Preparation method for Au-Ce/AlTiOx applied to NO+CO reaction and application thereof

An au-ce, reaction technology, applied in the field of synthesis of Au-Ce/AlTiOx, can solve the problems of high reaction temperature, anti-poisoning ability, insufficient air-fuel ratio characteristics of ignition characteristics, etc., and achieve simple operation, good low-temperature catalytic activity, good The effect of the channel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

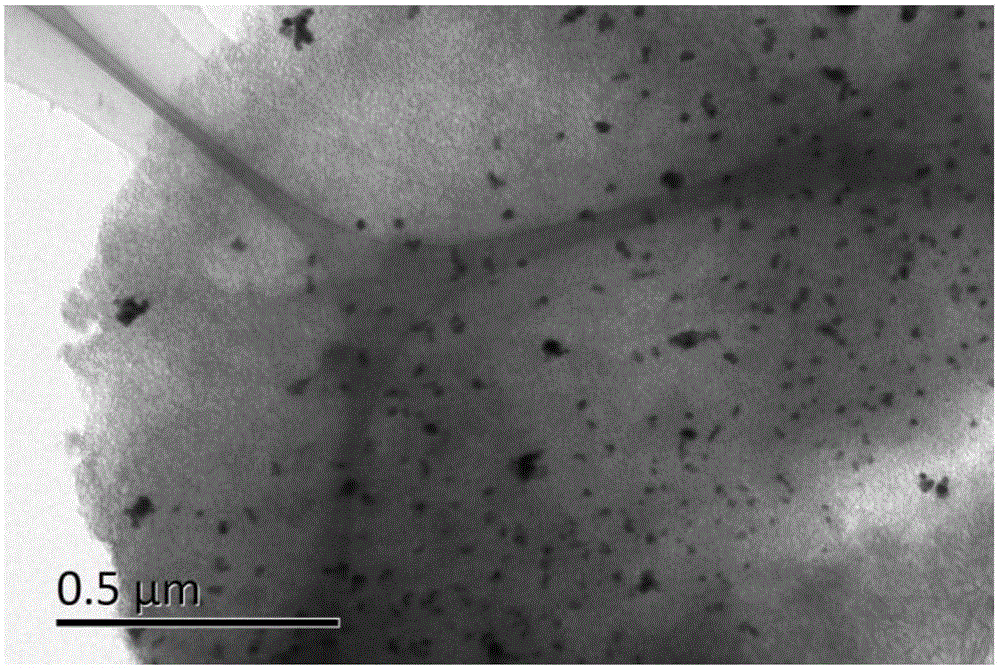

[0023] Solution A: Dissolve 5.0 g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer and 5.0 mmol of titanium isopropoxide in 50 mL of absolute ethanol, and stir for 4 h; solution B: Dissolve 45mmol of aluminum isopropoxide in a mixture of 8ml of nitric acid and 25mL of absolute ethanol; mix solutions A and B, and continue to stir for 5h; place the resulting solution in a blast drying oven at 50°C for 48h to dry, and then The solid was calcined in a muffle furnace at 400 °C for 4 h under air atmosphere. 0.6 μg / mL of HAuCl 4 ·3H 2 Under the condition of 70℃, slowly add 1mol / mL ammonia water to adjust the pH of the solution to 7.0, at this time, a yellow gold colloidal solution is formed; then add the catalyst carrier AlTiO x Make the mass fraction of gold element 3%, stir for 1 h to obtain a suspension; then vacuum filter the obtained suspension at room temperature, and the obtained Au / AlTiO x The solid was dried in a drying oven at 50 °C, and ca...

Embodiment 2

[0025] According to Example 1, in the present invention, 10.0 g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer and 10.0 mmol of titanium isopropoxide are dissolved in 100 mL of absolute ethanol, and stirred for 4 h ; Dissolve 90mmol of aluminum isopropoxide in the mixed solution of 16ml of nitric acid and 50mL of absolute ethanol, and keep other conditions unchanged to obtain Au-Ce / TiAlO x .

Embodiment 3

[0027] According to Example 1, in the present invention, 20.0 g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer and 20.0 mmol of titanium isopropoxide are dissolved in 200 mL of absolute ethanol, and stirred for 4 h ; 180mmol aluminum isopropoxide was dissolved in the mixed solution of 32ml nitric acid and 100mL absolute ethanol, and other conditions were constant, to obtain Au-Ce / TiAlO x .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com