Preparation method and application of copper-cobalt composite oxide catalyst

A composite oxide and catalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Density and other problems, to achieve the effect of good catalytic combustion activity of toluene volatile organic compounds, large reaction interface, and good catalytic combustion activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the copper-cobalt composite oxide catalyst of the present embodiment is:

[0032] S1, by copper nitrate: cobalt nitrate: the mol ratio of oxalic acid is 1:2:3, carry out mixing and grinding into dry matter;

[0033] S2. Roast the dry material in S1. The roasting condition is to raise the temperature to 450°C at a heating rate of 10°C / min, and then roast at a constant temperature of 450°C for 2 hours. After the end, after the temperature drops to normal temperature, take it out, Instantly.

Embodiment 2

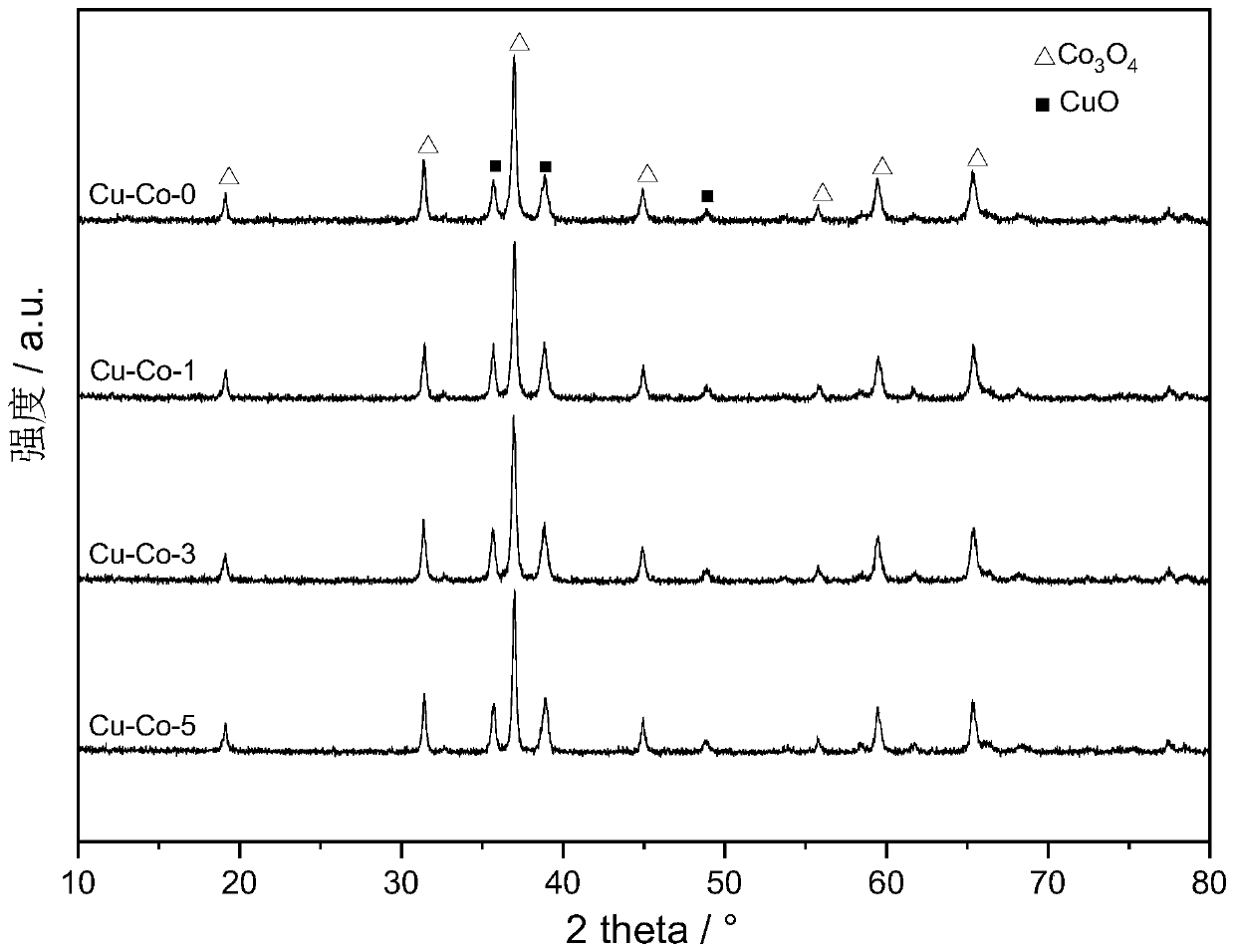

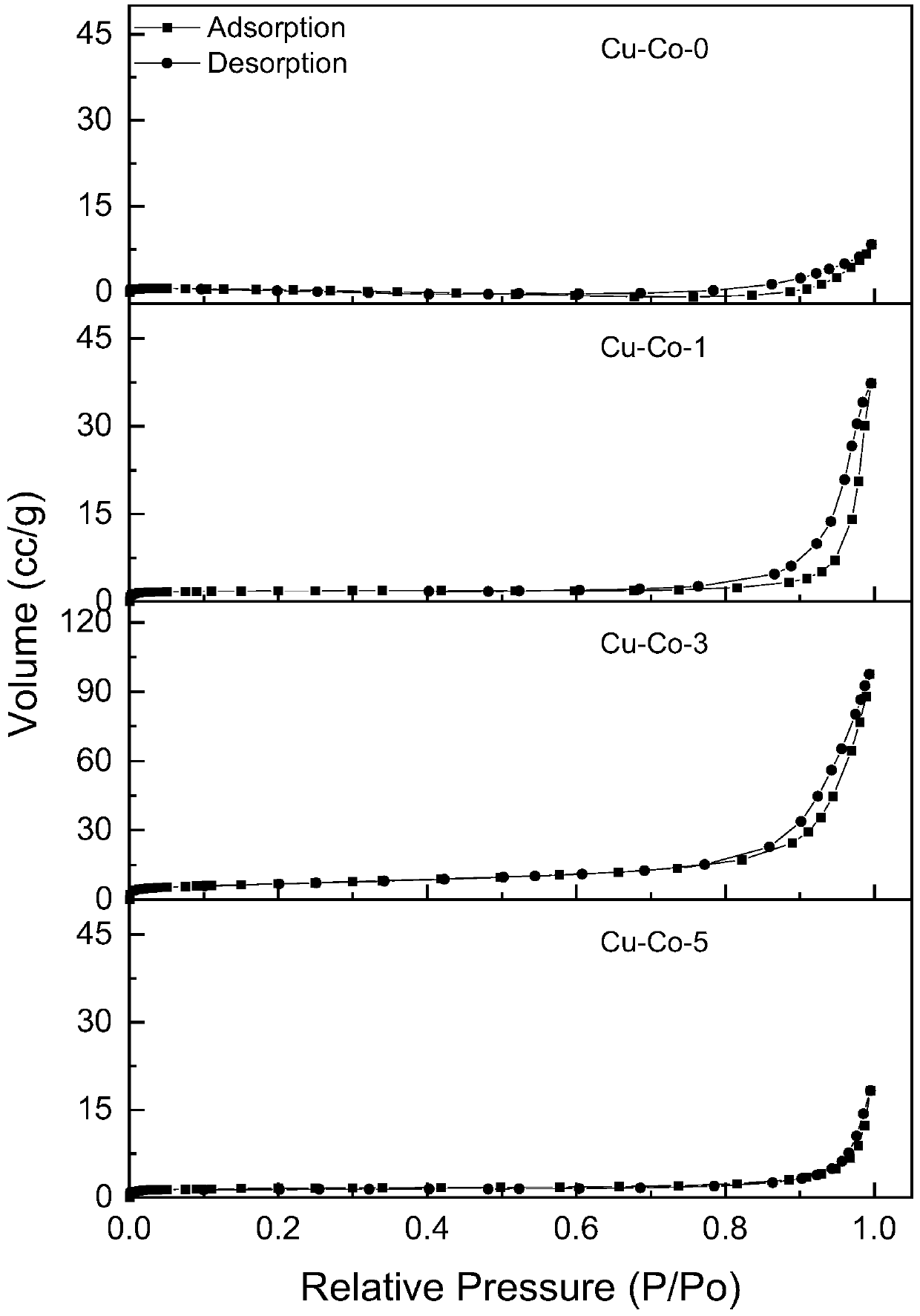

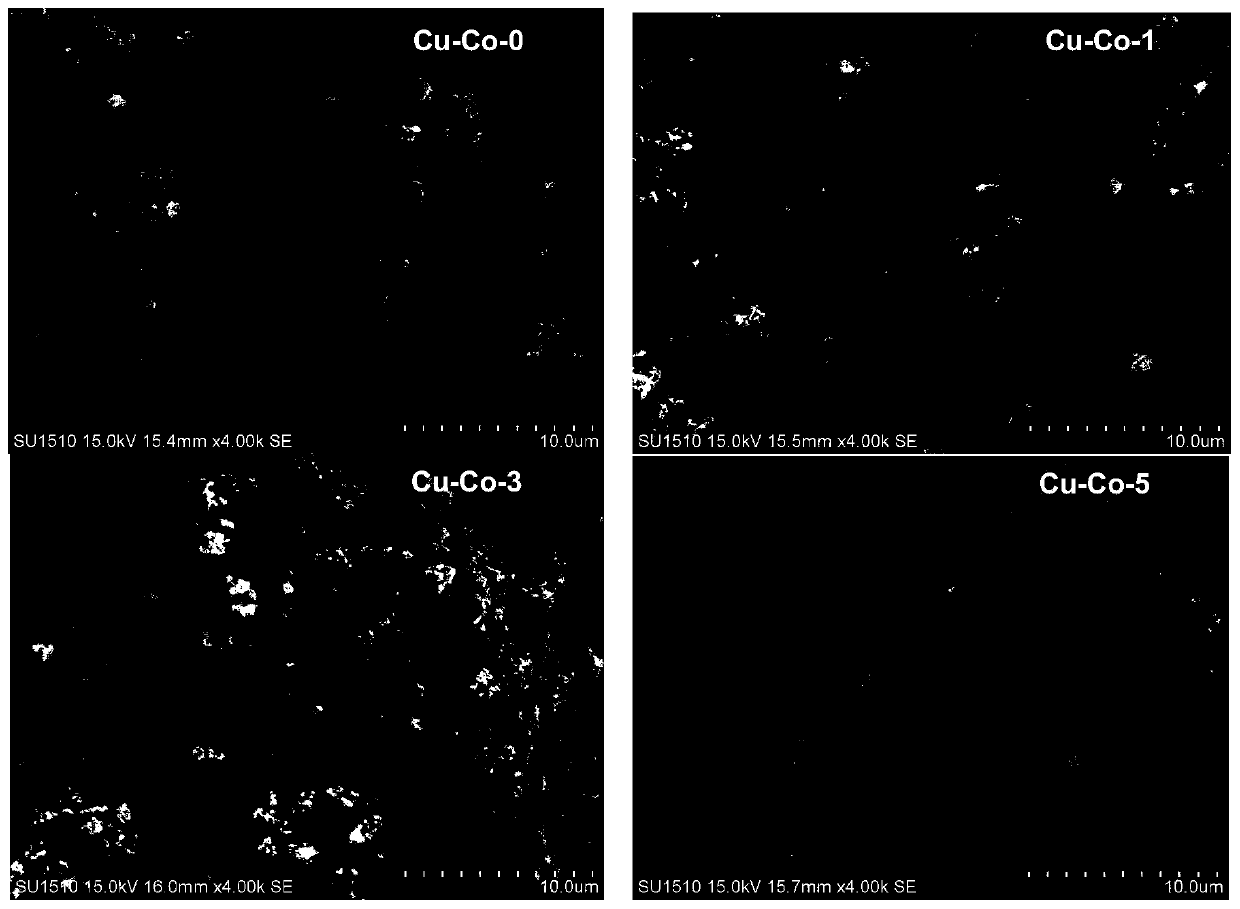

[0035] This example studies the influence of the proportion of oxalic acid on the performance of the catalyst. In this example, except that the molar ratio of copper nitrate: cobalt nitrate: oxalic acid is replaced by 1:2:0, 1:2:1 and 1:2:5, the rest are the same as in Example 1.

[0036] The prepared copper-cobalt composite oxide catalyst is marked as Cu-Co-0, Cu-Co-1 and Cu-Co-5 respectively with the content of oxalic acid, and the copper-cobalt composite oxide catalyst prepared in Example 1 is marked as Cu-Co-3.

[0037] The copper-cobalt composite oxide catalysts in Example 1 and Example 2 were used in the catalytic combustion of toluene to evaluate the activity of the catalyst. The activity evaluation of the catalyst was carried out in a micro-tubular fixed-bed reactor with an inner diameter of 8 mm under normal pressure, and a thermocouple was built in the reactor, and the reaction temperature was determined by -708P-type temperature program temperature controller con...

Embodiment 3

[0052] This example studies the effect of calcination temperature on catalyst performance. In this example, except that the calcination temperature is replaced by 300° C., 350° C. and 550° C., the rest are the same as in Example 1. The prepared copper-cobalt composite oxide catalyst is marked as 300-Cu-Co, 350-Cu-Co and 550-Cu-Co with the reaction temperature respectively, and the copper-cobalt composite oxide catalyst prepared in Example 1 is marked as 450- Cu-Co.

[0053] Catalysts are respectively used for the catalytic combustion of toluene, and the activity evaluation of catalyst is carried out, and the activity evaluation method is the same as embodiment 2. The conversion rate results of the toluene catalytic combustion of the copper-cobalt composite oxide catalyst obtained by the catalyst activity evaluation experiment are shown in Table 2:

[0054] Table 2 Effect of calcination temperature on the catalytic combustion performance of catalyst toluene

[0055]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com