Preparation method for composite silver catalyst, and composite silver catalyst and application thereof

A silver catalyst and composite technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of reducing the selectivity decline rate of catalysts, and achieve high selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

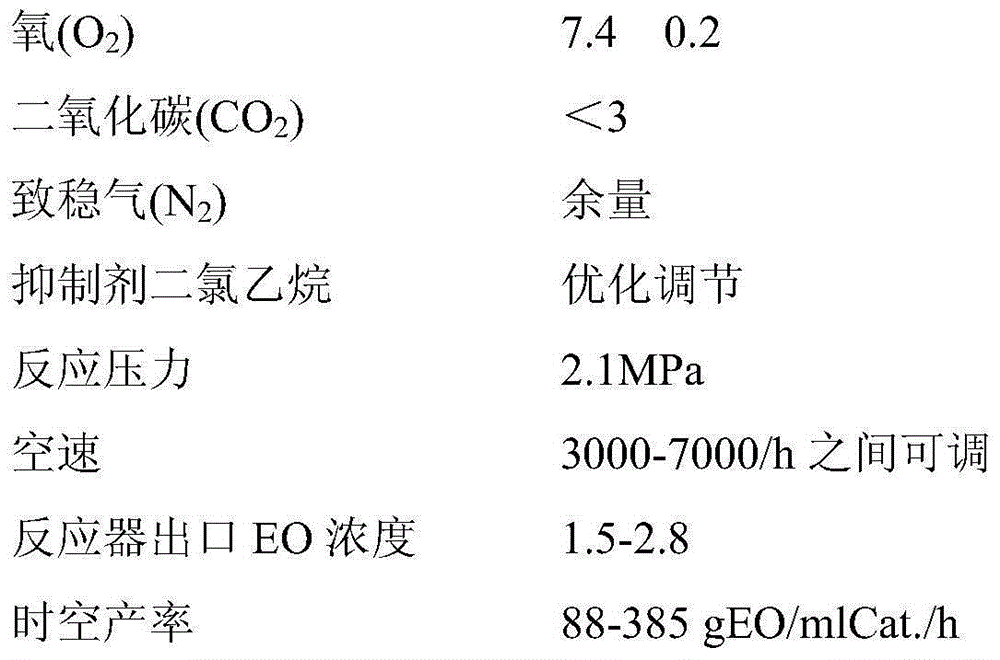

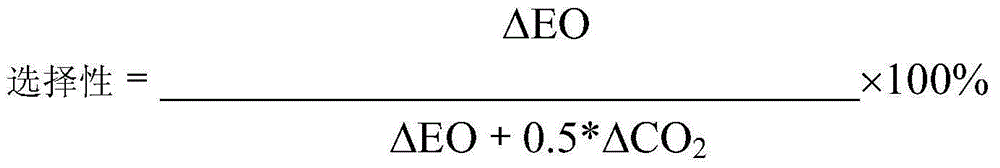

Examples

Embodiment 1

[0031] First Dip:

[0032] Add 2.68 g of ethylenediamine, 0.9 g of ethanolamine and 36.21 g of deionized water to a stirred container to obtain a mixed solution. Slowly add 6.21g of silver oxalate into the mixture under constant stirring, keeping the temperature below 30°C to dissolve all the silver oxalate. Then add 4.0ml of potassium dichromate aqueous solution (concentration is 0.0025g / ml, based on the atomic weight of chromium), mix well to make 50g of the first impregnating solution for use. Based on the total mass of the first impregnating solution, the concentration of silver was 8 wt % (by atomic weight of silver), and the concentration of chromium was 200 ppm by weight (by atomic weight of chromium).

[0033] Take 15g of α-Al 2 o 3 For the carrier, put it into a container that can be vacuumed, and add the above first impregnating solution, and then completely immerse the carrier. Vacuum to above 10mmHg for about 15 minutes, then filter to remove excess solution. ...

Embodiment 2

[0038] Composite silver catalyst is prepared in the same way as in Example 1, except that the amount of silver oxalate added in the first impregnation is adjusted to 3.11g, so that based on the total mass of the first impregnation solution, silver in the first impregnation solution The concentration of chromium is 4wt% (calculated by atomic weight of silver), and the concentration of chromium is 200 ppm by weight (calculated by atomic weight of chromium), that is, the silver catalyst 2 is made.

Embodiment 3

[0040] The method identical with embodiment 1 prepares composite silver catalyst, and difference only is that the volume of the potassium dichromate that adds in impregnating for the first time is adjusted to 6.0ml (concentration of potassium dichromate is constant), so that based on the first The total mass of the impregnating solution, the concentration of silver in the first impregnating solution is 8wt% (by silver atomic weight), and the concentration of chromium is 300 wtppm (by chromium atomic weight) to make the silver catalyst 3.

[0041] Analyzing the catalysts 1-3 of the present invention, it is found that the content of silver in the composite silver catalyst of the present invention is all in the range of 2-50wt% based on the total weight of the composite silver catalyst. And, in the composite silver catalyst of the present invention, all contain two kinds of silver grains that respectively contain different additives, the first silver grains include chromium based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com