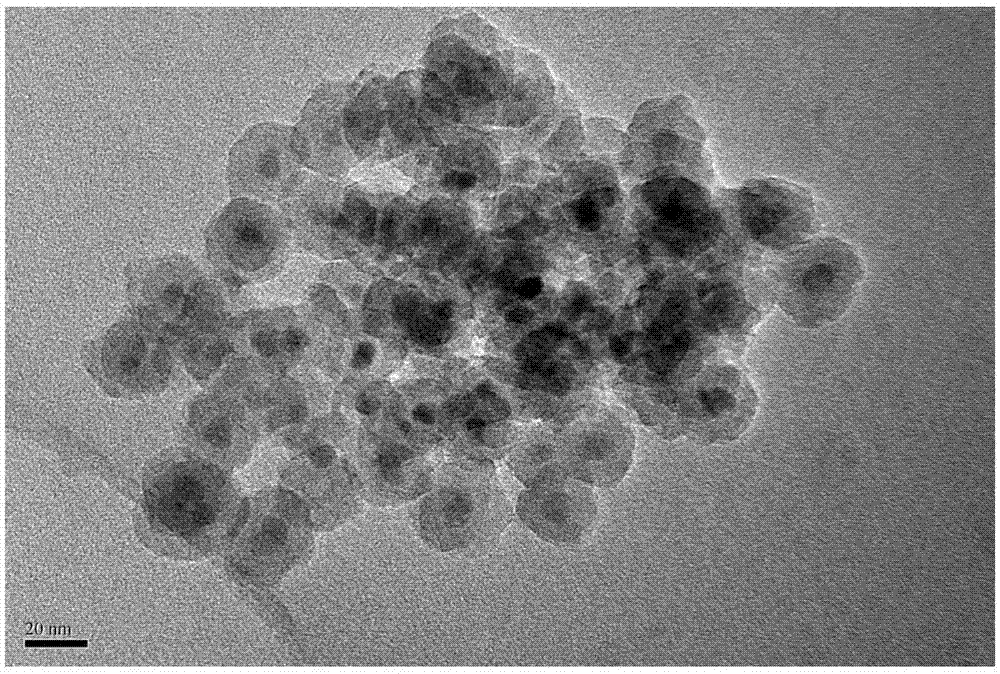

Double metal cobalt-based catalyst and preparation method and application

A metal cobalt-based, catalyst technology, used in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc., can solve the problem that active oxide nanoparticles are limited by the immobilization of carriers. , active oxide sintering, mutual agglomeration and other problems, to achieve the effect of improving hydrothermal stability, accelerating catalytic cycle and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

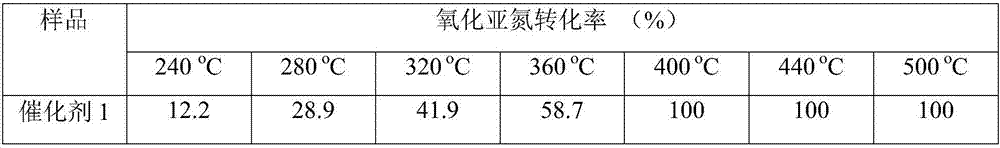

Embodiment 1

[0043] Weigh 1.79g CoCl 2 ·6H 2 O, 1.87g Co(Ac) 2 4H 2 O, 0.13g CuCl 2 2H 2 O, 0.15g Cu(Ac) 2 ·H 2 O and 42.2g of hexamethylenetetramine were added into 1L with a volume ratio of 2.5:1 and stirred in an aqueous ethanol solution (Co ion concentration 0.015mol / L, the mole fraction ratio of its inorganic salt and organic salt was 1:1; co-active metal The concentration of Cu ions is 0.0015mol / L, and the mole fraction ratio of its inorganic salt and organic salt is 1:1; the concentration of hexamethylenetetramine is 0.30mol / L), and the operating temperature is increased to 50°C, and added to the mixed solution 8.0 g of polyvinylpyrrolidone until complete dissolution. Continue to add 0.045mol H to the mixed solution 2 o 2 After the solution system gradually turns brown, the reaction system is sealed and kept under vigorous stirring for 24 hours to obtain a highly uniformly dispersed nanoparticle suspension of tricobalt tetroxide and copper oxide bimetallic composite oxide. ...

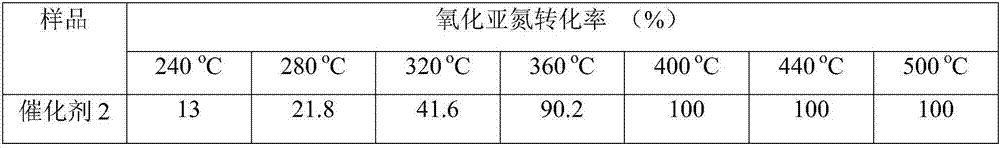

Embodiment 2

[0049] Weigh 1.82g Co(NO 3 ) 2 ·6H 2 O, 1.61g Co(acac) 2 , 0.15g Cu(NO 3 ) 2 ·3H 2 O, 0.16g Cu(acac) 2 Add 35.1g of hexamethylenetetramine into 1L of ethanol aqueous solution with a volume ratio of 2:1 and stir and mix (Co ion concentration 0.0125mol / L, the mole fraction ratio of its inorganic salt and organic salt is 1:1; the auxiliary active metal Cu The ion concentration is 0.00125mol / L, and the mole fraction ratio of its inorganic salt and organic salt is 1:1; the concentration of hexamethylenetetramine is 0.25mol / L), and the operating temperature is increased to 60°C, and 6.1 g polyvinylpyrrolidone until complete dissolution. Continue to add 0.025mol H to the mixed solution 2 o 2 After the solution system gradually turns brown, seal the reaction system and keep vigorously stirring for 18 hours to obtain a highly uniformly dispersed suspension of bimetallic composite oxide nanoparticles of tricobalt tetroxide and copper oxide.

[0050] Take 0.31g Zr(NO 3 ) 4 ·5...

Embodiment 3

[0055] Weigh 1.46g Co(NO 3 ) 2 ·6H 2 O, 1.25g Co(Ac) 2 4H 2O, 0.12g Cu(NO 3 ) 2 ·3H 2 O, 0.10gCu(Ac) 2 ·H 2 O and 23.4g of hexamethylenetetramine were added into 1L of 0.1:1 ethanol aqueous solution and stirred and mixed (Co ion concentration 0.01mol / L, the mole fraction ratio of its inorganic salt and organic salt was 1:1; co-active metal The concentration of Cu ions is 0.001mol / L, and the mole fraction ratio of its inorganic salt and organic salt is 1:1; the concentration of hexamethylenetetramine is 0.17mol / L), and the operating temperature is raised to 80°C, and added to the mixed solution 5.0 g of polyvinylpyrrolidone until complete dissolution. Continue to add 0.01mol H to the mixed solution 2 o 2 After the solution system gradually turned brown, the reaction system was sealed and kept vigorously stirred for 12 hours to obtain a highly uniformly dispersed suspension of bimetallic composite oxide nanoparticles of tricobalt tetroxide and copper oxide.

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com