Method for removing NOx in sintering flue gas through low-temperature SCR (Selective Catalytic Reduction) catalyst

An SCR catalyst, sintering flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of high cost of sintering flue gas denitrification catalyst, few cycles, and difficulty in large-scale promotion. , to achieve the effect of continuous and stable denitration ability, good low-temperature catalytic activity, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

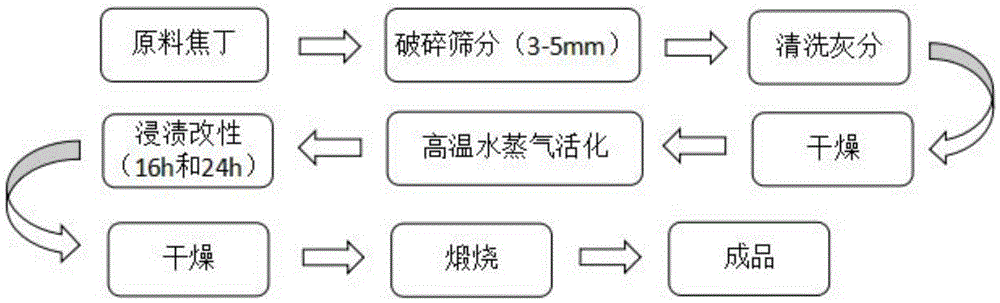

[0025] This example is obtained by conducting industrial tests in the sintering plant of Iron and Steel Company 1. The sintering machine area of the steel plant is 450m 2 ,use figure 1 Shown technological process, comprises the following steps:

[0026] 1) The defective coke in the process of producing metallurgical coke in the coking plant is crushed and screened to obtain metallurgical coke with a particle size of 3-5mm;

[0027] 2) Wash the metallurgical coke obtained in step 1) with clean water, drain, and put the drained metallurgical coke into a drying oven for constant temperature drying at a temperature of 120° C. for 2 hours;

[0028] 3) The dried metallurgical coke obtained in step 2) is placed in a resistance furnace, and heated at a high temperature at a heating temperature of 800°C for a heating time of 6 hours, and a mixture of nitrogen and water vapor is introduced during the heating process;

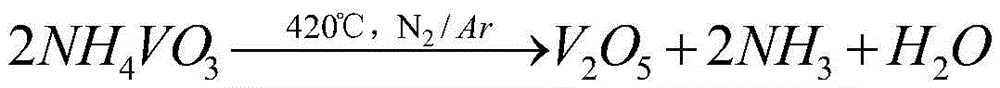

[0029] 4) Prepare oxalic acid and ammonium metavanadate into so...

Embodiment 2

[0035] This example is obtained by conducting industrial tests in the sintering plant of Iron and Steel Company 2. The sintering machine area of the steel plant is 360m 2 ,use figure 1 Shown technological process, comprises the following steps:

[0036] 1) The defective coke in the process of producing metallurgical coke in the coking plant is crushed and screened to obtain metallurgical coke with a particle size of 3-5mm;

[0037] 2) Wash the metallurgical coke obtained in step 1) with clean water, drain, and put the drained metallurgical coke into a drying oven for constant temperature drying at a temperature of 120° C. for 2 hours;

[0038] 3) The dried metallurgical coke obtained in step 2) is placed in a resistance furnace, and heated at a high temperature at a heating temperature of 800°C for a heating time of 6 hours, and a mixture of nitrogen and water vapor is introduced during the heating process;

[0039] 4) Prepare oxalic acid and ammonium metavanadate into so...

Embodiment 3

[0045] This embodiment is obtained by conducting industrial tests in the sintering plant of Iron and Steel Company 3. The sintering machine area of the steel plant is 240m 2 ,use figure 1 Shown technological process, comprises the following steps:

[0046] 1) The defective coke in the process of producing metallurgical coke in the coking plant is crushed and screened to obtain metallurgical coke with a particle size of 3-5mm;

[0047] 2) Wash the metallurgical coke obtained in step 1) with clean water, drain, and put the drained metallurgical coke into a drying oven for constant temperature drying at a temperature of 120° C. for 2 hours;

[0048] 3) The dried metallurgical coke obtained in step 2) is placed in a resistance furnace, and heated at a high temperature at a heating temperature of 800°C for a heating time of 6 hours, and a mixture of nitrogen and water vapor is introduced during the heating process;

[0049] 4) Prepare oxalic acid and ammonium metavanadate into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com