Novel ceramic catalytic electrode and preparation method thereof

A catalytic electrode and ceramic technology, which is applied in the field of oxygen sensors, can solve the problems of three-phase interface loss, easy peeling, poor reliability of electrode materials and substrates, and achieve good low-temperature catalytic activity, reduce production costs, and excellent catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

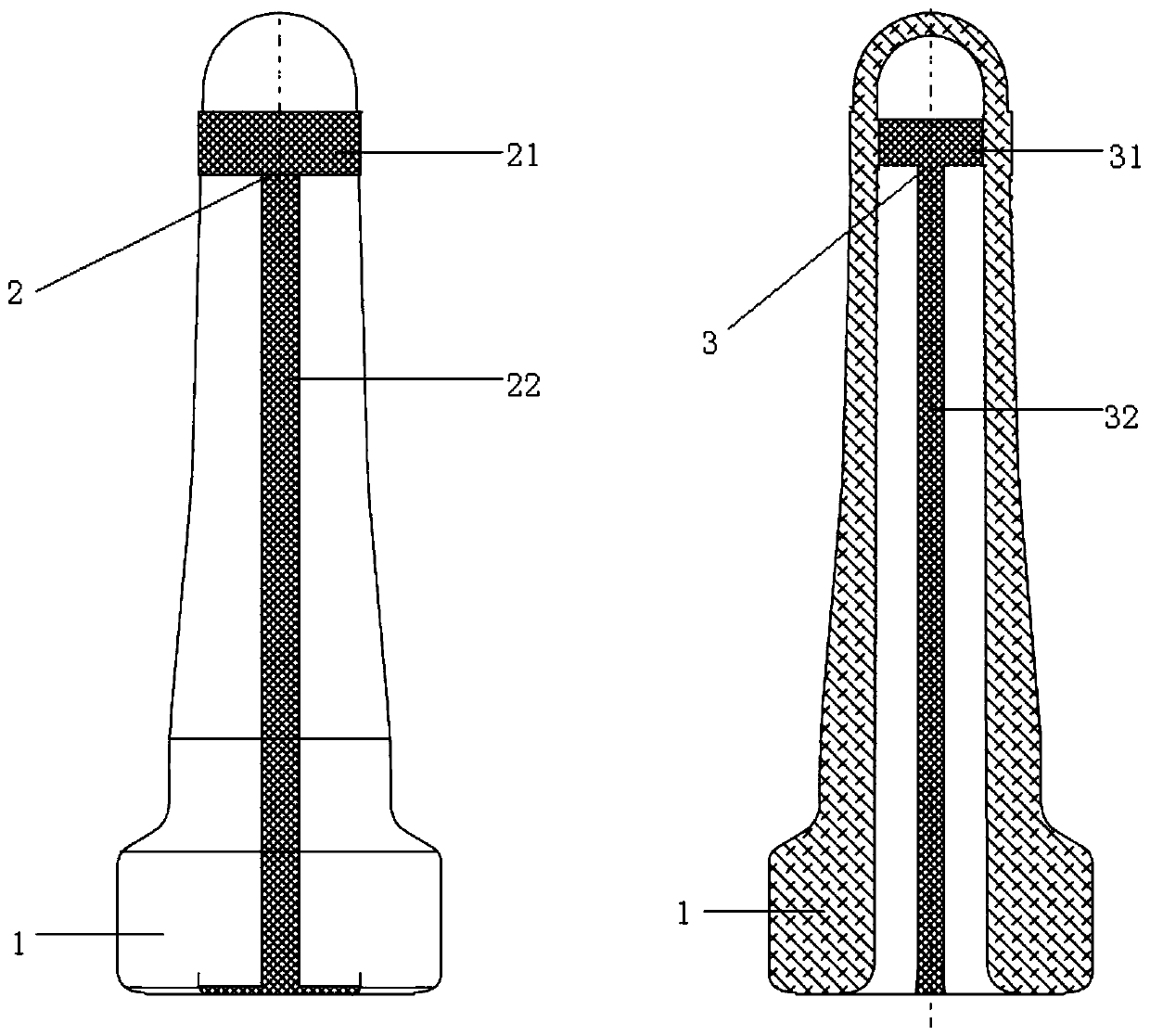

[0082] On the basis of the preparation method of the novel ceramic catalytic electrode provided in the first embodiment of the present invention, this embodiment also provides a preparation method of the above sensing element, the specific steps are as follows:

[0083] (1) Provide a solid electrolyte substrate green body; provide a slurry for forming a catalytic electrode ceramic matrix; provide a slurry for forming a co-fired electrode slurry (hereinafter referred to as co-fired electrode slurry).

[0084] When the solid electrolyte substrate green body is tubular, the preparation method of the solid electrolyte substrate green body can refer to the preparation method of the solid electrolyte substrate green body provided in the first embodiment. When the solid electrolyte substrate green body is in the form of a sheet, the solid electrolyte substrate green body can be prepared by a tape casting process, which is a molding method of ceramic products in the prior art, and is a...

Embodiment

[0124] The inner electrode of the sensing element is still prepared by the process of co-fired electrode, and the outer electrode is prepared by the preparation method of the new ceramic catalytic electrode provided in the first embodiment. Samples 1 to 6 are obtained according to the same packaging method as the comparative example. The amount of metal platinum on the inner catalytic electrode part of the 6 oxygen sensors is 0.01g, and the loading amount of metal platinum on the outer catalytic electrode part is 0.002g. The thickness of the outer catalytic electrode part is 0.3mm and the length is 5mm.

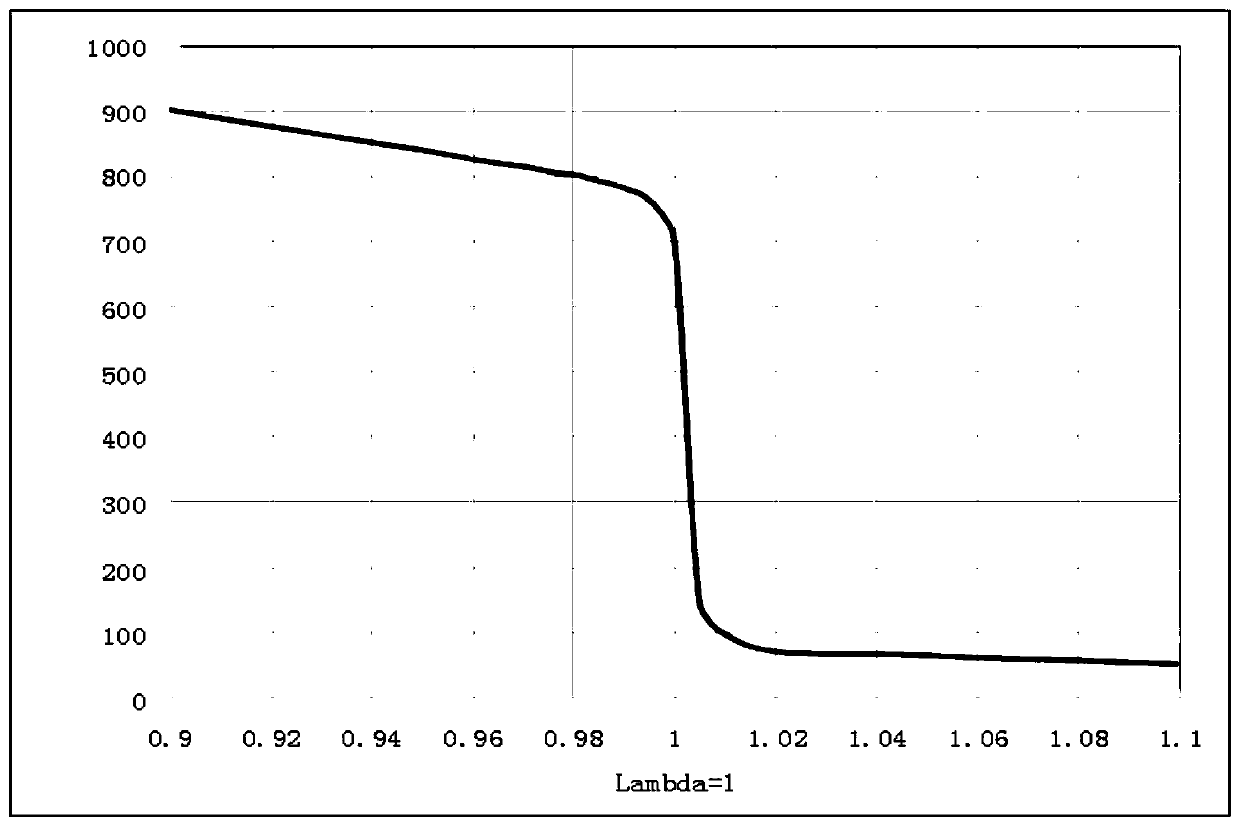

[0125] Test according to the same test conditions and test method as the comparative example, obtain the following data:

[0126] Example High voltage (mV) Low voltage (mV) T2(mS) T4(mS) sample 1 873.72 42.27 249.1 116.2 sample 2 866.32 51.61 258.2 108.1 sample 3 861.23 52.13 286.1 137.2 Sample 4 875.76 52.32 202.6 111.3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com