Catalyst used for preparing glycol from hydrogenation of oxalates and preparation method thereof

A catalyst, ethylene glycol technology, applied in chemical instruments and methods, hydroxyl compound preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of unmentioned catalyst stability, decrease in copper active surface area, The problem of catalyst activity decline, etc., to achieve excellent low-temperature catalytic activity, easy industrial scale production, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Weighing pipe diameter is 20~40nm, purity 98%, length 1~2μm, specific surface area 180m 2 8.0 g of multi-walled carbon nanotubes / g was put into a round-bottomed flask, and 250 mL of concentrated nitric acid was added, stirred at 90°C for 12 hours, cooled to room temperature, washed with deionized water until neutral, and dried at 120°C Backup.

[0027] Weigh 4.57g of copper nitrate trihydrate, dissolve it in 50mL of deionized water, add 28wt% ammonia solution dropwise under stirring until the precipitate disappears, and obtain a transparent dark blue copper ammonia complex solution, which is transferred into a prepacked 0.30g 11.25g of 40wt% silica sol and 10mL of 20wt% urea aqueous solution were slowly dropped into the glass container of the treated multi-walled carbon nanotubes under strong mechanical stirring at a rate of about 1mL / min, and the temperature was raised to above 60°C. Stir at a speed of 500r / min for 8h, after cooling, wash the precipitate...

Embodiment 2

[0029] Embodiment 2: The specification and pretreatment method of carbon nanotubes are the same as in Embodiment 1.

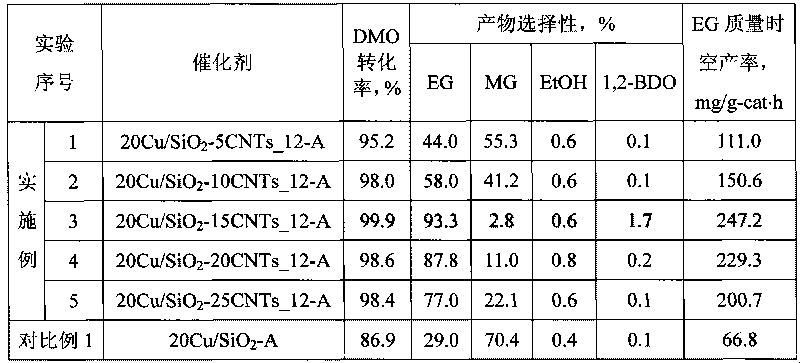

[0030] The preparation method of the carbon nanotube-promoted copper-silicon-based catalyst is the same as in Example 1, but the addition of multi-walled carbon nanotubes and 40wt% silica sol is changed to 0.6g and 10.5g, and the other compositions are unchanged, and a carbon nanotube-promoted type is obtained. Copper-silicon-based catalyst 20Cu / SiO 2 -10CNTs_12-A, ICP-MS analysis results show that the copper content is 17.7wt%. The activity evaluation and product analysis conditions of the catalyst for the hydrogenation of dimethyl oxalate to ethylene glycol are the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0031] Embodiment 3: The specification and pretreatment method of carbon nanotubes are the same as in Embodiment 1.

[0032] The preparation method of the carbon nanotube-promoted copper-silicon-based catalyst is the same as in Example 1, but the addition of multi-walled carbon nanotubes and 40wt% silica sol is changed to 0.9g and 9.8g, and the other compositions are unchanged, so that the carbon nanotube-promoted Copper-silicon-based catalyst, denoted as 20Cu / SiO 2 -15CNTs_12-A, ICP-MS analysis results show that the copper content is 19.1wt%; after nitrogen static adsorption test, the specific surface area is 323.0m 2 / g, the pore volume (the range of pore diameter is 1.7~300nm) is 0.95ml / g, and the average pore diameter is 11.1nm; figure 1 . The activity evaluation and product analysis conditions of the catalyst for the hydrogenation of dimethyl oxalate to ethylene glycol are the same as in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com