SCR (Selective Catalytic Reduction) catalyst and preparation method thereof

A SCR catalyst, RP-CHOP technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as low compressive strength, poor mechanical properties of catalysts, energy waste, etc., and achieve excellent low-temperature catalysis active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

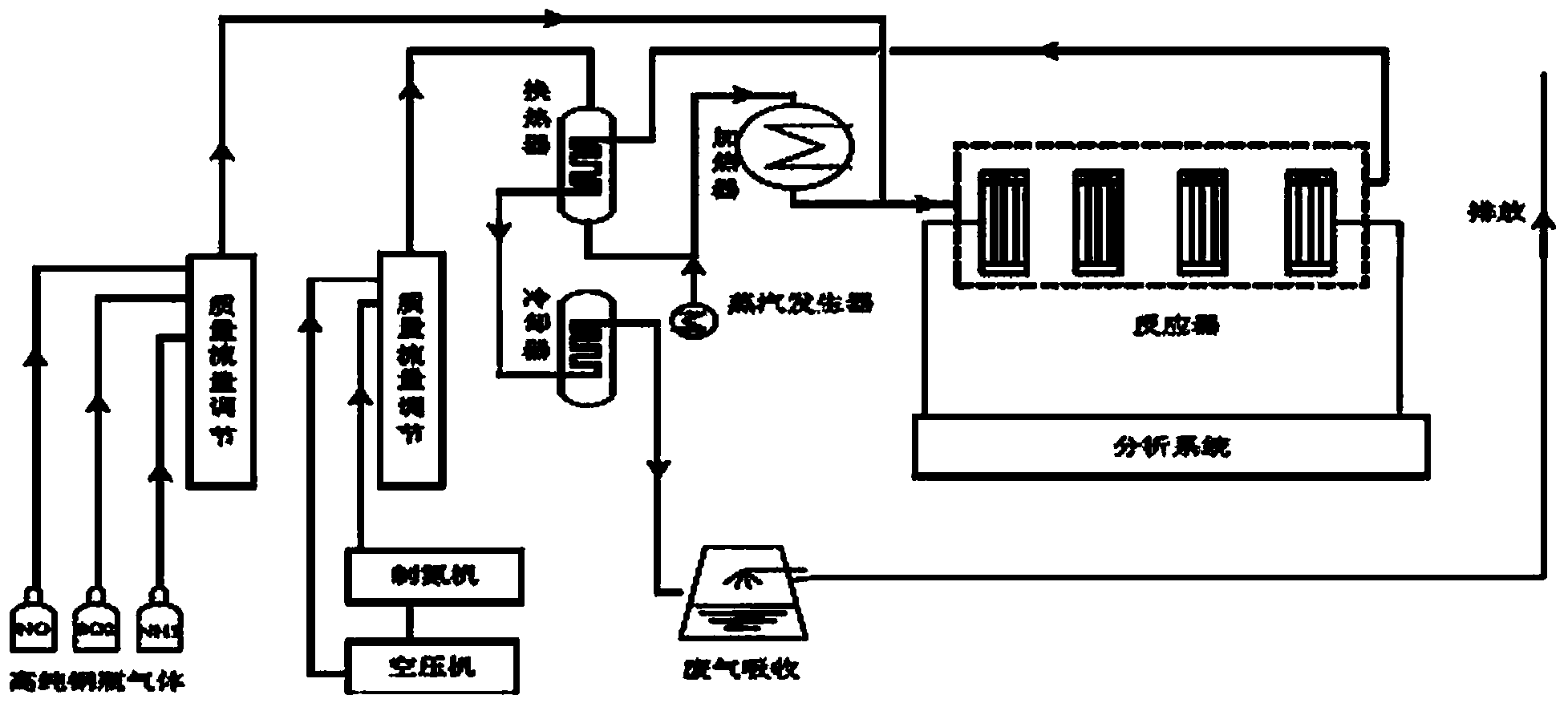

Method used

Image

Examples

Embodiment 1

[0020] A kind of SCR catalyst, by weight, it is prepared from following raw material: 90 parts of TiO 2 , 4 copies of WO 3 , 2 copies of V 2 o 5 , 6 parts of glass fiber, 8 parts of ammonia water, 8 parts of CMC, 50 parts of ionized water and 6 parts of RP-CHOP functional fiber.

[0021] The specific preparation method is as follows:

[0022] 1) The raw materials are mixed according to the stated ratio, and then stored for 40 hours;

[0023] 2) Pre-extrude the rotted material in step 1), and then enter the molding machine for molding;

[0024] 3) The formed product is dried once and twice until the moisture content reaches 5%, and then enters the kiln and is calcined at 620°C for 12 hours;

[0025] 4) Cutting, grading and packing the products burnt in step 3) and putting them into storage.

[0026] The honeycomb-type catalyst unit body prepared in this embodiment is measured and calculated: length 801mm, inner wall thickness 1.05mm, outer wall thickness 2.24mm, pore diam...

Embodiment 2

[0028] A kind of SCR catalyst, by weight, it is prepared from following raw material: 85 parts of TiO 2 , 5 copies of WO 3 , 1 copy of V 2 o 5 , 8 parts of glass fiber, 5 parts of ammonia water, 8 parts of CMC, 50 parts of ionized water and 6 parts of RP-CHOP functional fiber.

[0029] The specific preparation method is as follows:

[0030] 1) The raw materials are mixed according to the stated ratio, and then stored for 50 hours;

[0031] 2) Pre-extrude the rotted material in step 1), and then enter the molding machine for molding;

[0032] 3) The formed product is dried once and twice until the moisture content reaches 5%, and then enters the kiln and is calcined at 620°C for 12 hours;

[0033] 4) Cutting, grading and packing the products burnt in step 3) and putting them into storage.

Embodiment 3

[0035] A kind of SCR catalyst, by weight, it is prepared from following raw material: 95 parts of TiO 2 , 3 copies of WO 3 , 3 copies of V 2 o 5 , 5 parts of glass fiber, 10 parts of ammonia water, 8 parts of CMC, 50 parts of ionized water and 6 parts of RP-CHOP functional fiber.

[0036] The specific preparation method is as follows:

[0037] 1) The raw materials are mixed according to the stated ratio, and then stored for 50 hours;

[0038] 2) Pre-extrude the rotted material in step 1), and then enter the molding machine for molding;

[0039] 3) The formed product is dried once and twice until the moisture content reaches 5%, and then enters the kiln and is calcined at 620°C for 12 hours;

[0040] 4) Cutting, grading and packing the products burnt in step 3) and putting them into storage.

[0041] Effect experiment example

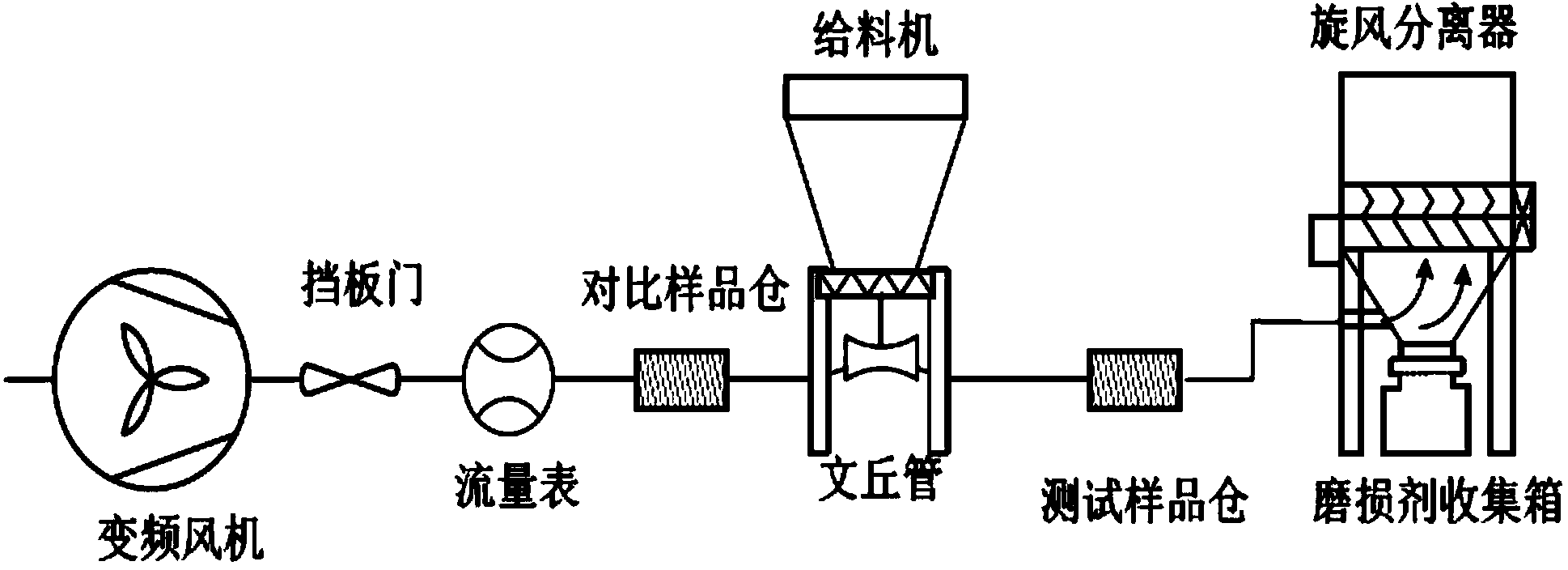

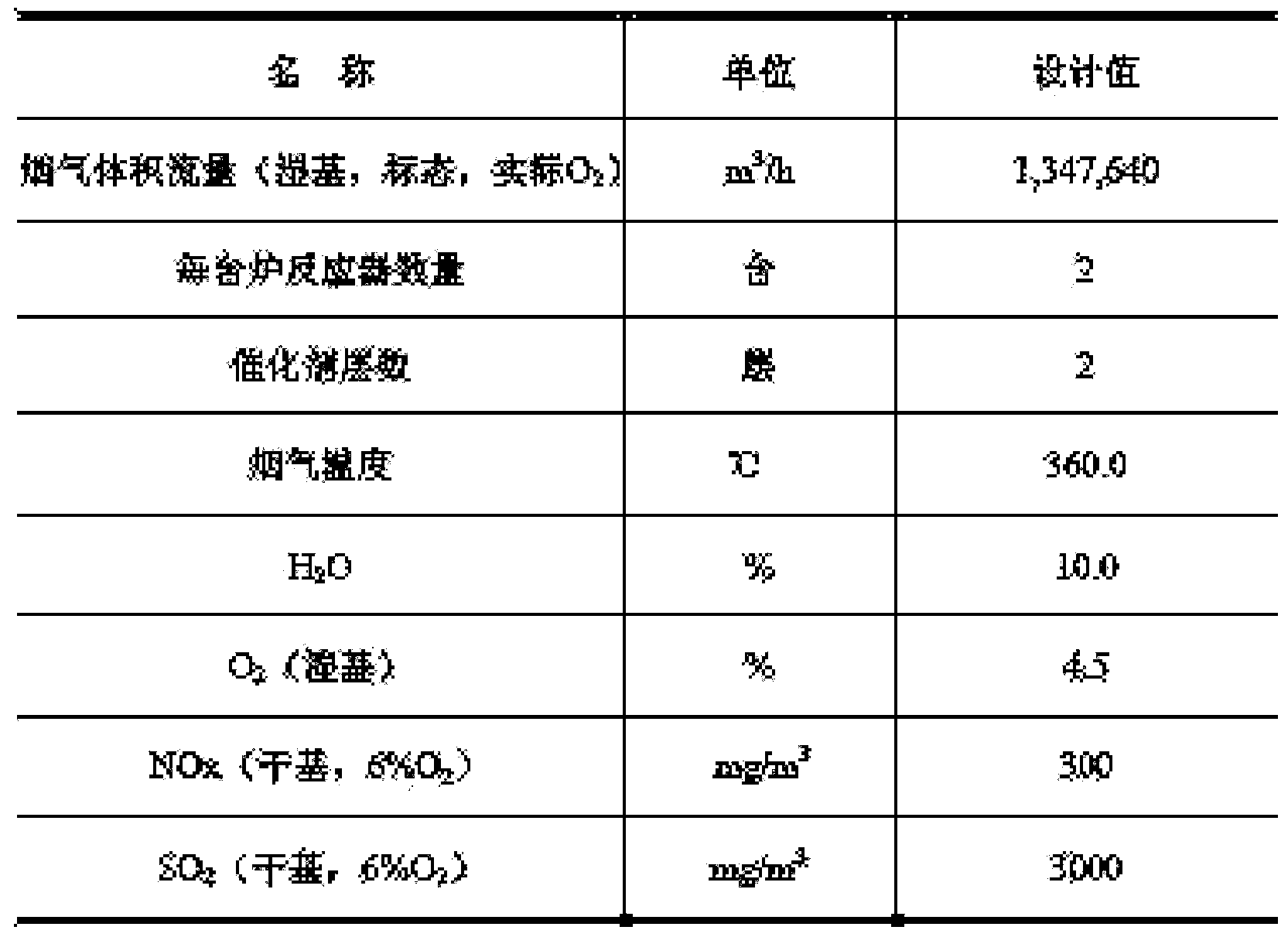

[0042] Carry out activity, SO with the catalyst prepared by the embodiment of the present invention as test sample 2 / SO 3 The detection of con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com