Composite lithium battery membrane and method for making same

A battery diaphragm and lithium composite technology, which is applied in the field of new composite polypropylene lithium battery diaphragm and its preparation, can solve problems such as limited liquid absorption, poor mechanical properties of the diaphragm, and impact on battery cycle performance, so as to achieve good cycle performance and improve Effect of Room Temperature Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

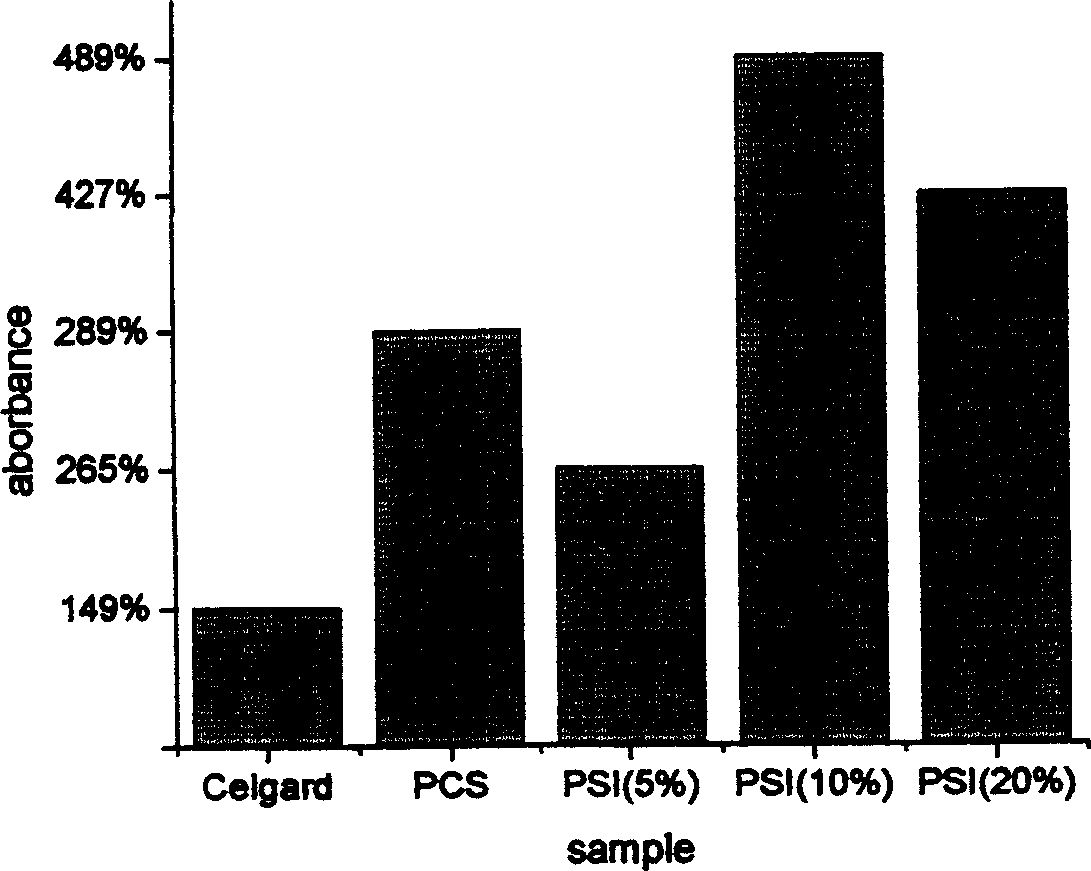

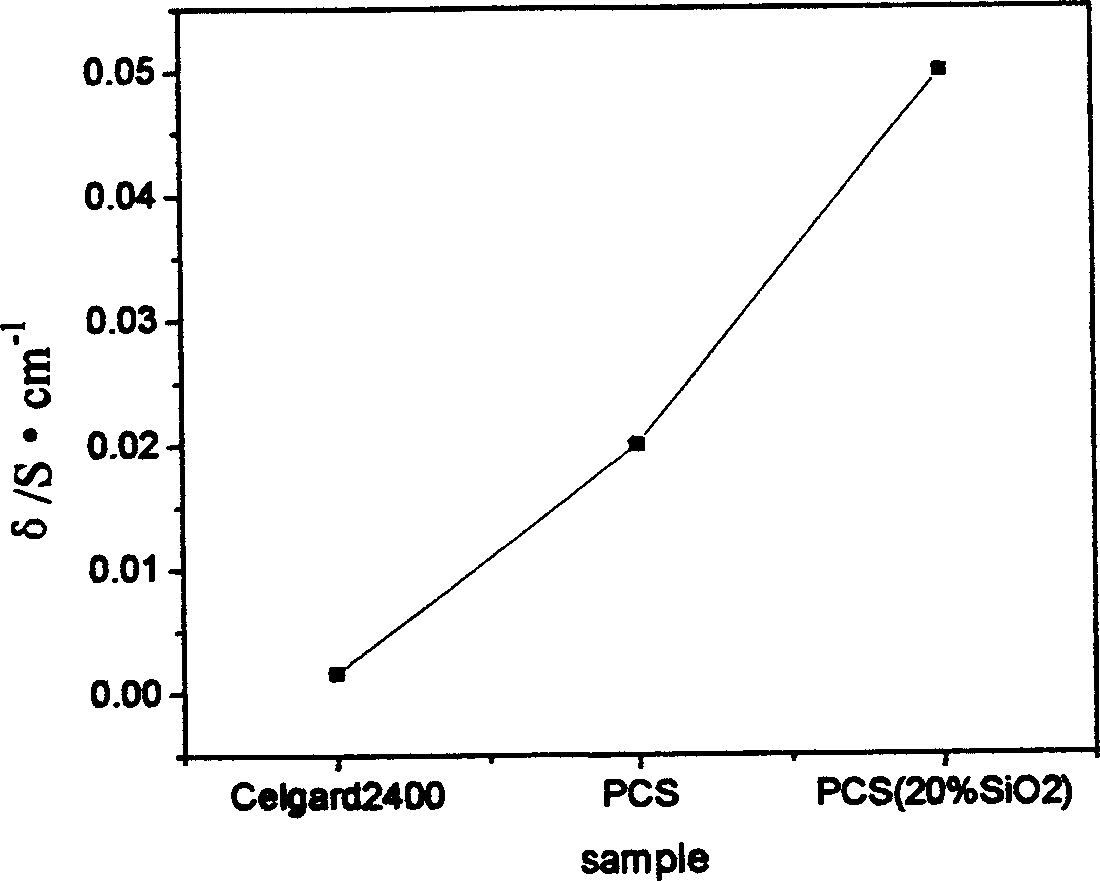

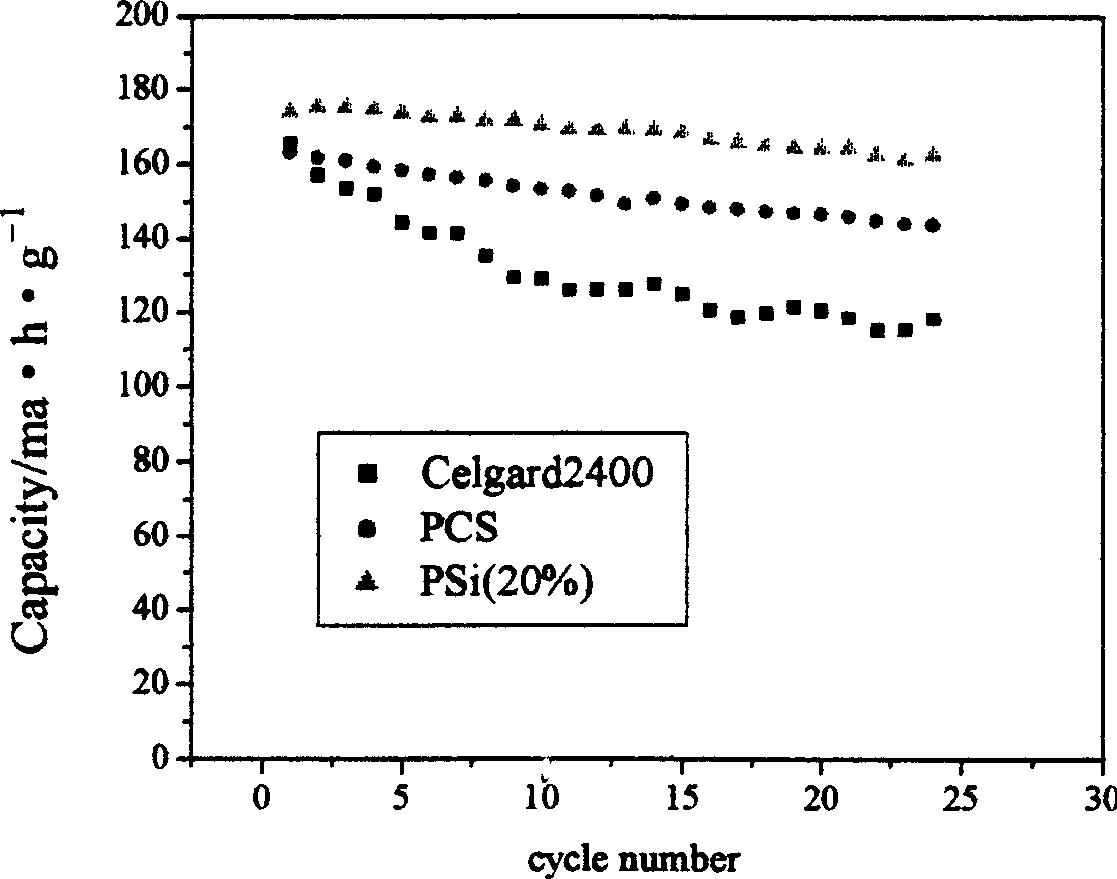

[0023] Embodiment 1. Get 0.7000g PEO (Mw~600,000), dry nano-SiO 2 (TS530) 0.0500g dissolved in 30ml CH 3 CN, stirred for 24 hours, the temperature was controlled at 80 °C, and the whole process was under N 2 under protection. After the mixture becomes a sol, transfer it to a petri dish, soak Celgard2400 in it for 1.2 hours, take it out and put it in a vacuum oven at 60°C for 48 hours, and wait for CH 3 After the CN was completely volatilized, a composite separator (PCS) with a thickness of about 25 μm was fabricated in this way.

Embodiment 2

[0024] Embodiment 2. Get 0.7000g PEO (Mw~600,000), dry nano-SiO 2 (TS530) 0.1400g dissolved in 40ml CH 3 In CN, the preparation process is the same as in Example 1, and a composite diaphragm PSi (TS530) (20%) with a thickness of about 25 μm is produced.

Embodiment 3

[0025] Embodiment 3. Get 0.7000g PEO (Mw~600,000), dry nano-SiO 2 (TS530) 0.0700g dissolved in 40ml CH 3 In CN, the preparation process is the same as in Example 1, and a composite diaphragm PSi (TS530) (10%) with a thickness of about 25 μm is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com