Method for catalytically oxidizing NO by dielectric barrier discharge plasma modified catalyst

A dielectric barrier discharge and plasma technology, applied in the field of air pollution purification, can solve the problems of low catalytic oxidation activity, complex preparation process, high reaction temperature, etc., and achieve the effects of simple operation, short modification time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: The method for catalytic oxidation of NO by dielectric barrier discharge plasma modification catalyst, the specific operation is as follows:

[0023] (1) Catalyst preparation: Mix manganese acetate, potassium permanganate and cobalt nitrate, grind them thoroughly for 30 minutes, place them in an oven at 70°C for 48 hours at a constant temperature, wash the product three times with deionized water, filter with suction, and then use Wash with water and ethanol for 3 times, and filter with suction; dry the solid at 100°C for 12 hours, press into tablets, grind, and sieve to make 40-60 mesh particles to obtain the manganese-cobalt oxide catalyst Mn-Co-O x , wherein the mol ratio of manganese acetate and potassium permanganate is 2:3, and the mol ratio of Mn:Co is 9:1;

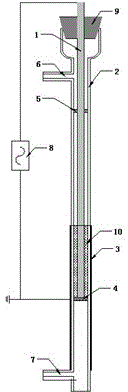

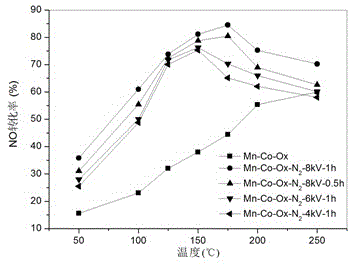

[0024] (2) Mn-Co-O x The catalyst is placed in a plasma reactor for modification. The plasma adopts a coaxial cylindrical dielectric barrier reactor. A stainless steel high-voltage elect...

Embodiment 2

[0026] Example 2: The method for catalytic oxidation of NO by dielectric barrier discharge plasma modification catalyst, the specific operation is as follows:

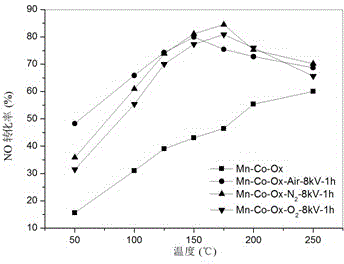

[0027] (1) The catalyst preparation method is the same as in Example 1, and then the Mn-Co-O x The catalyst is placed in a plasma reactor for modification, and the structure of the plasma reactor is the same as in Example 1. The modification condition is air plasma, the output voltage is 8kV, and the modification time is 1h. The catalyst obtained after modification is denoted as Mn-Co-O x -air-8kV-1h;

[0028] (2) The plasma-modified catalyst Mn-Co-O x -air-8kV-1h is placed in a glass tube fixed bed reactor, and NO, O 2 , N 2 Mixed gas, the temperature is controlled by the program temperature controller at 50~250°C, in which, the gas composition (volume percentage) at the reactor inlet is NO 0.05%, O 2 3%, N 2 It is the balance gas, the total flow rate of the mixed gas is 200ml / min, and the space veloci...

Embodiment 3

[0029] Example 3: The method for catalytic oxidation of NO by dielectric barrier discharge plasma modification catalyst, the specific operation is as follows:

[0030] (1) The catalyst preparation method is the same as in Example 1, and then the Mn-Co-O x The catalyst is placed in a plasma reactor for modification. The structure of the plasma reactor is the same as in Example 1, except that the inner diameter of the dielectric glass tube is 8 mm, and the diameter of the stainless steel high-voltage electrode is 3 mm. The modification condition is oxygen plasma, the output voltage is 8kV, and the modification time is 1h. The catalyst obtained after modification is denoted as Mn-Co-O x -O 2 -8kV-1h;

[0031] (2) The plasma-modified catalyst Mn-Co-O x -O 2 -8kV-1h is placed in a glass tube fixed bed reactor, and NO, O 2 , N 2 Mixed gas, the temperature is controlled by the program temperature controller at 50~250°C, in which, the gas composition (volume percentage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com