Porous molecular sieve catalyst for assembling tungsten carbide and its preparation

A mesoporous molecular sieve and tungsten carbide technology, applied in the field of catalysis, can solve the problems of easy agglomeration of tungsten carbide active component particles, inconvenient use, decreased catalytic activity, etc., and achieves low cost, simple method, and good low-temperature catalysis. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

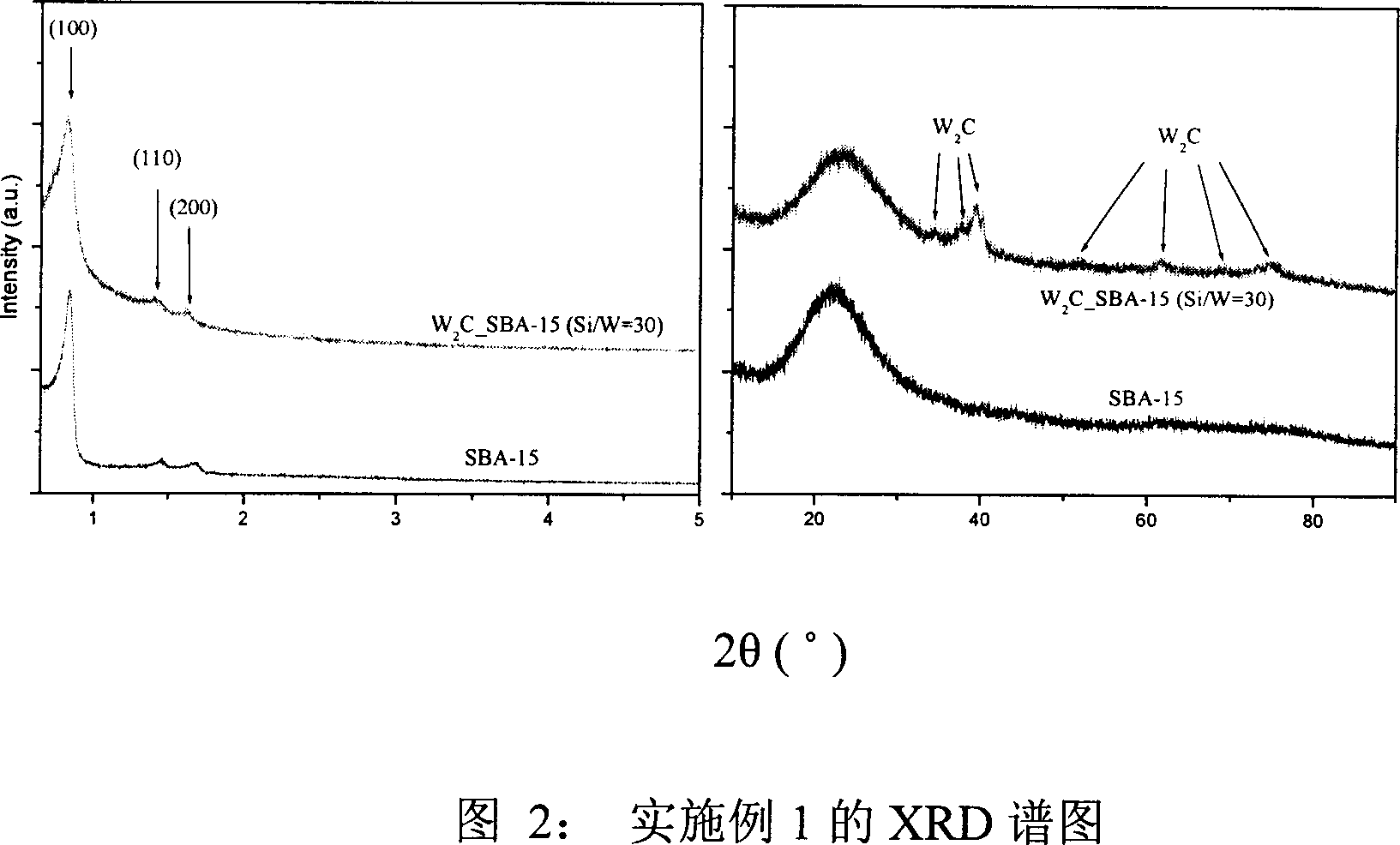

Embodiment 1

[0024] (1) Add 0.35g EO 20 PO 70 EO 20 The template agent (molecular weight is 5800) was dissolved in 95ml deionized water, and 31.25g hydrochloric acid (4M) was added in a 50°C water bath with stirring, and the stirring was continued for 3 hours; the ammonium paratungstate (5(NH 4 ) 2 O·12WO 3 ·5H 2 O) 1.30g (containing 0.005 moles of tungsten) was dissolved in 30ml of deionized water, then added to the above solution, continued to stir for 3 hours, then added 31.25g of tetraethyl orthosilicate (containing 0.15 moles of Si), continued to stir for 22 hours, and then , transferred to a Teflon-lined autoclave, crystallized at 100°C for 24 hours, the product was filtered, washed, and suction filtered, and the obtained solid was naturally dried at room temperature for 24 hours, and then placed in a heating furnace. Raise the temperature to 550°C at a heating rate of 2°C / min, and keep the temperature constant for 7 hours, which is the solid product of the tungsten carbide prec...

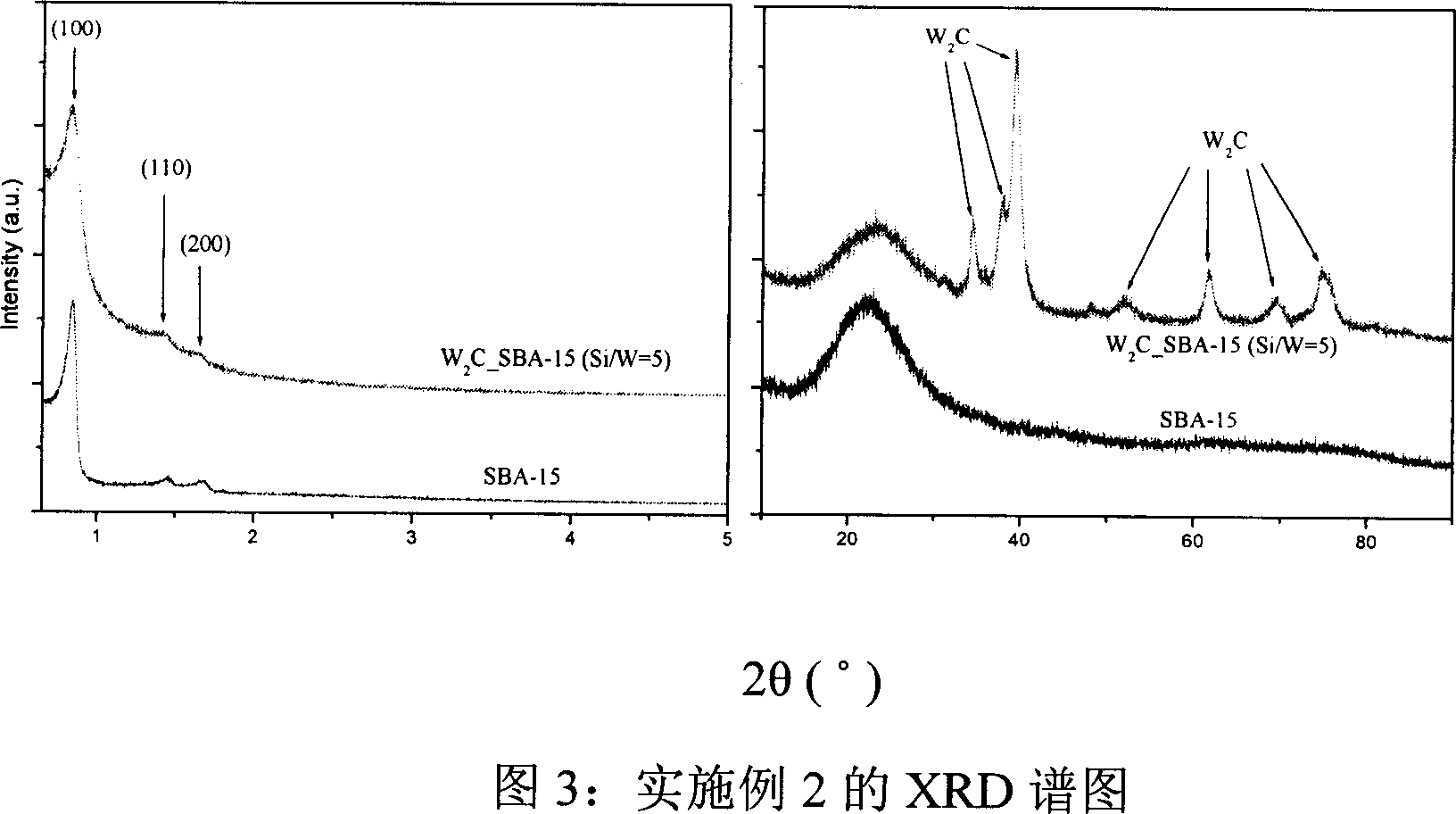

Embodiment 2

[0028] (1) Add 0.67g EO 20 PO 70 EO 20(Molecular weight is 5800) template agent is dissolved in 106ml deionized water, in 40 ℃ water bath, add 62.5g hydrochloric acid (4M) under stirring condition, continue stirring for 5 hours; Weigh ammonium paratungstate (5(NH 4 ) 2 O·12WO 3 ·5H 2 O) 2.61g (containing 0.01 mol of tungsten) was dissolved in 50ml of deionized water, then added to the above solution, continued to stir for 8 hours, then added 10.42g of tetraethyl orthosilicate (containing 0.05 mol of Si), continued to stir for 30 hours, and then , transferred to a Teflon-lined autoclave, crystallized at 85°C for 32 hours, filtered, washed, and suction filtered, and the obtained solid was naturally dried at room temperature, then put into a heating furnace, and heated at 2°C / min The heating rate is increased to 600 ° C, and the temperature is kept constant for 6 hours, which is the solid product of the tungsten carbide precursor assembled in the prepared SBA-15 mesoporous m...

Embodiment 3

[0032] (1) Add 0.42g EO 20 PO 70 EO 20 (Molecular weight is 5800) template agent is dissolved in 100ml deionized water, add 41.7g hydrochloric acid (4M) under stirring condition in 45 ℃ water bath, continue stirring for 4 hours; Weigh ammonium paratungstate (5(NH 4 ) 2 O·12WO 3 ·5H 2 O) 1.30g (containing 0.05 moles of tungsten) was dissolved in 30ml of deionized water, then added to the above solution, continued to stir for 7 hours, then added 20.84g of tetraethyl orthosilicate (containing 0.1 moles of Si), continued to stir for 24 hours, and then , transferred to a Teflon-lined autoclave, crystallized at 90°C for 26 hours, filtered, washed, and suction-filtered, and the obtained solid was naturally dried at room temperature, then placed in a heating furnace at 2°C / min The heating rate is increased to 550 ° C, and the temperature is kept constant for 7 hours, that is, the solid sample of the tungsten carbide precursor assembled in the prepared SBA-15 mesoporous molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com