Regenerable heterogeneous Fenton catalyst, and preparation method and application thereof

A catalyst and Fenton-type technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of affecting the chromaticity of the effluent, low pH required for the reaction, difficult to handle, etc., to achieve stability and Good regeneration performance, improved catalytic efficiency, and enhanced dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment.

[0034] Catalyst preparation:

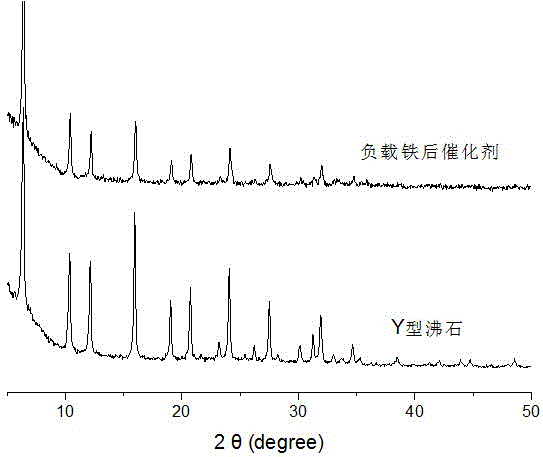

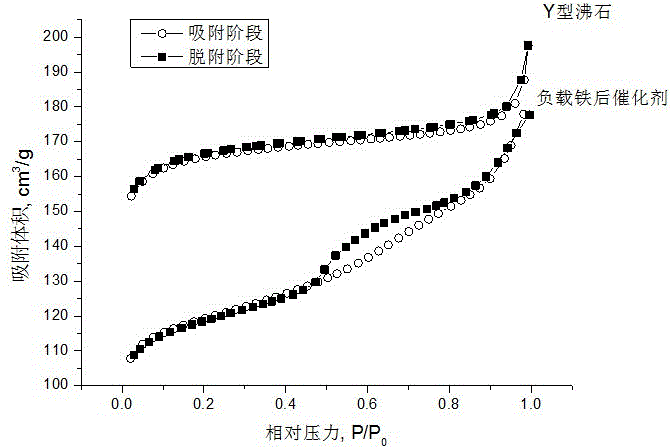

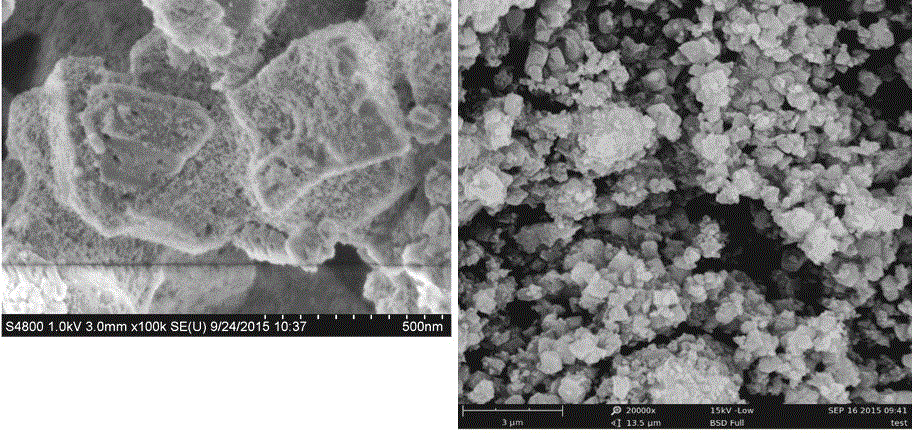

[0035] (1) Weigh 0.1g of polyethyleneimine, dissolve it in 10g of methanol, add 1g of Y-type zeolite to the above solution, stir at room temperature for 12h, remove methanol with a rotary evaporator, and dry the solid powder at 100°C overnight; High temperature activation;

[0036] (II) Weigh a certain amount of ferric nitrate, dissolve it in 10g of deionized water, put the powder obtained in I into the ferric nitrate solution, stir at room temperature for 12h, and dry the resulting mixture at 70°C for 5h to obtain a block solid; adjust Fe 3+ The concentration ranges are 0.18mol / L, 0.36mol / L, 0.54mol / L, 0.72mol / L and 0.90mol / L respectively, and catalysts A, B, C, D, and E are prepared respectively;

[0037] (Ⅲ) Calcined at 600°C for 5h to obtain a specific surface area of 367.6m 2 / g of Fenton solid catalyst.

[0038] Referring to the above cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com