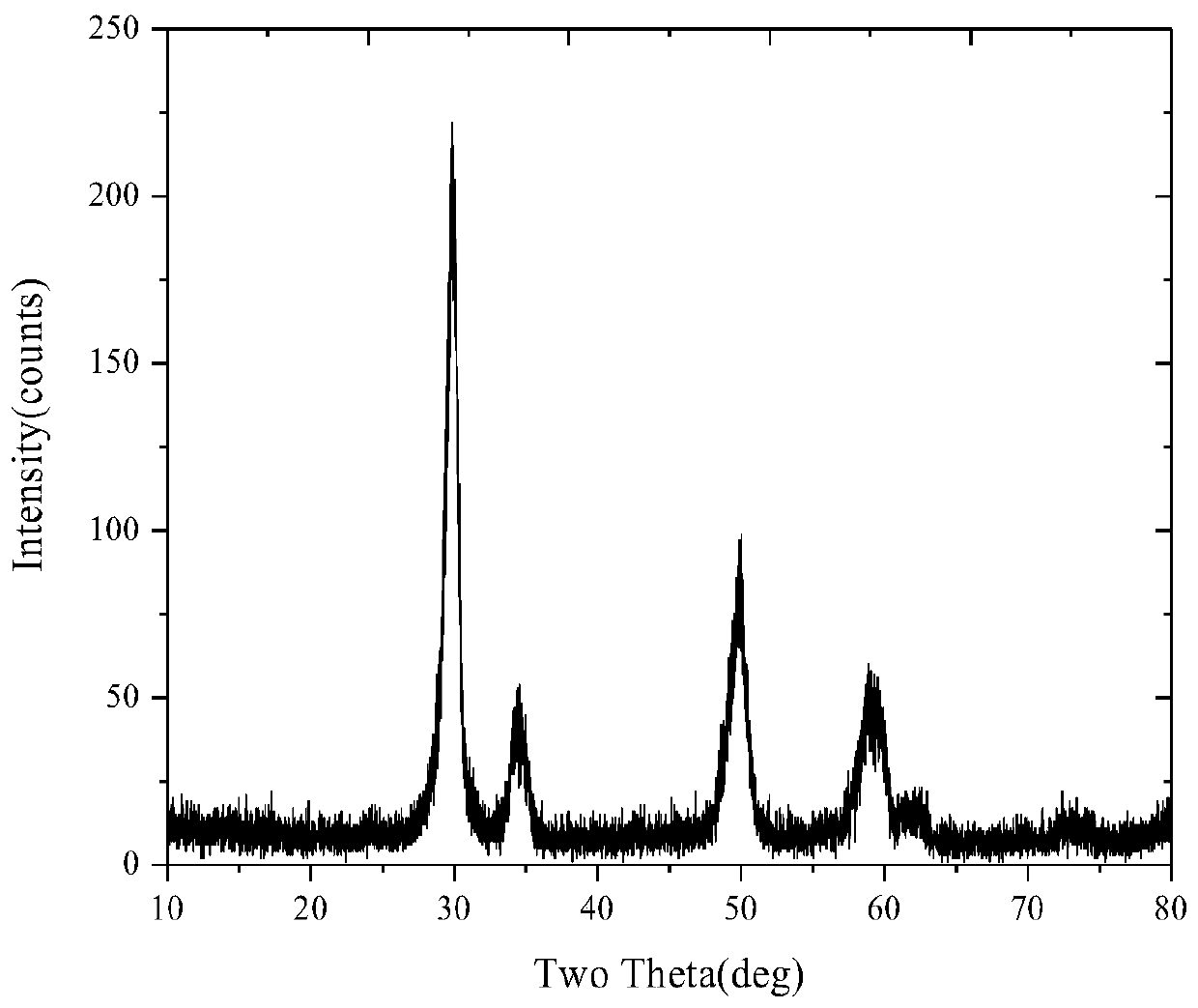

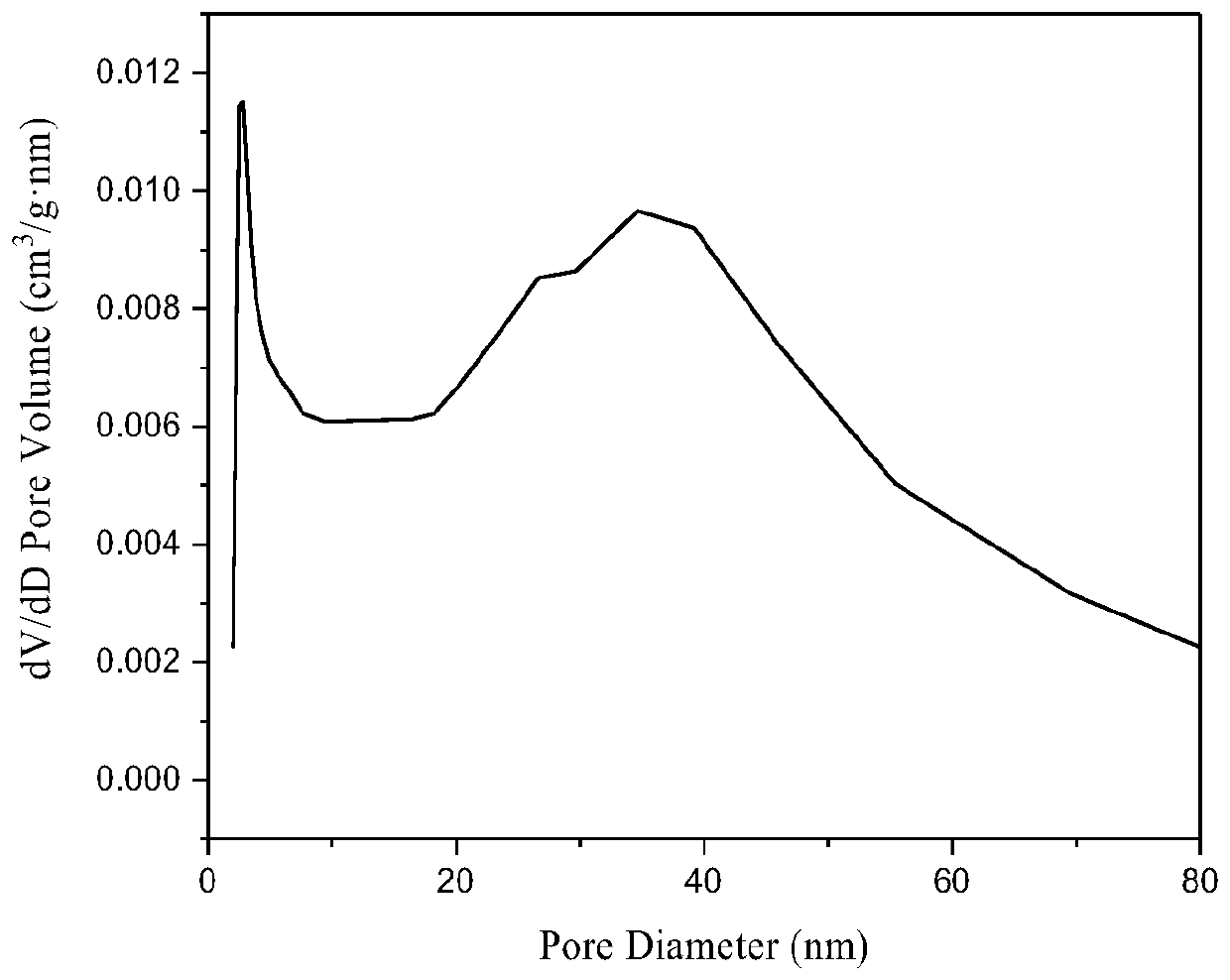

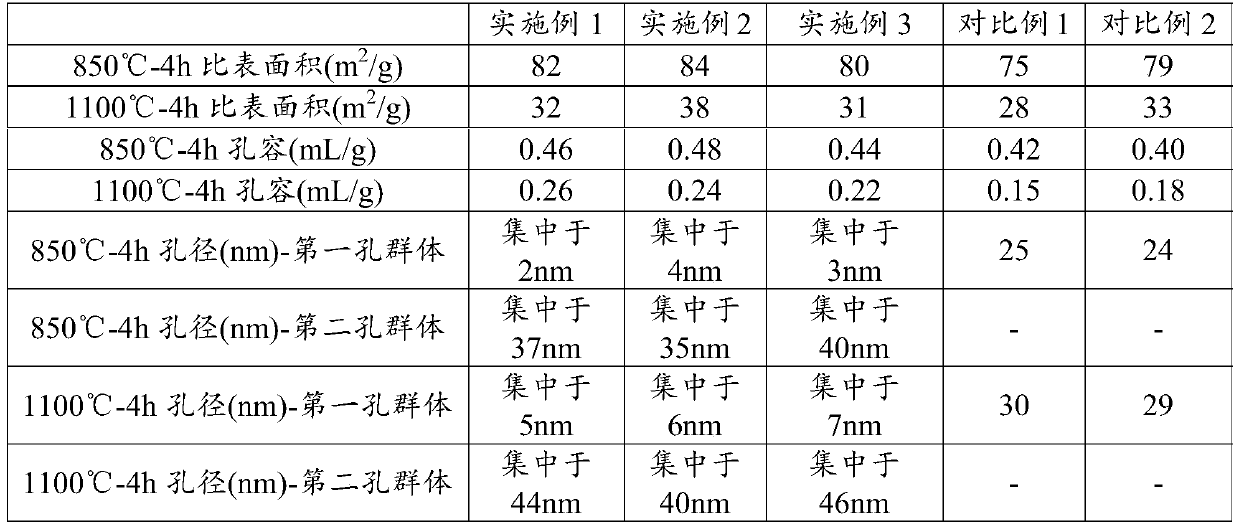

Cerium-zirconium composite oxide and preparation method thereof

A composite oxide, cerium zirconium technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problems of high cost, unsuitable for industrial production, etc. The effect of large pore volume, good low-temperature catalytic activity, and high oxygen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention provides a method for preparing a cerium-zirconium composite oxide, comprising the following steps:

[0047] S1, preparation of seed crystals: dissolving zirconium oxychloride in pure water to prepare a solution, and adjusting the pH value to 1.2-2.0. Add the zirconium oxychloride solution into the autoclave, heat and react at 150°C to 180°C for 24 hours, and obtain a white precipitate, which is filtered and washed for later use;

[0048] S2, liquid preparation: dissolving cerium source, zirconium source and other rare earth elements except cerium in pure water to obtain a mixed solution;

[0049] S3, Precipitation: adding the seed crystal obtained in step S1 into the ammonia solution, introducing the mixed solution obtained in step S2 into it, adjusting the pH to 10-11 to obtain a mixed precipitate, and washing until there is no chloride ion;

[0050] S4, hydrothermal: introduce the mixed precipitate obtained in step S3 into an autoclave and heat at 210°...

Embodiment 1

[0053] Example 1 provides a composition comprising CeO 2 40%, ZrO 2 50%, La 2 o 3 5%, Pr 6 o 11 5% cerium-zirconium composite oxide, prepared by the following method:

[0054] Dissolve 139g of zirconium oxychloride in pure water to make a solution, adjust the pH to 2, place it in a high-pressure reactor, and heat it at 180°C for 24 hours to obtain a zirconium seed crystal precipitate, which is filtered and washed and then added to the ammonia solution;

[0055] Take 559g of zirconyl chloride, 622g of cerium ammonium nitrate, 65g of lanthanum nitrate and 58g of praseodymium nitrate into 1500mL of ultrapure water, and stir for 0.5h to obtain a clear solution, which is introduced into the above-mentioned ammonia solution containing zirconium seed crystal precipitate , adjust the pH to 10 to obtain a mixed precipitate of cerium hydroxide-zirconium hydroxide-lanthanum hydroxide-praseodymium hydroxide;

[0056] Filter and wash the above mixed precipitate for at least 3 tim...

Embodiment 2

[0062] Example 2 provides a composition comprising CeO 2 20%, ZrO 2 73%, La 2 o 3 2%, Nd 2 o 3 5% cerium-zirconium composite oxide, prepared by the following method:

[0063] Dissolve 182g of zirconium oxychloride in pure water to make a solution, adjust the pH to 2, place it in a high-pressure reactor, and heat it at 170°C for 24 hours to obtain a zirconium seed crystal precipitate, which is filtered and washed and added to the ammonia solution;

[0064] Take 838g of zirconyl chloride, 311g of cerium ammonium nitrate, 26g of lanthanum nitrate and 65g of neodymium nitrate into 1500mL of ultrapure water, and stir for 0.5h to obtain a clear solution, which is introduced into the above-mentioned ammonia solution containing zirconium seed crystal precipitate , adjust the pH to 10 to obtain a mixed precipitate of cerium hydroxide-zirconium hydroxide-lanthanum hydroxide-neodymium hydroxide;

[0065] Filter and wash the above precipitate for at least 3 times, then add it to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com