VOCs catalytic oxidation catalyst and preparation method and application thereof

A catalytic oxidation and catalyst technology, applied in the field of VOCs treatment, can solve the problem that the oxidation mechanism is not very clear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1), commercially available ZSM-5 molecular sieves were placed in 0.5mol / L NaOH solution, stirred at 20°C for 5h;

[0043] (2), the slurry of step (1) is centrifuged, washed with deionized water, and the resulting solid is placed in 0.5mol / L NH 4 In Cl solution, stir at 20°C for 5h;

[0044] (3) The slurry in step (2) was centrifuged, washed with deionized water until neutral, and the obtained solid was dried at 90°C for 10 hours, and then calcined at 500°C for 5 hours to obtain a hydrogen-type multi-stage porous ZSM-5 molecular sieve.

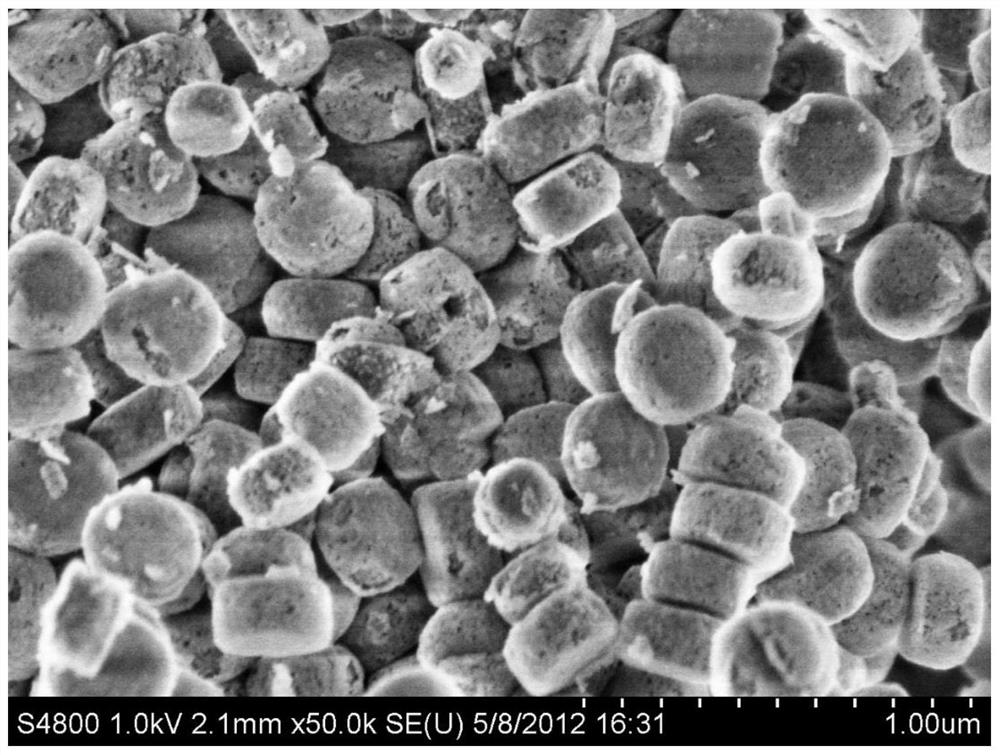

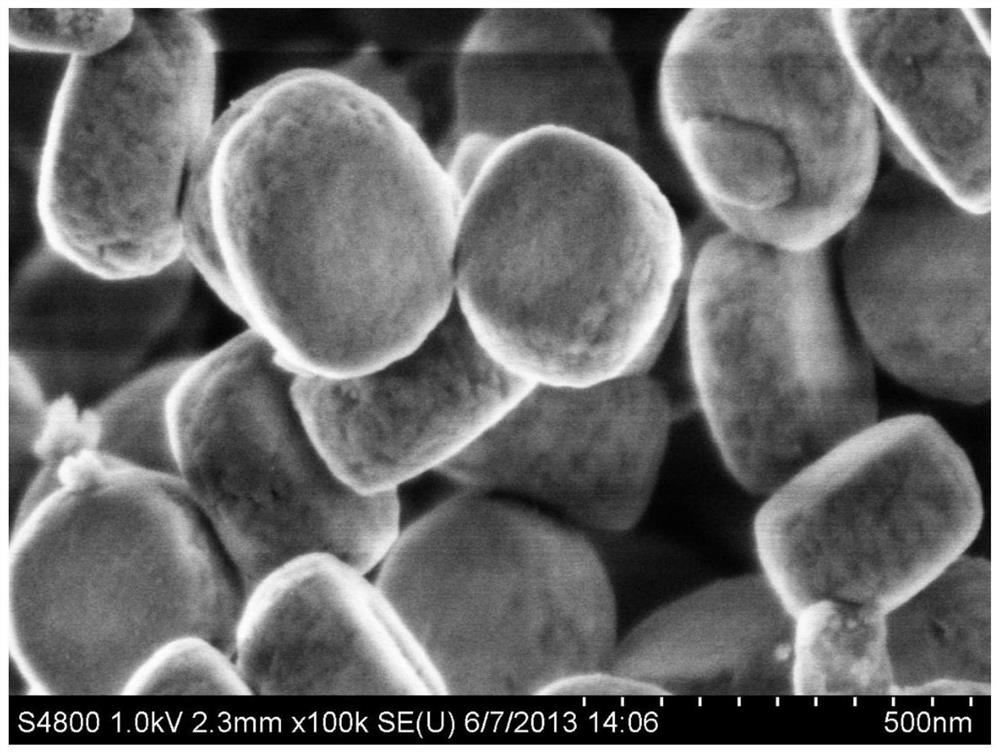

[0045]The morphology of the obtained multi-porous ZSM-5 molecular sieve is shown in figure 1 SEM, shown by figure 1 It can be seen that there are many mesopores etched by alkali on the surface of ZSM-zeolite, and the size of mesopores is 2-20 nm.

[0046] The hydrogen-type hierarchical porous ZSM-5 molecular sieve obtained in this example has a specific surface area of 480 m 2 / g, pore volume 0.42 mL / g.

Embodiment 2

[0048] (1), place commercially available ZSM-5 molecular sieves in a 0.1 mol / L NaOH solution, and stir at 50°C for 2h;

[0049] (2), the slurry of step (1) is centrifuged, washed with deionized water, and the obtained solid is placed in the NH of 0.1mol / L 4 In the Cl solution, stir at 90°C for 2h;

[0050] (3) Centrifuging the slurry in step (2), washing with deionized water until neutral, drying the obtained solid at 150°C for 5h, and calcining at 650°C for 2h to obtain a hydrogen-type hierarchical porous ZSM-5 molecular sieve.

[0051] The morphology of the obtained multi-porous ZSM-5 molecular sieve is shown in figure 2 SEM, shown by figure 2 It can be seen that there are many mesopores etched by alkali on the surface of ZSM-zeolite, and the size of mesopores is 2-20 nm.

[0052] The hydrogen-type hierarchical porous ZSM-5 molecular sieve obtained in this example has a specific surface area of 400 m 2 / g, pore volume 0.30 mL / g.

Embodiment 3

[0055] (1), mix 2.89g manganese nitrate (II) tetrahydrate and 3.03g copper nitrate (II) trihydrate and dissolve in 48g deionized water to obtain solution A;

[0056] (2), adding the multi-stage porous ZSM-5 molecular sieve of 8g embodiment 1 gained in solution A, ultrasonic dispersion 10min, stirring 1h, obtain slurry B;

[0057] (3), the slurry B is evaporated to dryness with a rotary evaporator to obtain solid C;

[0058] (4), dissolve 0.05g cerium nitrate hexahydrate (III) and 0.05g neodymium nitrate hexahydrate (III) in 24g deionized water to obtain solution D;

[0059] (5), adding solid C into solution D, ultrasonically dispersing for 10min, stirring for 1h to obtain slurry E;

[0060] (6), the slurry E is evaporated to dryness with a rotary evaporator to obtain solid F;

[0061] (7), put solid F on the support placed in the reactor, put 2g deionized water at the bottom of the reactor, solid F does not directly contact with water, seal the reactor, and leave standstill ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com