Cesium-containing high-voltage lithium ion battery electrolyte composite additive, electrolyte and battery thereof

A technology of lithium-ion batteries and composite additives, applied in the direction of secondary batteries, composite electrolytes, secondary battery repair/maintenance, etc., can solve the problems of battery performance deterioration, cycle performance deterioration, and aggravated side reactions, etc., to facilitate widespread application , improve electrochemical performance, improve the effect of interface characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

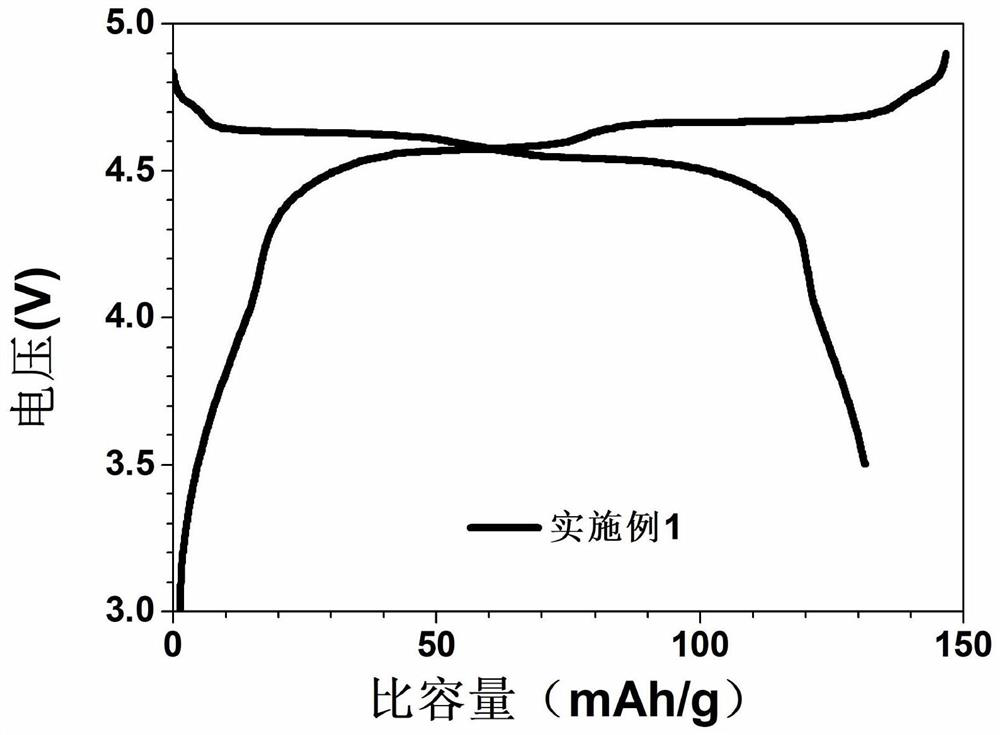

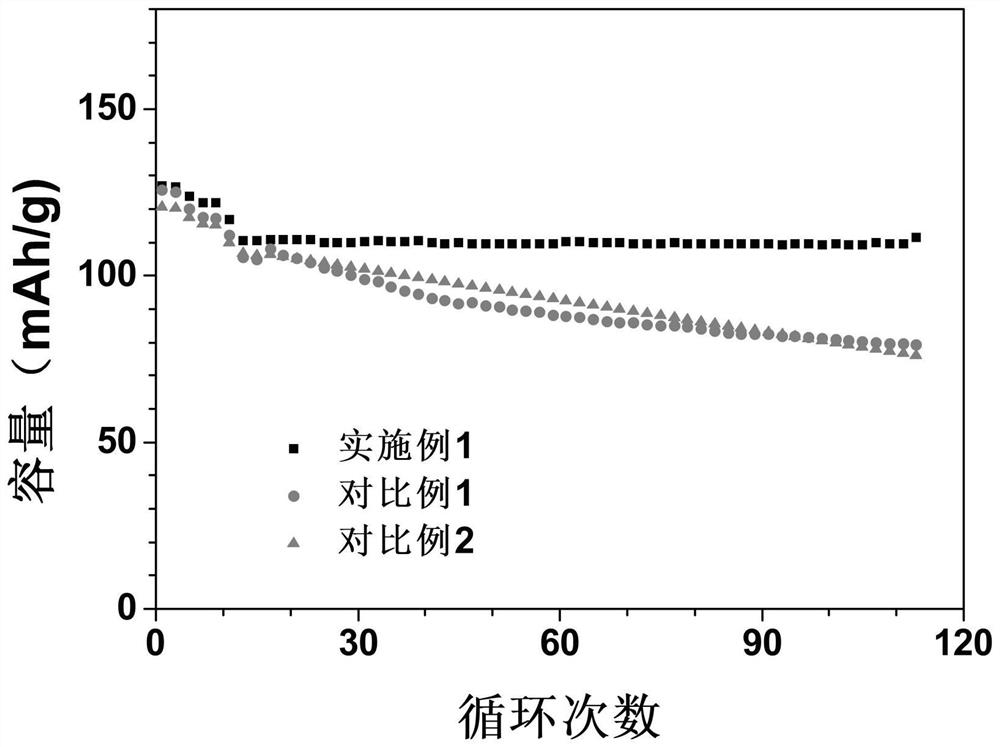

Embodiment 1

[0029] Preparation of cesium-containing high-voltage lithium-ion battery electrolyte:

[0030] In a glove box filled with argon, ethylene carbonate and dimethyl carbonate were mixed uniformly at a mass ratio of 1:1, and 0.05% cesium acetate and 1% tris(trimethylsilane) were added to the mixed solution. Phosphite and 2% lithium difluorophosphate, then slowly add lithium salt LiPF 6 , and stirred until it was completely dissolved to obtain cesium-containing high-voltage lithium-ion battery electrolyte solution A1.

[0031] Preparation of high-voltage lithium-ion batteries:

[0032] Will LiNi 0.5 mn 1.5 o 4 (LNMO) is used as the positive electrode active material, carbon black is used as the conductive additive, and carboxymethyl cellulose (CMC), styrene-butadiene copolymer (SBR) is used as the binder, and the mass ratio is 92:5:1 :2 After mixing evenly in water, coat the aluminum foil current collector, dry, cold press, cut into discs with a diameter of φ14mm, and place the...

Embodiment 2

[0034] Its difference from Example 1 is the preparation of cesium-containing high-voltage lithium-ion battery electrolyte:

[0035] In a glove box filled with argon, ethylene carbonate and dimethyl carbonate were mixed uniformly at a mass ratio of 1:1, and the mass fraction of 3% cesium trifluoroacetate, 2% tri(trimethylsilane) was added to the mixed solution ) phosphate and 0.1% lithium difluorodioxalate phosphate, then slowly add lithium salt LiPF 6 , and stirred until it was completely dissolved to obtain cesium-containing high-voltage lithium-ion battery electrolyte A2.

Embodiment 3

[0037] Its difference from Example 1 is the preparation of cesium-containing high-voltage lithium-ion battery electrolyte:

[0038]In a glove box filled with argon, ethylene carbonate and dimethyl carbonate were mixed uniformly at a mass ratio of 1:1, and 1% cesium azide, 3% bis(trimethyl Silicon-based) phosphite and 1% lithium tetrafluorooxalate phosphate, then slowly add lithium salt LiPF 6 , and stirred until it was completely dissolved to obtain cesium-containing high-voltage lithium-ion battery electrolyte solution A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com