide a novel ceramic catalytic electrode with low cost and high performance. The number of three-phase interfaces among precious metal, porous solid electrolyte ceramic and oxygen is greatly increased due to the structure, so that the novel ceramic catalytic electrode also has excellent catalytic capability under the condition of using a small amount of precious metal, and the production cost is greatly reduced. Another purpose of the invention is to provide a preparation method of the novel ceramic catalytic electrode, and the ceramic electrode prepared by the method is simple in process operation, good in combinability of the electrode material and the ceramic substrate, and less in precious metal consumption.

Owner:苏州工业园区传世汽车电子有限公司

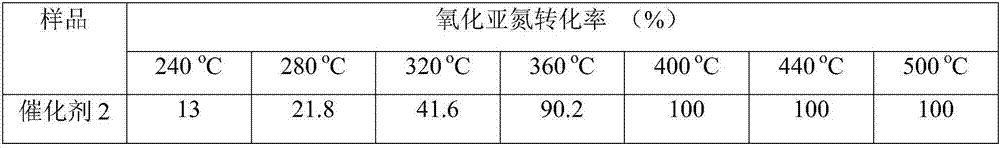

Porous graphene-molecular sieve double-carrier denitration catalyst and preparation method thereof

InactiveCN109999901AHigh activityIncreased effective adsorption areaGas treatmentMolecular sieve catalystsPorous grapheneMolecular sieve

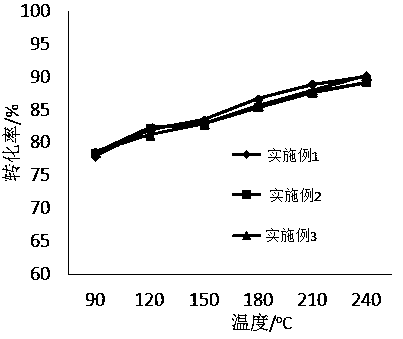

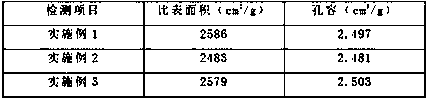

The invention belongs to the technical field of air pollution prevention, and relates to a porous graphene-molecular sieve double-carrier denitration catalyst and a preparation method thereof. Carriers of the catalyst are graphene-molecular sieve double carriers, and an active component of the catalyst is MnOx-CeO2. According to the method provided by the invention, the catalyst prepared by the method has a denitration rate of 90% after the temperature reaches 240 DEG C; compared with a conventional denitration catalyst, the catalyst provided by the invention has the advantage of significant low-temperature catalytic activity; and the catalyst shows low-temperature high activity due to the following reasons: the catalyst has a higher comparative area and pore volume, so that the effectiveadsorption area of the catalyst is increased; soaking treatment is performed on the catalyst carriers by an acidic solution, so that the catalyst carriers have certain acidity; and the catalyst has excellent electron transfer orbits, so that MnOx and CeO2 have excellent reducing ability and remarkable oxygen storage capacity, and the catalyst has higher activity at low temperature.

Owner:宫子凡

Nickel base crouse vent gas hydrogenation catalysts and coprecipitation manufacturing method

InactiveCN100591418CLow costExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentPolyethylene glycol

The invention relates to a hydrogeneration catalyst for the tail gas of a Crouse sulphur recycle device and a preparation method for the catalyst. A nickel-based Crouse tail gas hydrogeneration catalyst, which is characterized in that the catalyst essentially comprises a main active component, a secondary active component and alumina, the mass percentage of each component is like follows: the mainactive component 20.1-60%, the secondary active component 0-10%, the alumina 40-79.9%, the sum of the three components is 100%; wherein, the main active component is nickel oxide, the secondary active component is one or the mixture of any two or three of chrome oxide, copper oxide and iron oxide, when the secondary active component is a mixture, the compounding ratio among the oxides is random.The invention has the advantages of the good catalyzing activity at low temperature and the low cost.

Owner:WUHAN UNIV OF TECH

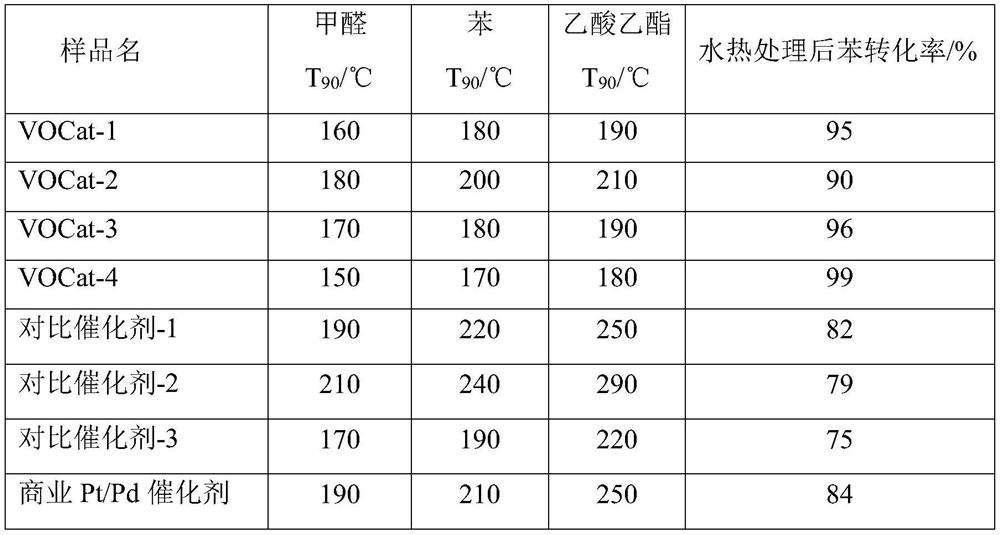

VOCs catalytic oxidation catalyst and preparation method and application thereof

ActiveCN112844459ALow costGood dispersionGas treatmentMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a VOCs catalytic oxidation catalyst and a preparation method and application thereof. According to the catalyst, a hierarchical pore ZSM-5 molecular sieve serves as a carrier, transition metals Cu and Mn serve as active components, one or more of Ce, Nd and Co serve as auxiliaries, and the active metals and the auxiliaries are loaded into pore channels of the hierarchical pore molecular sieve through a step-by-step impregnation method; and steam treatment is then conducted to obtain the high-dispersion transition metal composite oxide catalyst. The well-developed pore channel structure of the hierarchical pore ZSM-5 molecular sieve provides the highly-dispersed surface for the active metal and the auxiliary, and the acidic center on the surface of the ZSM-5-molecular sieve provides the synergistic effect for the catalytic oxidation of VOCs, such that the VOCs catalytic oxidation activity of the catalyst is significantly improved; the catalyst is simple to prepare, adopts cheap raw materials, is suitable for mass production and industrial application, and has better application value and prospect.

Owner:安徽省博广运环保科技有限公司

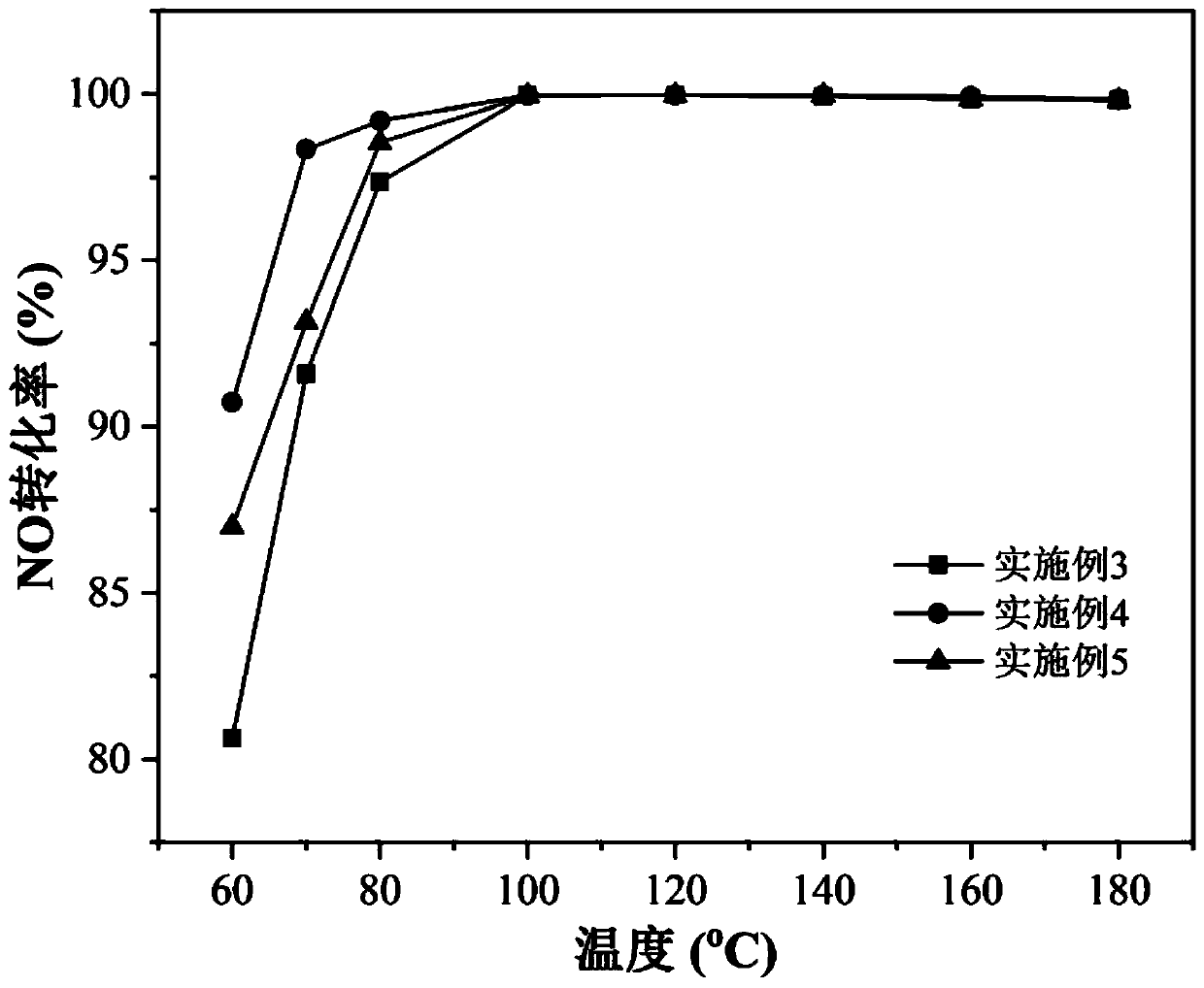

Low-temperature SCR denitration catalyst and preparation method and application thereof

ActiveCN110721676ASimple preparation processGood catalytic activity at low temperatureGas treatmentDispersed particle separationGraphite oxideFlue gas

The invention discloses a low-temperature SCR denitration catalyst and a preparation method thereof, and application of the catalyst to a low-temperature SCR flue gas denitration system. The preparation method comprises the following steps: weighing graphite oxide, putting the weighed graphite oxide in a beaker, adding deionized water, and carrying out ultrasonic dispersion to obtain a graphene oxide dispersion liquid; adding KMnO4 and L-ascorbic acid into the graphene oxide dispersion liquid, carrying out stirring at room temperature, centrifuging a reaction liquid, washing the obtained precipitate with deionized water and absolute ethyl alcohol, and drying the precipitate in a blast drying oven; and carrying out low-temperature pre-oxidation treatment on a sample in the blast drying ovento obtain the low-temperature SCR denitration catalyst. The preparation method is simple, and the prepared catalyst is fine in particle, large in specific surface area, good in dispersity, high in purity and good in low-temperature catalytic activity.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com