Patents

Literature

44 results about "Cesium compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

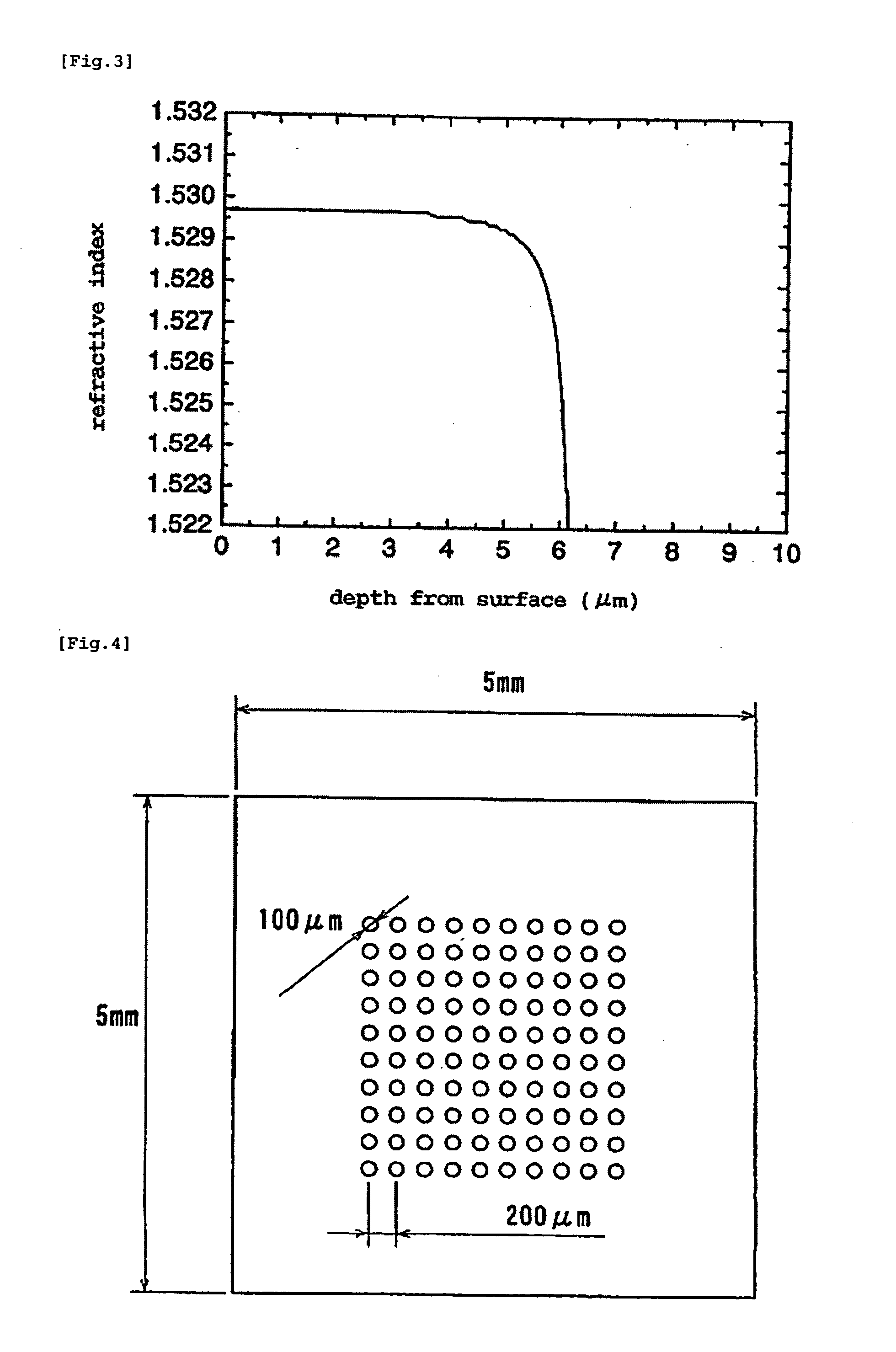

Method for Manufacturing Gradient-Index Optical Element Having Infrared Absorbing Ability

InactiveUS20100165454A1Low costProductionElectrostatic spraying apparatusCoatingsRubidium compoundGradient-index optics

A method of readily producing a gradient optical element having infrared absorbing ability by easily forming a refractive index distribution in a desired portion of a glass substrate having infrared absorbing ability without requiring a specific treatment atmosphere nor using a molten salt.More specifically, the present invention provides a method for producing a gradient-index optical element having infrared absorbing ability, the method comprising applying a paste containing an organic resin, an organic solvent, and at least one compound selected from the group consisting of lithium compounds, potassium compounds, rubidium compounds, cesium compounds, silver compounds, copper compounds, and thallium compounds onto a glass substrate containing an alkali metal component, at least one member selected from the group consisting of iron, copper, cobalt and vanadium, and over 3 wt. % of iron, when contained singly among iron, copper, cobalt and vanadium, on an Fe2O3 basis, taking the total weight of the glass as 100 wt. %, and heating the glass substrate at a temperature below the softening temperature of the glass substrate.

Owner:ISUZU GLASS +1

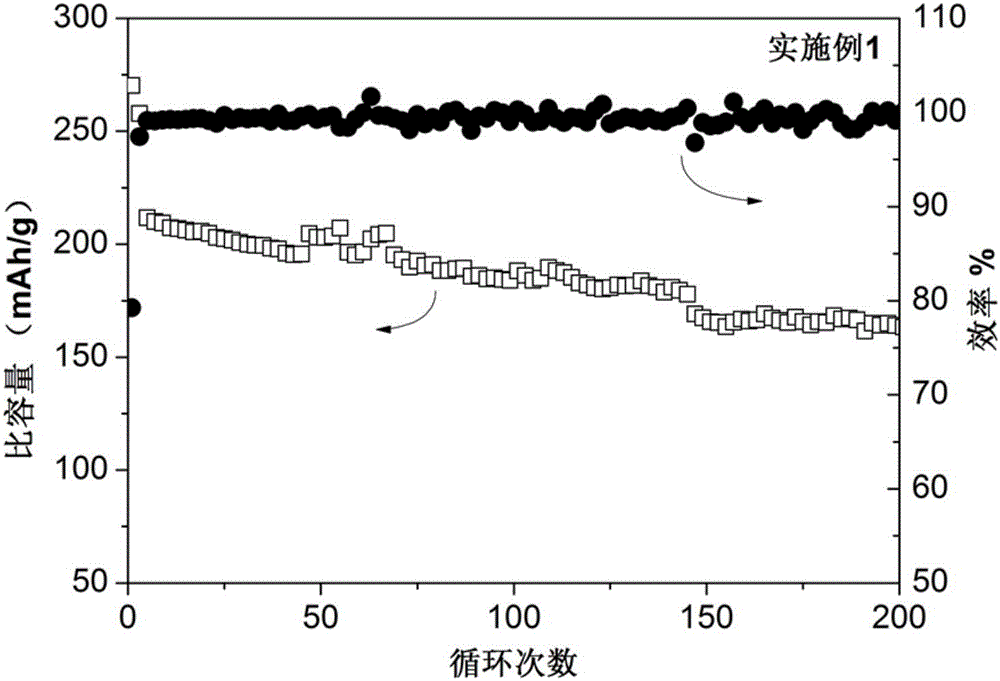

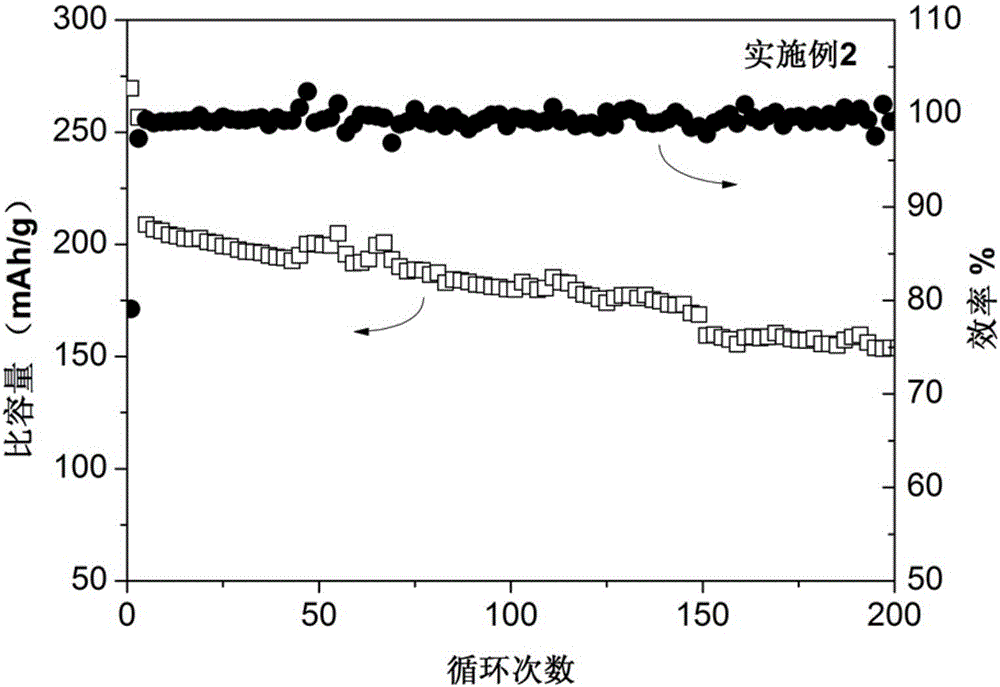

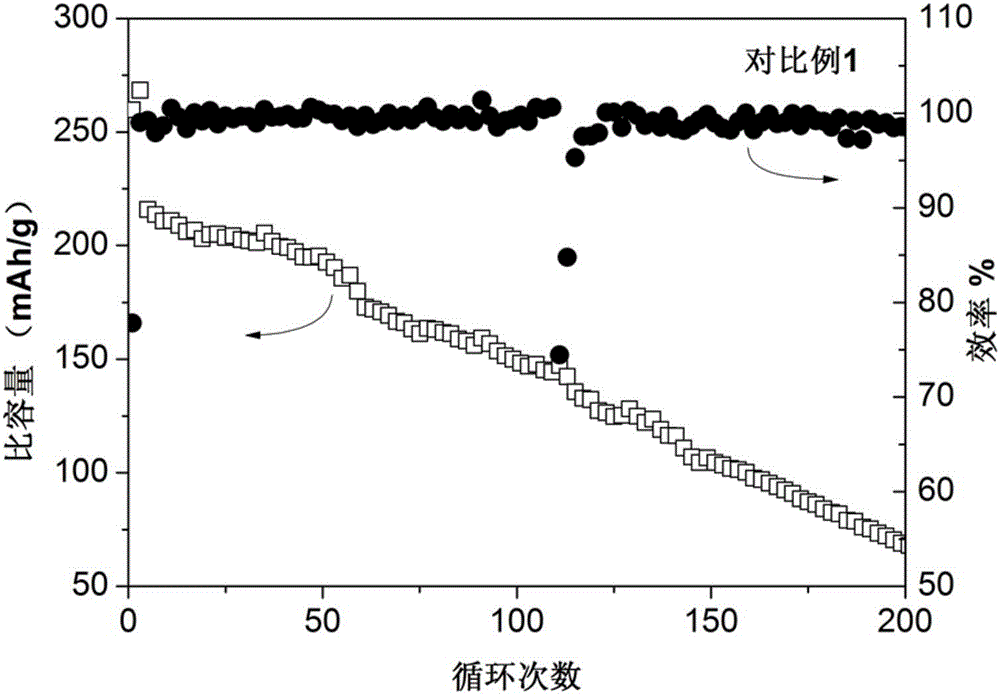

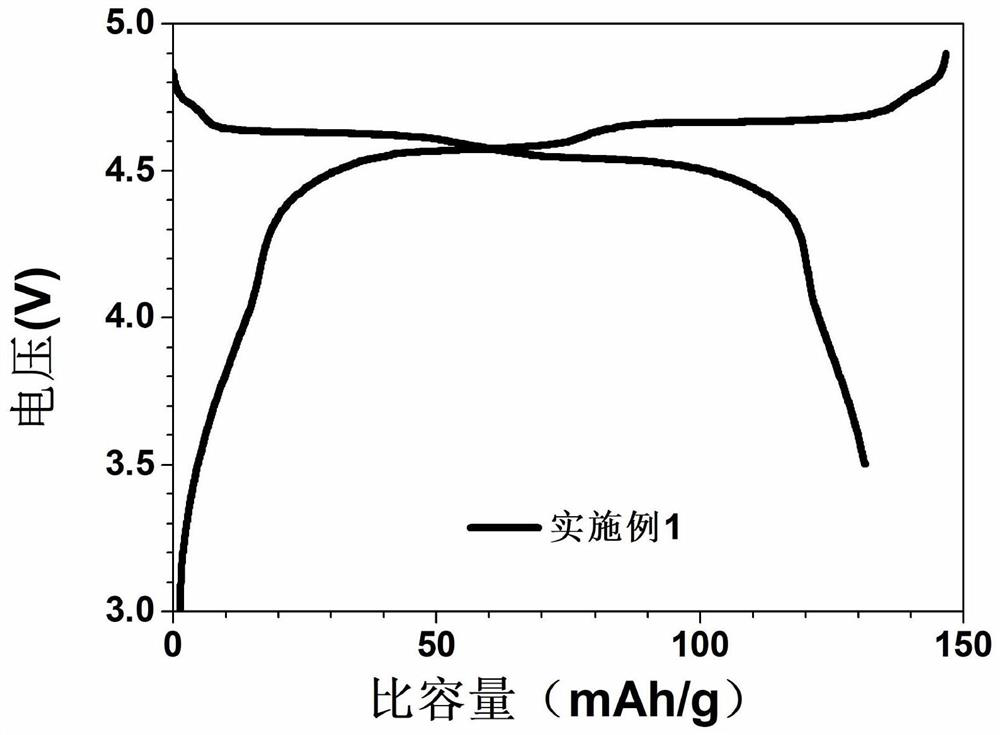

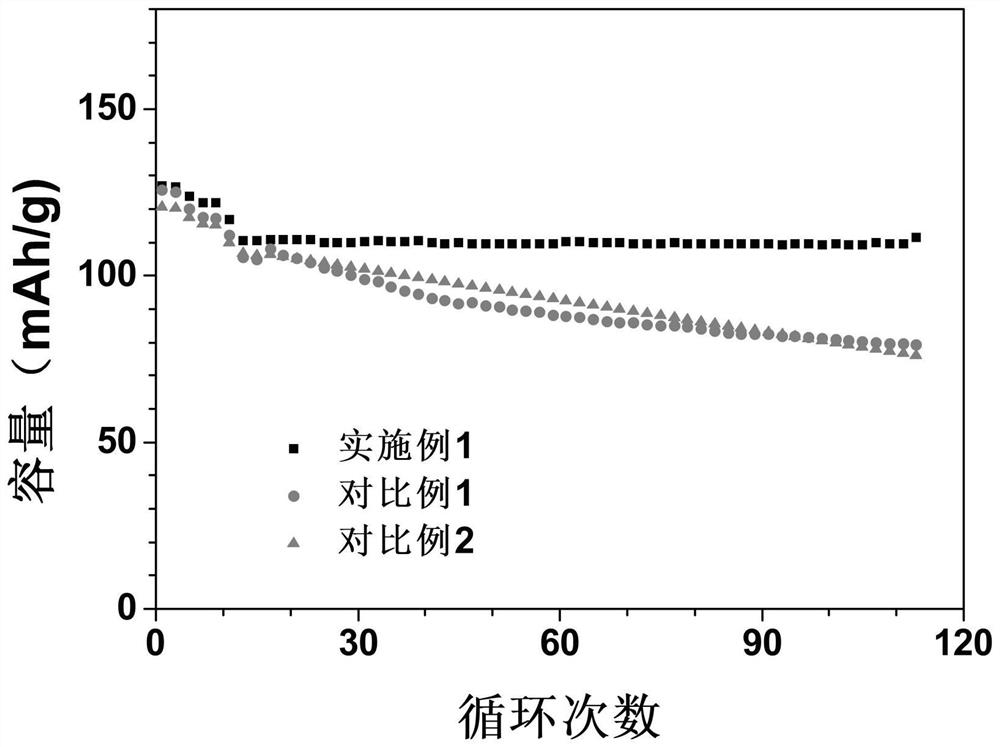

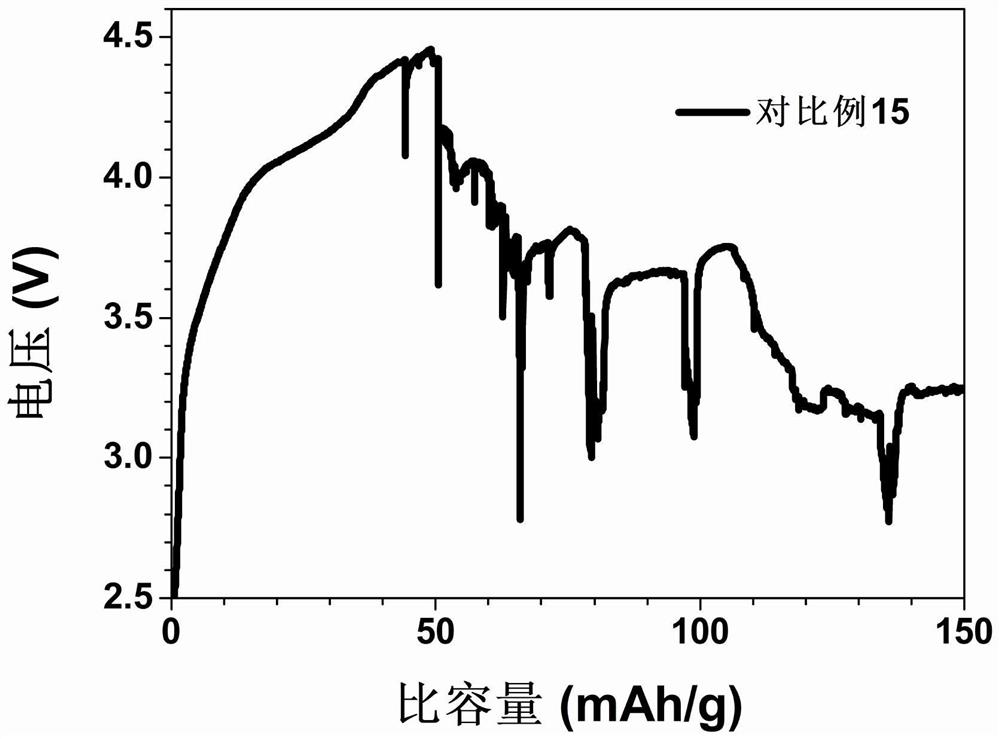

New use of rubidium cesium compound, high-voltage electrolyte additive, high-voltage electrolyte and lithium ion battery

InactiveCN106450452AImprove cycle stabilityExtend your lifeSecondary cellsOrganic electrolytesHigh current densityRubidium

The invention discloses a new use of a rubidium cesium compound in the field of lithium ion batteries as an additive in a high-voltage electrolyte, a high-voltage electrolyte additive, the high-voltage electrolyte and a lithium ion battery. The high-voltage electrolyte consists of an electrolyte lithium salt, an organic solvent and 0.05%-5% of rubidium cesium compound. The rubidium cesium compound as the high-voltage electrolyte additive for the lithium ion battery can protect an anode material, effectively reduces oxidative decomposition of the electrolyte on the anode surface, greatly upgrades the cycling stability of a battery, increases the battery life, and promotes truly commercial application of the high-voltage anode material. The high-voltage electrolyte using the rubidium cesium compound or the high-voltage electrolyte additive can effectively improve the discharge capacity of the high-voltage anode material under high current density, prolongs the cycling life of the high-voltage anode material battery, and simultaneously upgrades the power characteristic of the battery under high current density.

Owner:SHANGHAI RUGE TECH DEV CO LTD +1

Nanometer vanadium catalyst for preparing sulfuric acid through oxidizing SO2 and preparation method thereof

ActiveCN102489320AReduce energy consumptionLower operating temperaturePhysical/chemical process catalystsSulfur compoundsPtru catalystThio-

The invention relates to a nanometer vanadium catalyst for preparing sulfuric acid through oxidizing SO2 and a preparation method thereof. The nanometer vanadium catalyst which uses diatomite as a carrier to load V2O5 contains cesium oxide and lanthanum oxide, and raw materials of the nanometer vanadium catalyst comprise, by mass, 4-5.5% of V2O5, 0.01-5% of a cerium-containing compound, 1-3% of a thiosulfate, 1-10% of a cesium-containing compound, 0.01-5% of a lanthanum-containing compound, and 0.5-7% of a surfactant and an organic macromolecular compound. According to the finished nanometer vanadium catalyst, V2O5 is nanometer grade V2O5; the ignition temperature is 340-350DEG C; the operation temperature of the catalytic reaction is 360-370DEG C; and the SO2 volume concentration is 3-12%, the total conversion rate is equal to or greater than 99.7% and the SO2 emptying amount is equal to or less than 400mg / m<3> when the catalytic reaction adopts a 3+2 flow of a converter. The prepared catalyst has the advantages of low ignition temperature, high activity, high use stability, good compressive strength, and low abrasion.

Owner:南京云高新型材料有限公司

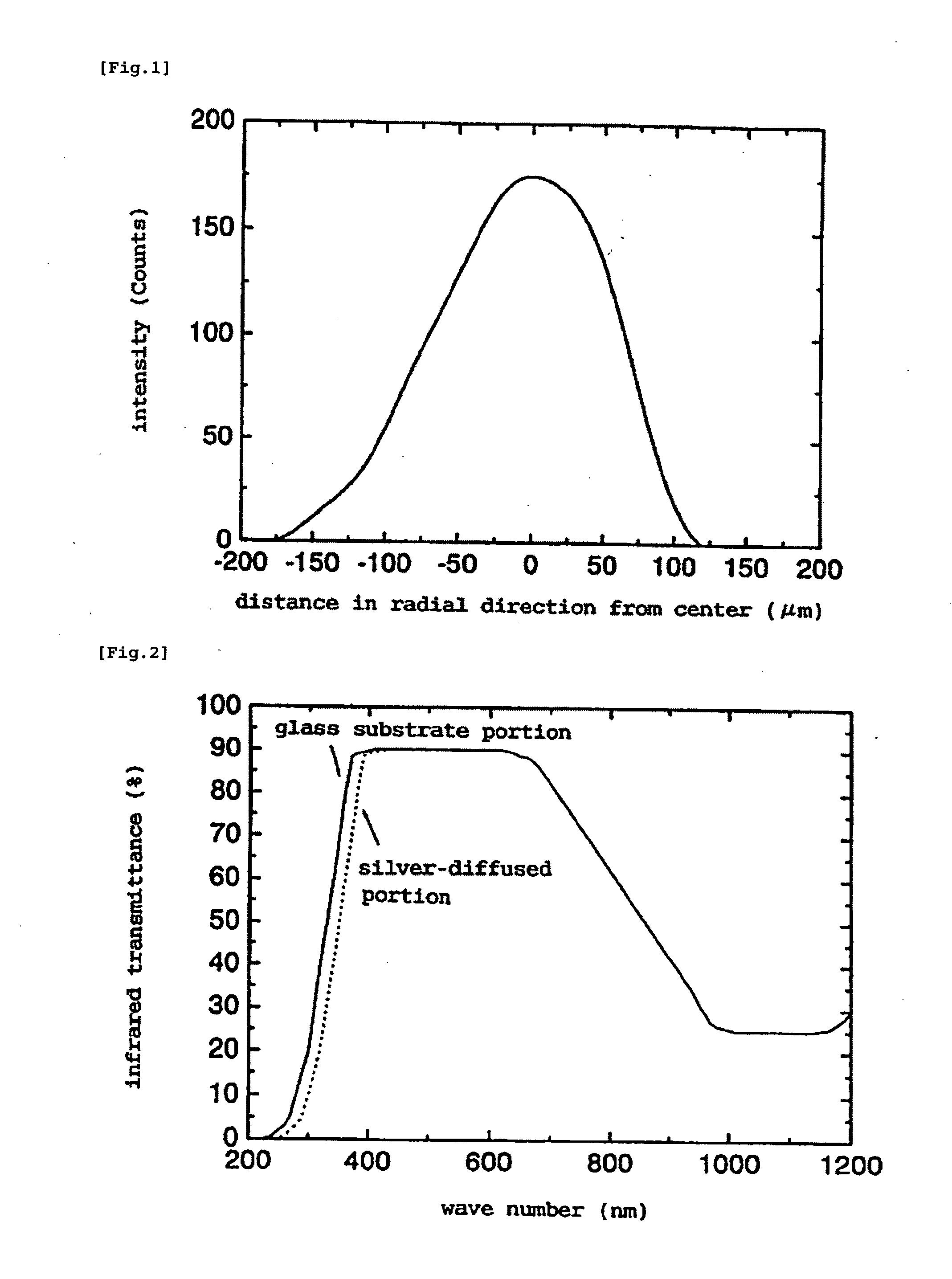

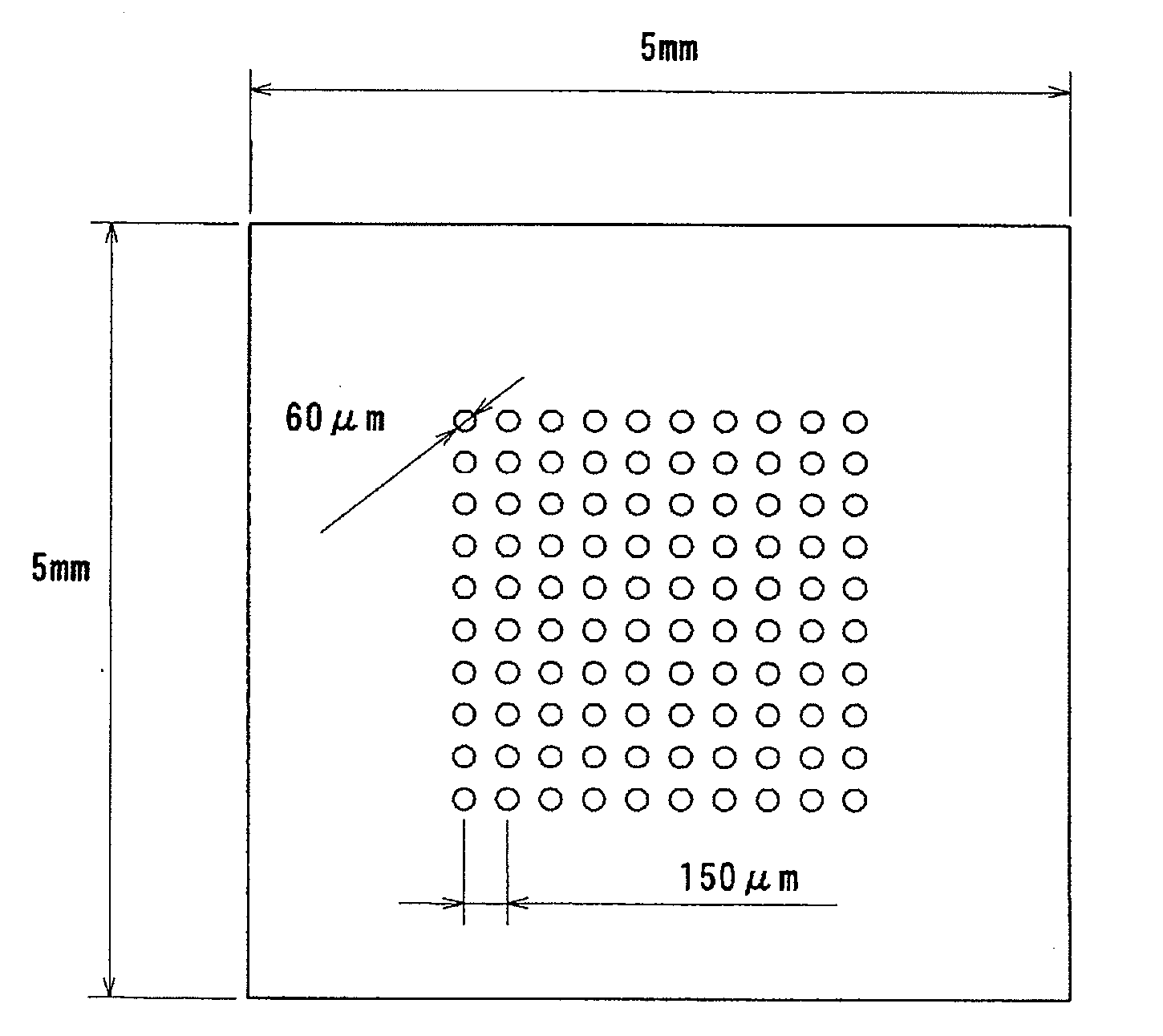

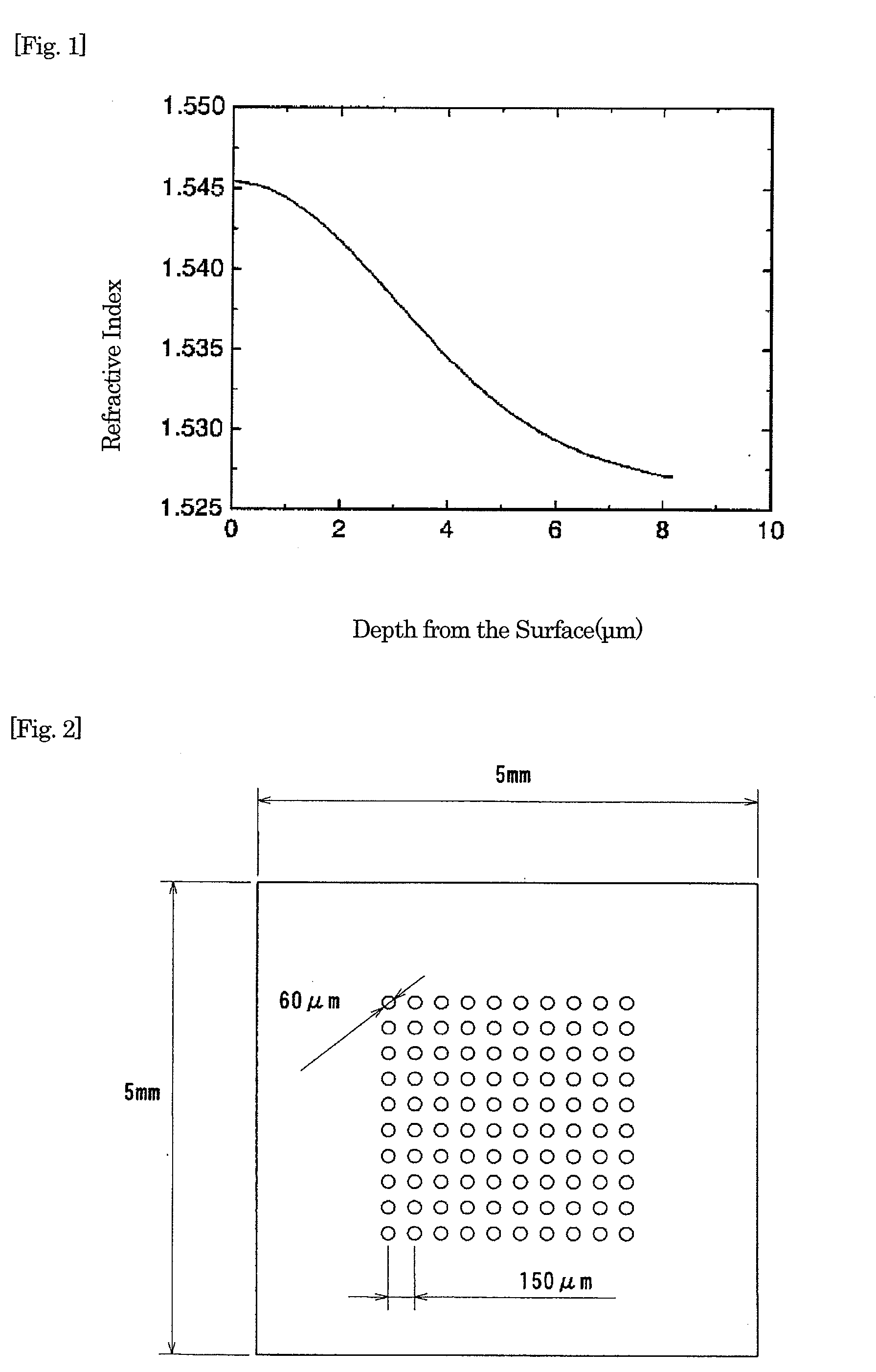

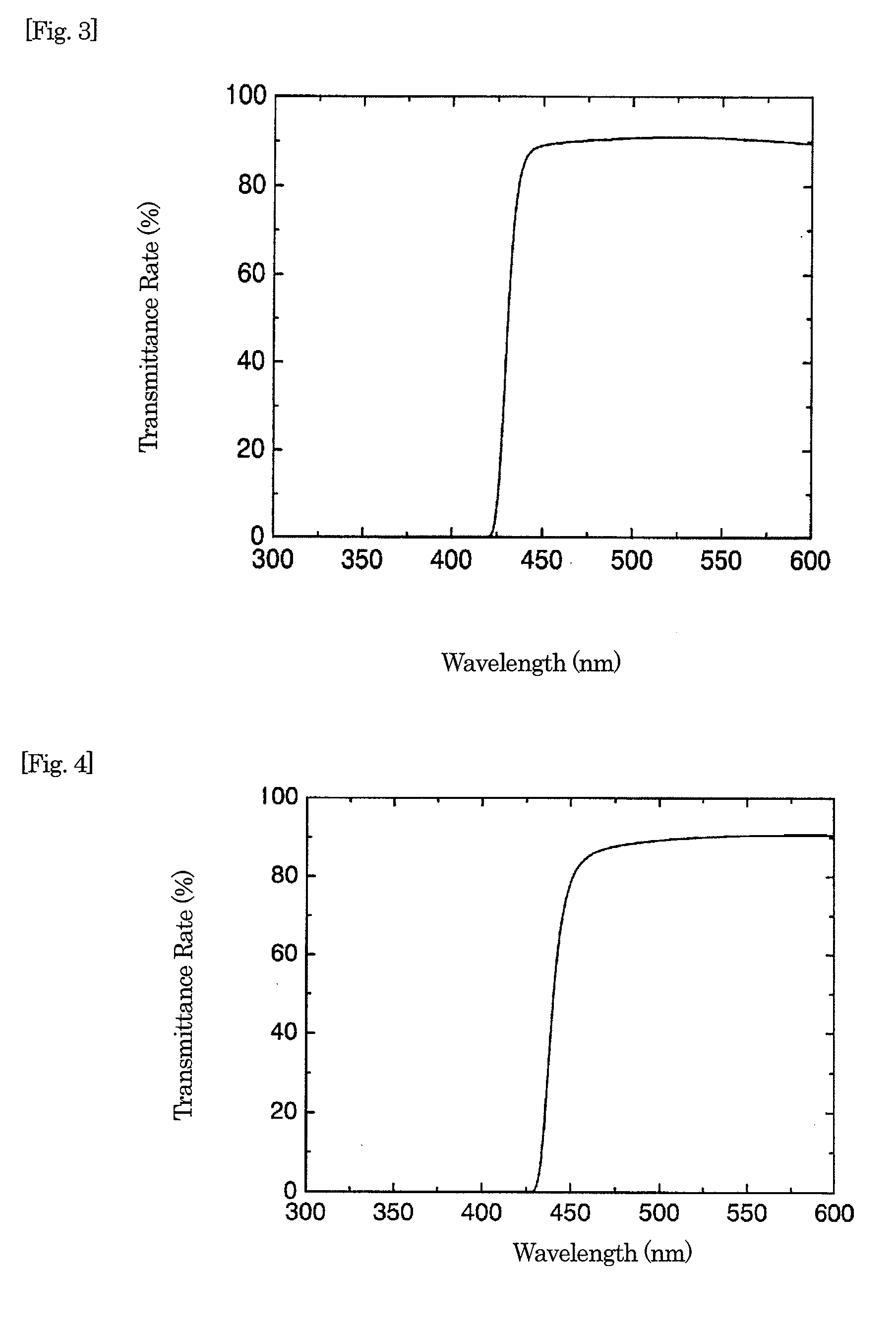

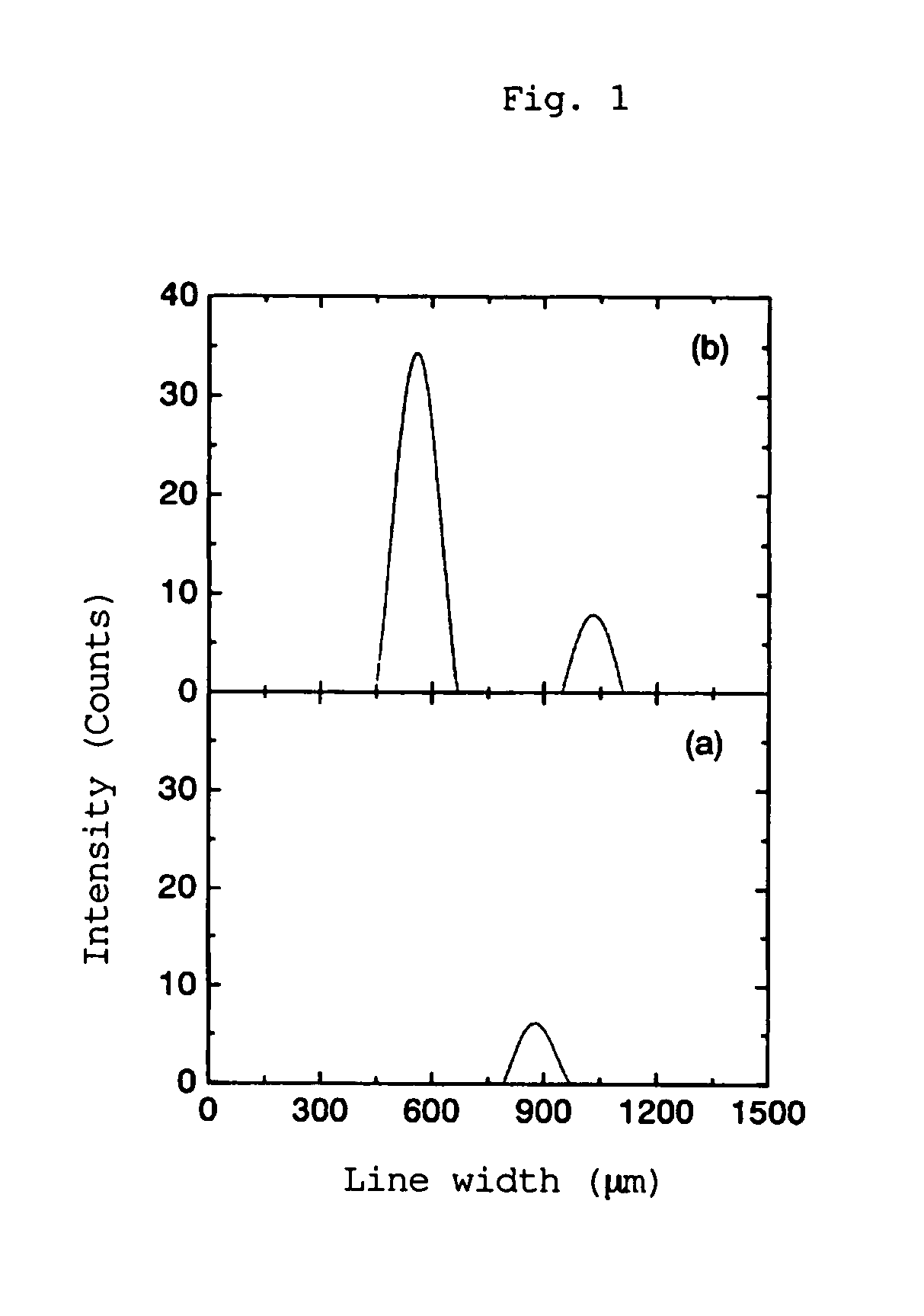

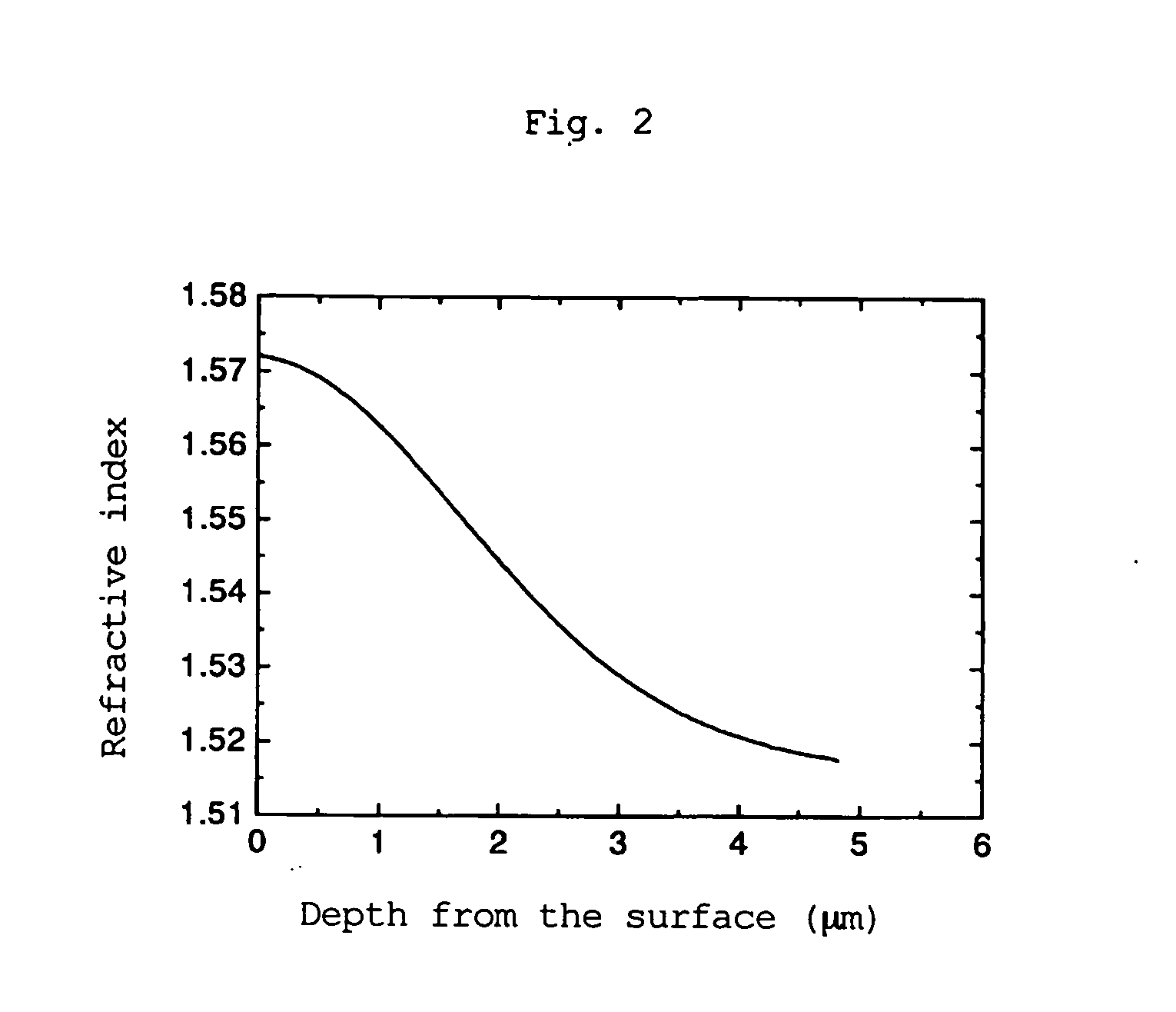

Method for production of distributed refractive index-type optical element having ultraviolet ray-absorbing ability

InactiveUS20100067101A1Simple designSimple processOptical filtersSpecial surfacesRubidium compoundUltraviolet

The present invention provides a method for producing a distributed refractive index-type optical element which can be optically designed readily, enables to provide a desired optical element in a simple manner and has an ultraviolet ray-absorbing ability.The present invention provides a method for producing a distributed refractive index-type optical element having an ultraviolet ray-absorbing ability, which comprises of the steps of: applying a paste comprising at least one compound selected from the group consisting of a lithium compound, a potassium compound, a rubidium compound, a cesium compound, a silver compound, a copper compound and a thallium compound, an organic resin and an organic solvent onto a glass substrate comprising an alkali metal component and an ultraviolet ray-absorbing component as glass constituent components; and heat-treating the resulting substrate at a temperature lower than the softening point of the glass substrate.

Owner:ISUZU GLASS

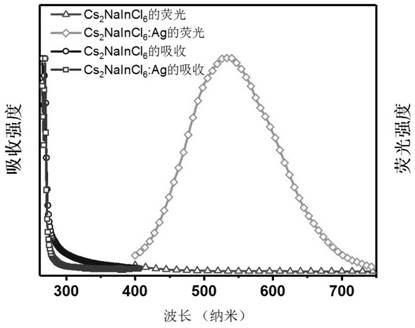

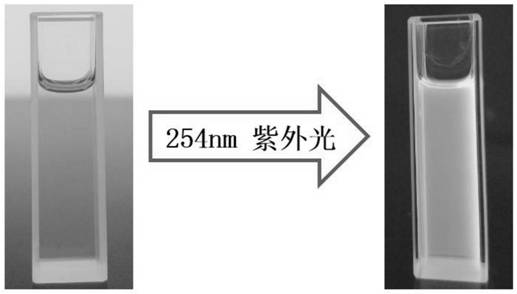

Sodium-indium-based double-perovskite nanocrystal material, preparation and application thereof

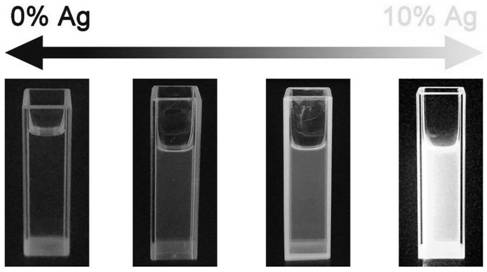

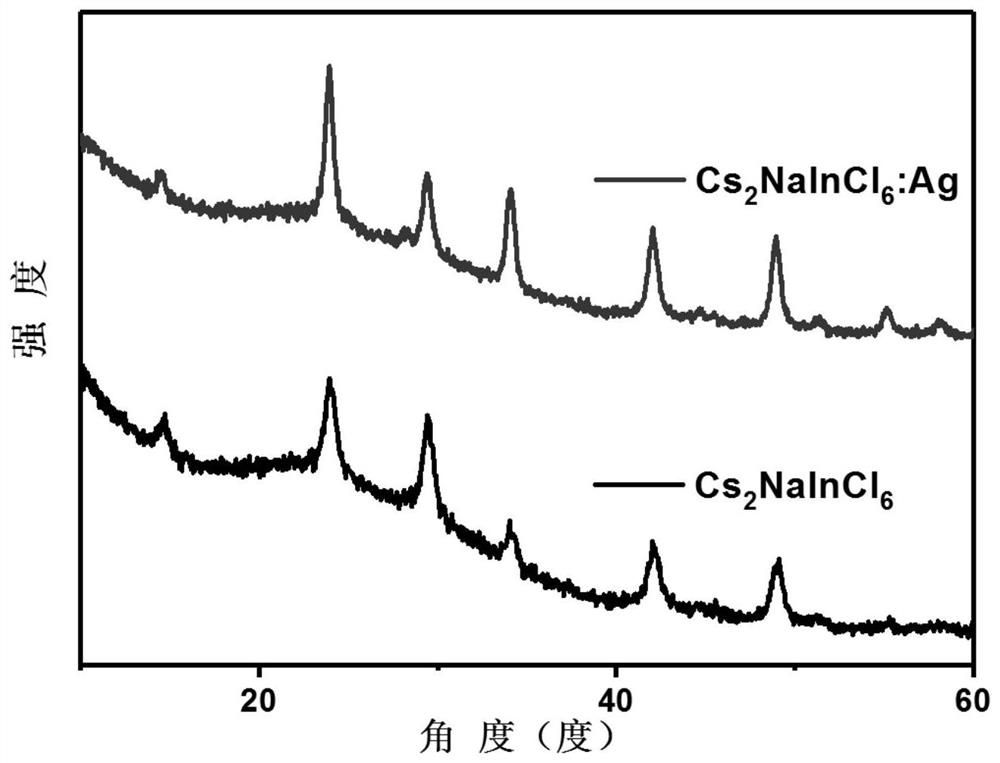

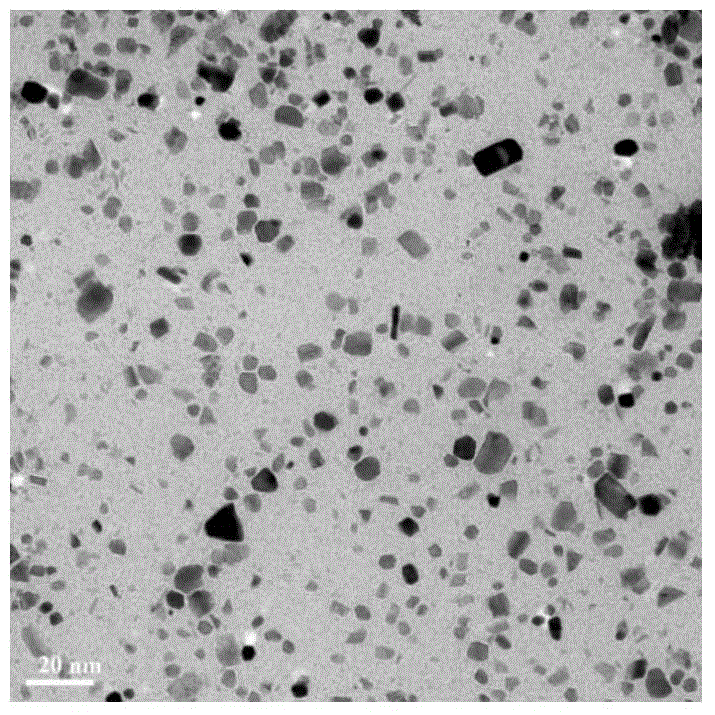

InactiveCN112480912AStrong yellow fluorescenceImprove stabilityMaterial nanotechnologyPhotometry for measuring UV lightSodium acetateFluorescence

The invention discloses a novel undoped and silver-doped non-lead full-inorganic sodium-indium-based double perovskite nanocrystal material, which is prepared from the following steps: adding a cesium-containing compound, sodium acetate, indium acetate and silver acetate into a flask, adding 1-octadecene, oleic acid and oleylamine, stirring and mixing, and vacuumizing at 100-110 DEG C for 1 hour;introducing nitrogen, heating to 180-185 DEG C at the speed of 4-8 DEG C / min, injecting a chlorine-containing compound at the temperature of 165-170 DEG C, quickly performing ice bath to room temperature when the temperature is 180 DEG C, centrifuging to remove supernatant, washing twice with methylbenzene, centrifuging to remove supernatant, dispersing precipitates into n-hexane, and centrifugingto remove the precipitates to obtain nanocrystal colloid. According to the invention, the preparation method is simple, the toxicity problem of the lead-based perovskite is solved, the stability of the perovskite nanocrystal is improved through silver doping, the fluorescence property of the perovskite nanocrystal is improved, and the perovskite nanocrystal material has a good application prospect in the photoelectric field.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-transparency high-heat-insulation thermal phase change material preparation method

The invention discloses a high-transparency high-heat-insulation thermal phase change material preparation method. The method includes steps: firstly, preparing VO2 nanopowder with primary particle size not larger than 20nm, namely preparing powder V; secondly, preparing antimony-tin hydroxide precursors with primary particle size not larger than 20nm; thirdly, preparing indium-tin hydroxide precursors with primary particle size not larger than 20nm, namely preparing powder I; fourthly, preparing tungsten-cesium compound precursors with primary particle size not larger than 20nm, namely preparing powder W; fifthly, adding 1wt%-99wt% of the powder V into a composition formed by any one, two or three of the powder A, the powder B and the powder W, putting in a dispersion tank, grinding, dispersing, performing freeze drying, pouring into a crucible, calcining for 3-48h at 460-680 DEG C under an atmosphere of inert gas shielding, and cooling to obtain a high-transparency high-heat-insulation thermal phase change material. The prepared nanopowder can be widely applied to window glass surface coating materials of automobiles, buildings and the like and has significant economic and energy saving values.

Owner:李佳怡

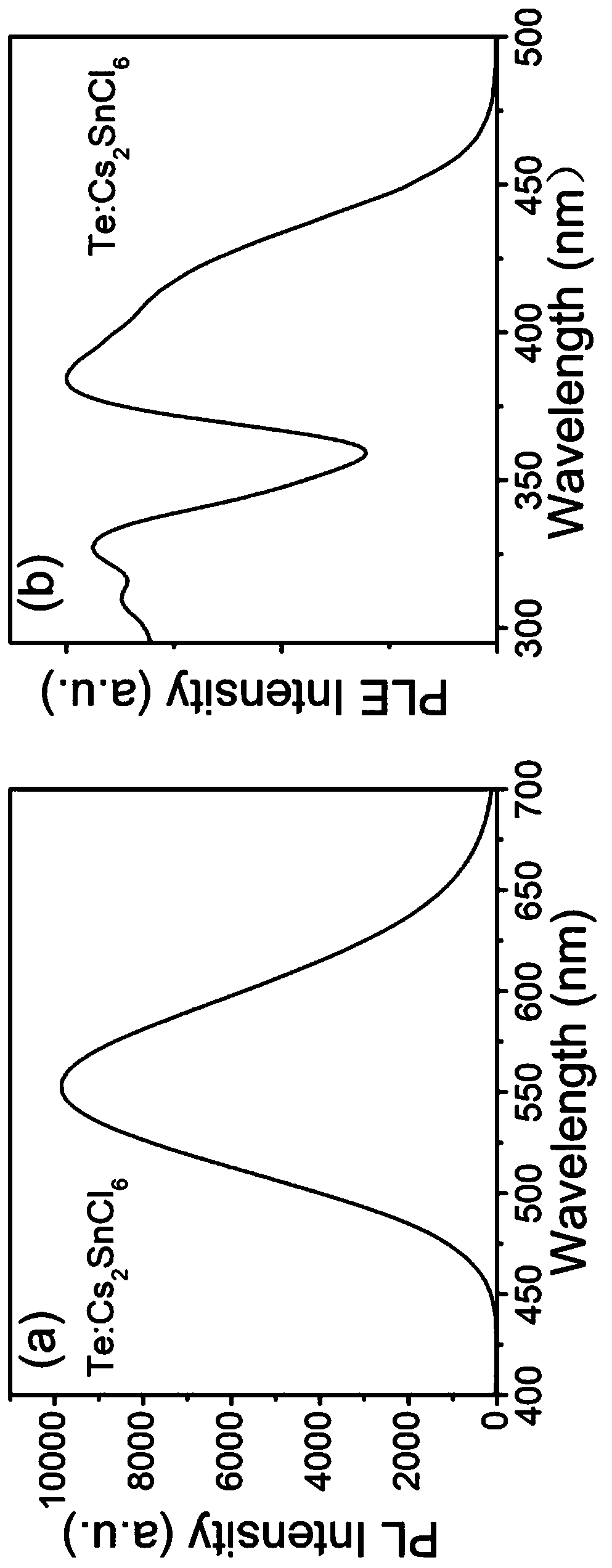

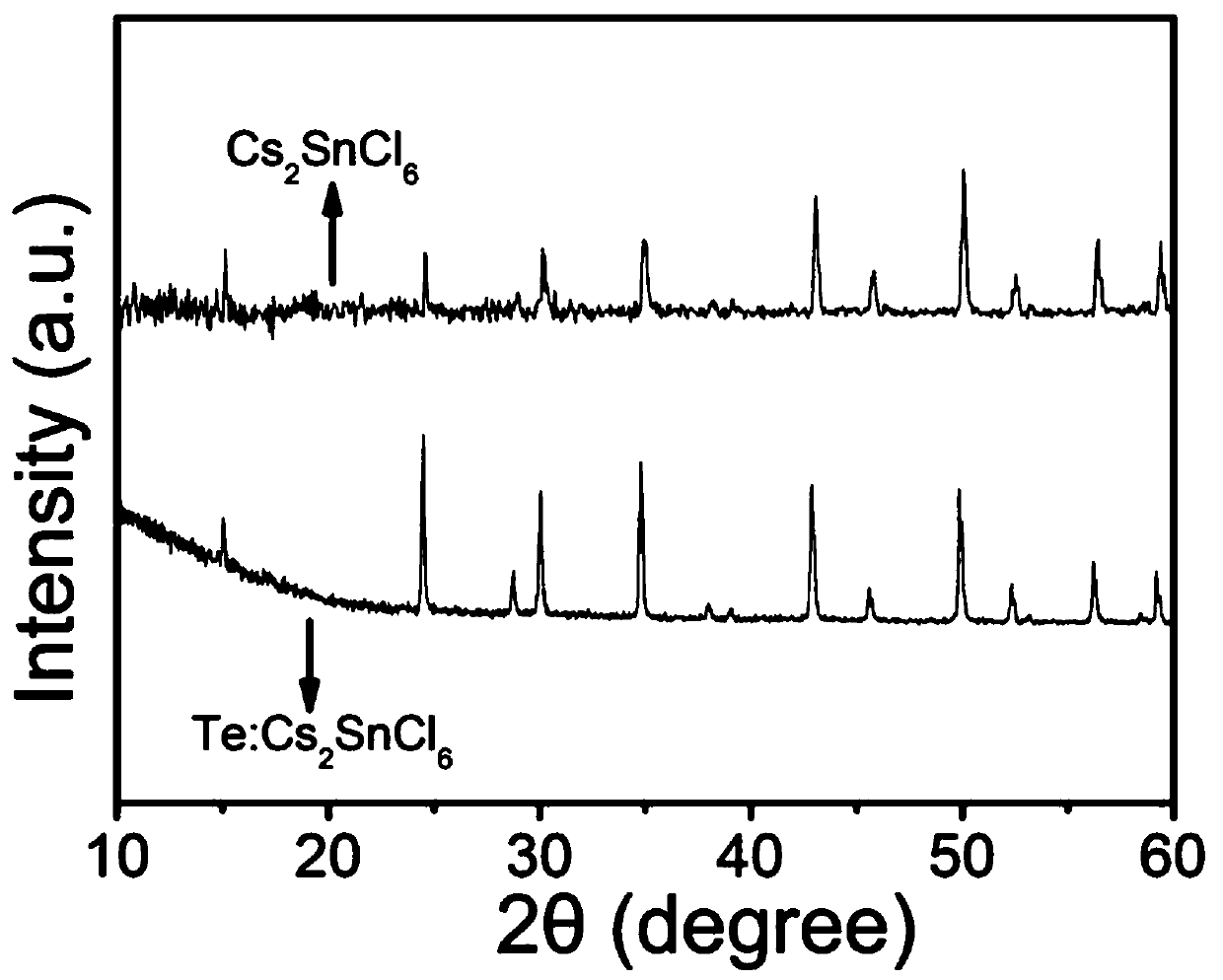

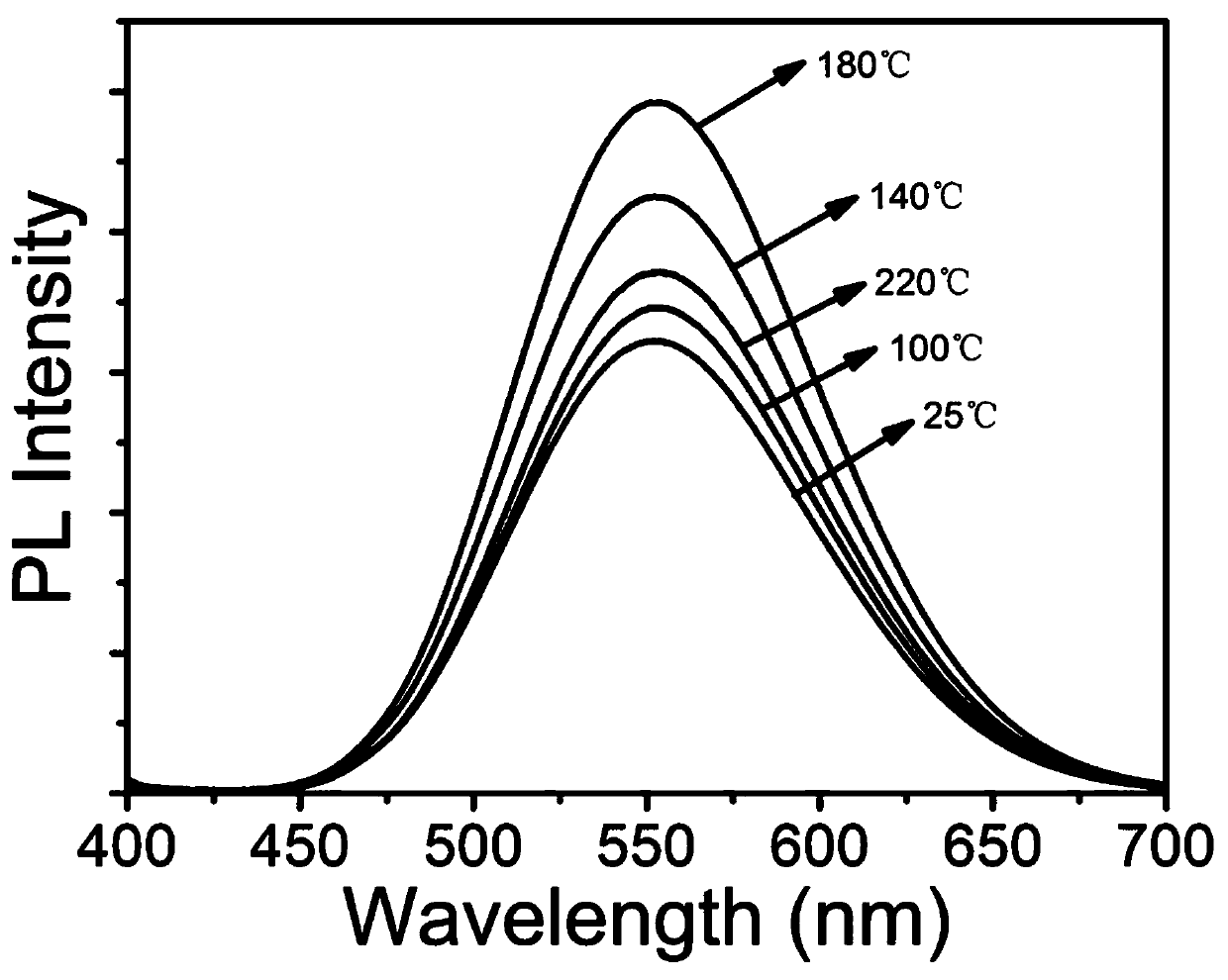

Te-doped A2SnCl6 perovskite material and preparation method thereof

InactiveCN110803711AHigh quantum yieldImprove stabilityTin halidesLuminescent compositionsCesium compoundRubidium compound

The invention discloses a Te-doped A2SnCl6 perovskite material and a preparation method thereof. In the Te-doped A2SnCl6 perovskite material, A = Cs, Rb and K, a cesium-containing compound, a rubidium-containing compound, a potassium-containing compound, a tin-containing compound and a tellurium-containing compound are used as reaction reagents, and concentrated HCl is used as a solvent; the Te-doped A2SnCl6 perovskite material is prepared, and the influence of the temperature on the luminous efficiency of the A2SnCl6 perovskite material is explored. The Te-doped A2SnCl6 perovskite material prepared by adopting a solvothermal method is good in crystallization, high in quality, capable of being rapidly synthesized in quantity and simple and controllable in process, doping of different concentrations can be effectively realized by adjusting the feeding ratio of Te / Sn, and the Te-doped A2SnCl6 perovskite material has good repeatability..

Owner:GUILIN UNIV OF ELECTRONIC TECH

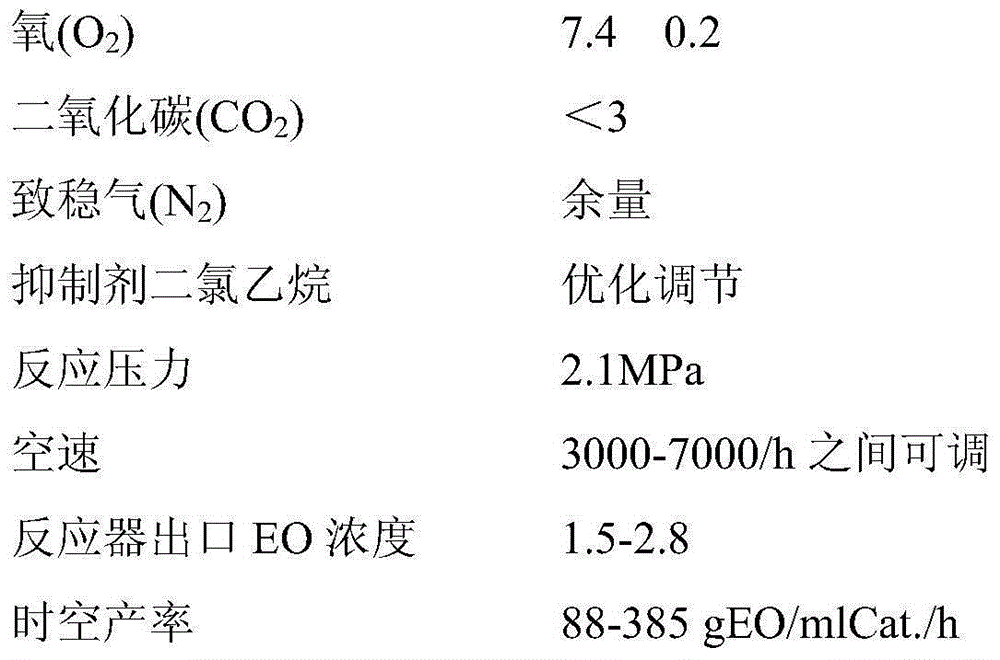

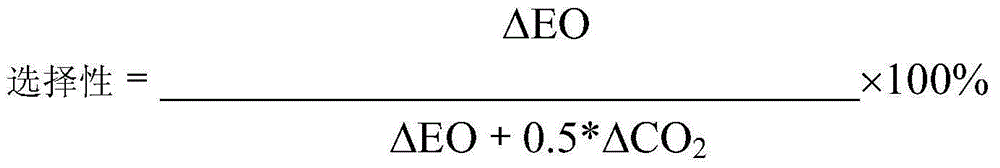

Preparation method for composite silver catalyst, and composite silver catalyst and application thereof

ActiveCN106311234AHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsRheniumWork in process

The invention relates to a preparation method for a composite silver catalyst used for producing ethylene oxide through ethylene oxidation. The preparation method comprises the following steps: 1) dissolving a compound containing silver and a compound containing chromium in an amine-contained solution or ammonia water so as to prepare a silver-ammonia solution; 2) subjecting an alpha-Al2O3 carrier to soaking in the silver-ammonia solution prepared in the step 1), taking out the soaked alpha-Al2O3, then carrying out draining, and carrying out calcination treatment so as to prepare a semi-finished silver catalyst; 3) dissolving the compound containing silver, the compound containing rhenium and an optional compound containing cesium in the amine-contained solution or the ammonia water so as to prepare the silver-ammonia solution; and 4) subjecting the semi-finished silver catalyst prepared in the step 2) to soaking in the silver-ammonia solution obtained in the step 3), taking out the soaked semi-finished silver catalyst, then carrying out draining, and carrying out calcination treatment so as to prepare the composite silver catalyst. The invention also relates to the composite catalyst and application of the catalyst in production of ethylene oxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Filter type trapping agent for volatile cesium compound and trapping method for volatile cesium compound thereof

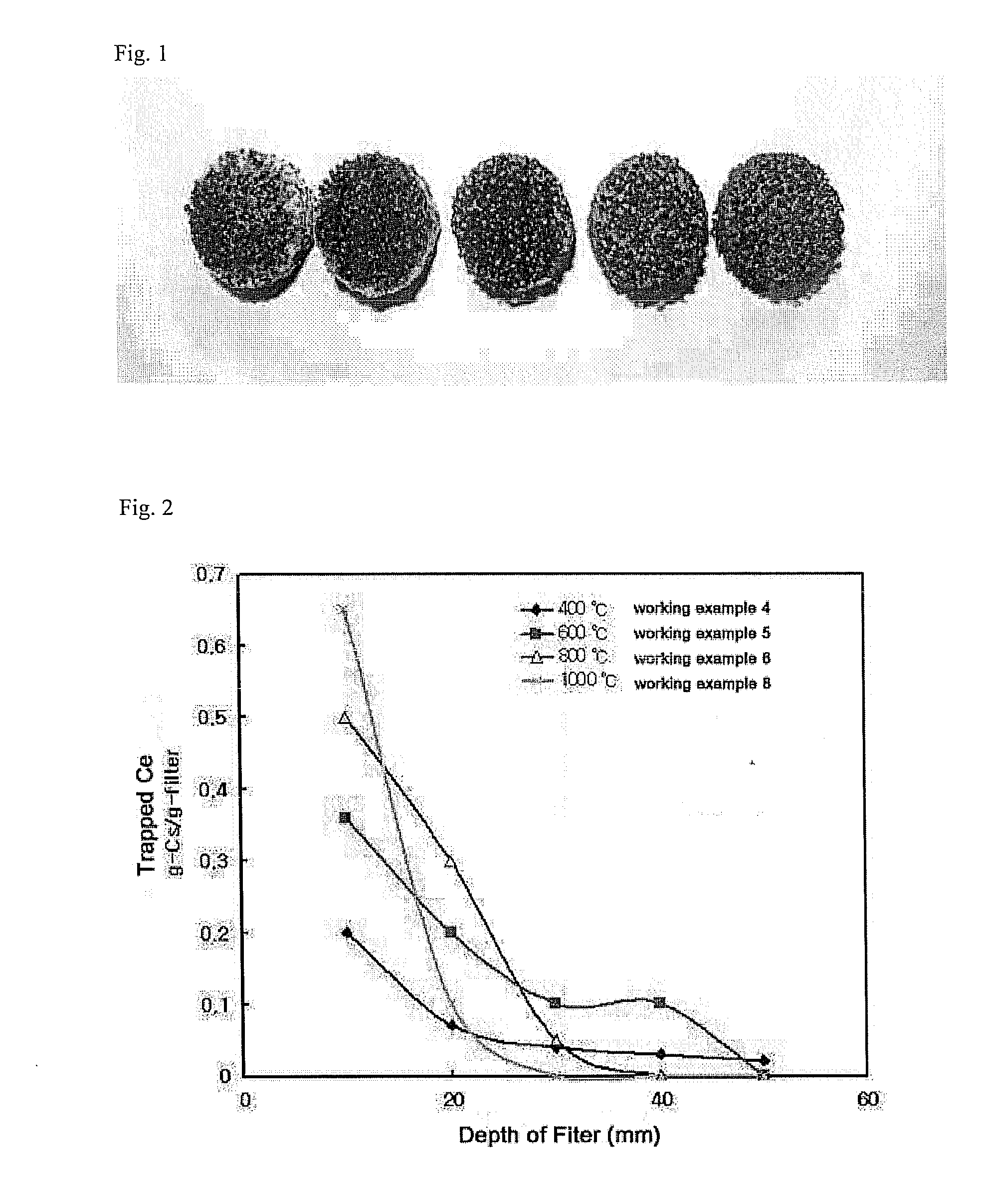

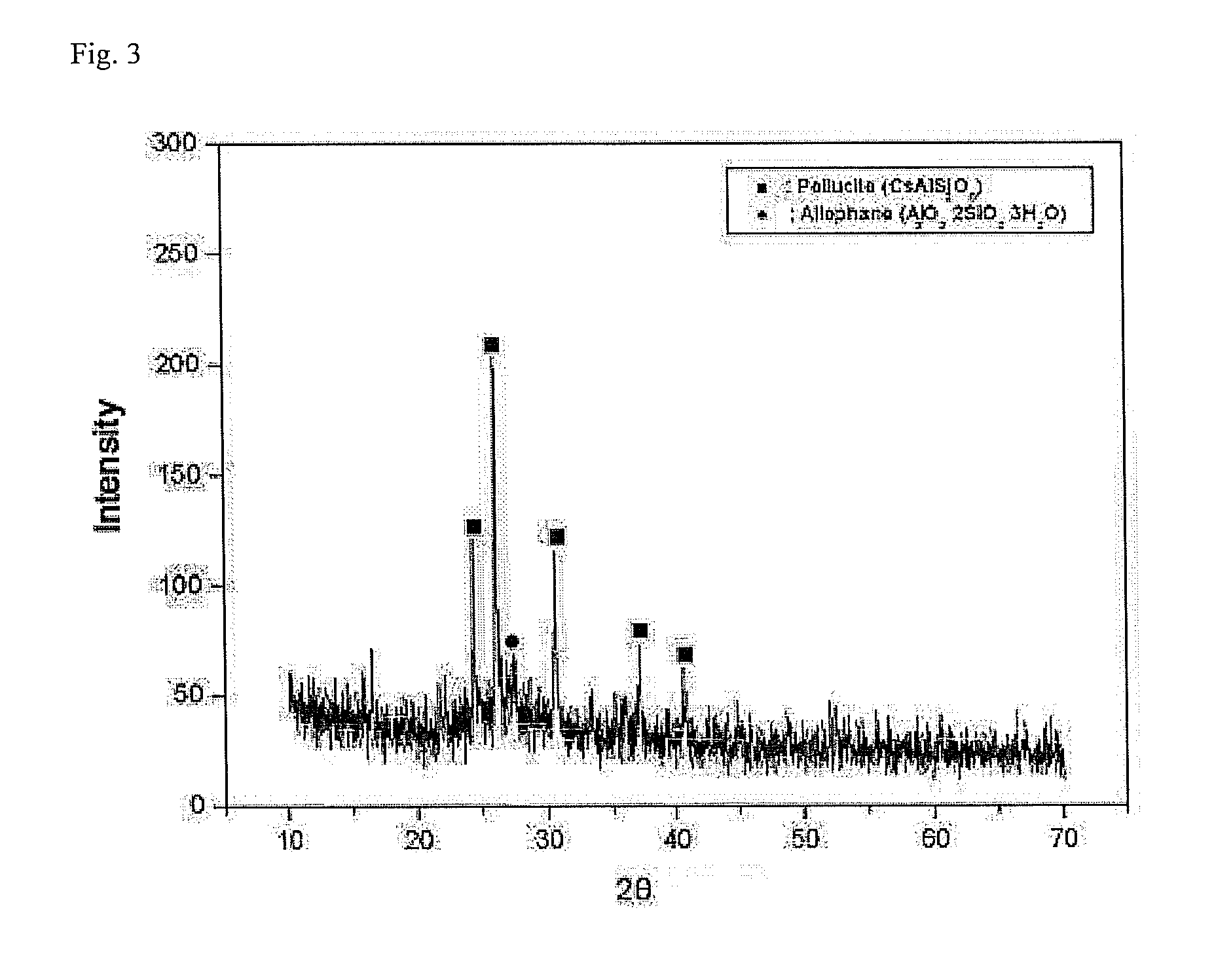

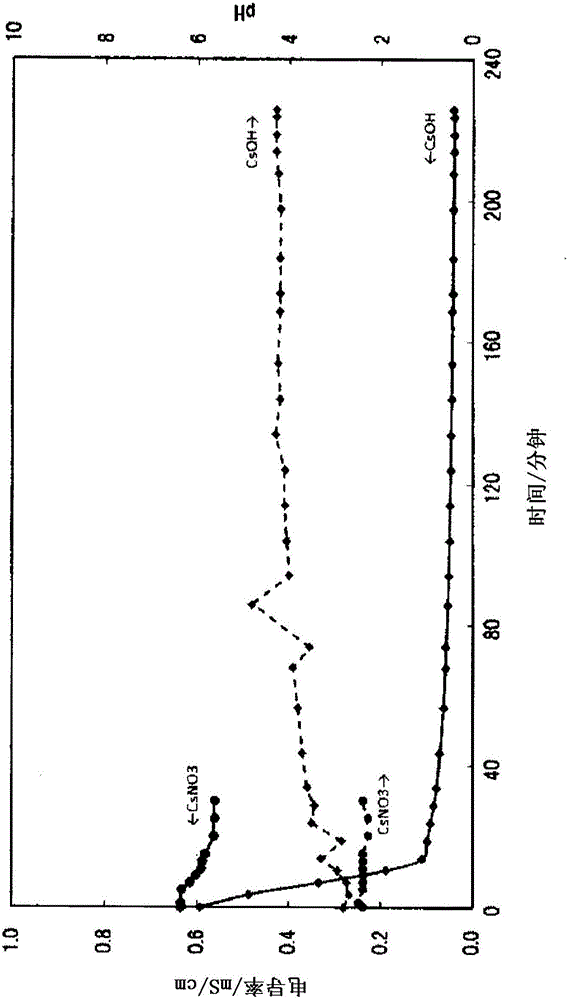

InactiveUS20110052461A1Efficient processingReduce expensesDispersed particle filtrationOther chemical processesCesium compoundTrapping

A filter type trapping agent for volatile cesium compound and trapping method for volatile cesium compound thereof are provided. More particularly, a filter type trapping agent for volatile cesium compound including silica 40˜65% by weight of silica, 15˜30% by weight of alumina, 5˜15% by weight of iron oxide, 1˜15% by weight of molybdenum oxide, 1˜10% by weight of chromium oxide, and 1˜10% by weight of vanadium oxide and trapping method for volatile cesium compound thereof are provided. Through a filter type trapping agent for volatile cesium compound and a trapping method, only cesium can be selectively separated among the nuclear fission gases. Accordingly, by disposing only the filter where cesium is trapped, the efficiency of an off-gas process improves, expense for disposing filter wastes decreases, and a cesium isotope of the waste filter can be recycled. Therefore, many forms of cesium compound gas are made insoluble efficiently.

Owner:BUMA CO LTD

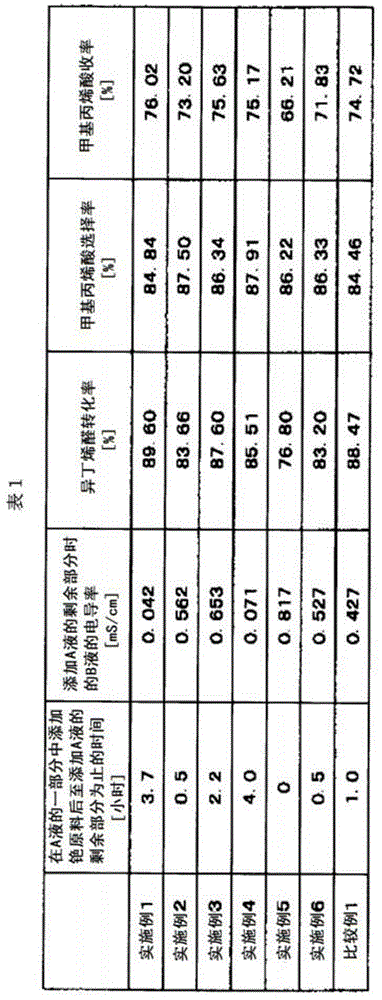

Catalyst for methacrylic acid production, method for producing same, and method for producing methacrylic acid

InactiveCN105121011AHigh yieldHigh selectivityOrganic compound preparationOrganic chemistry methodsCesium compoundActive component

A method for producing a catalyst for methacrylic acid production, said catalyst being used for the purpose of producing a methacrylic acid by vapor-phase catalytic oxidation of methacrolein or the like and containing Mo, V, P, Cs, NH4 and Cu as essential active components. This method for producing a catalyst for methacrylic acid production comprises: a step (a) wherein an aqueous heteropolyacid solution or the like (liquid (A)), which contains Mo, P and V as constituent elements, is prepared; a step (b) wherein a slurry liquid (liquid (B)) is prepared by mixing some of the thus-obtained liquid (A) with an aqueous cesium compound solution or the like; and a step (c) wherein a slurry liquid (liquid (C)) is prepared by mixing the rest of the liquid (A) with the liquid (B).

Owner:NIPPON KAYAKU CO LTD

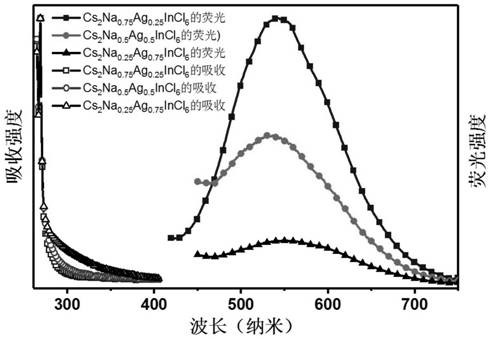

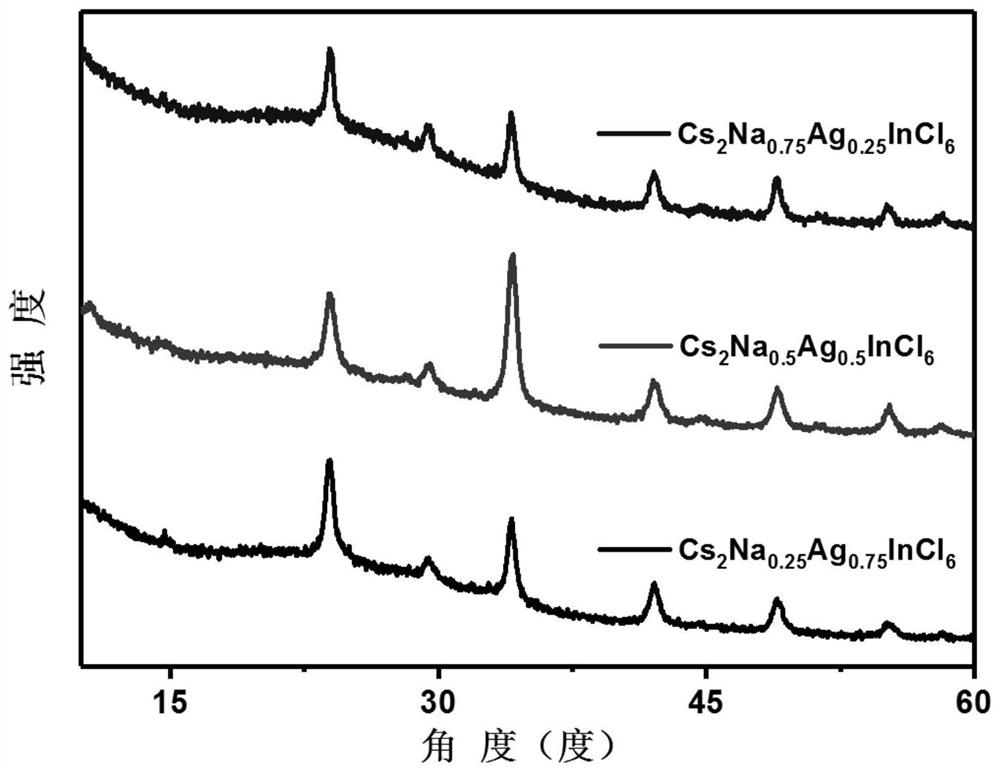

Silver-sodium mixed double perovskite alloy nanocrystal material, preparation and application thereof

InactiveCN112480913AStrong orange fluorescenceImprove stabilityMaterial nanotechnologyNanoopticsSodium acetateIndium

The invention discloses a series of lead-free full-inorganic silver-sodium mixed double perovskite alloy nanocrystal materials, which are prepared by the following steps: adding a cesium-containing compound, sodium acetate, silver acetate and indium acetate into a flask, adding 1-octadecene, oleic acid and oleylamine, stirring and mixing, and vacuumizing at 105 DEG C for 1 hour; introducing nitrogen, heating to 185 DEG C at a speed of 5 DEG C / min, injecting a chlorine-containing compound at 170 DEG C, quickly performing ice bath to room temperature when the temperature is 185 DEG C, centrifuging to remove the supernatant, washing twice with toluene, centrifuging to remove the supernatant, dispersing the precipitate into n-hexane, and centrifuging to remove the precipitate, thereby obtaining the nanocrystal colloid. According to the invention, the preparation method is simple, the toxicity problem of the lead-based perovskite is solved, the stability of the perovskite nanocrystal is improved, the fluorescence property of the perovskite nanocrystal is improved by regulating the ratio of sodium to silver, and the perovskite nanocrystal material has a good application prospect in the photoelectric field.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Cesium-containing high-voltage lithium ion battery electrolyte composite additive, electrolyte and battery thereof

ActiveCN112086684AImprove interface propertiesImprove electrochemical performanceSecondary cells servicing/maintenanceComposite electrolytesElectrolytic agentCesium compound

The invention discloses a cesium-containing high-voltage lithium ion battery electrolyte composite additive, an electrolyte and a battery thereof. The cesium-containing high-voltage lithium ion battery electrolyte composite additive provided by the invention is formed by compounding a cesium compound, silicon-based phosphate and a phosphorus-containing lithium salt. Through the synergistic effectof the cesium compound, the silicon-based phosphate and the phosphorus-containing lithium salt, components of positive and negative electrode interfaces are changed, a composite interface film capableof stably existing at high voltage is formed on positive and negative electrode interfaces, and the composite interface film can effectively improve the interface characteristics of the high-voltagebattery, reduce the side reaction of an electrolyte and improve the electrochemical performance of the lithium ion battery. And the composite additive has the advantages of small addition amount, lowcost, simple synthesis and the like, is easy to implement and is beneficial to wide popularization and application.

Owner:SONGSHAN LAKE MATERIALS LAB +1

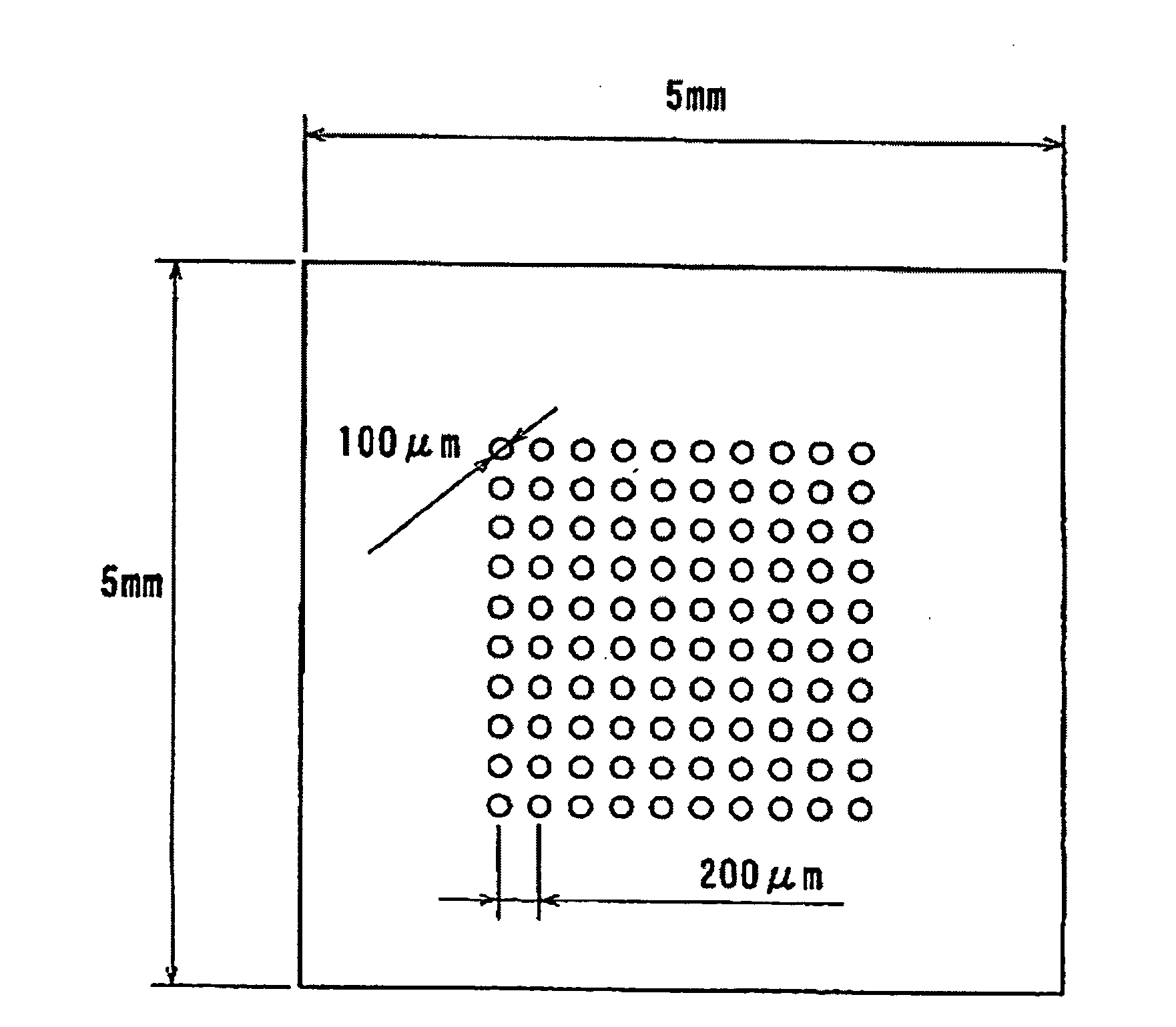

Process for Producing Optical Device

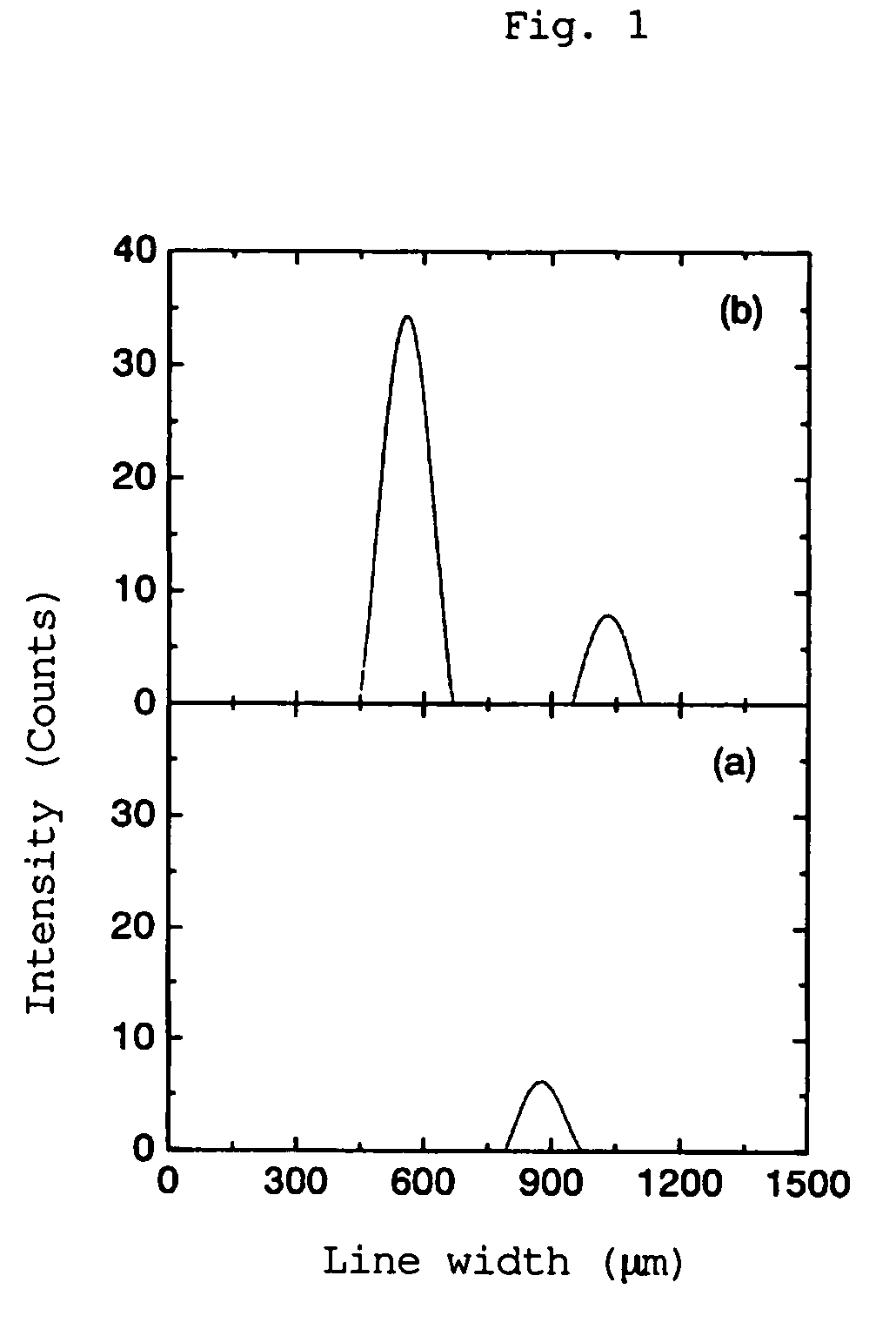

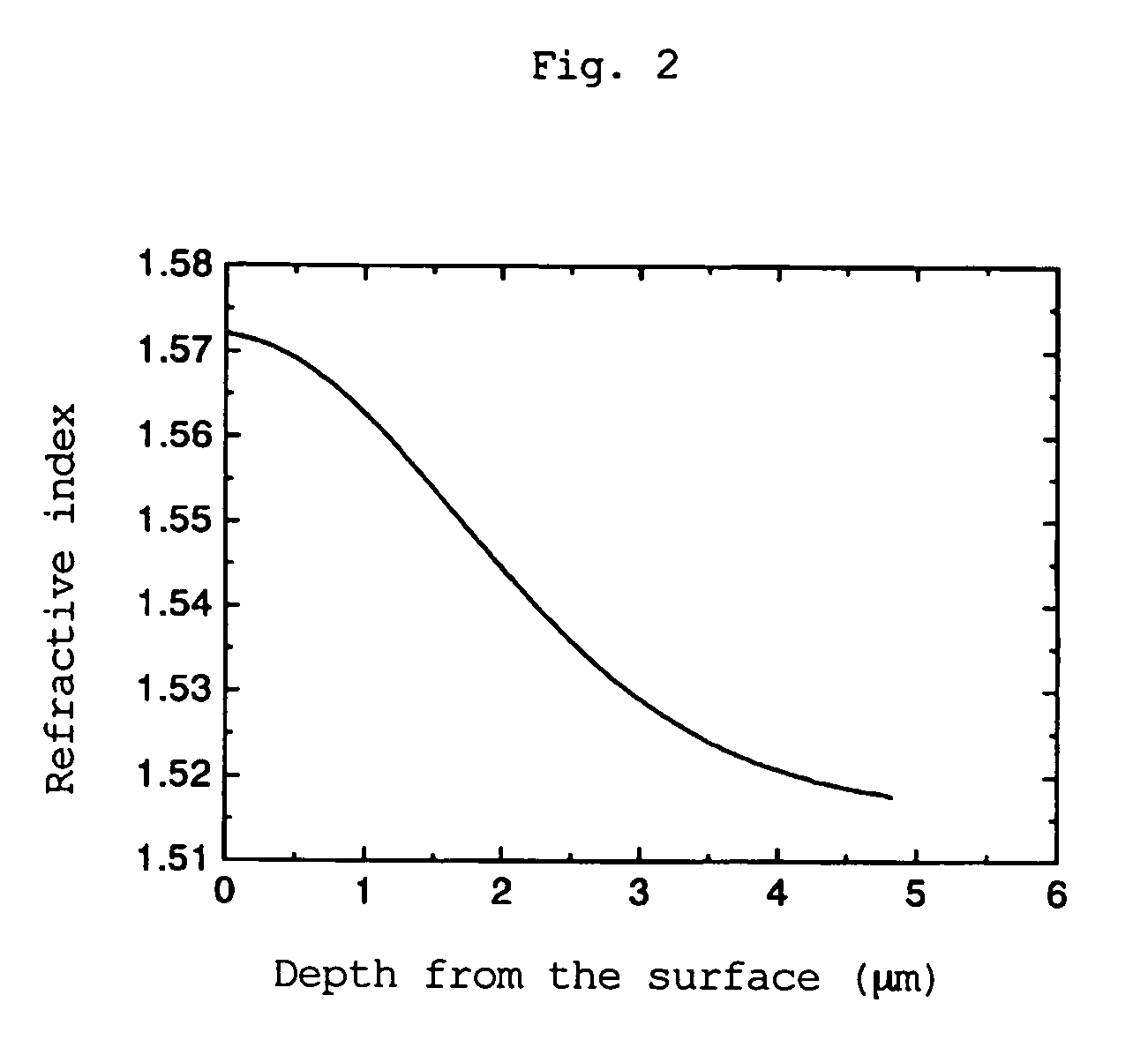

InactiveUS20080226248A1Low costIndependent controlGlass making apparatusOptical fibre with graded refractive index core/claddingCesium compoundOrganic solvent

The present invention provides a method of producing an optical element without the need for high vacuum, unlike the thin film deposition methods, and without using a molten salt. More specifically, the invention provides a method of producing an optical element comprising applying a paste containing at least one compound selected from lithium compounds, potassium compounds, rubidium compounds, cesium compounds, silver compounds, and thallium compounds, an organic resin, and an organic solvent to a glass substrate containing an alkali metal component as a glass component and then performing heat treatment at a temperature below the softening temperature of the glass substrate.

Owner:ISUZU GLASS +1

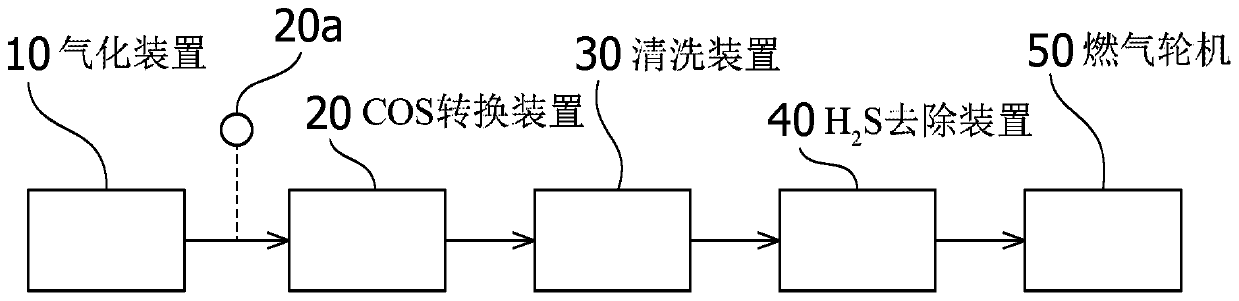

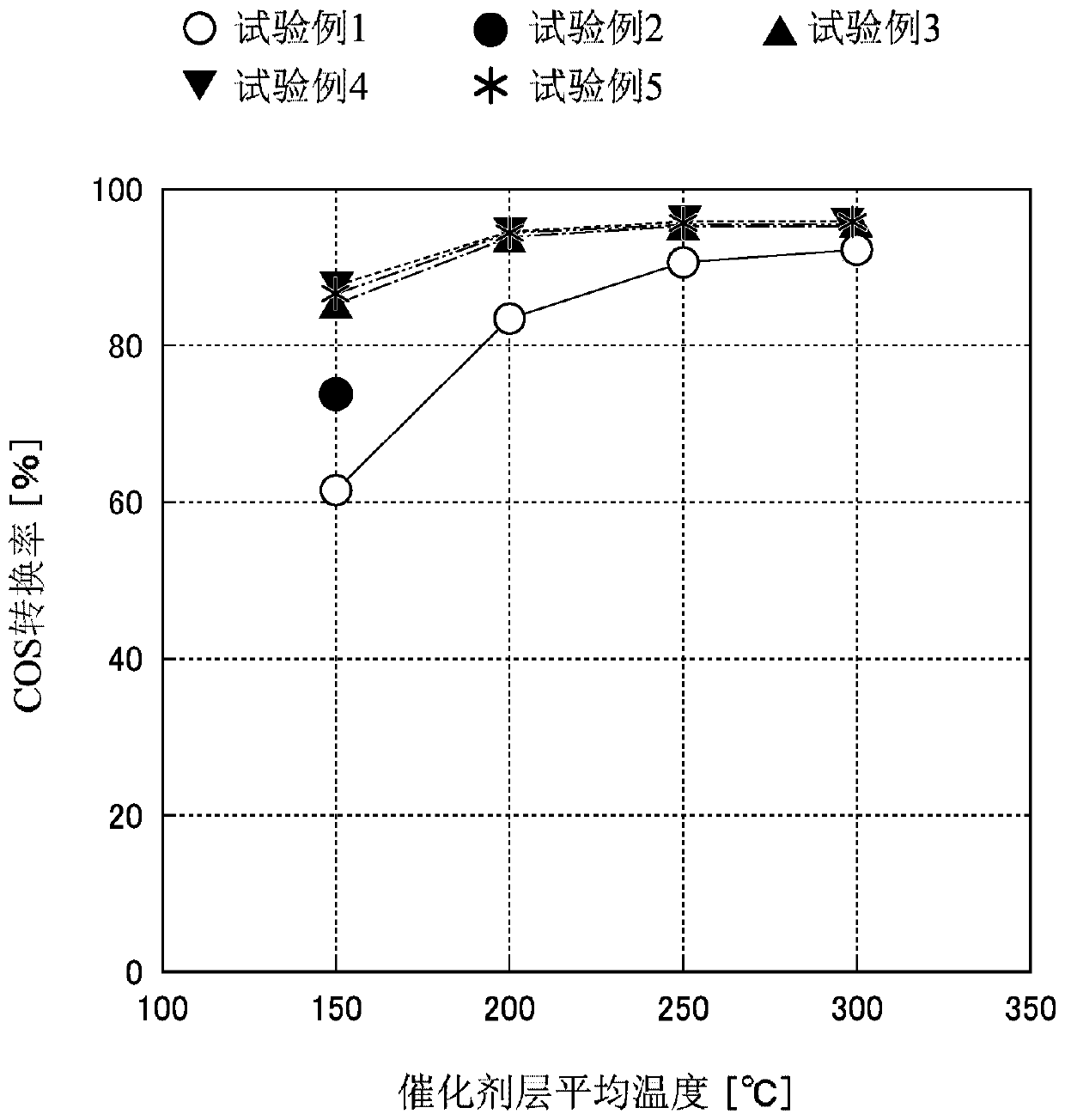

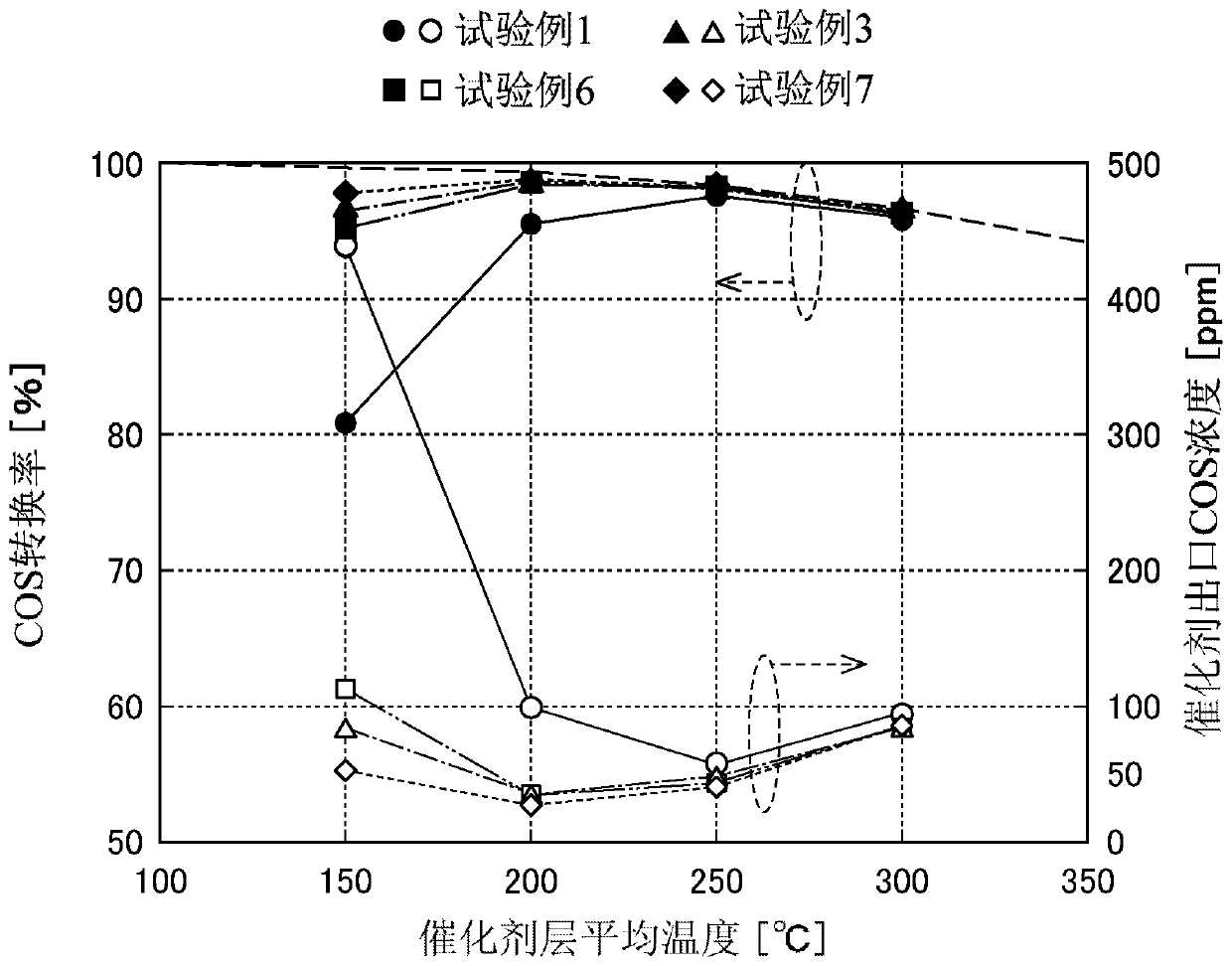

Catalyst for use in hydrolysis of carbonyl sulfide, and method for producing same

InactiveCN111432924AImprove conversion rateGas purification by catalytic conversionCatalyst activation/preparationCesium compoundPtru catalyst

Provided are: a catalyst for use in the hydrolysis of COS, which can improve a COS conversion rate at a low temperature; and a method for producing the catalyst. The catalyst for use in the hydrolysisof COS comprises a catalyst containing titanium dioxide supported on a barium compound and an auxiliary catalyst, wherein the auxiliary catalyst is at least one compound selected from the group consisting of a potassium compound, a sodium compound and a cesium compound.

Owner:三菱重工工程株式会社

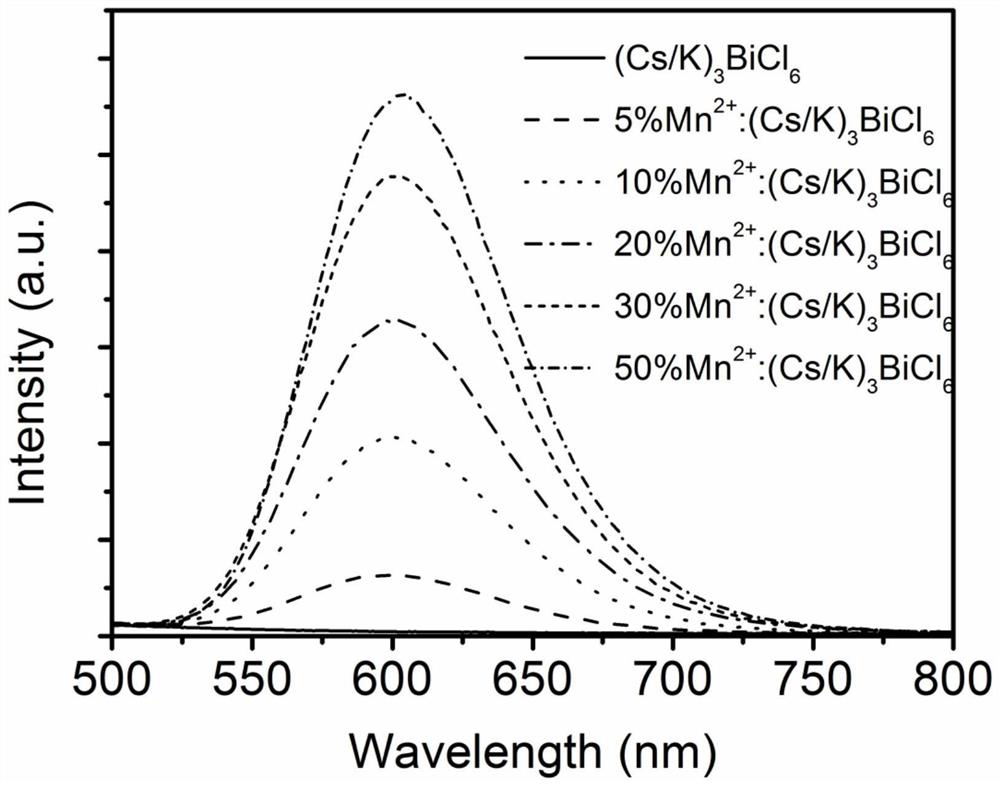

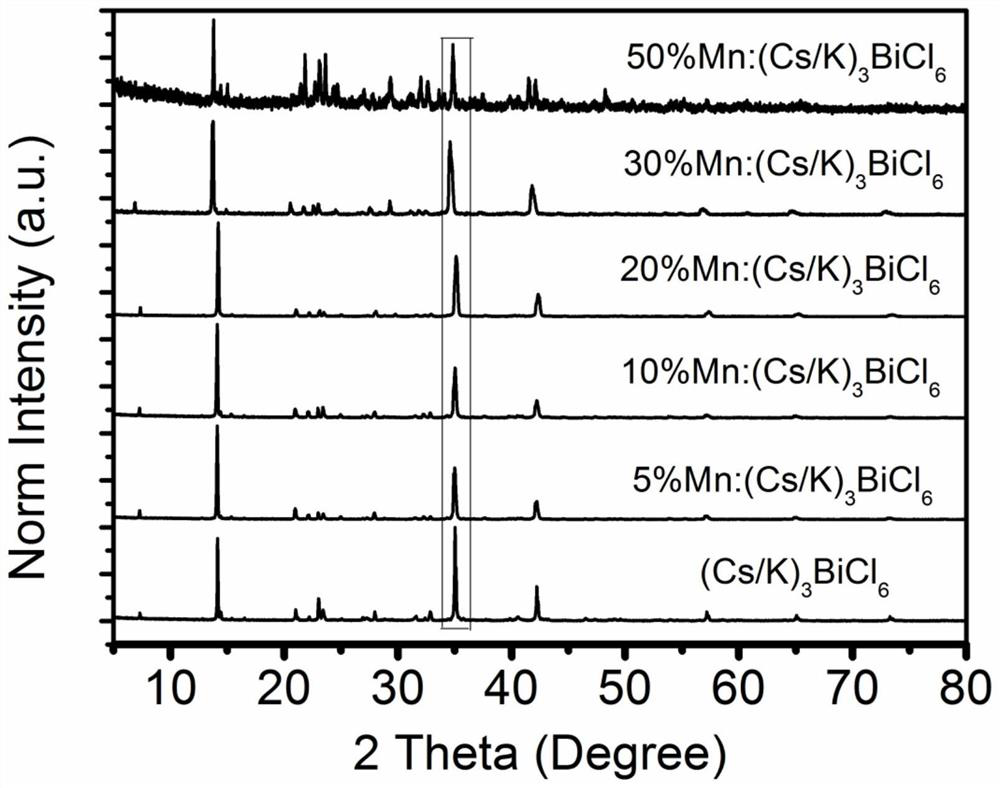

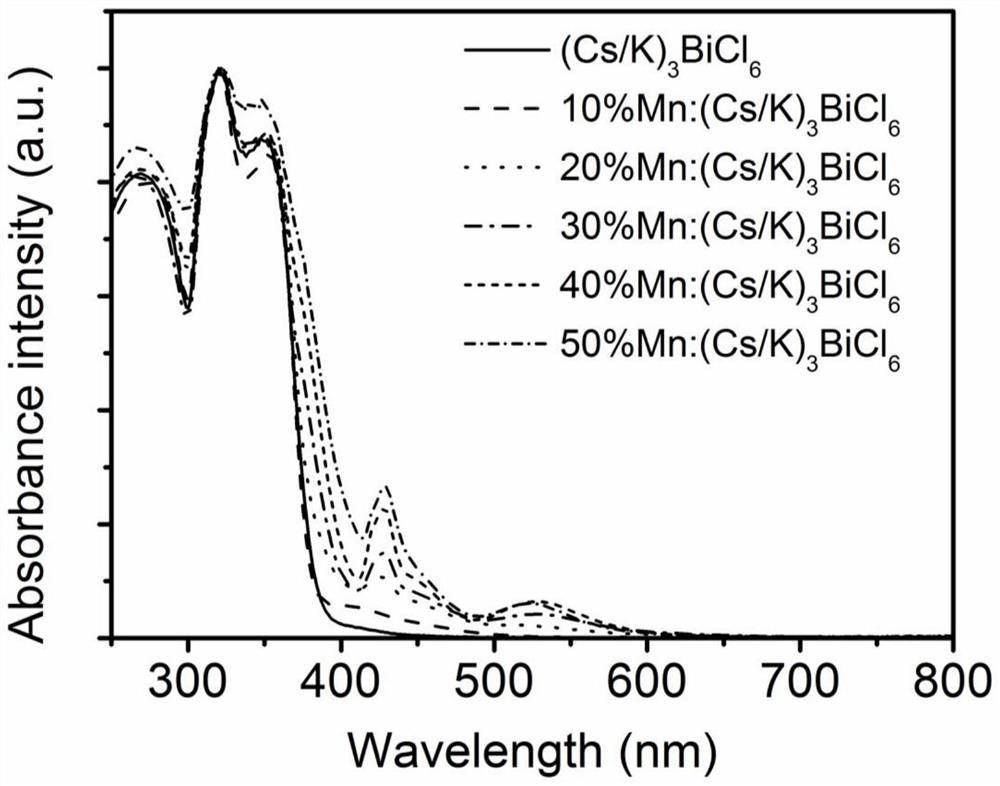

Mn-doped (Cs/K)3BiCl6 perovskite derivative material as well as preparation method and application thereof

ActiveCN112940722AFix stability issuesHigh photoluminescence efficiencyLuminescent compositionsFluoProbesFluorescence

The invention discloses a Mn-doped (Cs / K)3BiCl6 perovskite derivative material prepared by taking a cesium-containing compound, a manganese-containing compound, a potassium-containing compound and a bismuth-containing compound as reaction reagents and concentrated hydrochloric acid as a solution through a solvothermal method, and the influence of the Mn doping amount on the luminous efficiency is explored. The invention further provides a preparation method of the Mn-doped (Cs / K)3BiCl6 perovskite derivative material. The prepared Mn-doped (Cs / K)3BiCl6 perovskite derivative material is good in crystallinity, stable in structure, simple and convenient in preparation process, capable of being rapidly and massively synthesized and high in luminous efficiency. The toxicity problem of the lead-based perovskite is effectively solved by replacing lead with potassium and bismuth; and the fluorescent powder can realize emission of 603 nm broadband orange light under the excitation of ultraviolet light. The Mn-doped (Cs / K)3BiCl6 perovskite derivative material has good application prospects in the fields of illumination, display, projection, LEDs, fluorescent probes and the like.

Owner:GUANGXI UNIV

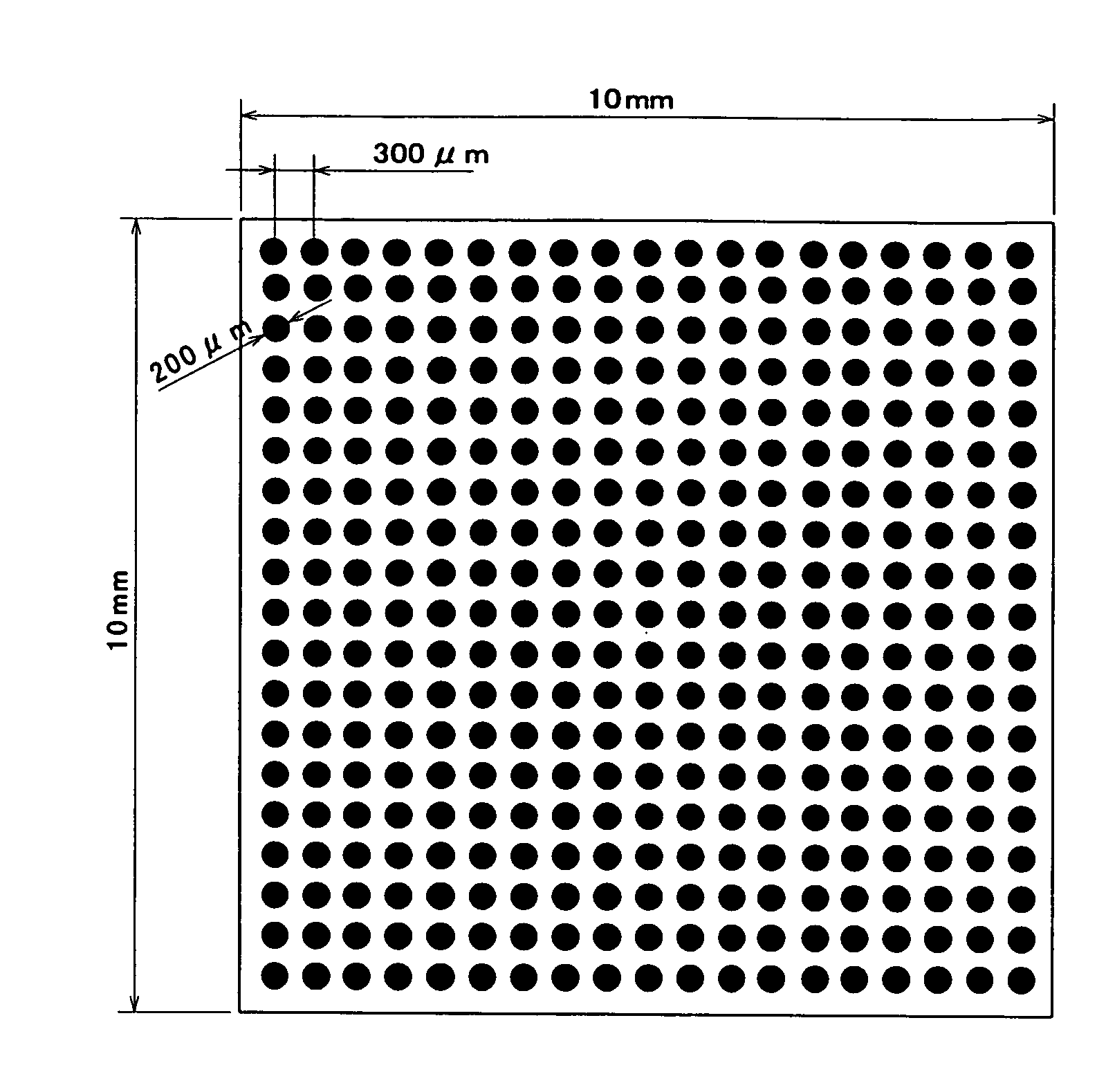

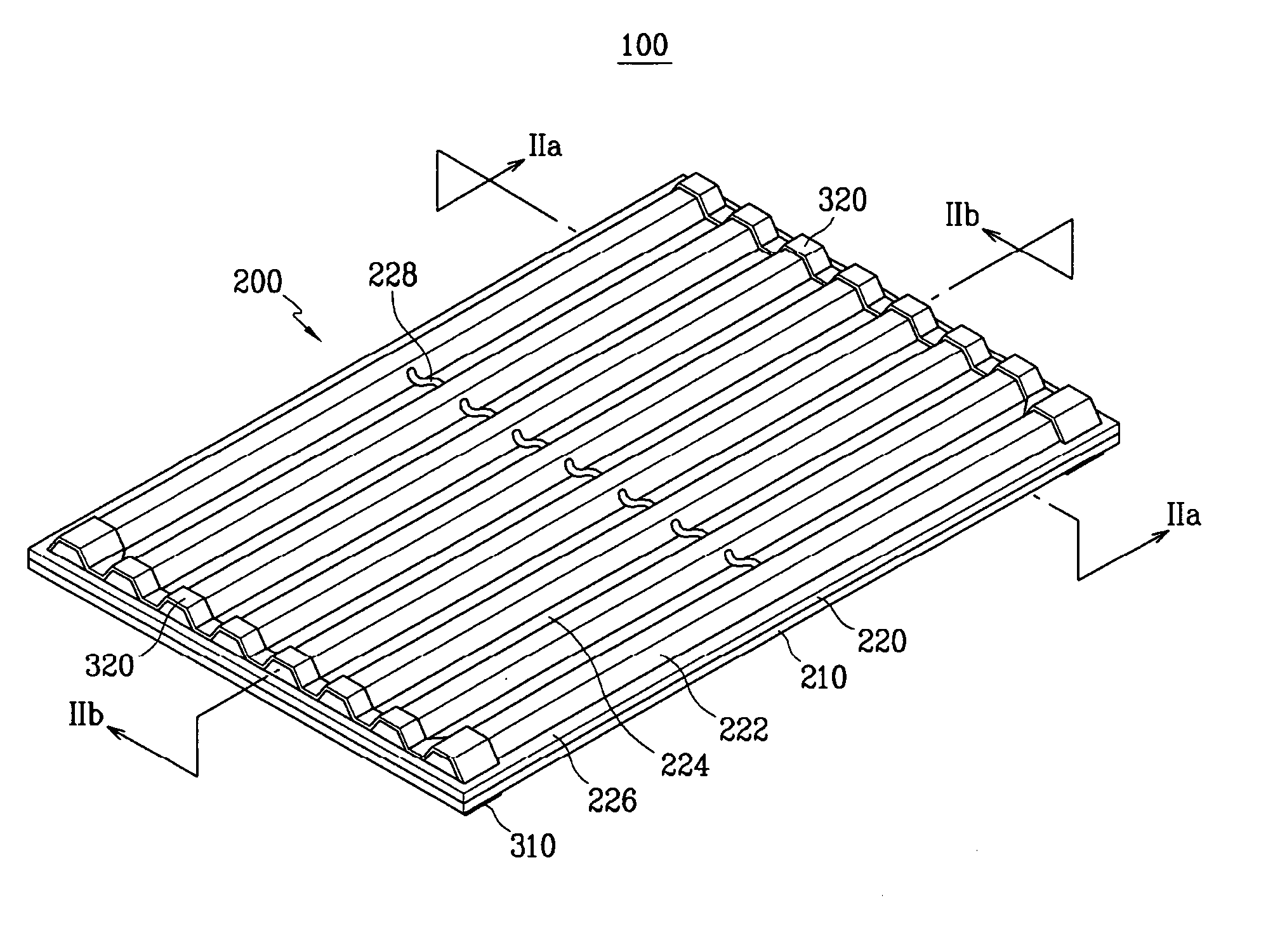

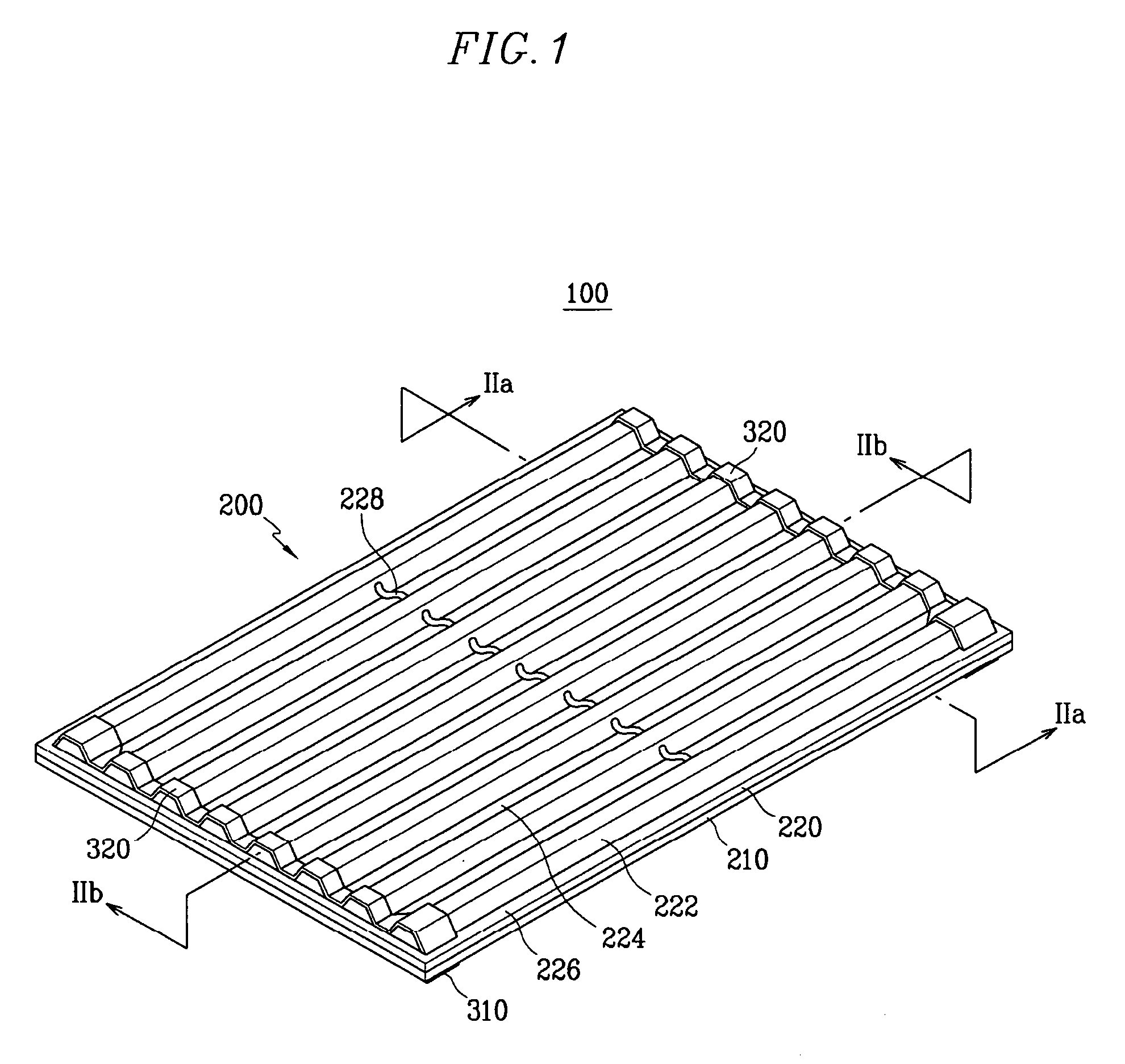

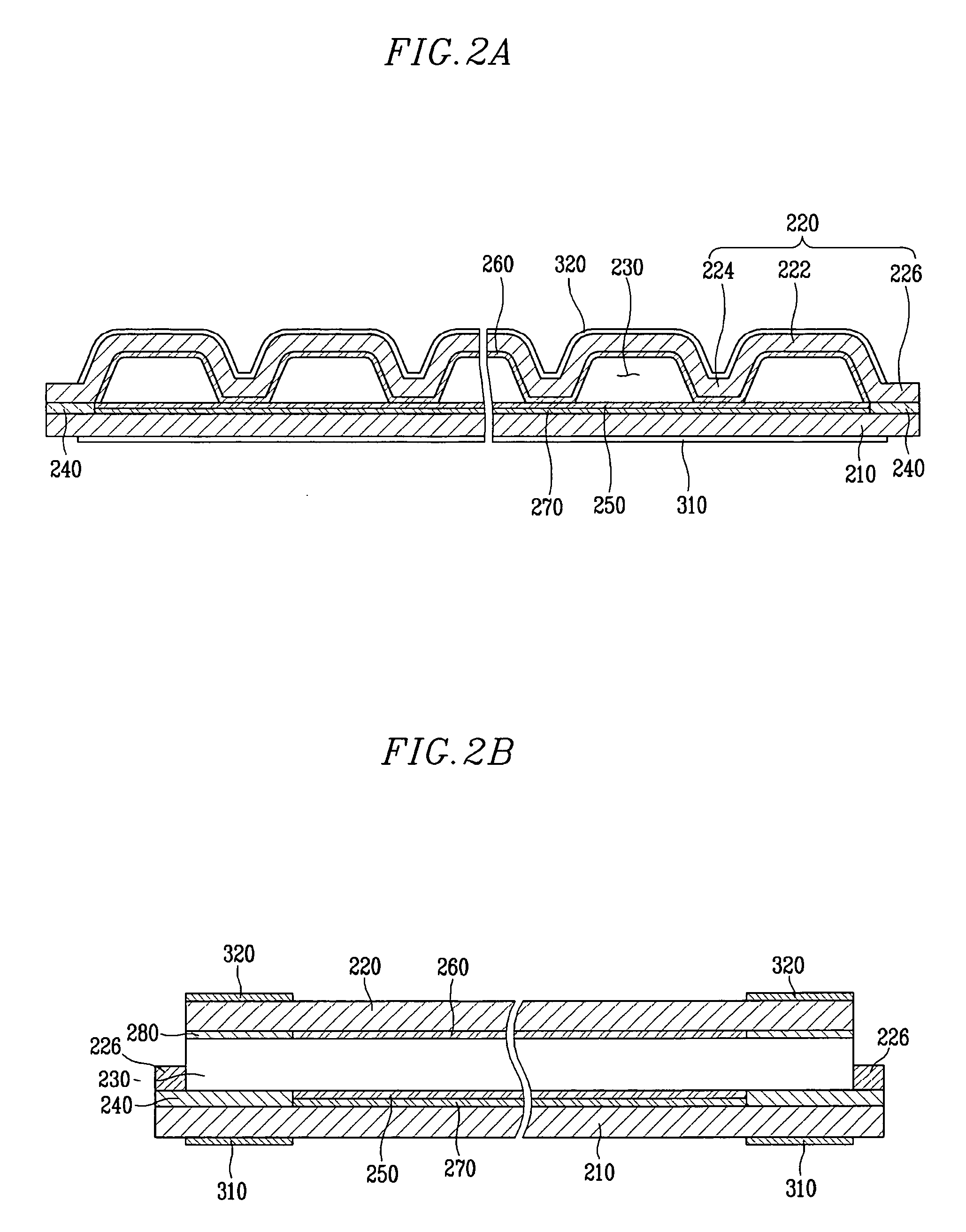

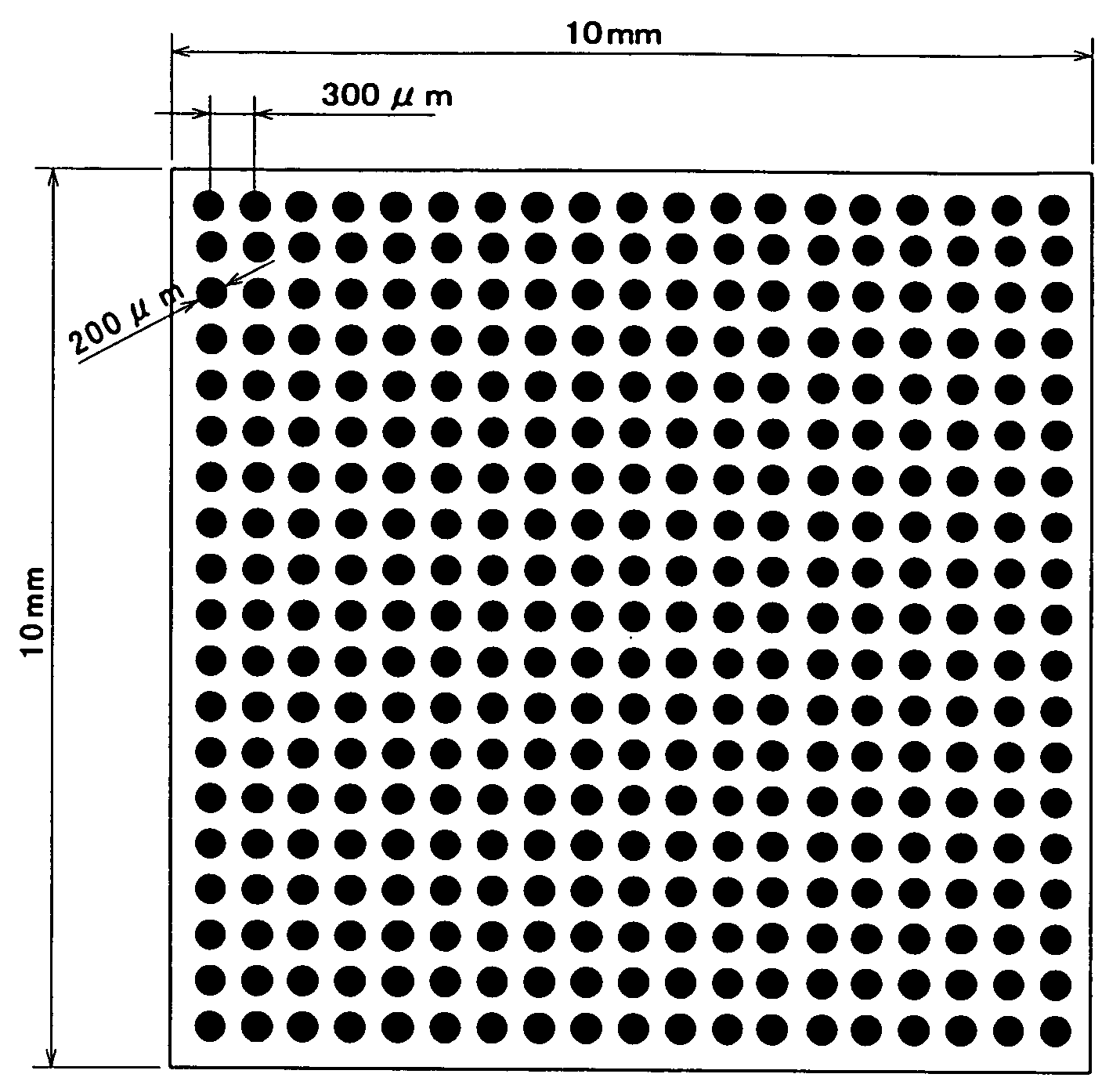

Flat fluorescent lamp and a display device having the same

InactiveUS20060232184A1Discharge tube luminescnet screensLamp detailsCesium compoundLiquid-crystal display

A flat fluorescent lamp and a liquid crystal display apparatus having the flat fluorescent lamp are provided. The flat fluorescent lamp includes a lamp body having first and second substrates that face each other and discharge spaces that are formed therebetween, and a protective member that is formed on an inner surface of at least one of the first or second substrates, wherein the protective member includes a cesium compound.

Owner:SAMSUNG ELECTRONICS CO LTD

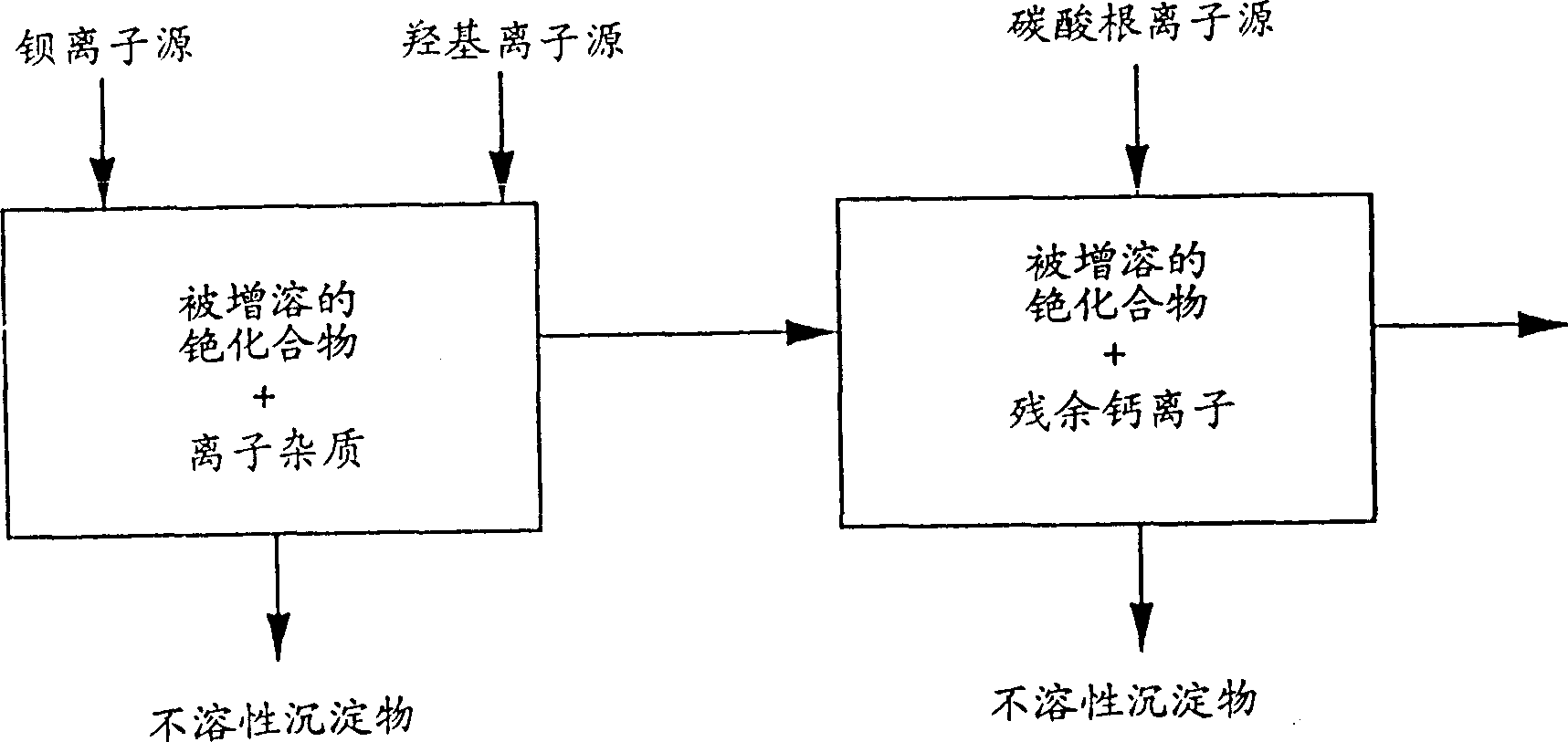

Method for production of cesium salt

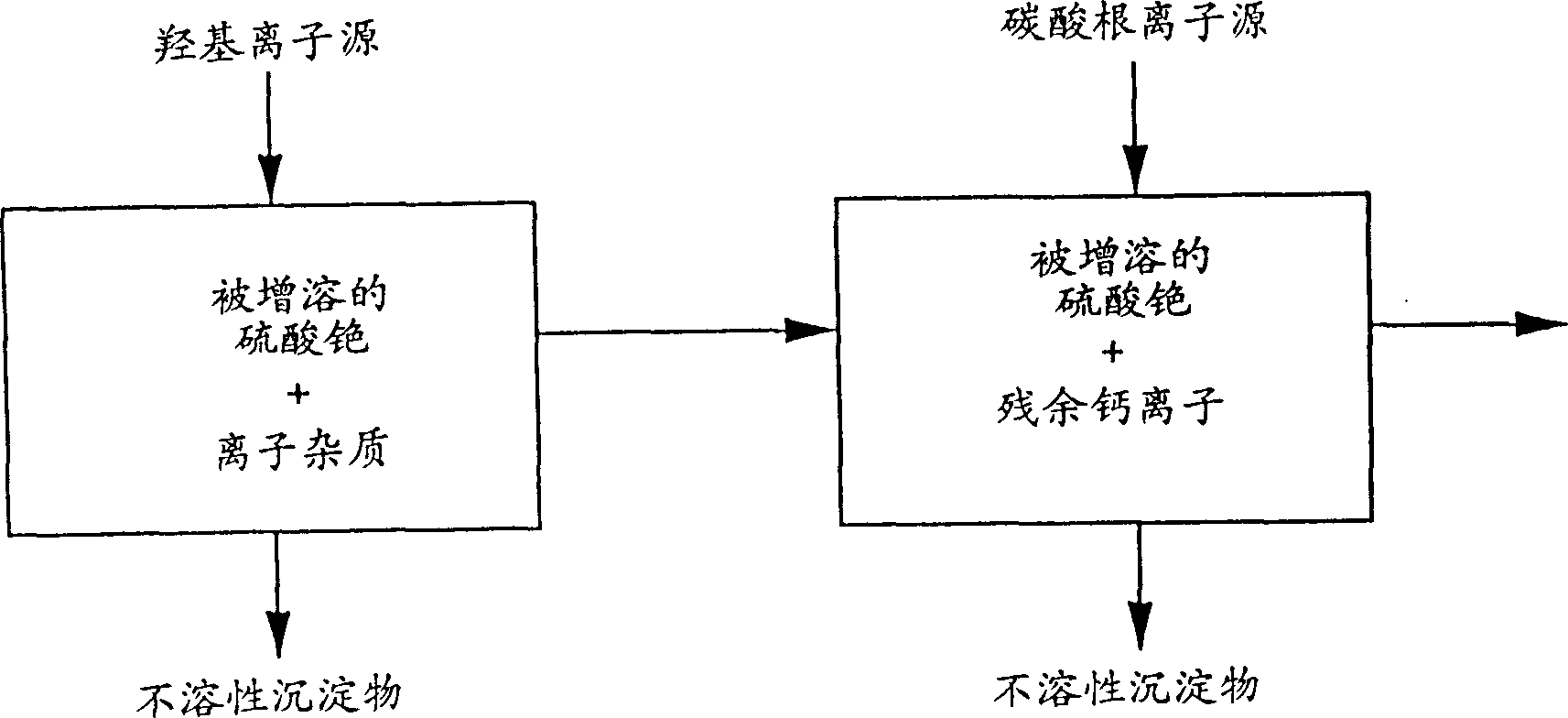

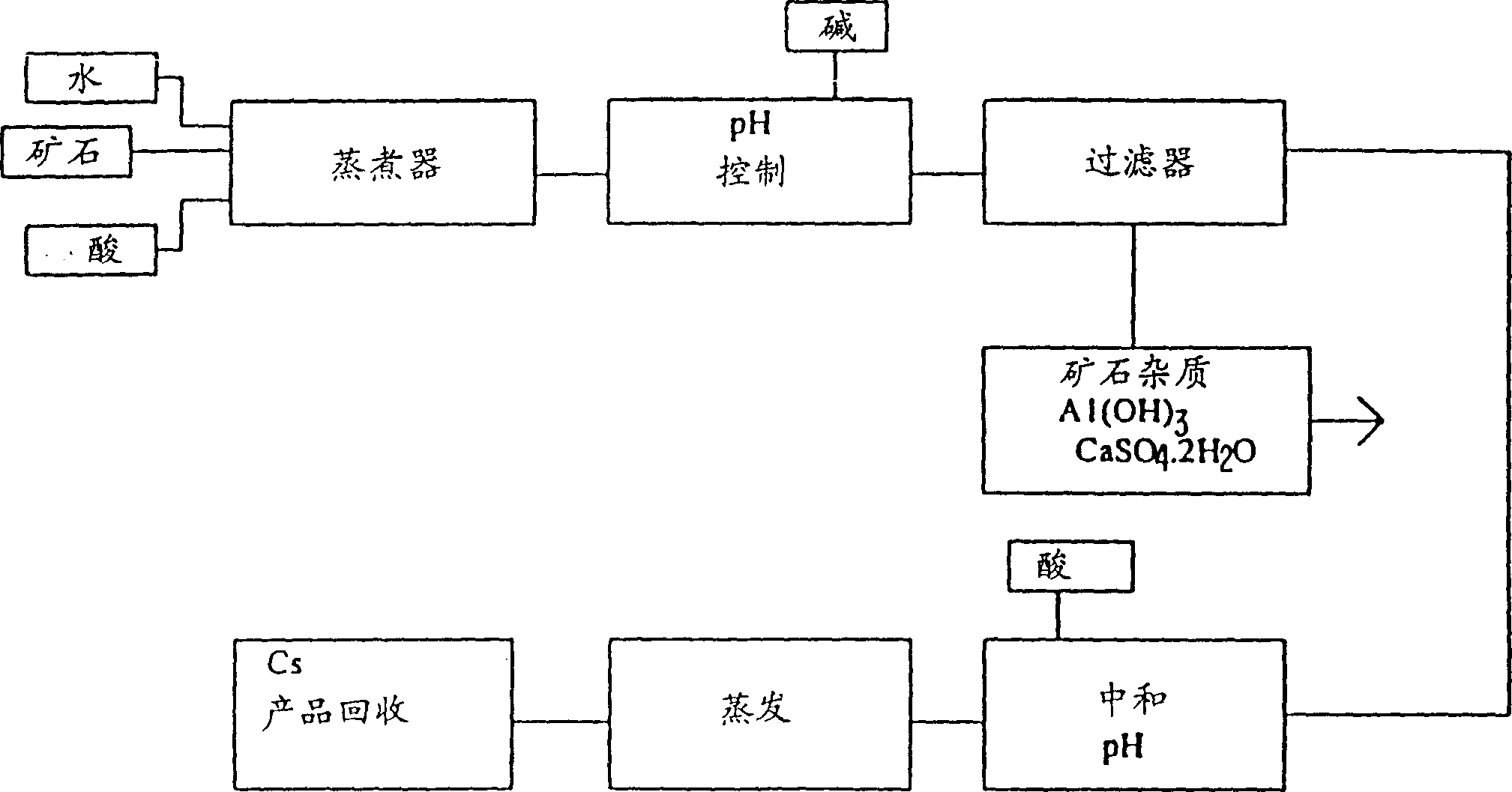

InactiveCN1106345CProfit productionGroup 1/11 element organic compoundsOrganic compound preparationSlurryImpurity

Disclosed is a process for purifying a cesium compound which includes an ionic impurity comprising: calcium, sulfate, magnesium or mixtures thereof comprising: reacting impurities comprising calcium, sulfate, magnesium or mixtures thereof in a solution including the solubilized starting cesium compound with suitable precipitating agents to form an insoluble precipitate including the impurity or impurities. Preferred precipitating agents include barium ion to precipitate sulfate ionic impurities as barium sulfate; hydroxyl ion to precipitate magnesium ionic impurities as magnesium hydroxide and to precipitate calcium ionic impurities as calcium hydroxide; and carbon dioxide or carbonate ion to precipitate calcium ionic impurities as calcium carbonate. Also disclosed is a process for producing a predetermined cesium compound. The process comprises treating a cesium-including material with a suitable reagent to dissolve at least a portion of the cesium contained in the material and form a slurry; adding a base comprising slaked lime or calcium carbonate and, if necessary to produce the desired cesium compound, an acid including the anion of the predetermined cesium compound to the slurry comprising the dissolved cesium; and separating the predetermined cesium compound. A drilling fluid or heavy medium separation fluid comprising a purified cesium compound and having a specific gravity of between about 1.2 g / cm<3> and about 2.5 g / cm<3> and having less than 85 % by weight of the predetermined cesium compound on a solution basis is also disclosed.

Owner:CABOT CORP

Curable, Blocked Polyisocyanate-Based Mixtures Free From Molybdenum and Tungsten Compounds But Containing Cesium Compounds, Their Preparation and Use

InactiveUS20080319111A1Reduce wettingImprove the level ofPolyurea/polyurethane coatingsCesium compoundPolymer science

Curable mixtures free from compounds of molybdenum and of tungsten and comprising(A) at least one constituent containing blocked isocyanate groups (a1) and isocyanate-reactive functional groups (a2), and(B) at least one cesium compound;processes for preparing them, and their use.

Owner:BASF COATINGS AG

Coating catalyst for catalytic gaseous phase oxidation of aromatic hydrocarbons

InactiveCN1121907CHigh selectivityHigh yieldOrganic compound preparationOrganic chemistry methodsCesium compoundGas phase

Owner:BASF AG

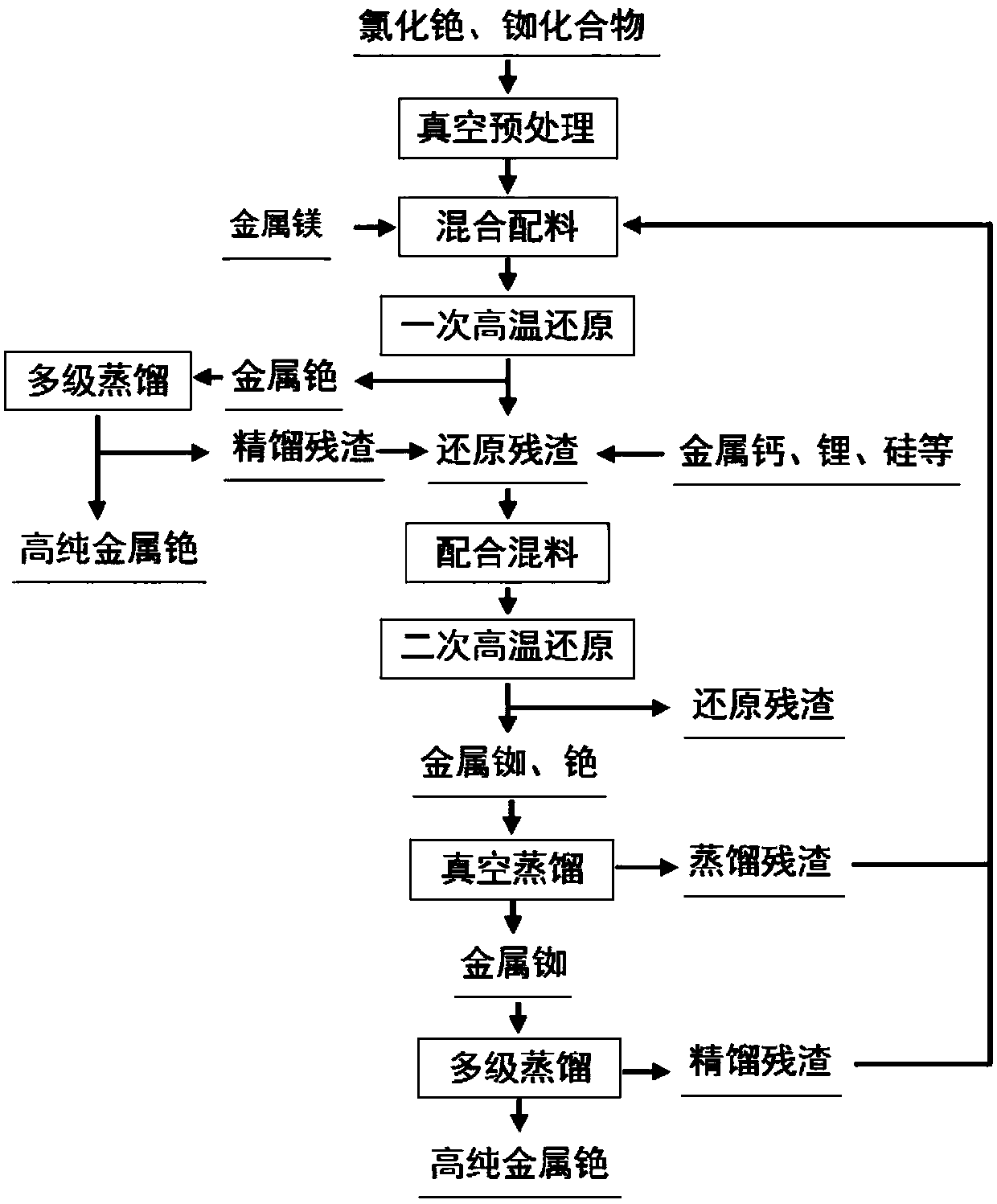

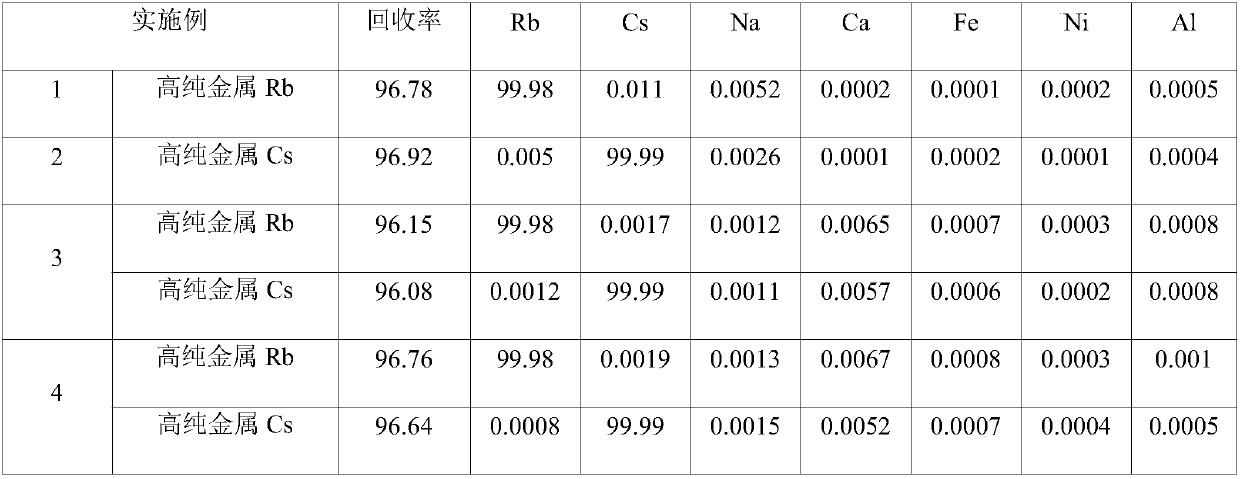

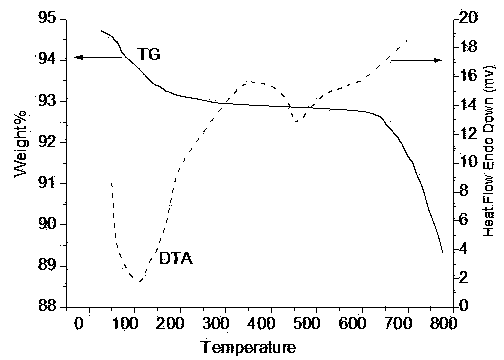

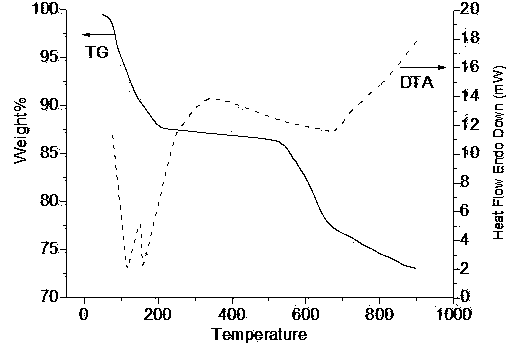

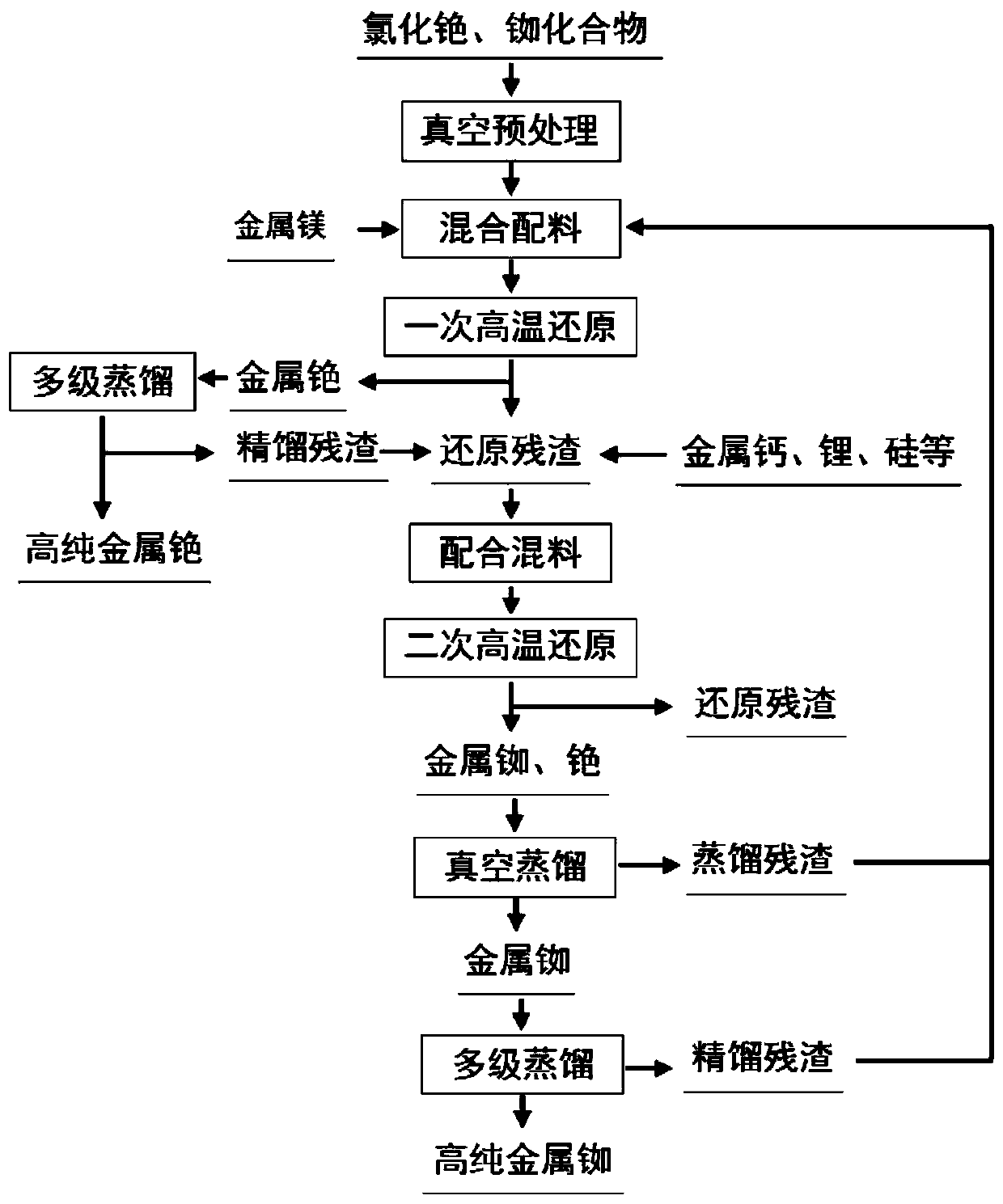

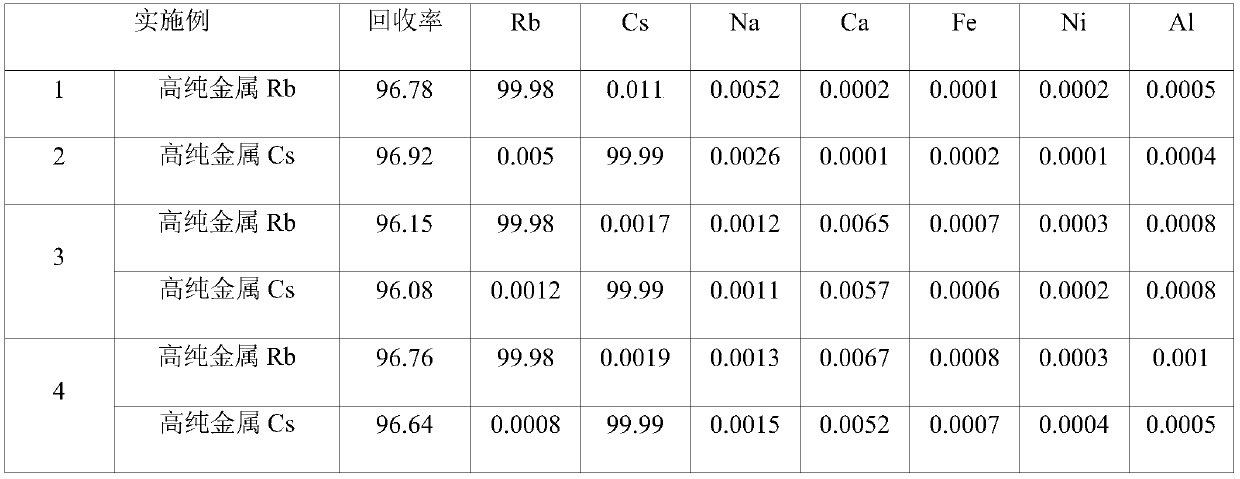

Preparation method of high-purity metallic rubidium and cesium

ActiveCN108018435AResolve not working from cesiumResolve separabilityProcess efficiency improvementCesium compoundRubidium

The invention discloses a preparation method of high-purity metallic rubidium and cesium. The preparation method comprises the steps of (1) preheating and dehydrating rubidium and cesium compounds; (2) carrying out primary reduction to obtain metallic cesium and primary reduction residues; (3) carrying out primary rectification on metallic cesium in the inert atmosphere, so as to obtain a primaryrectification product and primary rectification residues, and carrying out secondary rectification on the primary rectification product in the inert atmosphere, so as to obtain high-purity metallic cesium and secondary rectification residues; (4) mixing the primary reduction residues, the primary rectification residues and the secondary rectification residues with a secondary reducing agent, and carrying out secondary reduction to obtain metallic cesium, metallic rubidium and secondary reduction residues; (5) carrying out vacuum distillation separation on metallic cesium and metallic rubidium,so as to obtain a vacuum distillation product and a distillation residual liquid; and (6) carrying out distillation on the vacuum distillation product in the inert atmosphere for two times, so as toobtain two-time distillation products and high-purity metallic rubidium. The method is particularly suitable for separating the mixed rubidium and cesium compounds in which rubidium and cesium are mixed together to recycle and obtain high-purity metallic rubidium and high-purity metallic cesium.

Owner:湖南中大技术创业孵化器有限公司

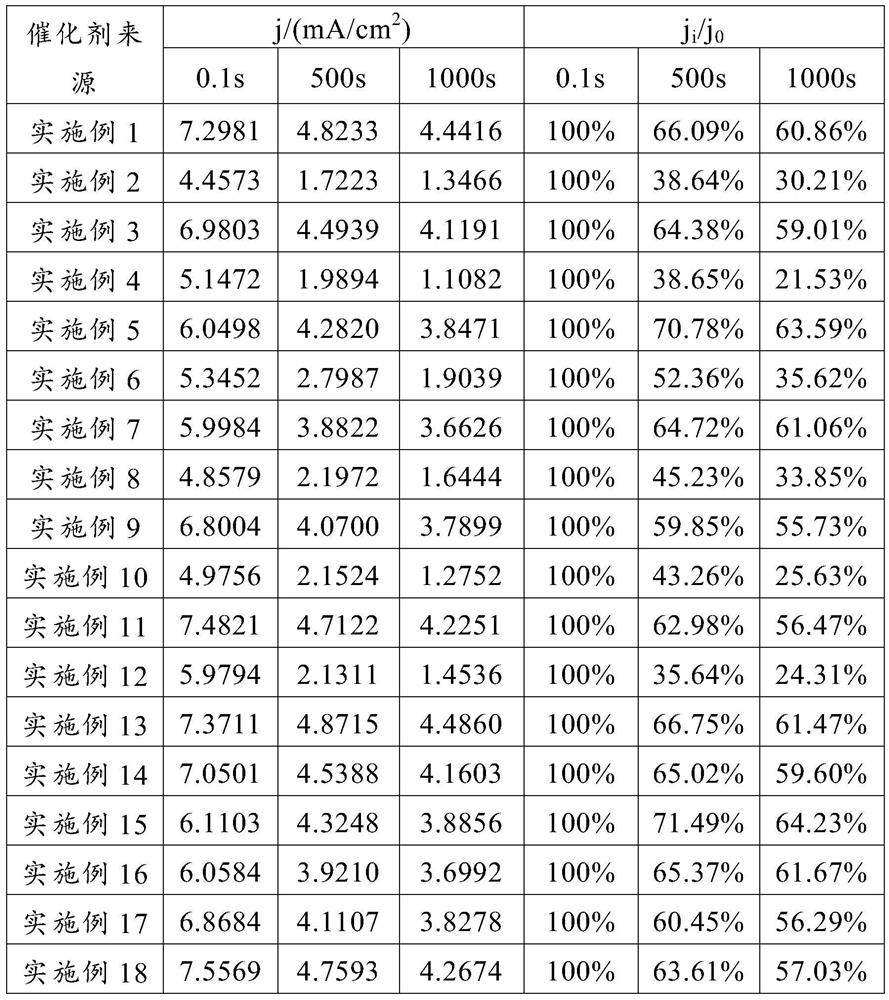

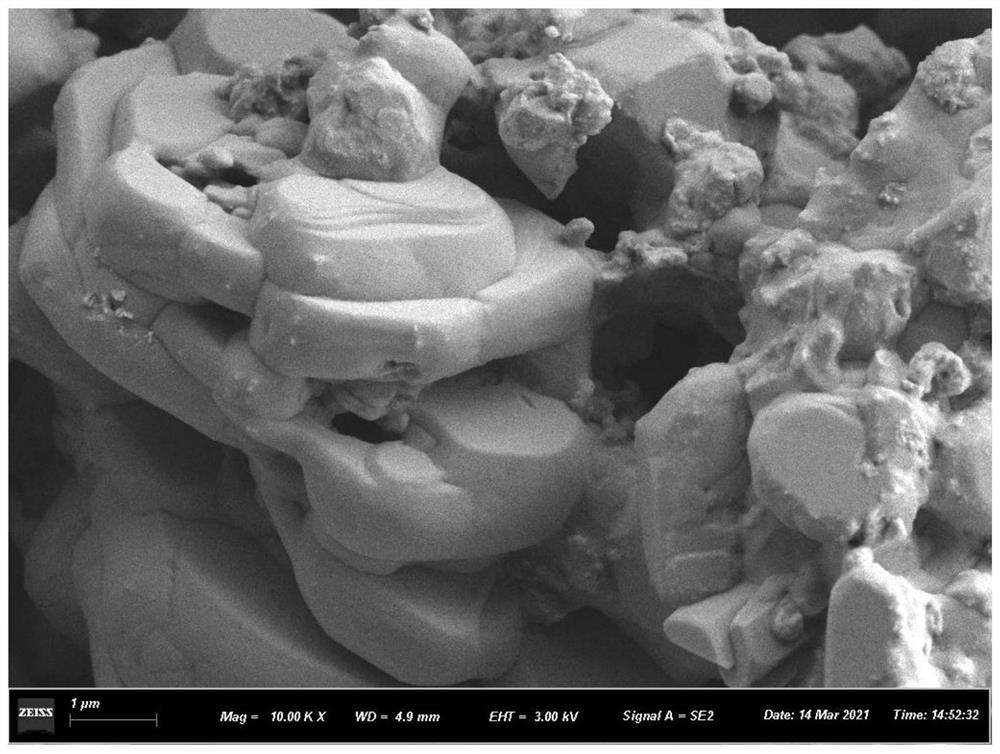

Platinum-based catalyst containing cesium or cesium compound

InactiveCN111659383AImprove catalytic performanceImprove stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCesium compoundPtru catalyst

The invention belongs to the technical field of catalysts, and relates to a platinum-based catalyst containing cesium or a cesium compound. The platinum-based catalyst comprises a catalytic active substance and a catalytic auxiliary substance, the catalytic active substance comprises metal platinum, the catalytic auxiliary substance comprises a cocatalyst, and the cocatalyst comprises one or moreof elementary substances or compounds of a single isotope Cs-134 or Cs-137 of cesium. The platinum-based catalyst containing cesium or the compound thereof has better catalytic performance and stability.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for determining cesium and cesium compounds in air of workplace

PendingCN114544281AOvercoming the flaws of detectionRealize analytical determinationPreparing sample for investigationMaterial analysis by electric/magnetic meansCesium compoundMicrofiltration membrane

The invention discloses a method for determining cesium and compounds thereof in air of a workplace. The method comprises the following steps: sampling for a short time and a long time at a sampling point by adopting a sampling clamp provided with a microfiltration membrane; placing the sampled microporous filter membrane in a beaker, adding pure water and dilute nitric acid for digestion, and finally fixing the volume to a volumetric flask to keep the nitric acid acidity of 1% (v / v); analyzing the sample solution by adopting an inductively coupled plasma mass spectrometer, and determining the content of cesium and compounds thereof in the sample solution according to the spectral intensity; and calculating through a formula to obtain the concentration of cesium and cesium compounds in air. The method overcomes the defects of traditional cesium and cesium compound detection, avoids chemical interference and ionization interference, improves the elution efficiency of cesium in the microfiltration membrane, realizes analysis and determination of trace and ultra-trace cesium and cesium compound, and ensures the accuracy and reliability of caesium and cesium compound occupational hazard factor detection results in a precise cesium processing technology.

Owner:SHANGHAI JINYI INSPECTION TECH

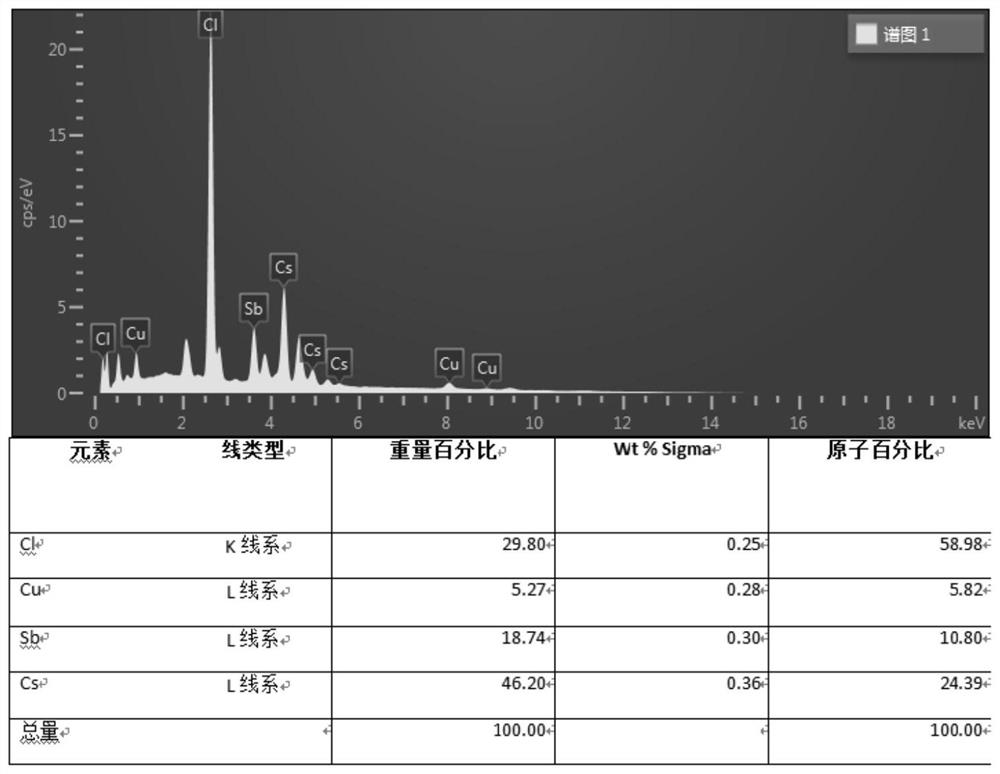

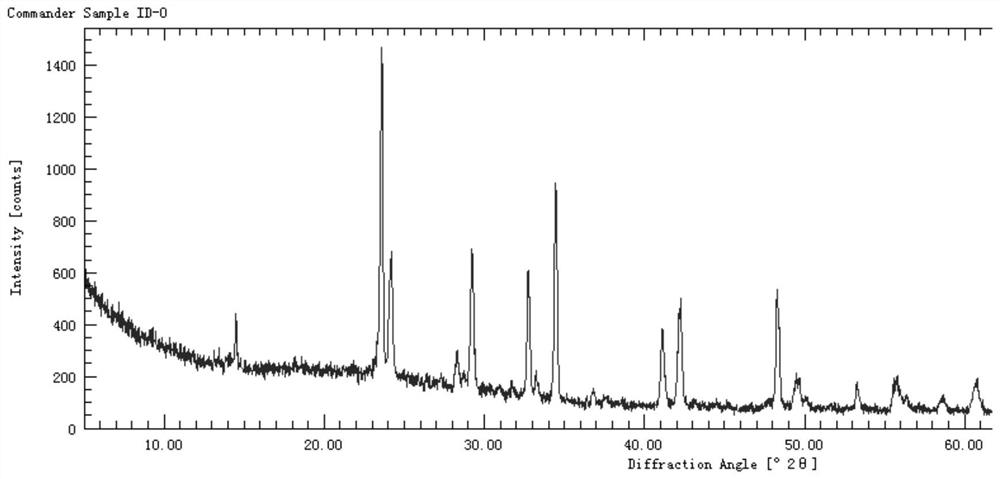

Cs4CuSb2Cl12 layered halide double perovskite material and preparation method and application thereof

The invention discloses a Cs4CuSb2Cl12 layered halide double perovskite material as well as a preparation method and application of the Cs4CuSb2Cl12 layered halide double perovskite material. The chemical formula of the layered halide double perovskite material is Cs4CuSb2Cl12. The preparation method comprises a solution preparation method and a mechanical force preparation method. The solution preparation method comprises the following steps: mixing a cesium-containing compound, an antimony-containing compound and a copper-containing compound according to a proper molar ratio, and adding the mixture into a mixed solution of an organic solvent and an acid solvent; performing ultrasonic treatment on the obtained solution to obtain black precipitate, and performing centrifugal treatment to separate out the black precipitate; and washing the obtained black precipitate with acetone so as to obtain the black Cs4CuSb2Cl12 layered halide double perovskite material. The mechanical force preparation method comprises the following steps: mixing the cesium-containing compound, the antimony-containing compound and the copper-containing compound according to a proper mass ratio, and putting the mixture into a mortar; grinding the mixture in the mortar to obtain a black product; and scraping off the black product, collecting powder, and washing the powder with acetone to obtain the black Cs4CuSb2Cl12 layered halide double perovskite material. The material provided by the invention has good stability, is friendly to human body and environment, has a direct band gap of 1.77 eV, is simple in preparation method and suitable for industrial production, and has wide application prospects in the photoelectric fields of photovoltaic cells, optical detectors, illumination, display, backlight sources and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

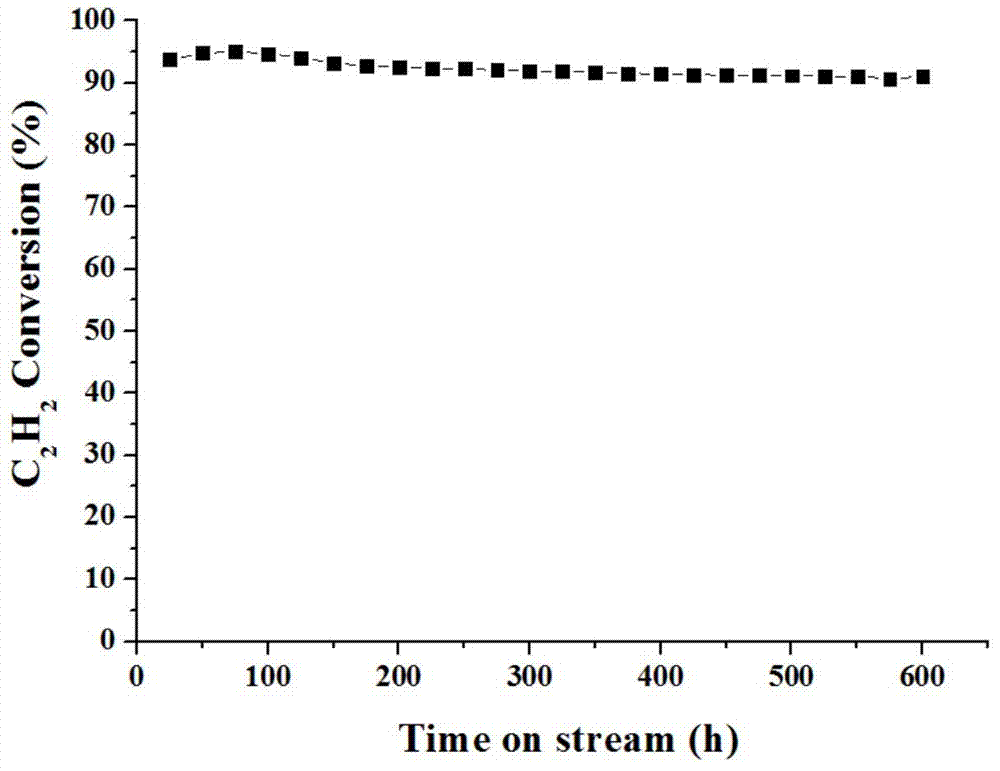

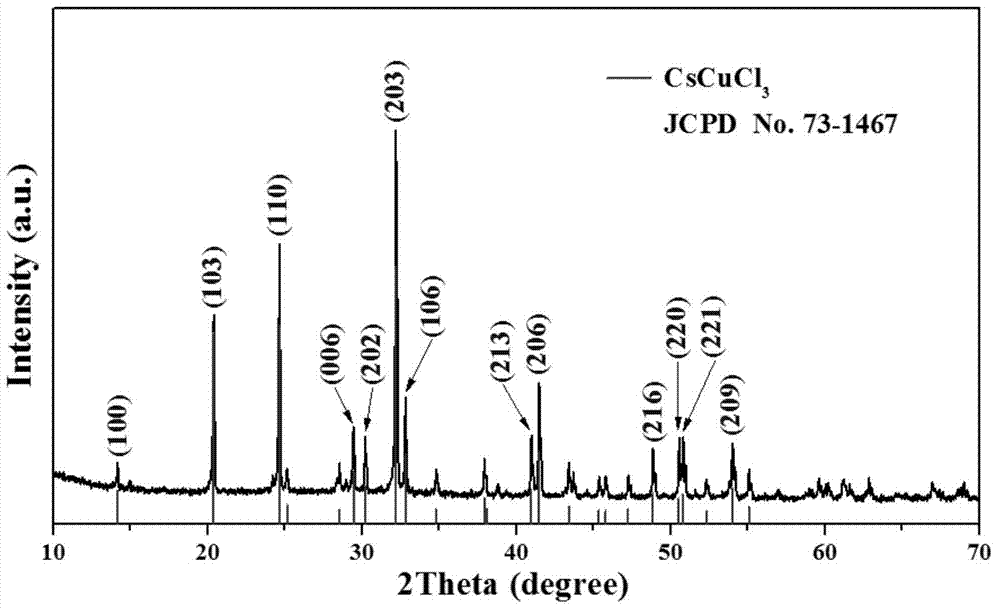

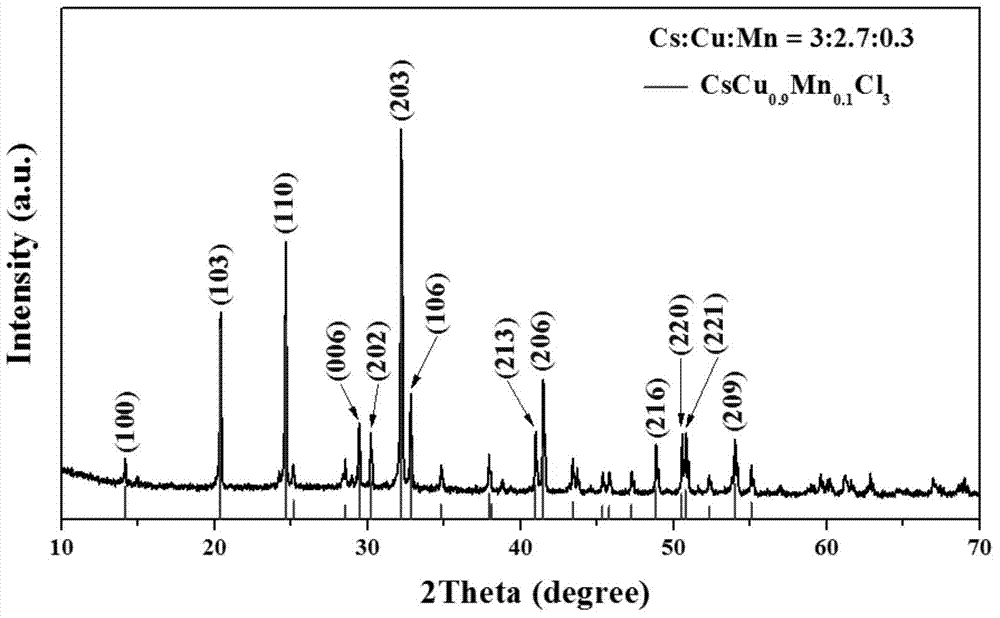

Perovskite compound chloride catalyst and application thereof

ActiveCN104741126AGood choiceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsPreparation by halogen additionMetal chlorideCesium compound

The invention discloses a perovskite compound chloride catalyst and application thereof. The catalyst comprises a carrier, a copper-cesium compound chloride of a perovskite structure loaded on the carrier or a copper-cesium compound chloride doped with a third metal chloride, wherein the third metal is selected from one of Sn, Mn, Bi, Ba, Sr, Zn and In and the carrier is selected from active carbon, a nitrogen-containing carbon material, a carbon nano tube and graphene; and the mass ratio of the carrier to the copper element to the cesium element to the third metal is 100 to (0.5-10) to (0.5-12) to (0-1). The perovskite compound chloride catalyst disclosed by the invention is applied to hydrochlorinating acetylene to synthesize chloroethylene, and has the advantages of high catalytic activity, good chloroethylene selectivity, good stability and long service life.

Owner:ZHEJIANG UNIV OF TECH

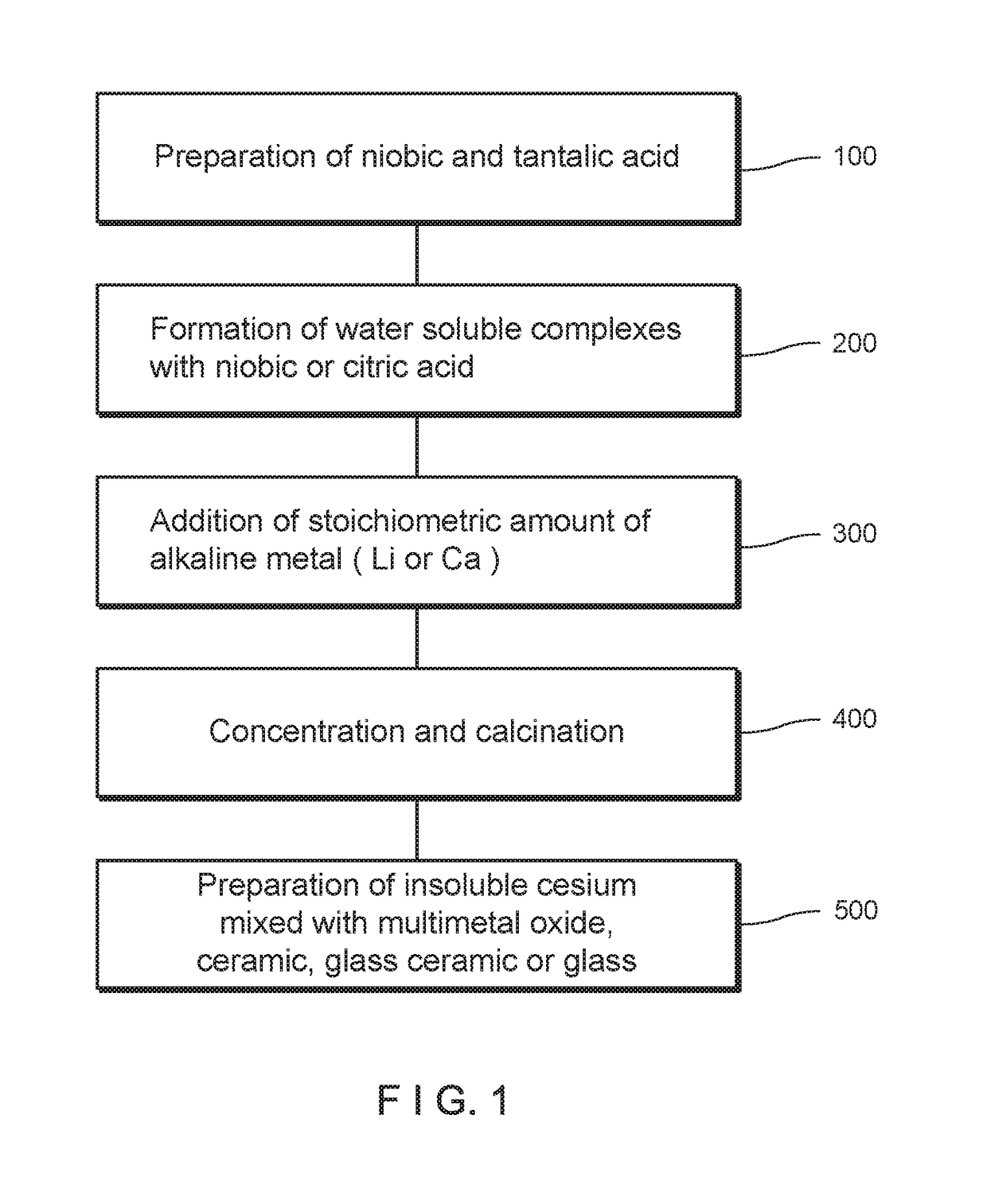

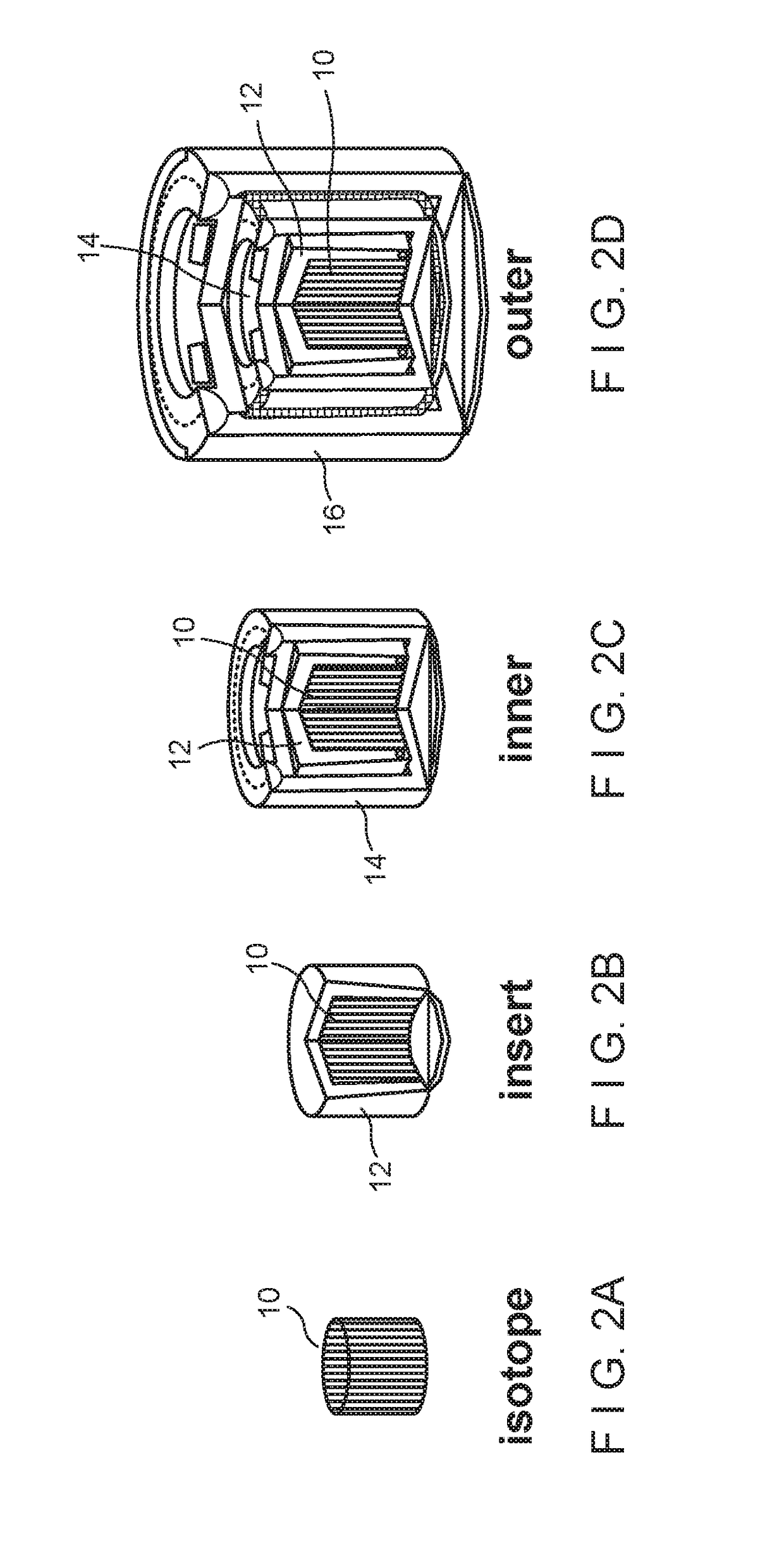

Insoluble cesium glass

ActiveUS10141080B2Increased radiological safetyReduce solubilityNuclear engineering solutionsRadioactive sourcesCesium compoundChloride

Owner:QSA GLOBAL

Process for producing optical device

InactiveUS7522803B2Simple processLow costGlass making apparatusOptical fibre with graded refractive index core/claddingCesium compoundOrganic solvent

The present invention provides a method of producing an optical element without the need for high vacuum, unlike the thin film deposition methods, and without using a molten salt. More specifically, the invention provides a method of producing an optical element comprising applying a paste containing at least one compound selected from lithium compounds, potassium compounds, rubidium compounds, cesium compounds, silver compounds, and thallium compounds, an organic resin, and an organic solvent to a glass substrate containing an alkali metal component as a glass component and then performing heat treatment at a temperature below the softening temperature of the glass substrate.

Owner:ISUZU GLASS +1

A kind of wet method vanadium catalyst and preparation method thereof

ActiveCN108067241BImprove conversion rateLower operating temperatureSulfur compoundsCatalyst activation/preparationPtru catalystPhosphate

The invention discloses a wet-method vanadium catalyst and a preparation method thereof. The wet-method vanadium catalyst comprises the following raw material components: 3-5% of V2O5, 1-3% of thiosulfate, 1-5% of a caesium-containing compound, 1-3% of a surfactant, 2-5% of an organic high polymer compound, 1-3% of hydroxide, 5-10% of diluted acid, 0.1-1% of anhydrous sodium sulfate, 3-10% of phosphate, 0.1-2% of a nickel-containing compound, 1-3% of sulfur, 20-36% of concentrated sulfuric acid and the balance of kieselguhr crude ore, wherein the mass of the concentrated sulfuric acid is 0.9-1.1 times of the mass of kieselguhr crude ore; the mass sum of all raw material components is 100%; the mass concentration of the diluted sulfuric acid is 20-60%; the mass concentration of the concentrated sulfuric acid is not less than 80%; the surfactant is sodium dodecyl benzene sulfonate; the organic high polymer compound is polyacrylamide. The wet-method vanadium catalyst disclosed by the invention is low in initiation temperature and is solid and fast, and the anti-powdering properties and the water resistance of the wet-method vanadium catalyst are remarkably improved.

Owner:南京云高新型材料有限公司

Nanometer vanadium catalyst for preparing sulfuric acid through oxidizing SO2 and preparation method thereof

ActiveCN102489320BReduce energy consumptionLower operating temperaturePhysical/chemical process catalystsSulfur compoundsPtru catalystThio-

Owner:南京云高新型材料有限公司

A kind of preparation method of high-purity metal rubidium and cesium

ActiveCN108018435BHigh recovery rateSimple processProcess efficiency improvementCesium compoundRubidium

The invention discloses a preparation method of high-purity metallic rubidium and cesium. The preparation method comprises the steps of (1) preheating and dehydrating rubidium and cesium compounds; (2) carrying out primary reduction to obtain metallic cesium and primary reduction residues; (3) carrying out primary rectification on metallic cesium in the inert atmosphere, so as to obtain a primaryrectification product and primary rectification residues, and carrying out secondary rectification on the primary rectification product in the inert atmosphere, so as to obtain high-purity metallic cesium and secondary rectification residues; (4) mixing the primary reduction residues, the primary rectification residues and the secondary rectification residues with a secondary reducing agent, and carrying out secondary reduction to obtain metallic cesium, metallic rubidium and secondary reduction residues; (5) carrying out vacuum distillation separation on metallic cesium and metallic rubidium,so as to obtain a vacuum distillation product and a distillation residual liquid; and (6) carrying out distillation on the vacuum distillation product in the inert atmosphere for two times, so as toobtain two-time distillation products and high-purity metallic rubidium. The method is particularly suitable for separating the mixed rubidium and cesium compounds in which rubidium and cesium are mixed together to recycle and obtain high-purity metallic rubidium and high-purity metallic cesium.

Owner:湖南中大技术创业孵化器有限公司

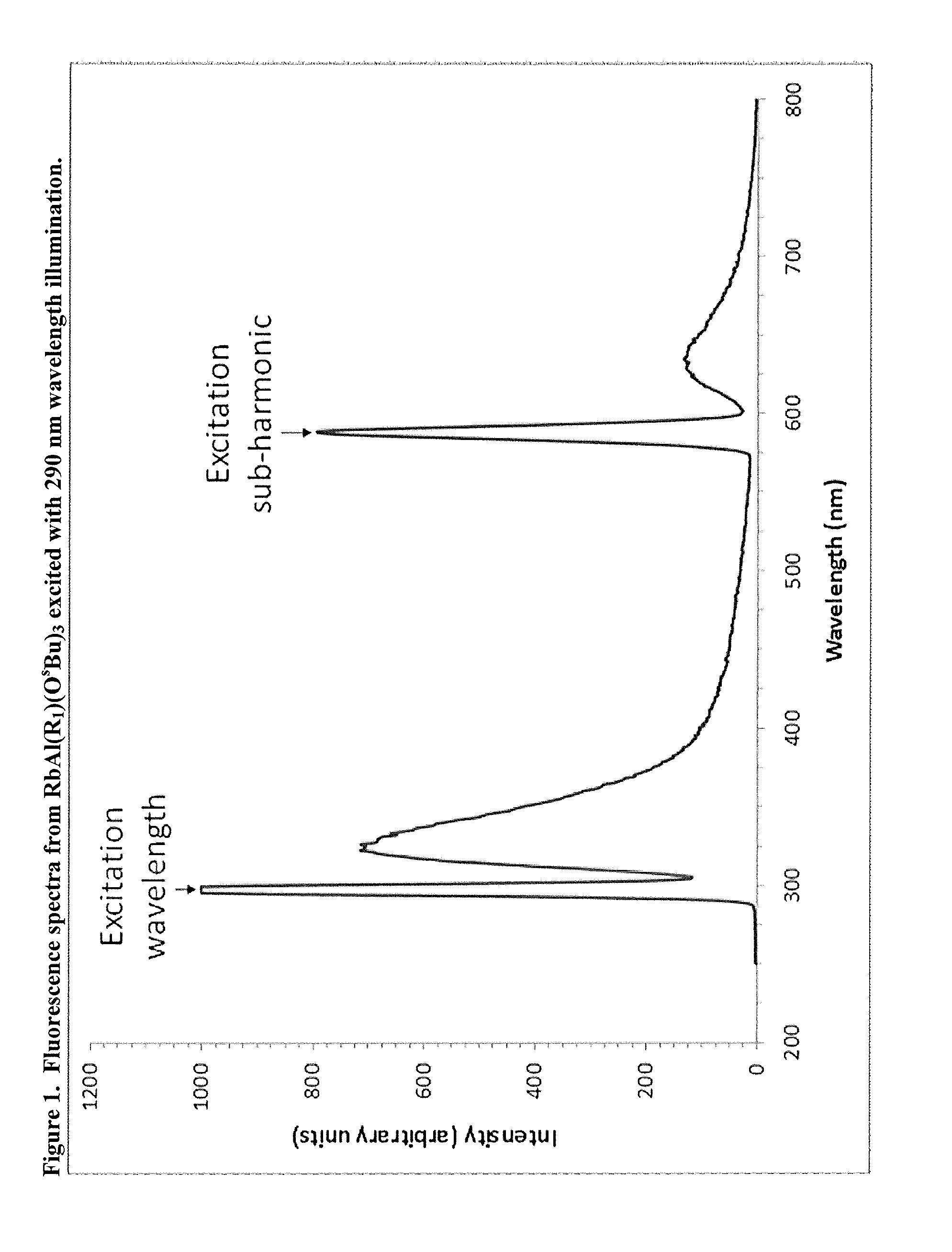

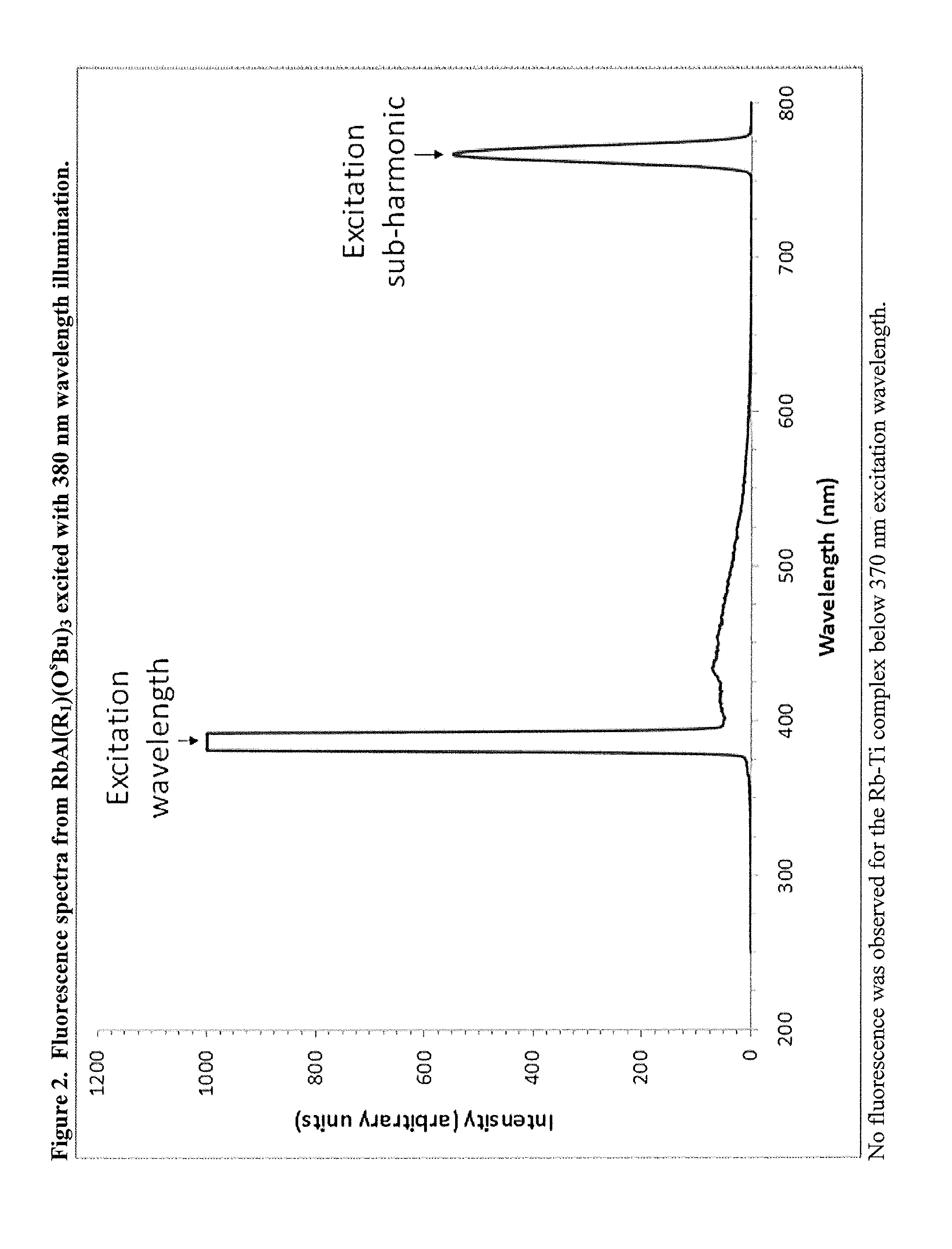

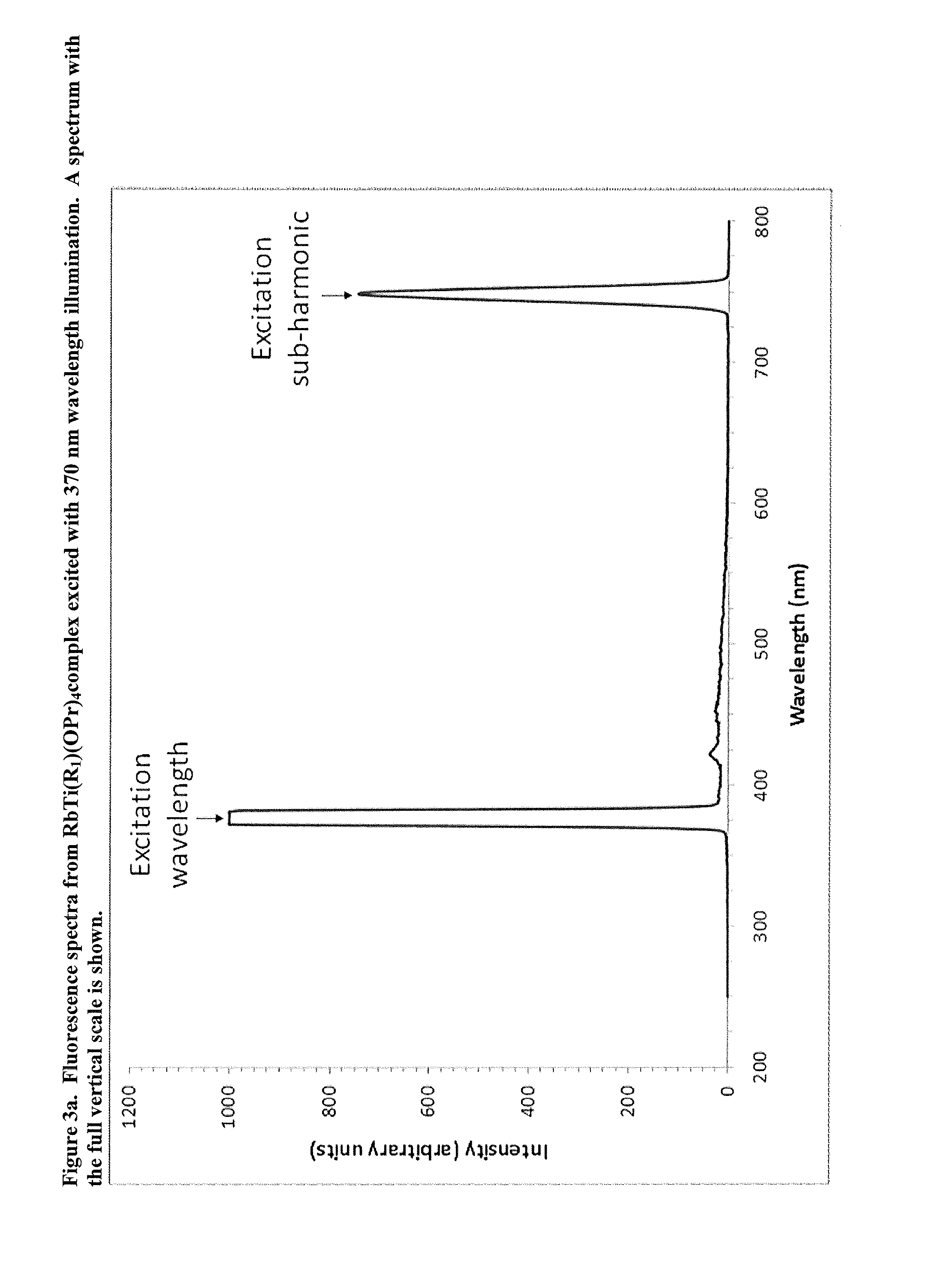

Rubidium and cesium compounds for two-photon absorption

A material which electronically isolates a rubidium or cesium atom, which is bonded to only one or two oxygen atoms. This electronic isolation is manifested in narrow photoluminescence emission spectral peaks. The material may be an alkali metal compound comprises the empirical formula: AM(R1)(OR)x; where A is selected from Rb and Cs; M is selected from Al, Ti and V; each R is an independently selected alkyl or aryl group, R1 is selected from alkyl alcohol, aryl alcohol, or a carboxyl group, where OR and R1 are not the same, and x is 2, 3, or 4.

Owner:BATTELLE MEMORIAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com