Low-temperature type vanadium catalyst for catalyzing SO2 oxidizing reaction

An oxidation reaction and catalyst technology, applied in the direction of physical/chemical process catalysts, inorganic chemistry, sulfur compounds, etc., can solve the problems of low quality and performance differences of vanadium catalysts, achieve excellent low-temperature catalytic activity, shorten the production process, and save construction The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

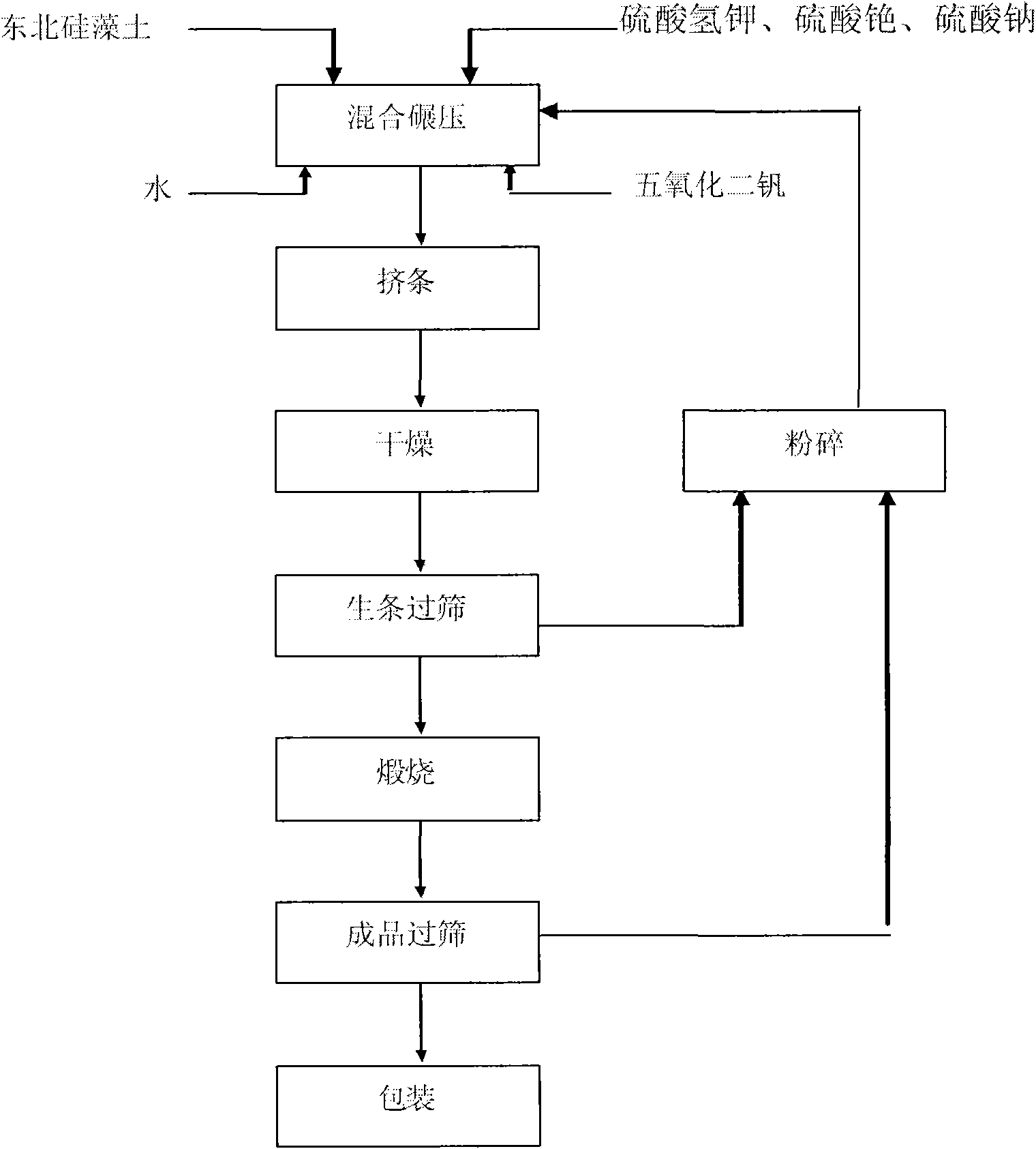

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the control study of the influence of auxiliary agent on conversion rate

[0040] In order to study the impact of adding different additives on the catalytic activity in the catalyst, in the proportioning of the vanadium-potassium-sodium-silicon system of the low-temperature sulfuric acid catalyst (6-7% of vanadium pentoxide, 20-30% of potassium hydrogensulfate, Sodium sulfate 8-10%, diatomaceous earth 50-63%) directly add a certain amount of nickel sulfate heptahydrate (NiSO 4 ·7H 2 O), manganese sulfate monohydrate (MnSO 4 H2O), antimony pentoxide (Sb 2 o 5 ), tin sulfate (SnSO 4 ), ammonium molybdate ((NH 4 )2Mo 4 ) and cesium sulfate (Cs 2 SO 4 ) additives were mixed and rolled to prepare samples, the numbers are TY-001, TY-002, TY-003, TY-004, TY-005, TY-006, and the S107 sample is a conventional low temperature without additives Type vanadium-potassium-sodium-silicon system catalyst comparison. These samples were tested for compressive stre...

Embodiment 2

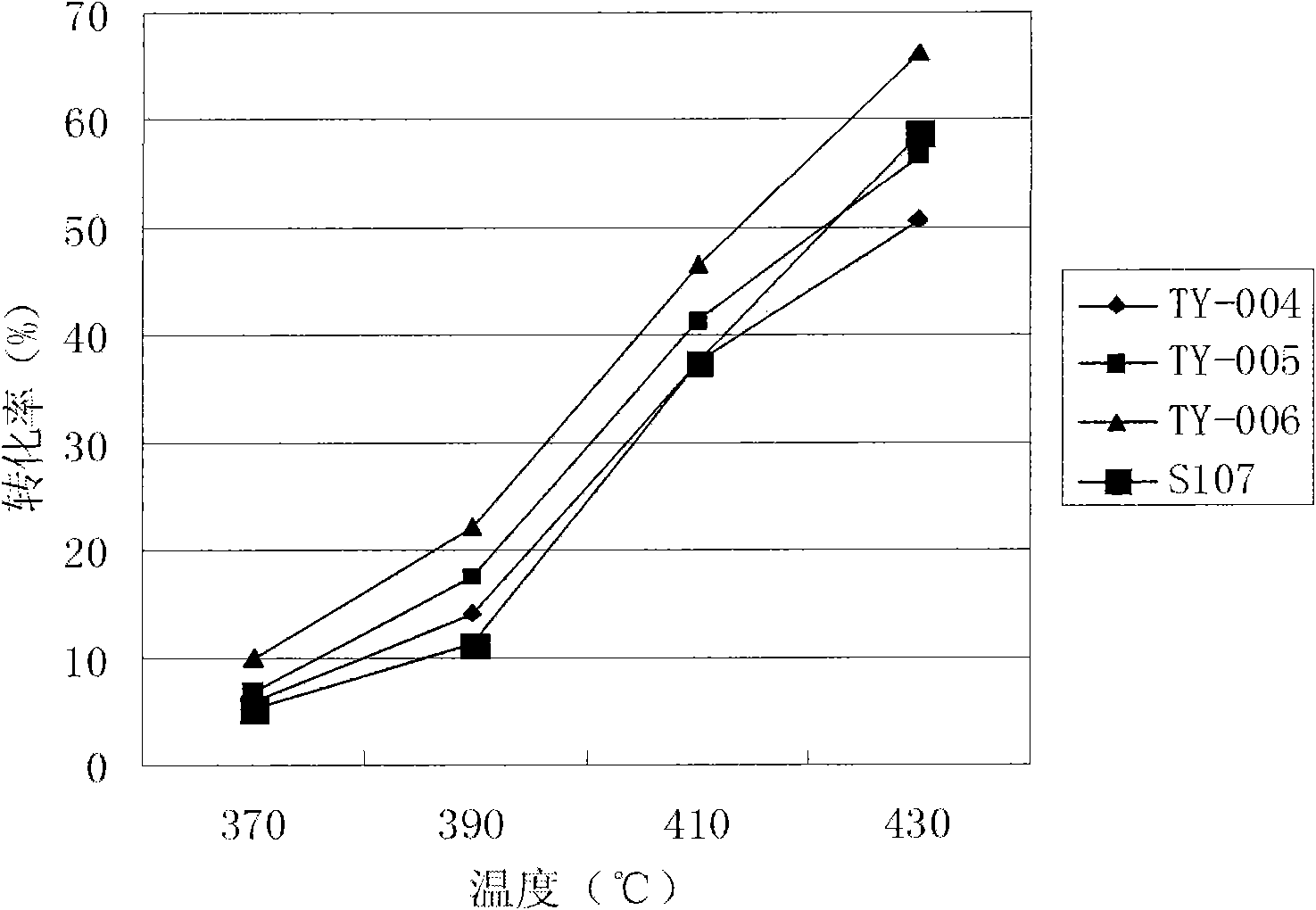

[0044] Embodiment 2: the influence of different reaction temperatures on conversion rate

[0045] According to the results in Table 2, the present invention measured the conversion rate of sulfur dioxide oxidation to sulfur trioxide at different reaction temperatures for TY-004, TY-005, TY-006 and S107 samples, and further investigated the reaction performance. The results are shown in Table 3 and figure 2 :

[0046] Table 3: Conversion rate of sulfur dioxide oxidation to sulfur trioxide at different reaction temperatures

[0047]

[0048] From Table 3 and figure 2 It can be clearly seen from the results that before the reaction temperature is 410°C, the conversion rates of sulfur dioxide to sulfur trioxide of TY-004, TY-005 and TY-006 samples are all higher than those of S107 sample, but at 430°C, only TY- The conversion rate of sulfur dioxide to sulfur trioxide in sample 006 is higher than that in sample S107. Note that after adding the SnSO 4 and (NH 4 ) 2 Mo 4...

Embodiment 3

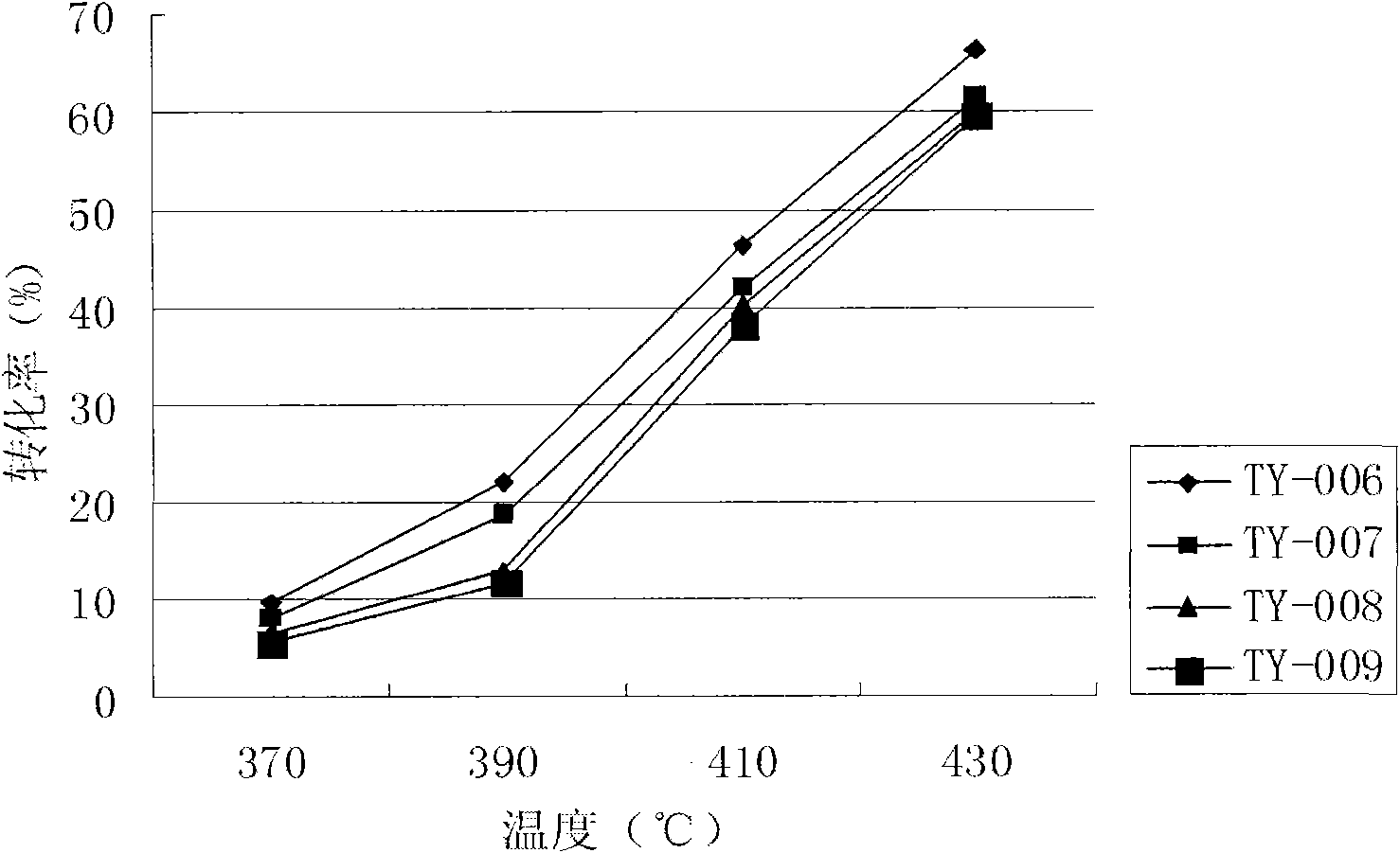

[0049] Embodiment 3: the determination of cesium compound

[0050] Cesium is a silver-white metal, soft and light, and malleable. Density 1.8785 g / cm 3 . The melting point is 28.40±0.01°C, and the boiling point is 678.4°C. Valence +1. The ionization energy is 3.894 electron volts. It is the most active among the alkali metals, and it can react violently with water and even with ice as low as -116°C. Due to its large ionic radius, it can form stable halides with halogens, and its hydroxides can also form corresponding salt compounds with sulfuric acid, nitric acid, hydrochloric acid and carbonic acid. Since halogen elements are generally considered to be catalyst poisons, the halides of cesium are not considered in this work, and only cesium hydroxide, cesium sulfate, cesium nitrate and cesium carbonate are investigated. The present invention directly adds a certain amount of cesium sulfate (Cs 2 SO 4 ), cesium nitrate (CsNO 3 ), cesium carbonate (Cs 2 CO 3 ) and ces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com