Porous graphene-molecular sieve double-carrier denitration catalyst and preparation method thereof

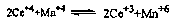

A technology of porous graphene and denitrification catalyst, which is applied in the field of porous graphene-molecular sieve dual carrier denitrification catalyst and its preparation, which can solve the problems of energy waste, catalyst deactivation, and catalyst activity decline, and achieve increased adsorption area and high activity. , Significant effect on oxygen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

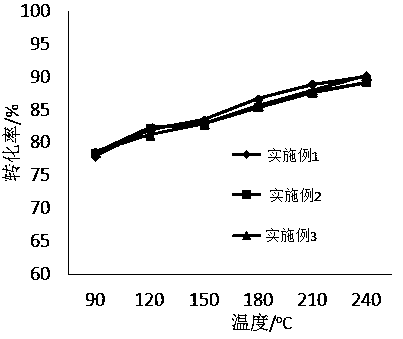

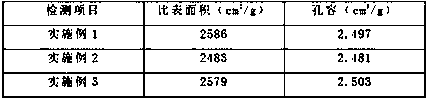

Examples

Embodiment 1

[0028] SAPO-11 molecular sieve raw powder is prepared by the following steps: successively add 5gAl 2 o 3 Add powder (purity above 80wt%), 80ml phosphoric acid (Sinopharm Group, analytically pure), 25ml silica sol (30wt.% aqueous solution), 30ml di-n-propylamine and 200ml pure water into the crystallization kettle in turn, and use in-situ hydrothermal crystallization Synthesis of SAPO-11 molecular sieves. After each material is added into the crystallization kettle according to the above-mentioned ratio and order, it is sealed, and with 5 o C / min speed up to 220 oC , and then left to crystallize for more than 48h. The resulting solid product was washed three times with pure water, and then placed under an argon atmosphere for 55 oC Dry for 1 hour to obtain SAPO-11 molecular sieve.

[0029] Take 50ml of 3mol / L nitric acid solution (with a density of about 1.3) and 50ml of a 2mol / L sulfuric acid solution (with a density of about 1.4) and mix to obtain an acidic activation s...

Embodiment 2

[0031] SAPO-11 molecular sieve was prepared by the same method as in Example 1.

[0032]Take 50ml of 3mol / L nitric acid solution (with a density of about 1.3) and 50ml of a 2mol / L sulfuric acid solution (with a density of about 1.4) and mix to obtain an acidic activation solution. After the graphene sheet is ground, pass through a 40-70 mesh sieve (200-300 microns), then weigh 1.5 g and add it to the acidic activation solution, stir and activate at room temperature for 8 hours at a stirring speed of 100 rpm. Add 0.5 g of the prepared SAPO-11 molecular sieve, and then sonicate for 5 minutes to obtain a mixed suspension. The mixed suspension was filtered, and the filter residue was dried under a nitrogen atmosphere at a drying temperature of 40 degrees Celsius and a drying time of 2 hours to obtain a carrier powder. Weigh Ce(NO 3 ) 3 •6H 2 O solid 1g, 50% manganese nitrate solution 2.8g, sequentially added to 50g (62.5ml) of ethanol, added 125ml of deionized water, mixed eve...

Embodiment 3

[0034] SAPO-11 molecular sieve was prepared by the same method as in Example 1.

[0035] Take 50ml of 3mol / L nitric acid solution (with a density of about 1.3) and 50ml of a 2mol / L sulfuric acid solution (with a density of about 1.4) and mix to obtain an acidic activation solution. After the graphene sheet is ground, pass through a 40-70 mesh sieve (200-300 microns), then weigh 1.5 g and add it to the acidic activation solution, stir and activate at room temperature for 8 hours at a stirring speed of 100 rpm. Add 0.5 g of the prepared SAPO-11 molecular sieve, and then sonicate for 10 minutes to obtain a mixed suspension. The mixed suspension was filtered, and the filter residue was dried under a nitrogen atmosphere at a drying temperature of 40 degrees Celsius and a drying time of 2 hours to obtain a carrier powder. Weigh Ce(NO 3 ) 3 •6H 2 O solid 1g, 50% manganese nitrate solution 2.8g, sequentially added to 50g (62.5ml) of ethanol, added 125ml of deionized water, mixed e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com