Low-temperature SCR denitration catalyst and preparation method and application thereof

A denitration catalyst and low-temperature technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as affecting catalytic activity, sintering and agglomerating metal particles, destroying the original appearance and pore structure of metal catalysts, and achieving good The effect of low temperature catalytic activity, good dispersibility and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The graphene oxide used in the following examples is prepared by improving the Hummers method, and the specific steps are:

[0030] Pour 96mL of concentrated sulfuric acid (98% mass concentration) into a dry round bottom flask, then add 2gNaNO 3 , after stirring and dissolving, add 2g flake graphite. After the flake graphite is uniformly dispersed in the solution, slowly add 12g KMnO4 into the flask and react for 1.45h. Then raise the temperature to 35°C, react under this condition for 2 hours, then add 80mL of deionized water very slowly, raise the temperature to 95°C, react for 30min, then add 200mL of deionized water, then add 10mL of 30% H2O2 solution, react for 10min , the reaction solution was centrifuged while it was hot, and the resulting precipitate was washed with 1000 mL of 5% hydrochloric acid to remove metal ions contained in the precipitate. Then, it was washed with deionized water until the pH of the solution was close to neutral, and dried in a vacuum o...

Embodiment 2

[0032] A preparation method of a low-temperature SCR denitration catalyst, the specific steps are:

[0033] (1) Weigh 6.6 mg of graphite oxide into a beaker, add 80 mL of deionized water, and perform ultrasonic treatment at 80 W and 40 KHz for 30 min to obtain a graphene oxide dispersion. Add 6mmol (0.948g) KMnO to the graphene oxide dispersion 4 , stirred magnetically at room temperature until completely dissolved, and solution A was obtained.

[0034] (2) Weigh 1.2mmol (0.211g) L-ascorbic acid and dissolve it in 20mL deionized water, stir it to completely dissolve to obtain solution B (here KMnO 4 The molar ratio to L-ascorbic acid is 1:0.2, and the mass ratio of graphene oxide to manganese is 0.02:1). Under stirring state, solution B was slowly added dropwise to A, stirred at room temperature for 30 min, and the stirring speed was 400 r / min.

[0035] (3) The reaction solution was centrifuged, washed three times with deionized water, and then washed twice with absolute et...

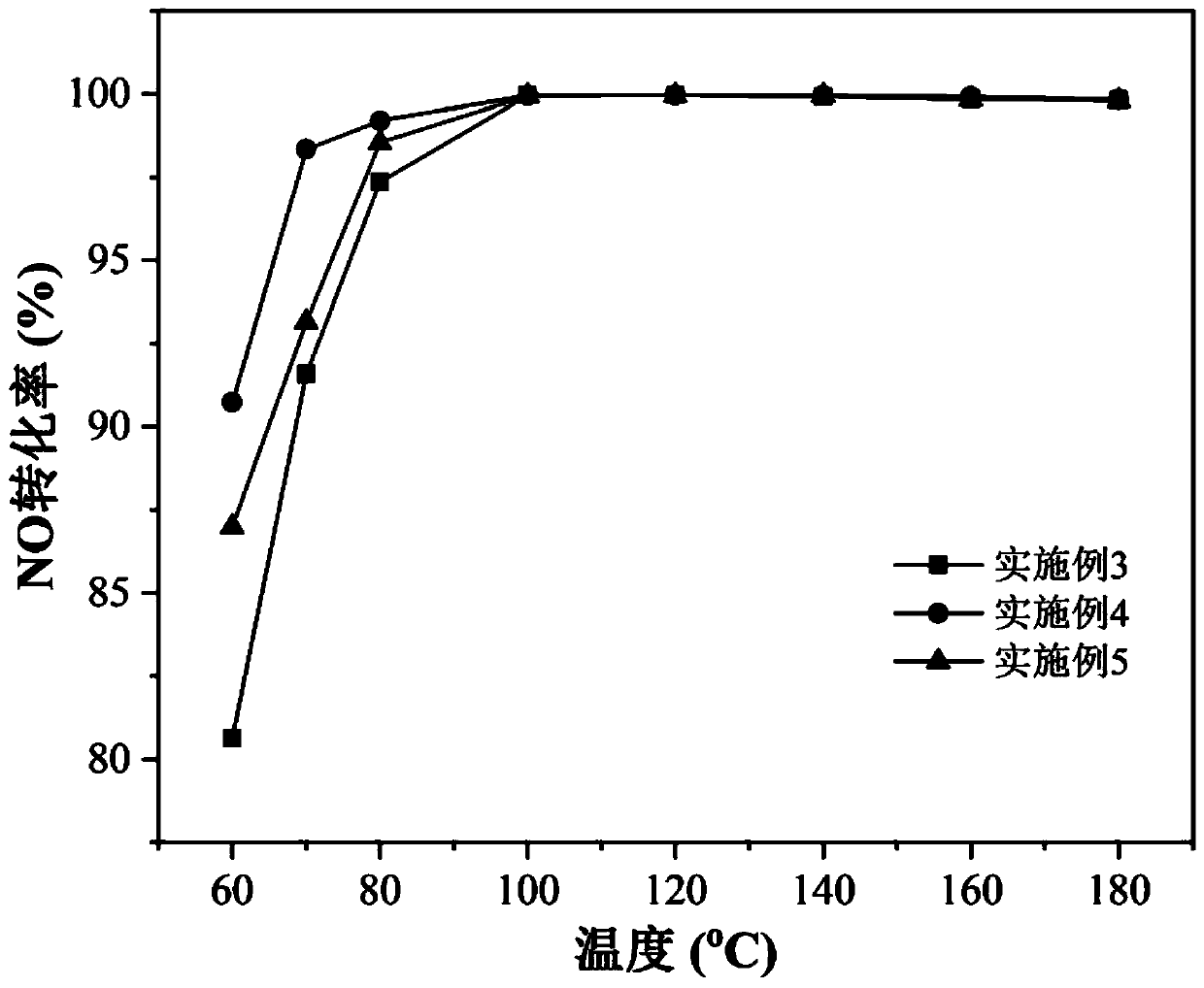

Embodiment 3

[0038] A preparation method of a low-temperature SCR denitration catalyst, the specific steps are:

[0039] (1) Weigh 6.6 mg of graphite oxide into a beaker, add 80 mL of deionized water, and perform ultrasonic treatment at 80 W and 40 KHz for 30 min to obtain a graphene oxide dispersion. Add 6mmol (0.948g) KMnO to the graphene oxide dispersion 4 , stirred magnetically at room temperature until completely dissolved, and solution A was obtained.

[0040] (2) Weigh 3mmol (0.528g) L-ascorbic acid and dissolve it in 20mL deionized water, stir to make it completely dissolve to obtain solution B (here KMnO 4 The molar ratio to L-ascorbic acid is 1:0.5, and the mass ratio of graphene oxide to manganese is 0.02:1). Under stirring state, solution B was slowly added dropwise to A, stirred at room temperature for 30 min, and the stirring speed was 400 r / min.

[0041](3) The reaction solution was centrifuged, washed three times with deionized water, and then washed twice with absolute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com