Patents

Literature

32results about How to "High oxygen storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cubic phase cerium and zirconium based composite oxide with high specific surface area and preparation method thereof

ActiveCN102247826AThe reaction process is easy to controlSave raw materialsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementPhysical chemistry

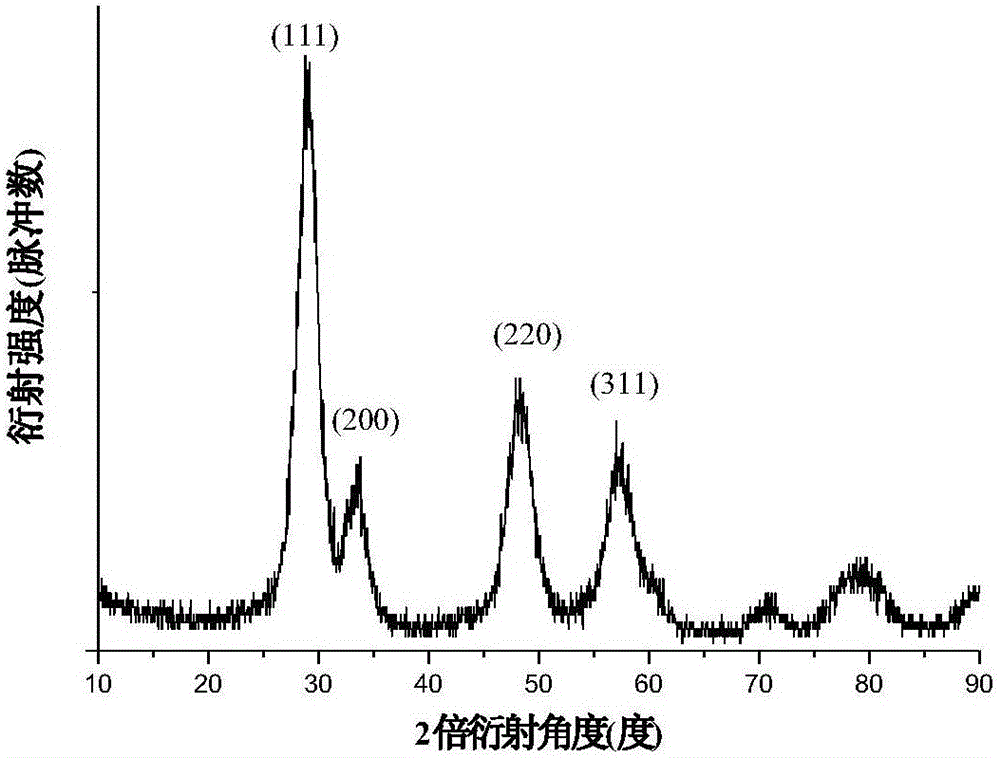

The invention discloses a cubic phase cerium and zirconium based composite oxide with high specific surface area. Rare earth elements are doped in the cerium-zirconium composite oxide and are selected from two or three of Pr, Nd and La, wherein the molar ratio of Zr to Ce is (1.8-2.5):1; the molar ratio of Pr to Ce is (0-0.32):1; the molar ratio of Nd to Ce is (0-0.32):1; the molar ratio of La toCe is (0-0.16):1; and the cerium and zirconium based composite oxide exists in a form of cerium-zirconium solid solution. The invention also discloses a preparation method of the cerium and zirconiumbased composite oxide. The composite oxide is prepared through different precursor precipitating and drying methods; the method has the advantages of simple reaction process and low requirements on drying equipment; the obtained cerium and zirconium based composite oxide has high specific surface area, high thermal stability and high oxygen storage and discharge capacity; and after sintering is performed at the temperature of 1,000 DEG C for 12 hours, the specific surface area is more than 35m<2> / g, particularly more than 60m<2> / g.

Owner:UNIV OF JINAN

Multi-doped cerium-zirconium carrier catalyst and preparation method thereof

ActiveCN104117363AHigh catalytic activityImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsYttriumCopper oxide

The invention relates to a solid solution carrier catalyst and particularly relates to a multi-doped cerium-zirconium carrier catalyst. The chemical components of the catalyst in parts by weight are as follows: 30-40 parts of cerium oxide, 30-40 part of zirconia, 1-20 parts of other rare earth oxides and 1-5 parts of transition metal oxides, wherein the other rare earth oxides are lanthanum oxide, praseodymium oxide, neodymium oxide, yttrium oxide and samarium oxide and the transition metal oxides are vanadium oxide, chromium oxide, manganese oxide, ferric oxide, cobaltosic oxide and copper oxide. The invention further provides a preparation method of the catalyst. The preparation method comprises the following steps: mixing all the raw materials with a surfactant, adjusting the pH to 8-10 to obtain a gel-like deposition and calcining to obtain the product. According to the method, the doping defect caused during cerium-zirconium carrier doping is overcome; meanwhile, the thermal stability, aging specific area and oxygen storage amount of the carrier catalyst are improved; the invention also provides the preparation method which is simple in technique process and is favorable for large-scale industrial production.

Owner:淄博加华新材料有限公司

Preparation method of low-cost large-specific-surface-area cerium oxide

ActiveCN104148116ALow priceSimple processOrganic-compounds/hydrides/coordination-complexes catalystsTriflic acidPerformance index

The invention relates to a solid solution carrier catalysis, and specifically relates to a preparation method of low-cost large-specific-surface-area cerium oxide. According to the invention, water solutions corresponding to all raw materials are mixed; a surfactant is added; the pH value is regulated to 8-10, such that a gel precipitate is obtained; washing and roasting are carried out; drying and grinding are carried out; trifluoromethanesulfonic acid is added to the product, and the mixture is well mixed; and drying is carried out, such that the cerium oxide is obtained. The raw materials are cheap, and the process procedure of the method is simple. With the method, a doping defect caused by doping in a cerium oxide carrier is overcome. Also, performance indexes such as thermal stability, aging specific surface area, oxygen storage capacity, and the like of the carrier catalyst are greatly improved.

Owner:淄博加华新材料有限公司

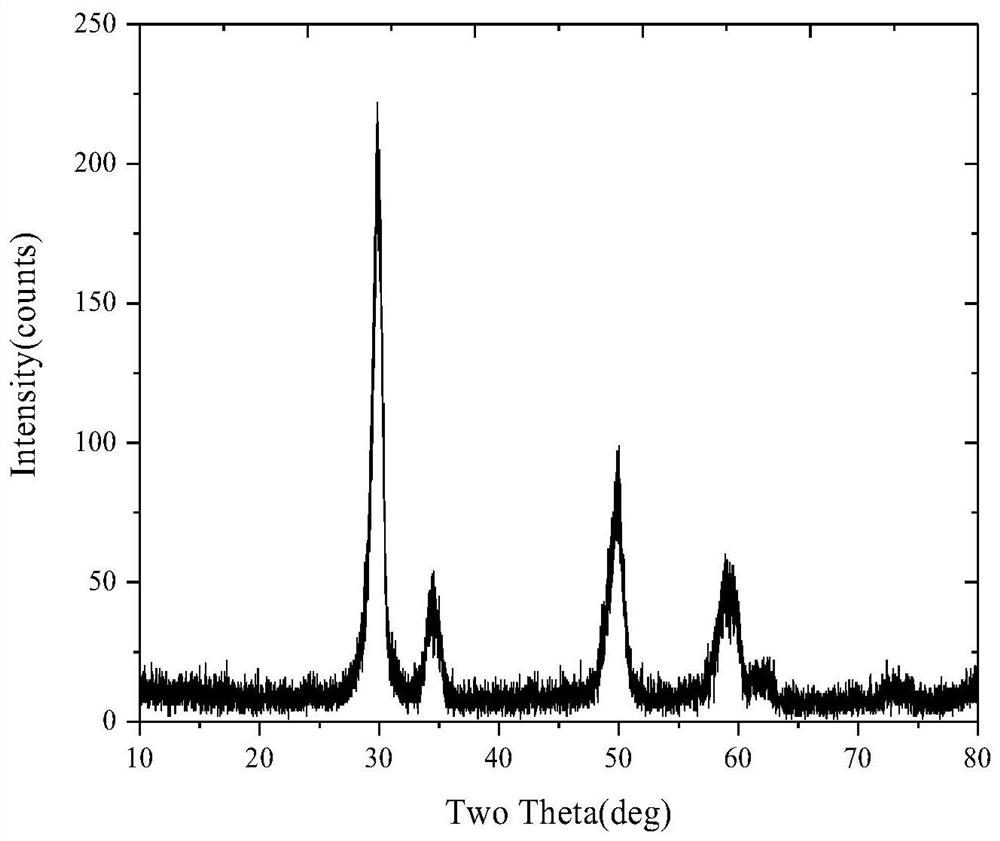

Nano cerium zirconium sosoloid and preparation thereof

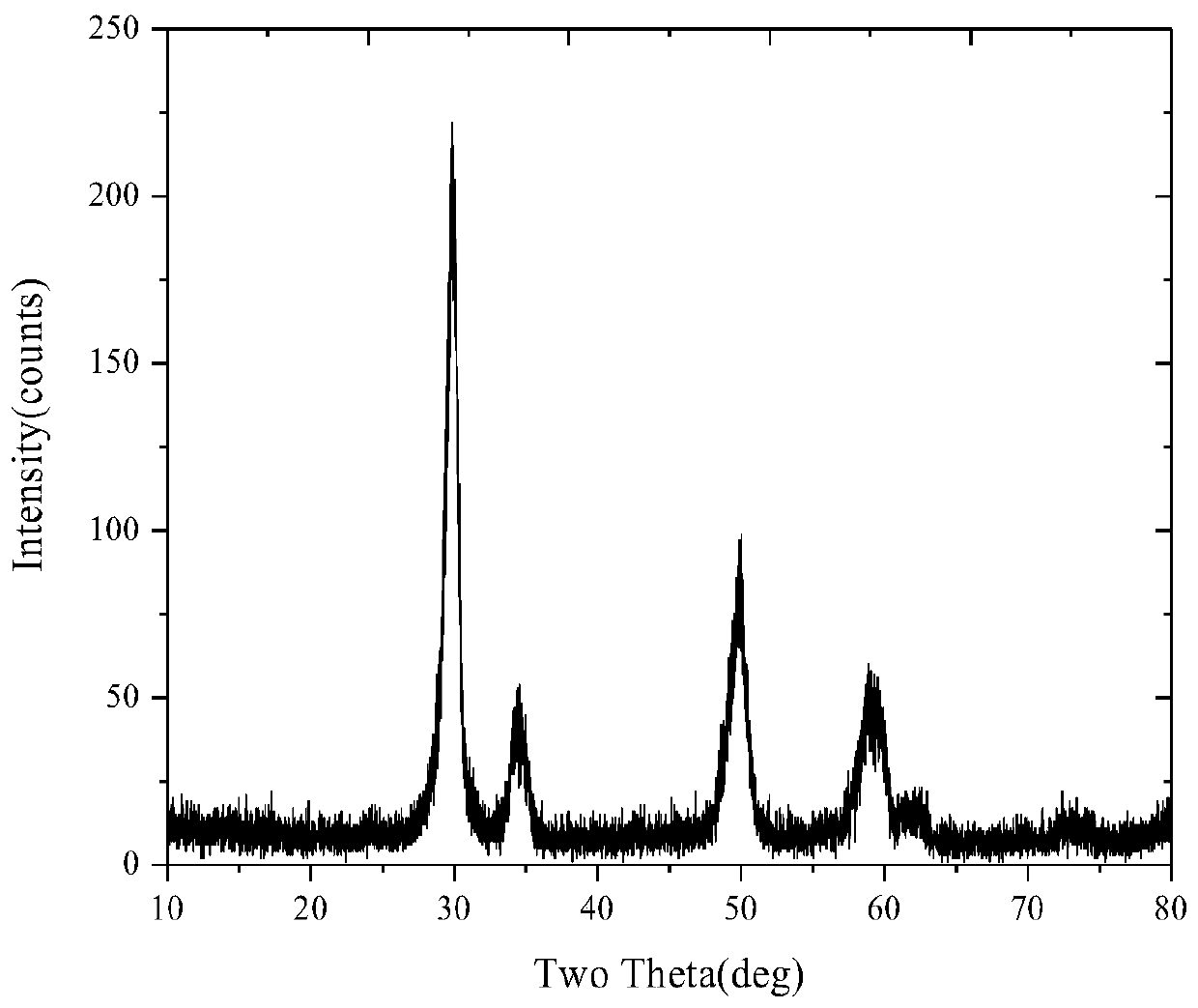

InactiveCN101214434ASmall particle sizeLarge specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumSolid solution

The invention provides a nano ceria-zirconia solid solution and a method of preparing the solution. The chemical general formula of the nano ceria-zirconia solid solution is Ce1-XZrO2, wherein, X is 0.05 to 0.95. Compared with the prior art, the nano ceria-zirconia solid solution of the invention is characterized by small grain size, large specific surface area, high oxygen storage, high oxygen storage and release speed, and strong sintering resistant capability.

Owner:北京英泰世纪环境科技有限公司

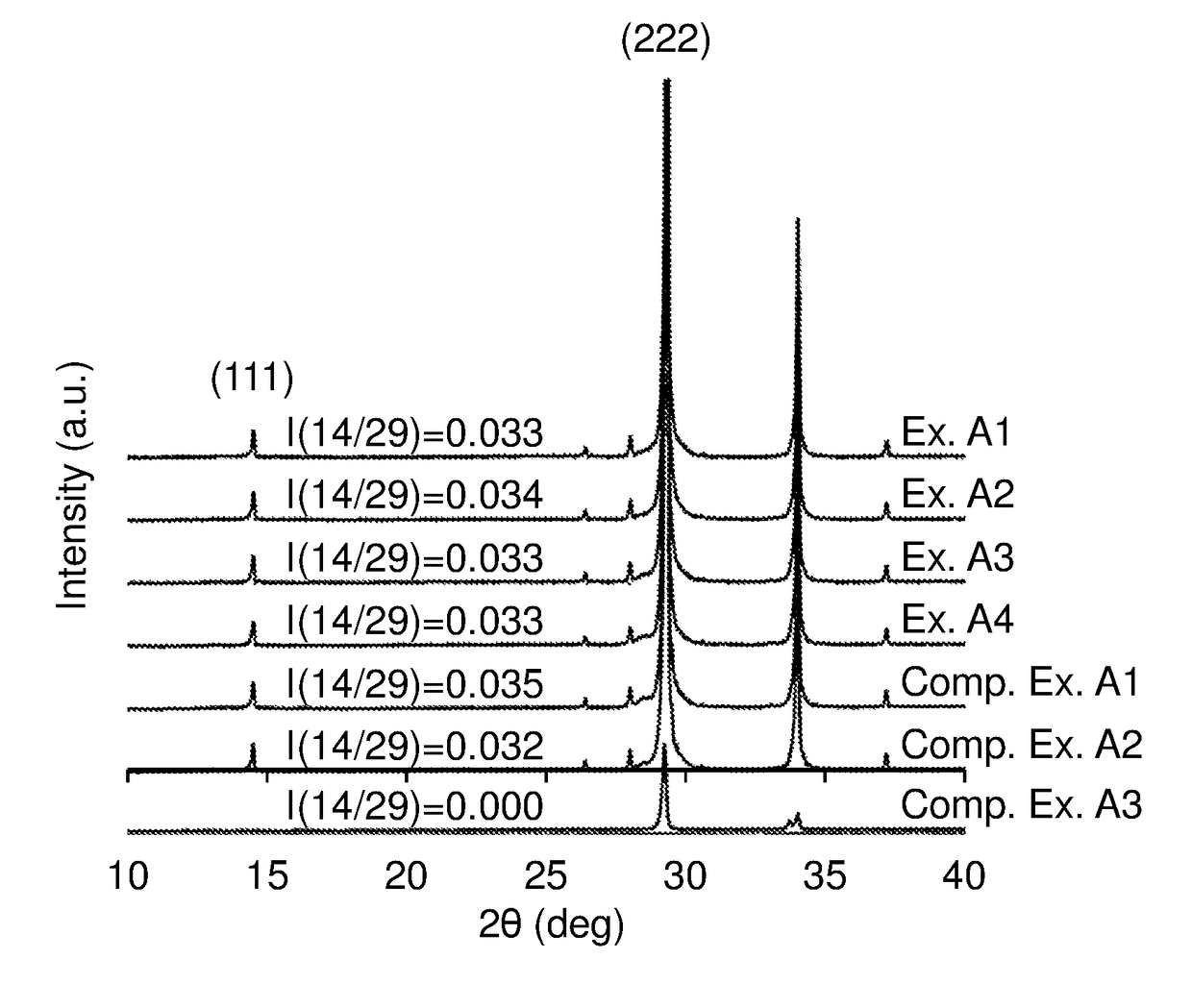

Core-shell oxide material, method for producing the same, and catalyst and method for purification of exhaust gas using the core-shell oxide material

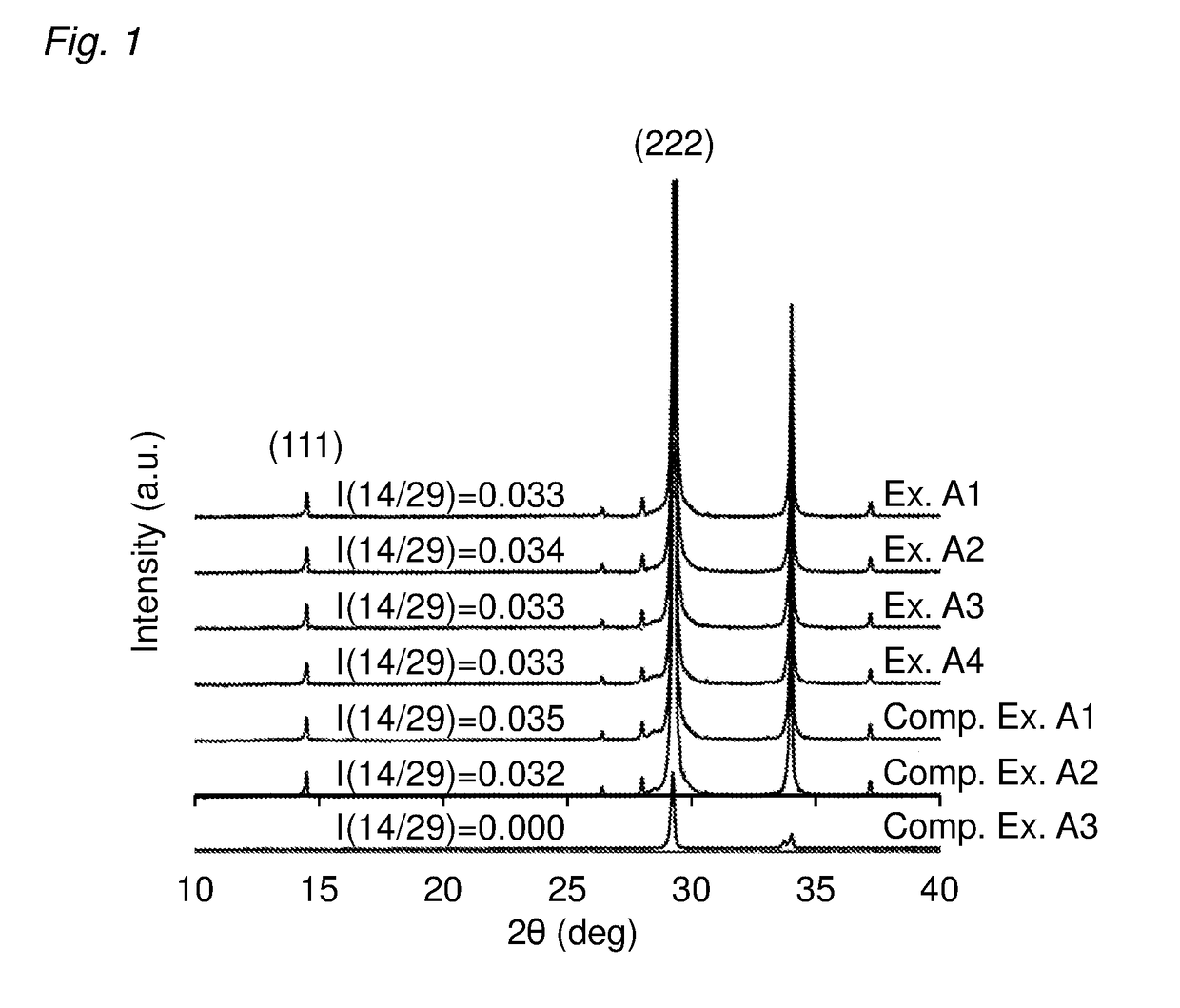

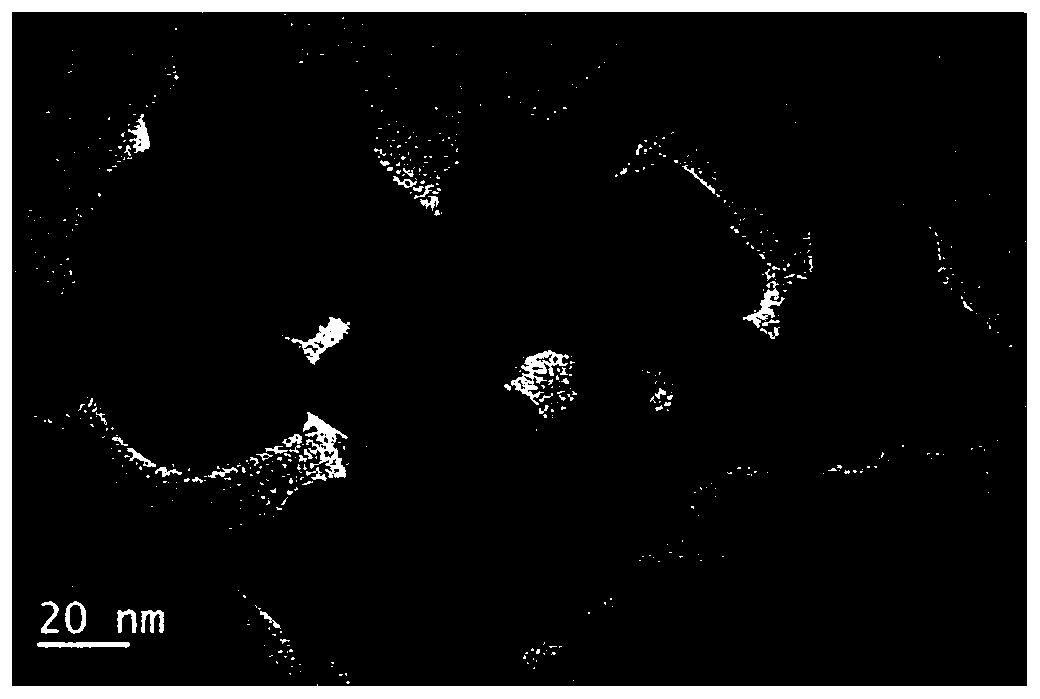

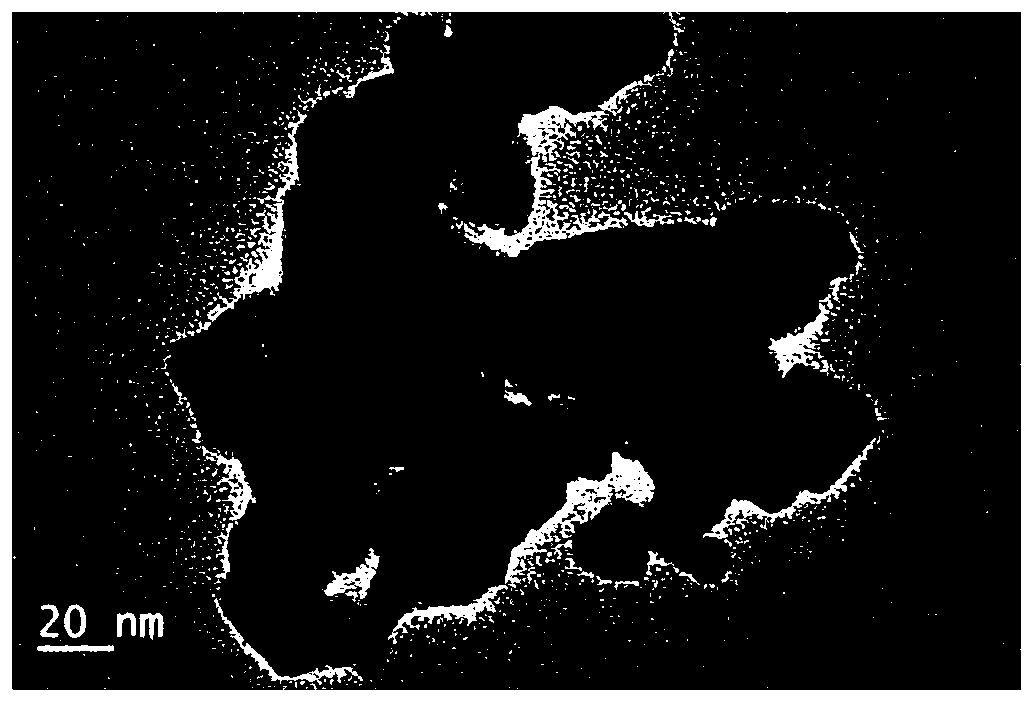

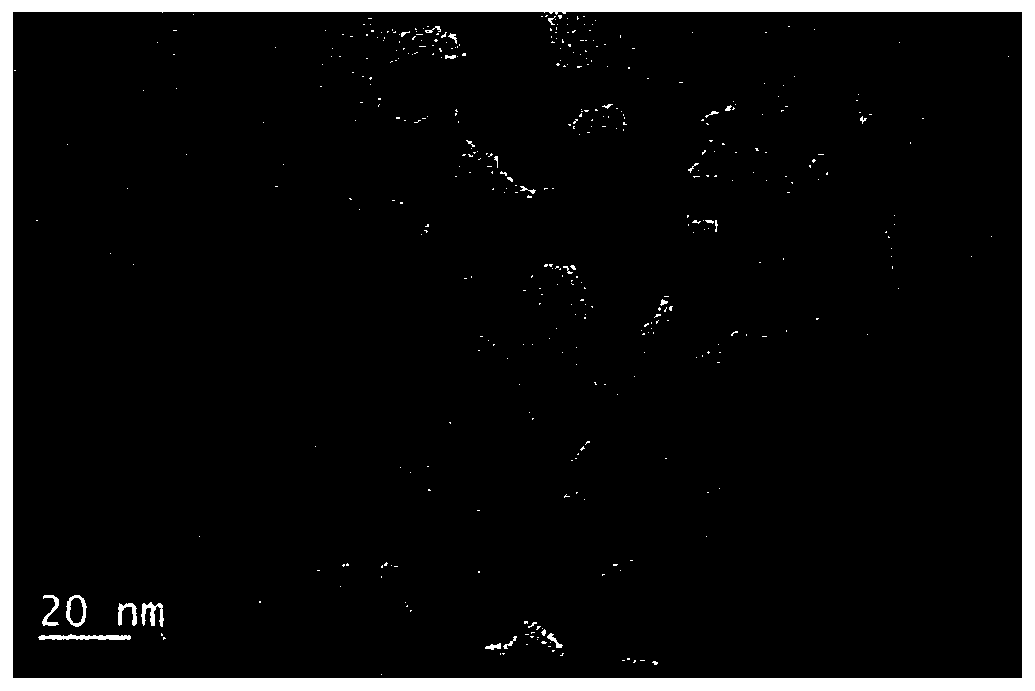

ActiveUS9868087B2Increase capacityShorten the purification processHeterogenous catalyst chemical elementsDispersed particle separationSolid solutionCore shell

Owner:TOYOTA JIDOSHA KK

Cerium-zirconium composite oxide and preparation method thereof

ActiveCN110385120AUniform distribution of dopingLarge specific surface areaHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsRare earthCerium

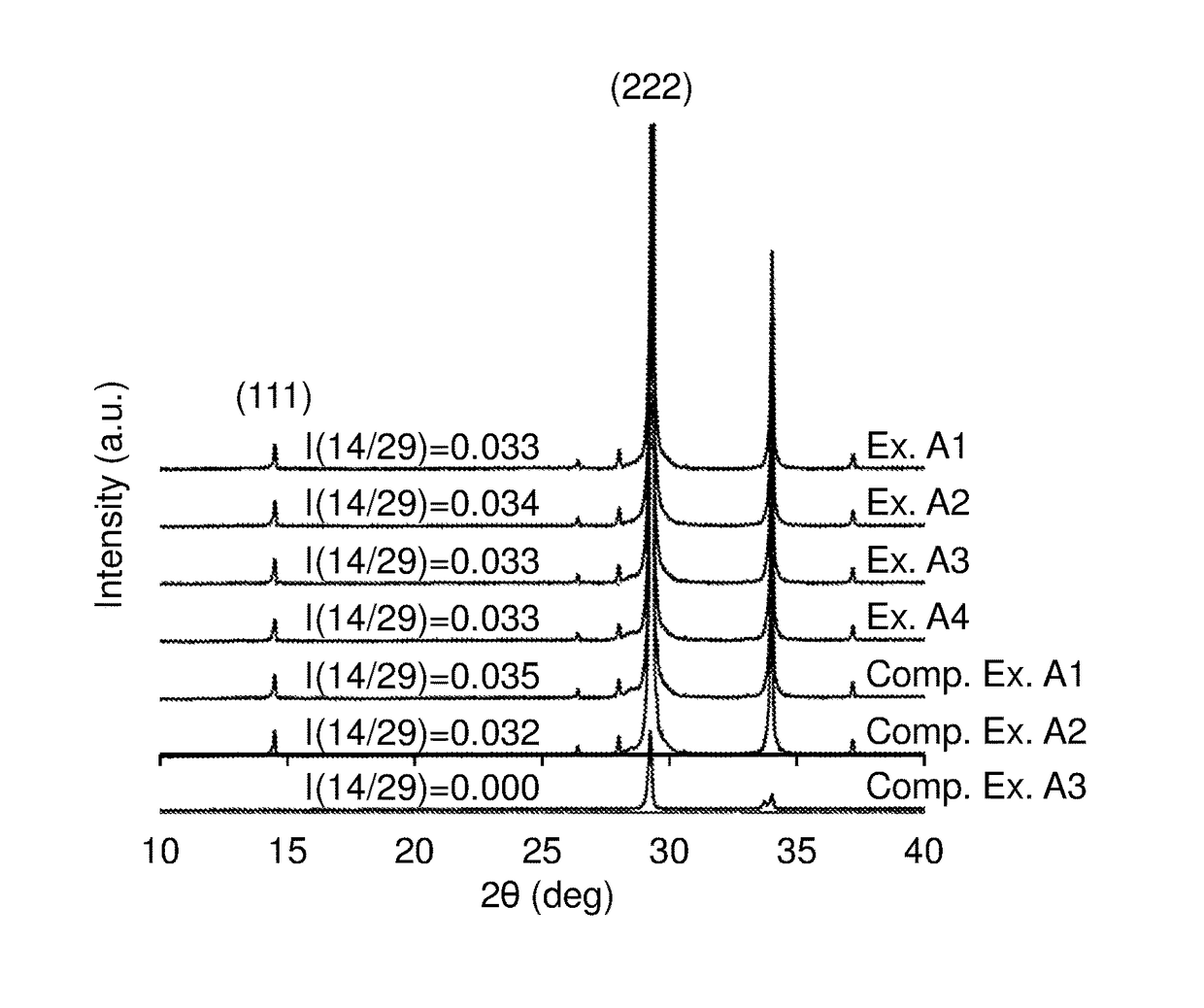

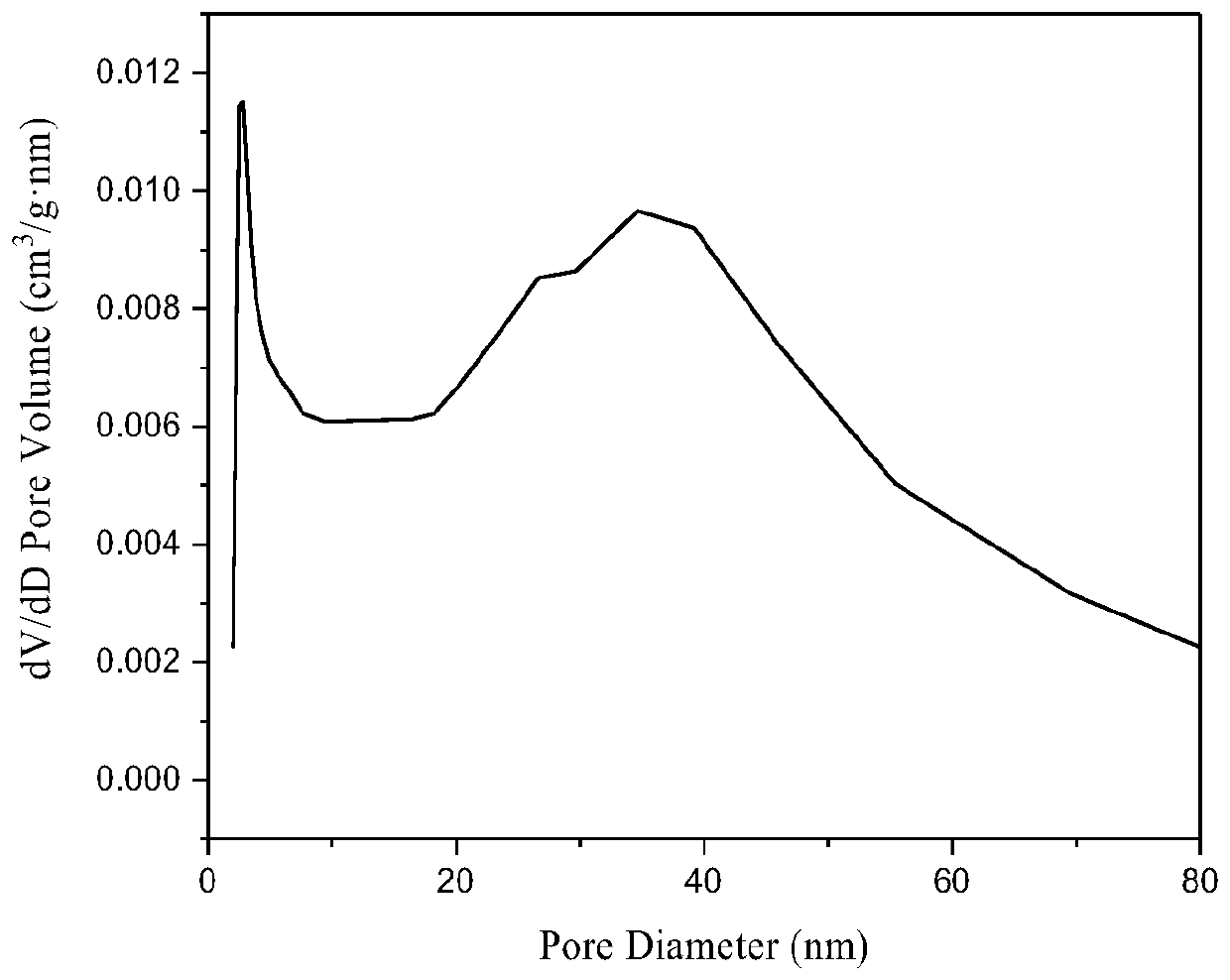

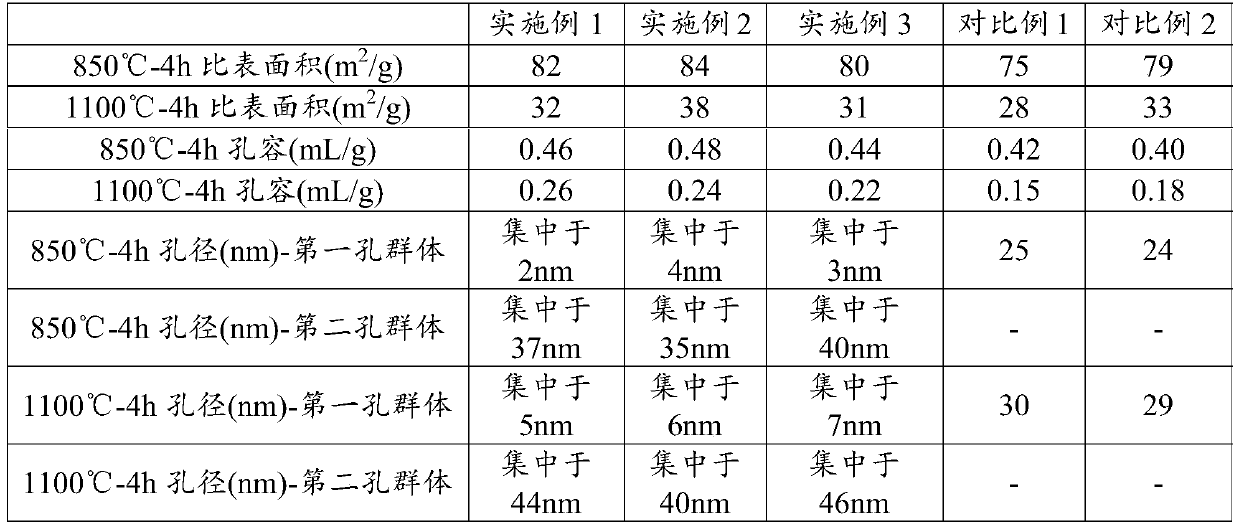

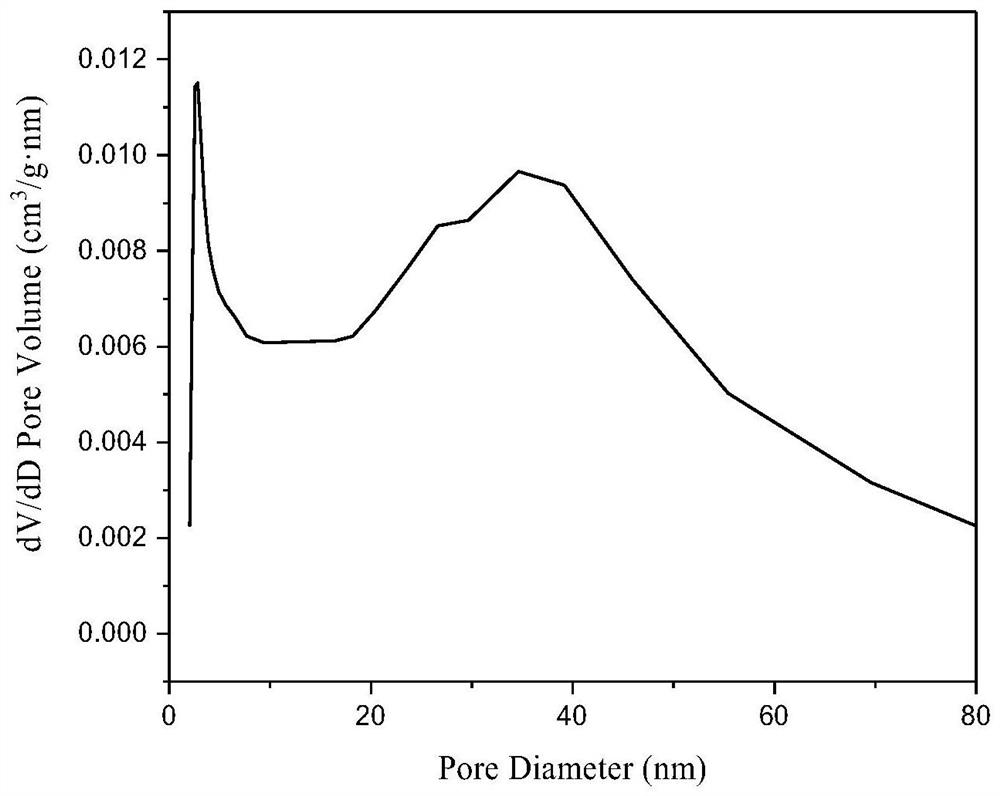

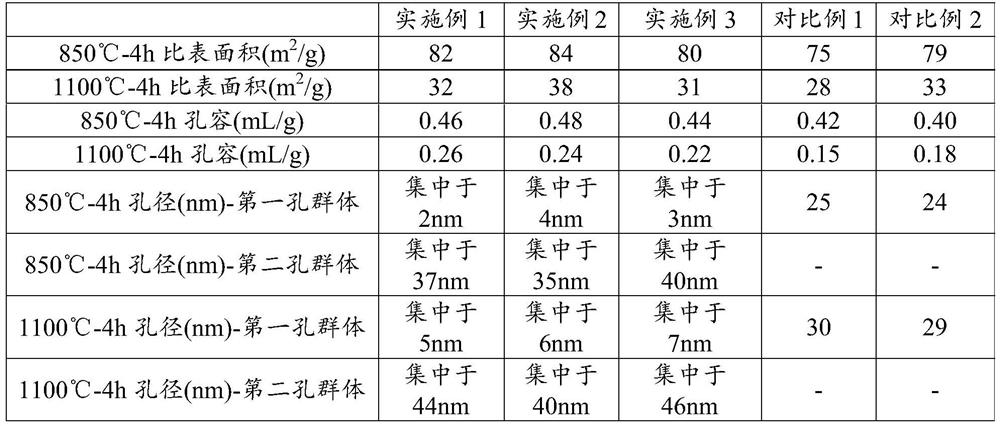

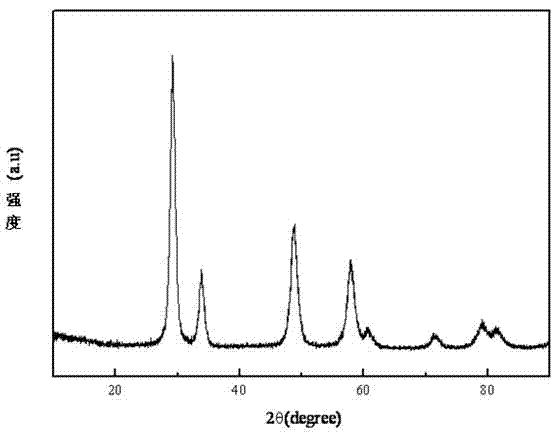

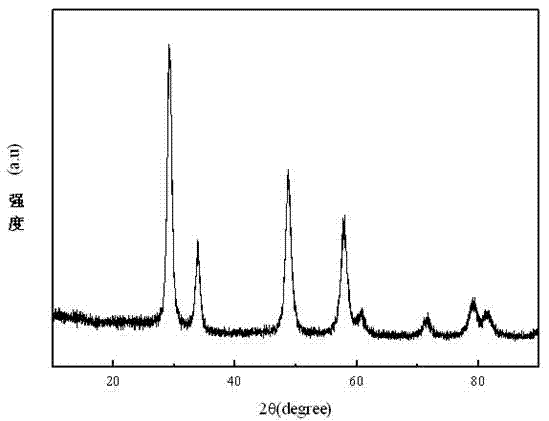

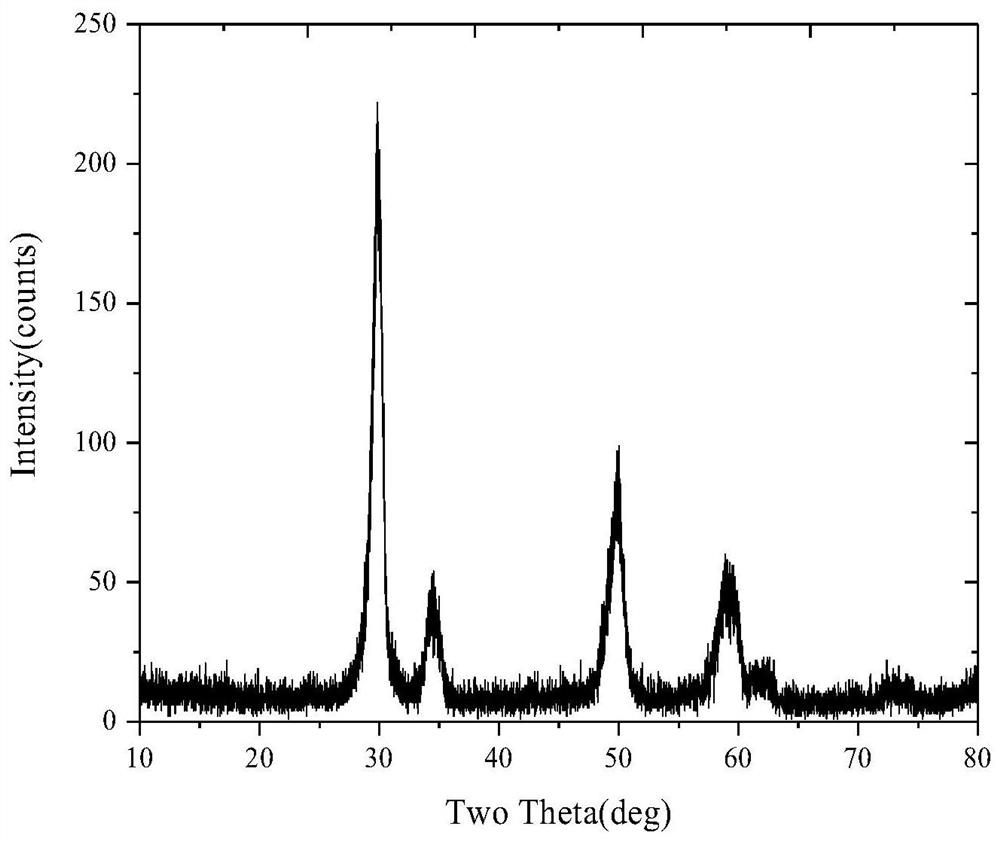

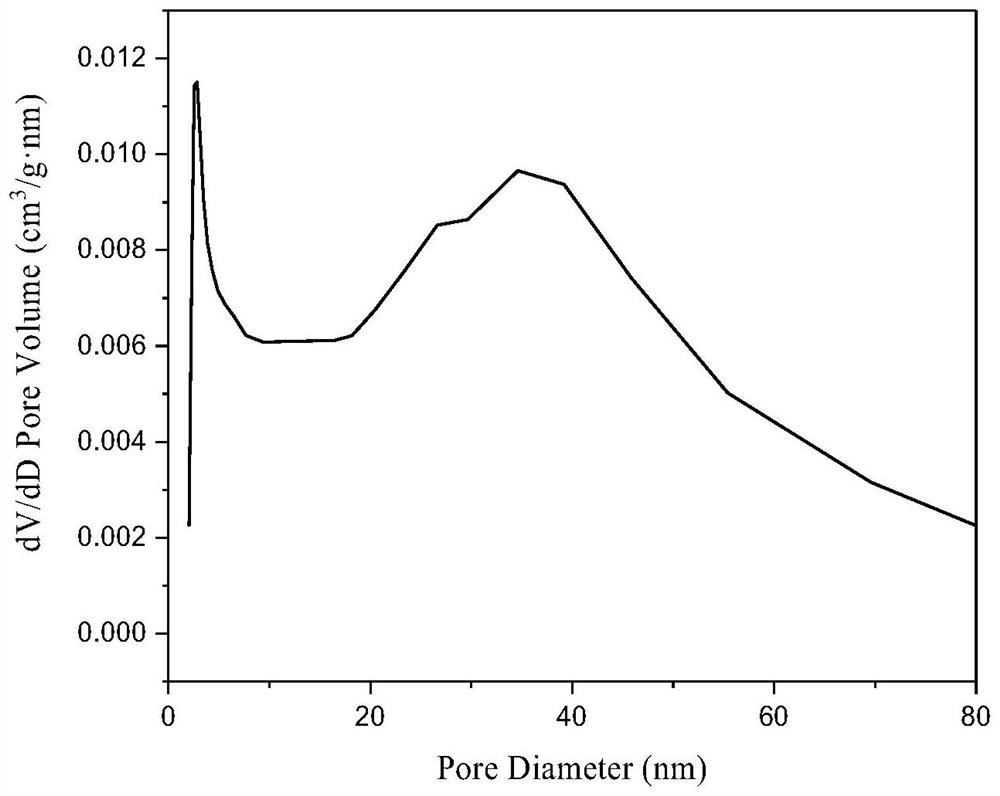

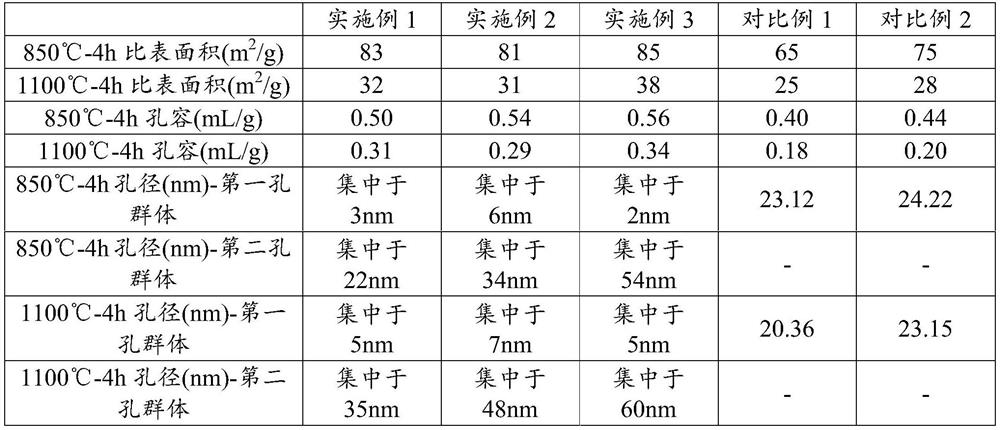

The invention provides a cerium-zirconium composite oxide, comprising cerium oxide, zirconium oxide and the oxide of at least one rare earth metal element except cerium. After the cerium-zirconium composite oxide is subjected to heat treatment at 850 DEG C for 4 to 8 h, the cerium-zirconium composite oxide has pore sizes in the form of dual pore group distribution, wherein the diameters of a firstpore group are concentrated in a range of 2 to 10 nm, and the diameter of a second pore group is concentrated in a range of 15 to 80 nm. The cerium-zirconium composite oxide provided by the inventionhas remarkable low-temperature catalytic activity and can be used for catalyzing hydrocarbons, carbon oxides and / or nitrogen oxides in mobile-source exhaust gas. The invention also provides a preparation method for the cerium-zirconium composite oxide. The preparation method can prepare the cerium-zirconium composite oxide which is more uniform in lattice doping distribution and free of phase separation, and is of great significance to study on cerium-zirconium composite oxide-containing cleaning agents for treatment of mobile-source exhaust gas.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Low-cost high-performance supported catalyst and preparation method thereof

ActiveCN104128173AOvercome doping defectsImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCeriumPerformance index

The invention relates to a solid solution, namely a supported catalyst and in particular relates to a low-cost high-performance supported catalyst. The supported catalyst comprises the following chemical components in parts by weight: 10-30 parts of cerium oxide, 10-30 parts of zirconium oxide, 30-50 parts of aluminium oxide and 1-20 parts of other rare earth oxides, wherein other rare earth oxides are mixtures of lanthanum oxide, praseodymium oxide, neodymium oxide, yttrium oxide and samarium oxide. The invention also provides a preparation method of the supported catalyst. The preparation method comprises the steps of mixing all the raw materials, adding surfactants, then adjusting the pH value to 8-10 to obtain a colloidal precipitate, and roasting to obtain the product. The supported catalyst and the preparation method have the advantages that doping defects caused by doping in cerium-zirconium supports are overcome; meanwhile, the performance indexes of the supported catalyst, such as heat stability, aging specific surface area, oxygen storage capacity and the like are greatly improved; the preparation method is low in raw material price and simple in process and is beneficial to large-scale industrial production.

Owner:淄博加华新材料有限公司

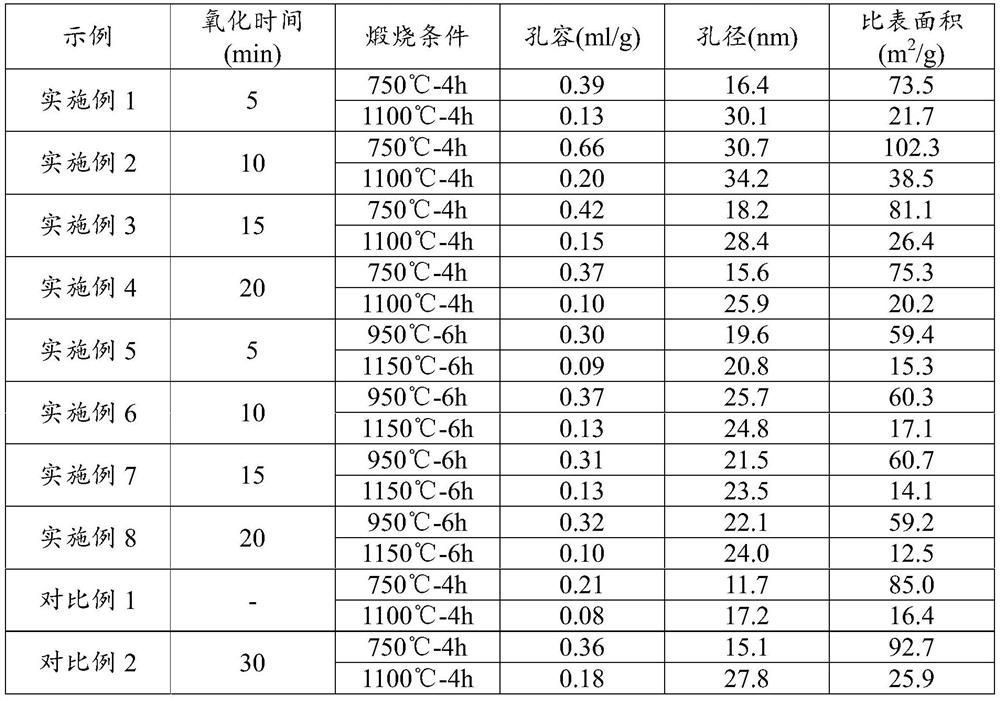

Preparation method of cerium-zirconium composite oxide with high oxygen storage capacity

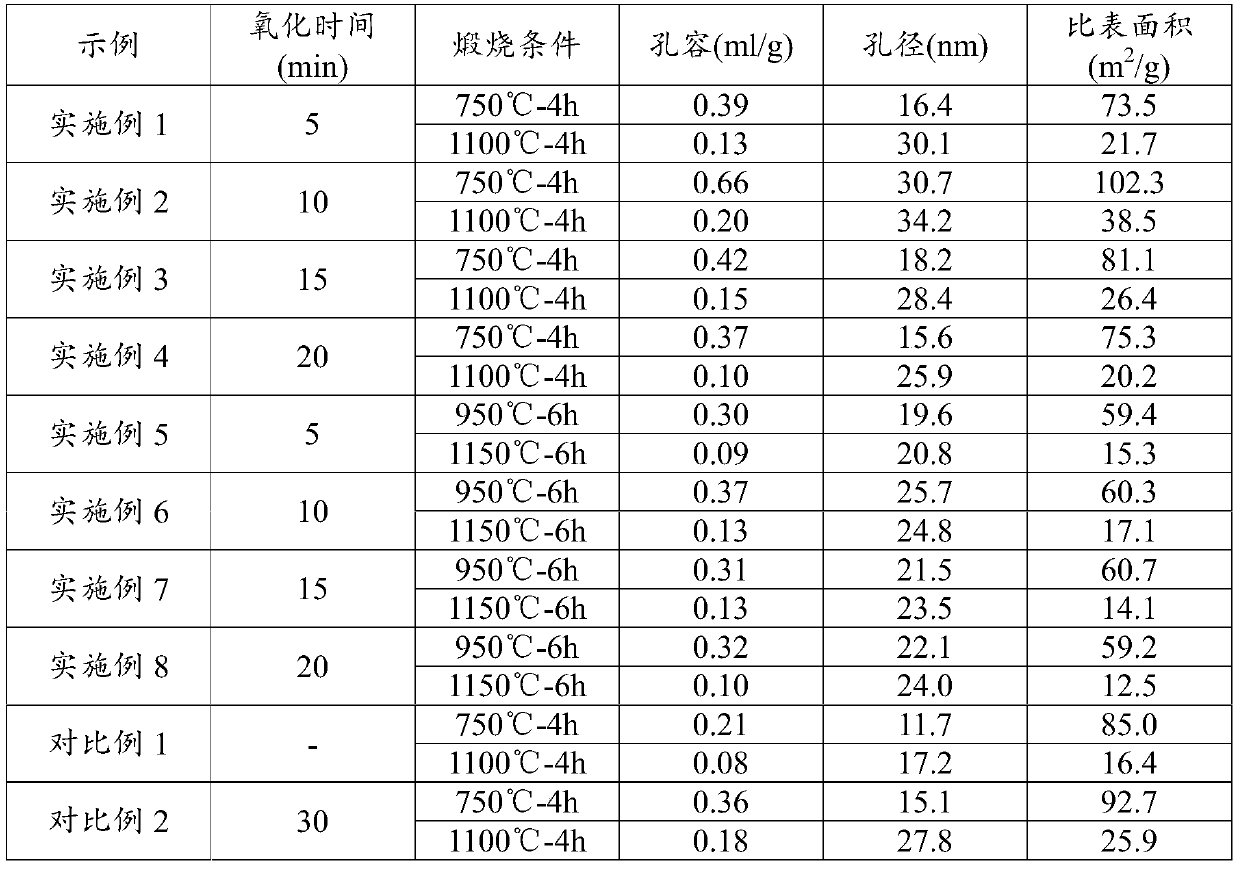

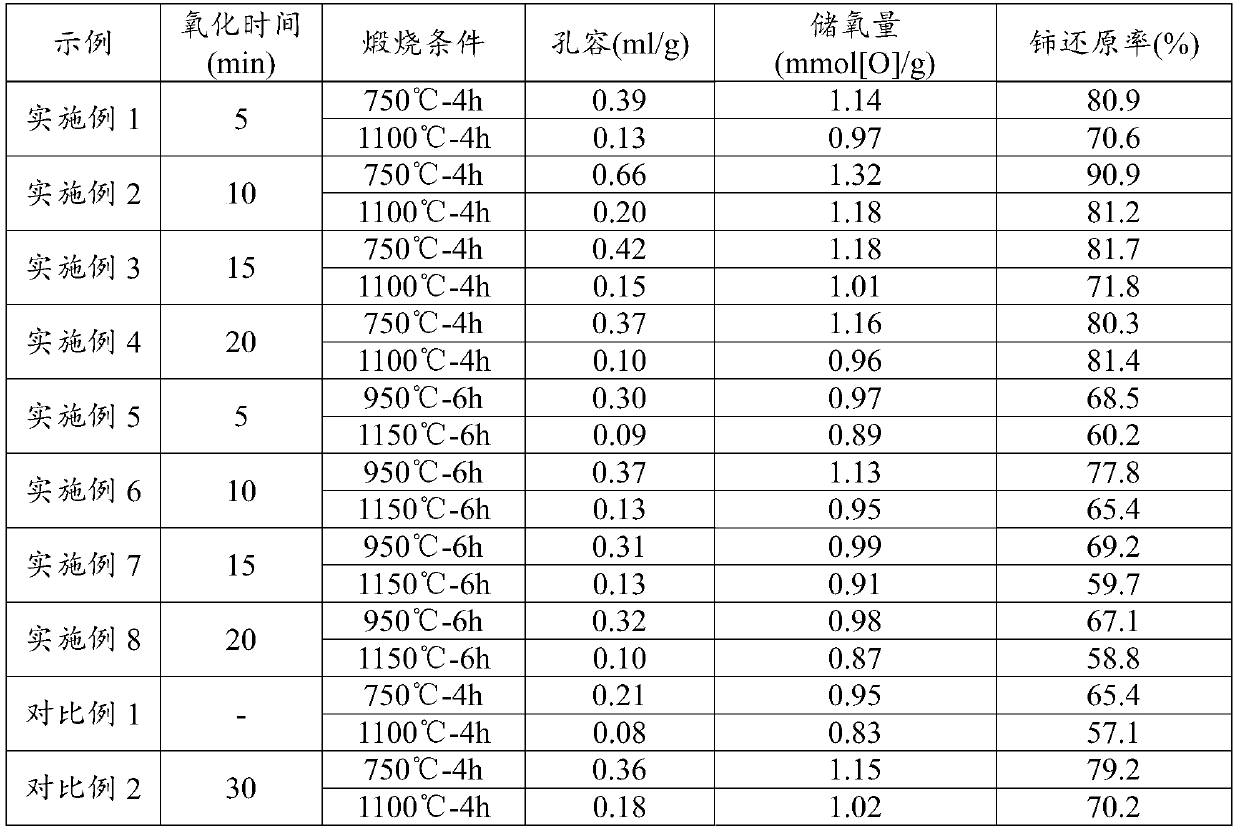

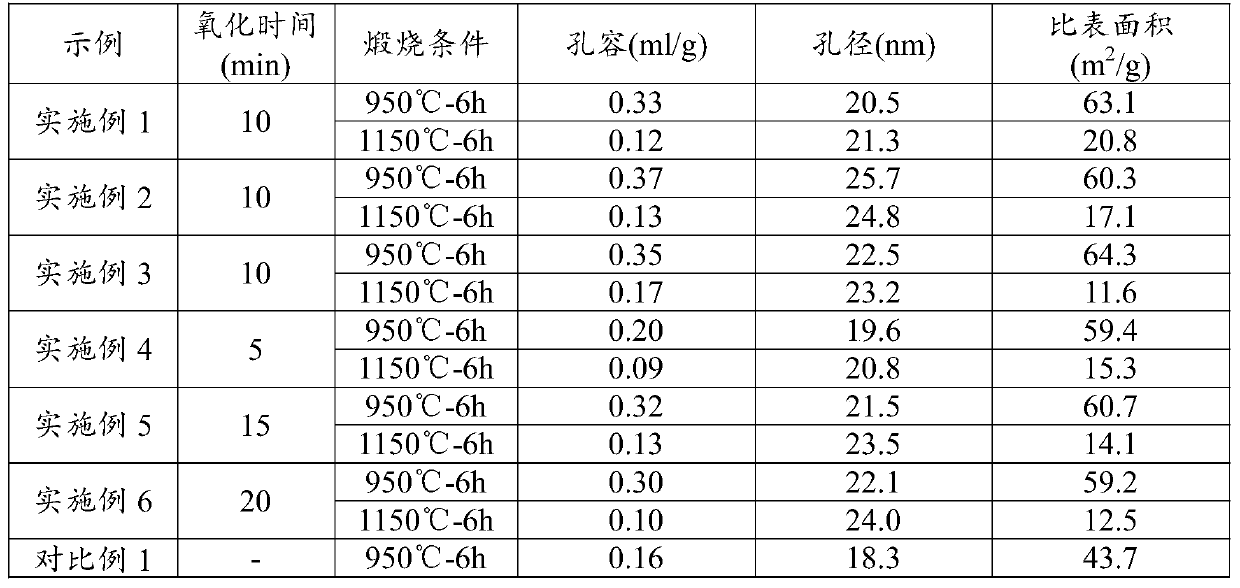

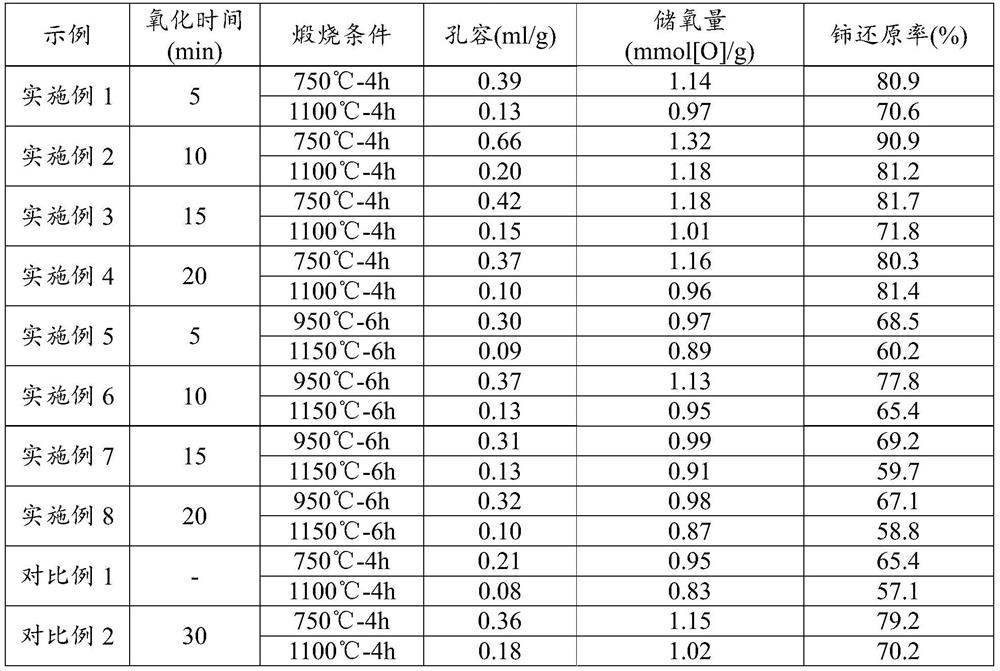

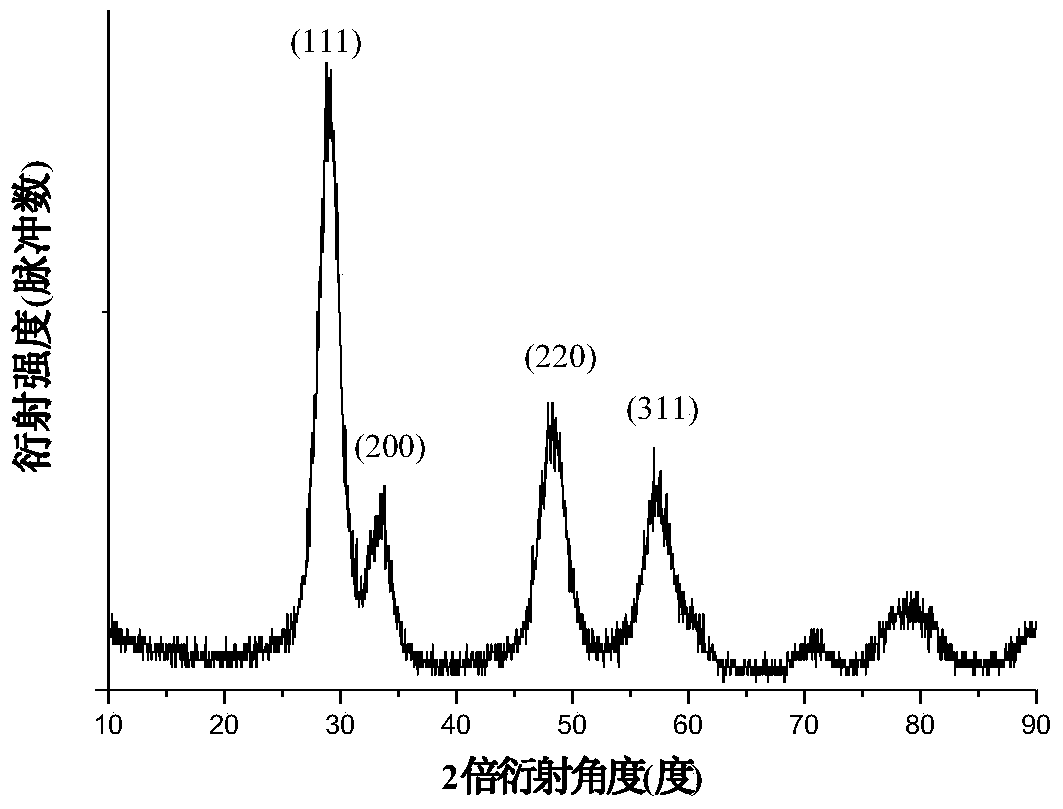

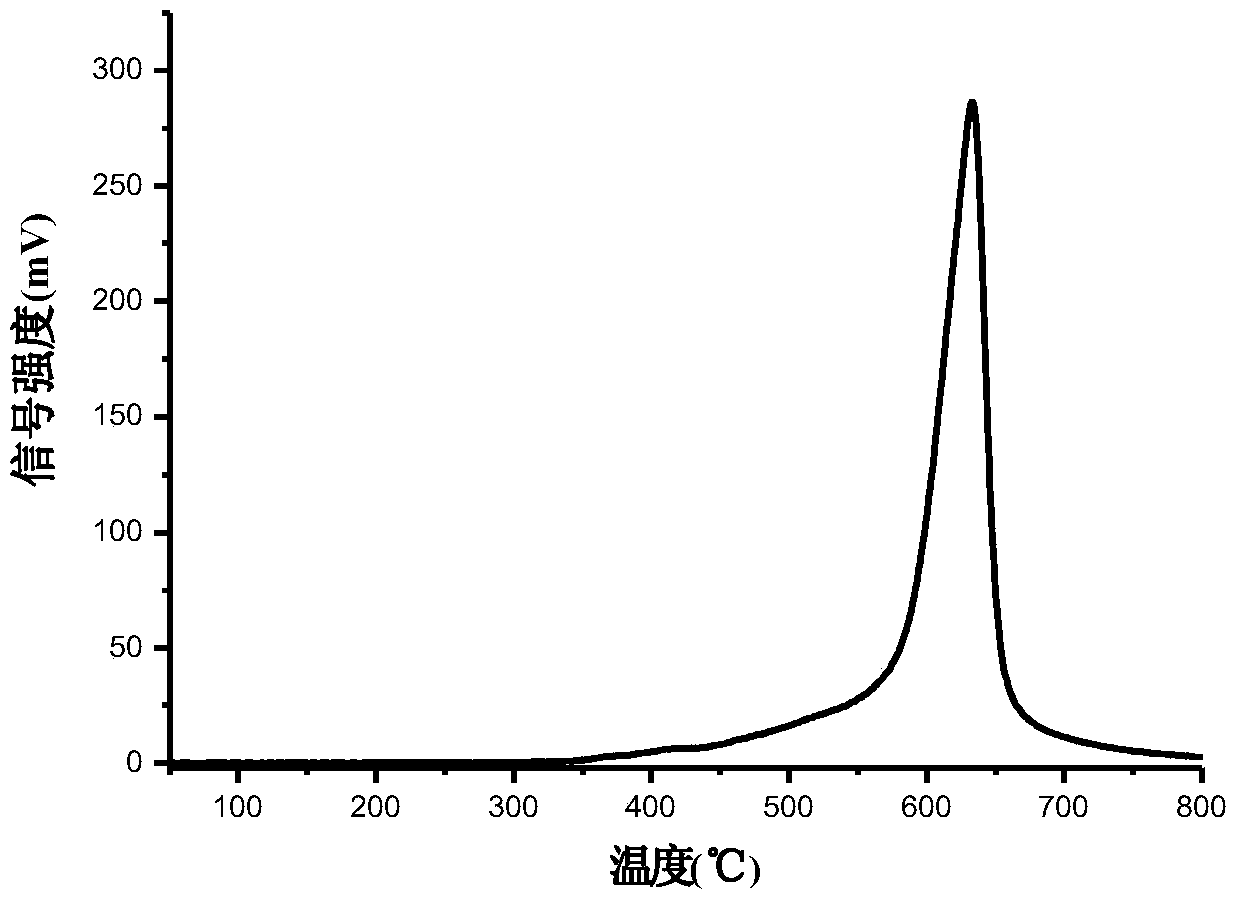

ActiveCN110327909AHigh oxygen storageLarge structureRare earth metal oxides/hydroxidesHeterogenous catalyst chemical elementsMischmetalCerium

The invention provides a preparation method of a cerium-zirconium composite oxide with high oxygen storage capacity, wherein the cerium-zirconium composite oxide comprises cerium oxide, zirconium oxide and at least one oxide of element selected from rare earth metal elements other than cerium, and the method comprises the step of pretreatment of cerium, zirconium and salts of rare earth metals inthe process of preparing the cerium-zirconium composite oxide by a hydrothermal method, wherein the pretreatment is oxidation treatment. The preparation method can obtain the cerium-zirconium composite oxide with high oxygen storage capacity, and the cerium-zirconium composite oxide has a larger pore volume structure and specific surface area, has remarkable oxygen storage capacity, and can stillmaintain a good oxygen storage effect after high-temperature aging.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

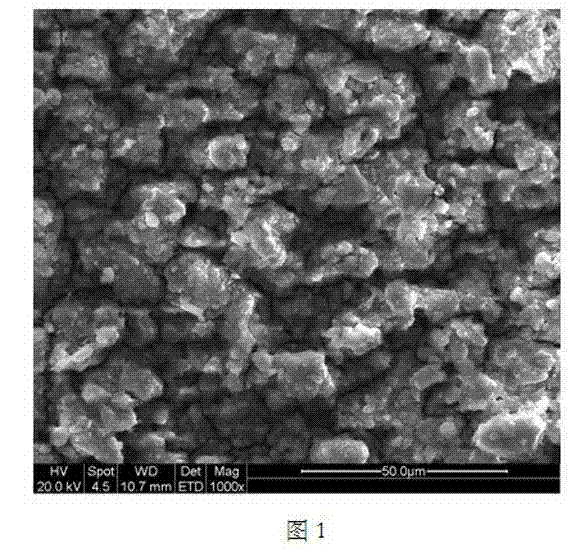

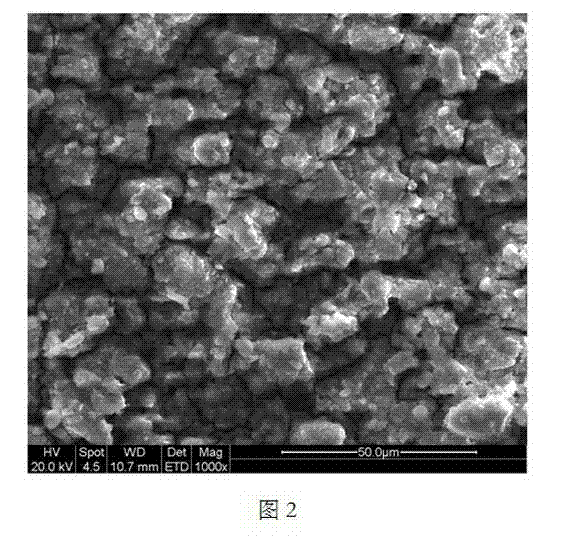

High oxygen storage cerium-zirconium solid solution prepared by adopting tobacco plant as template, and preparation method thereof

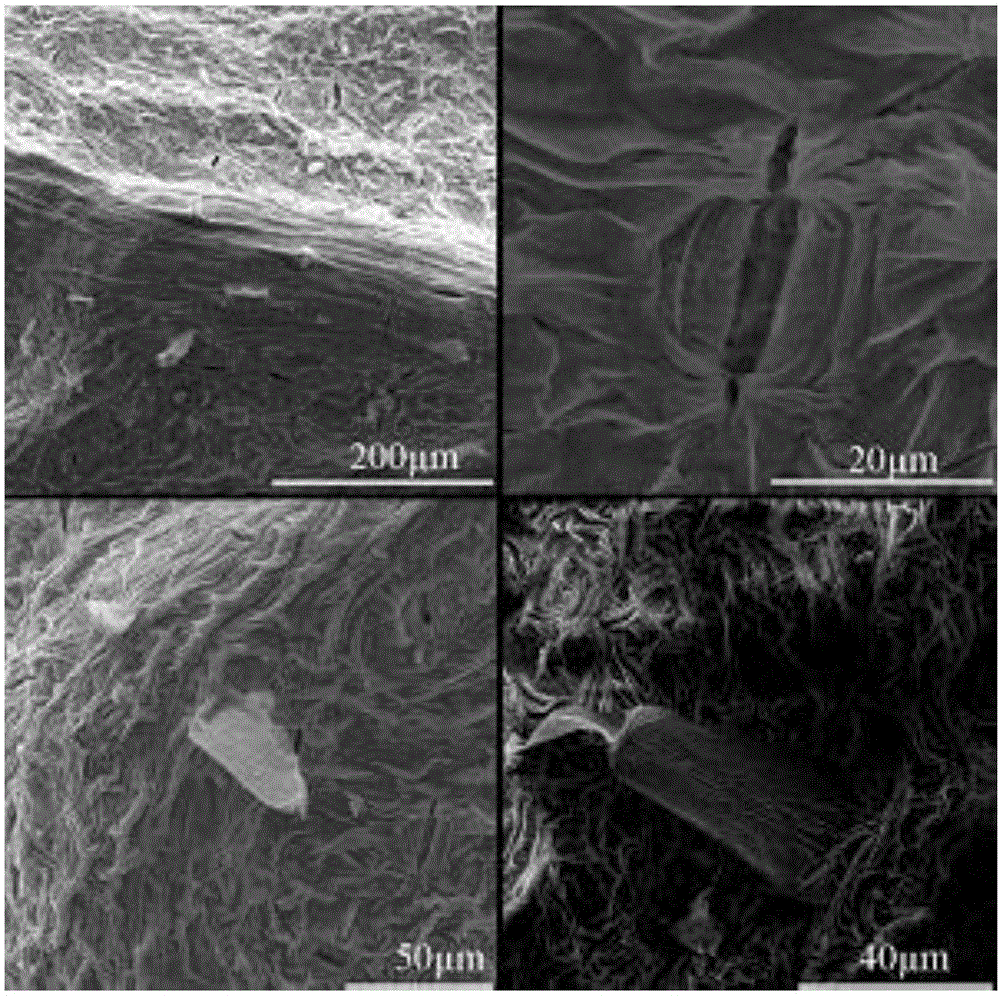

ActiveCN105013457ALarge specific surface areaImprove oxygen storage capacityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFine structureFiltration

The present invention relates to a cerium-zirconium solid solution, wherein the microstructure is copied from the microstructure of tobacco plant tissue in the morphology. The invention further relates to a cerium-zirconium solid solution preparation method, which comprises: (1) soaking a tobacco plant with hydrochloric acid, and carrying out filtration dehydration to prepare a tobacco plant template; (2) soaking the tobacco plant template prepared in the step (1) with a precursor solution, wherein the precursor solution is an aqueous solution or ethanol solution containing a cerium source, a zirconium source and a complexing agent (or precipitation agent); (3) filtering the mixture in the step (2), retaining the solid, and drying to obtain the initial solid product; and (4) calcining the solid product (4) obtained in the step (3) to obtain the cerium-zirconium solid solution. According to the present invention, the prepared cerium-zirconium solid solution has characteristics of nanometer fine structure, large specific surface area and high oxygen storage capacity, and the cerium-zirconium solid solution preparation method has characteristics of simple process, easy operation, low reaction condition, low production cost, high production efficiency, and good industrial production prospect.

Owner:CHINA TOBACCO YUNNAN IND

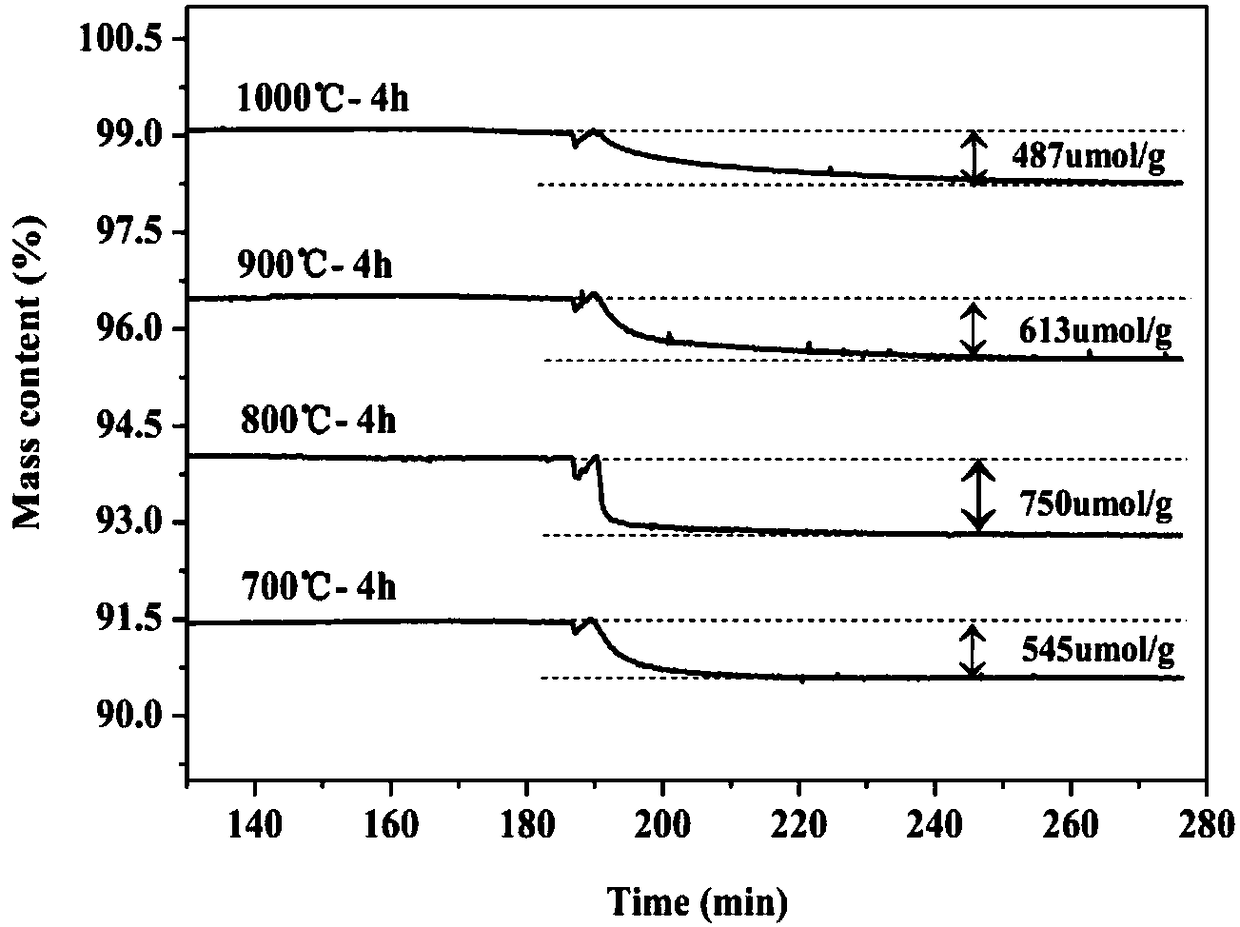

High-oxygen storage capacity Al2O3-CeO2-ZrO2-TiO2 coating material for automobile catalysts and preparation method thereof

InactiveCN108212140AHigh oxygen storageLarge specific surface areaGas treatmentCatalyst protectionTio2 coatingHigh oxygen

The invention relates to a high-oxygen storage capacity Al2O3-CeO2-ZrO2-TiO2 coating material for automobile catalysts and a preparation method thereof. The oxygen storage material is synthesized fromAl2O3, CeO2, ZrO2 and TiO2 according to a certain proportion by a sol-gel method, and has high specific surface area (about 180m<2> / g) and oxygen storage capacity (about 800Mu mol / g). Moreover, afterthe AlCeZrTiOx coating material involved in the invention is roasted under the high temperature of 1000 DEG C for 4 hours, the specific surface area is still higher than 80m<2> / g, the oxygen storagecapacity is higher than 480Mu mol / g, and the coating material can be used in motor vehicle exhaust purification catalysts. In addition, the invention further provides a preparation method for the oxygen storage material, the preparation method gets rid of the usage of precious metals and macromolecular dispersant, so that the production cost is greatly reduced, and the preparation method has the advantages of simple control process, simple production equipment, environment-friendliness and the like.

Owner:昆明贵研催化剂有限责任公司

Preparation method for palladium-doped cerium-zirconium composite oxide

ActiveCN104307518ASmall particle sizeLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsFiltrationCerium

The invention discloses a preparation method for a palladium-doped cerium-zirconium composite oxide. The preparation method includes the following steps: cerium acetate and zirconium acetate are dissolved in deionized water, and a first mixed solution is obtained after uniform mixing; OP-10, P123 and n-butyl alcohol are respectively dripped into a solvent (methylbenzene), the mass ratio of the OP-10, the P123 and the n-butyl alcohol is 5-6 to 2-3 to 10-15, and a second mixed solution II is obtained after uniform mixing; the first mixed solution and the second mixed solution are mixed and stirred at a high speed to obtain a mixed emulsion; 2 weight percent palladium acetate is dripped in the mixed emulsion, and the mixture is stirred uniformly; 20 weight percent ammonium hydroxide is prepared to serve as a precipitator; the mixed emulsion and the precipitator (the 20 weight percent ammonium hydroxide) are then mixed, the mixture is stirred at a high speed for 2 to 3 hours and then stands for 12 to 24 hours within a temperature range of 40 to 50 DEG C, and a dirty solution is obtained; the dirty solution goes through high-speed centrifugal separation and suction filtration, and obtained solid phase matters are dried within a temperature range of 100 to 120 DEG C and calcined within a temperature range of 400 to 500 DEG C to obtain the palladium-doped nanometer cerium-zirconium composite oxide. The palladium-doped cerium-zirconium composite oxide prepared through the method has the characteristics of small particle diameter (the diameter can reach the nanometer level), large specific surface area and oxygen storage capacity, high oxygen storage and discharge rates, and high sintering resistance.

Owner:JIANGSU LONGCHANG CHEM

Praseodymium-doped cerium-zirconium carrier catalyst and preparation method thereof

ActiveCN104148087AOvercome doping defectsImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCeriumPerformance index

The invention relates to a solid solution carrier catalyst, and specifically relates to a praseodymium-doped cerium-zirconium carrier catalyst. The carrier catalyst comprises the chemical components of, by weight, 30-50 parts of cerium oxide, 30-50 parts of zirconium oxide, 1-5 parts of praseodymium oxide and 1-5 parts of transition metal. The transition metal is a mixture of vanadium oxide, chromium oxide, manganese oxide, iron oxide, cobalt oxide and copper oxide. The invention also provides a preparation method of the carrier catalyst. According to the invention, all the raw materials are mixed; a surfactant is added; the pH is regulated to 8-10, and a colloidal precipitate is obtained; and the product is obtained by baking. With the method provided by the invention, a doping defect caused by doping in a cerium-zirconium carrier is overcome, and carried catalyst thermal stability and performance indexes such as aging specific surface area, oxygen storage capacity, and the like are greatly improved. The invention also provides the preparation method of the carrier catalyst. The raw materials are cheap, process is simple, and the method is suitable for large-scale industrialized productions.

Owner:淄博加华新材料有限公司

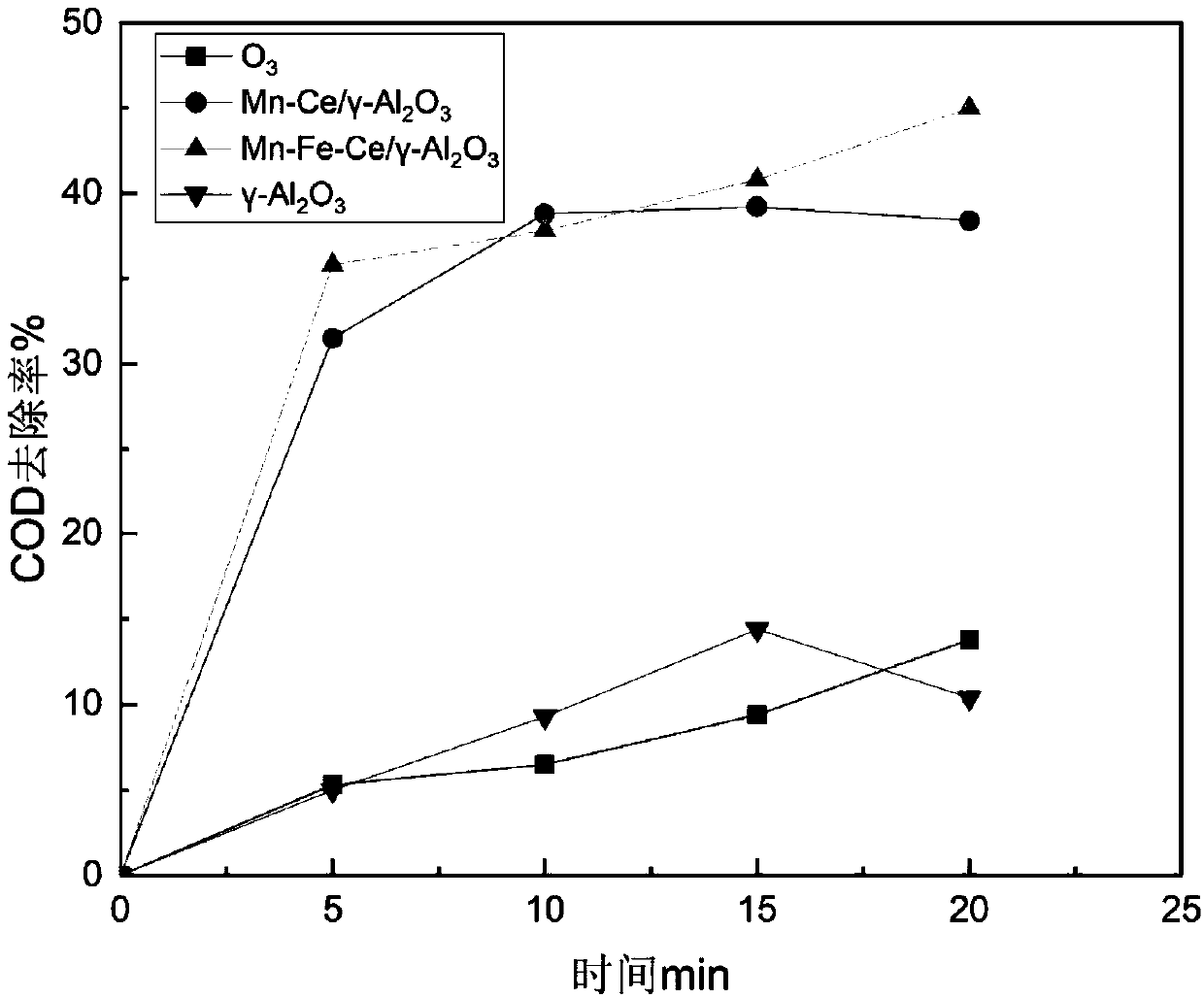

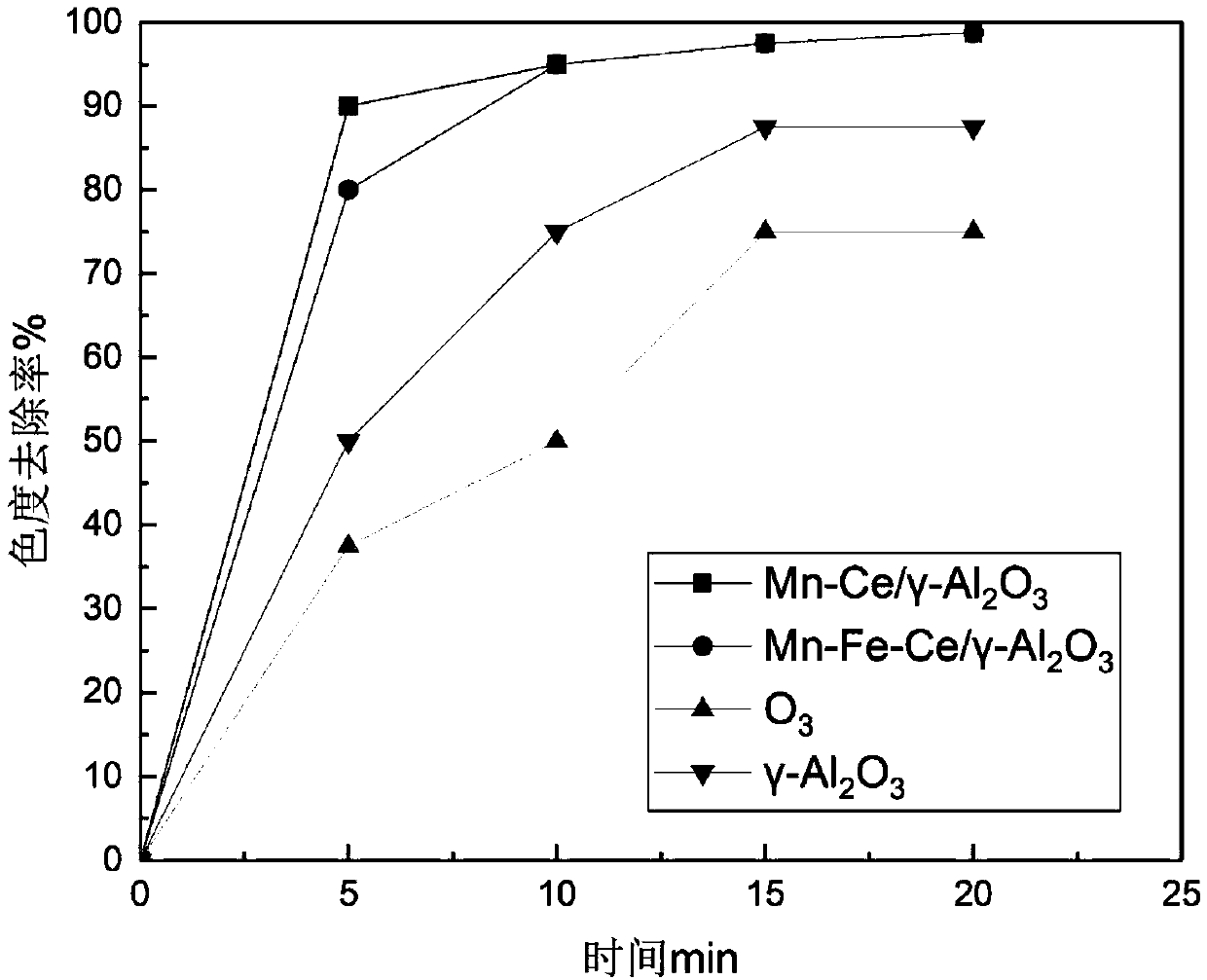

Ternary catalyst and preparation method and application thereof

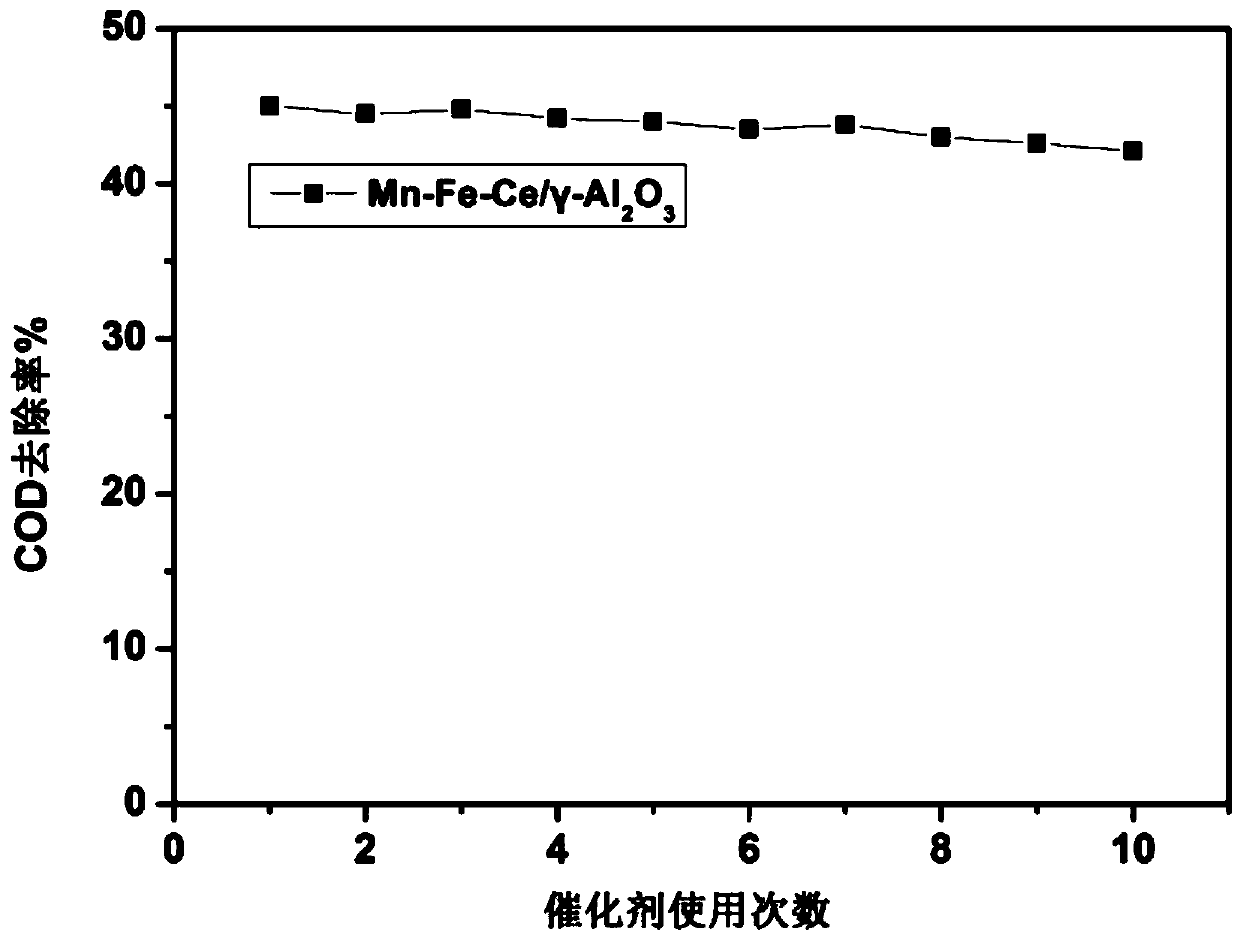

PendingCN109647430AImprove the effect of aerobic water effluentMany poresWater treatment compoundsWaste water treatment from animal husbandryManganeseCerium

The invention relates to the technical field of catalysts, in particular to a ternary catalyst and a preparation method and application thereof. The preparation method of the ternary catalyst comprises the following steps of: step 1, mixing aqueous solution containing a manganese compound, aqueous solution containing an iron compound and aqueous solution containing a cerium compound to obtain precursor solution; step 2, soaking a modified gamma-Al2O3 pellet in precursor solution, and respectively drying and roasting to obtain the ternary catalyst. The preparation method adopts an immersion roasting method, which is simple to operate, and can ensure that three metal oxides of manganese, iron and cerium can be stably attached to the surface of the gamma-Al2O3 pellet and the prepared ternarycatalyst is high in catalytic activity, and problems that the existing preparation method of the ternary catalyst is complex and the catalytic effect of the prepared ternary catalyst is low are solved.

Owner:GUANGDONG UNIV OF TECH

Preparation method of cerium-aluminum composite oxide with low cost and large specific surface area

PendingCN106732518ALarge specific surface areaImprove oxygen storage capacityMaterial nanotechnologyDispersed particle separationAlumina hydrateCerium

The invention relates to a solid solution supported catalyst, and in particular to a preparation method of a cerium-aluminum composite oxide with low cost and large specific surface area. The preparation method is characterized by comprising the following steps: (1) adding alumina hydrate in 100-170g / L of a cerium chloride aqueous solution, pulping to obtain a mixed liquid, adding 0.1-1 percent of a surfactant (by weight percentage) of the mixed liquid, uniformly stirring, putting the mixed liquid in a constant-temperature tank, and standing for 1-2h; (2) adding ammonia water or ammonium carbonate in a feed solution subjected to treatment in the first step, and controlling a pH value to be 8-10 to obtain gelatinous precipitates; (3) washing the gelatinous precipitates obtained in the second step with deionized water, and carrying out dehydration; (4) putting a product obtained through dehydration in the third step in a kiln, and roasting the product under the condition with the temperature being 500-700 DEG C for 4-6h; and (5) grinding the product subjected to roasting until the maximum particle size is 10 microns to obtain the cerium-aluminum composite oxide with large specific surface area. The preparation method is low in cost of raw materials and simple in technological process and is beneficial to large scale industrial production.

Owner:陈思南

Preparation method of cerium oxide with low cost and large specific surface area

ActiveCN104148116BLow priceSimple processOrganic-compounds/hydrides/coordination-complexes catalystsTriflic acidPerformance index

The invention relates to a solid solution carrier catalysis, and specifically relates to a preparation method of low-cost large-specific-surface-area cerium oxide. According to the invention, water solutions corresponding to all raw materials are mixed; a surfactant is added; the pH value is regulated to 8-10, such that a gel precipitate is obtained; washing and roasting are carried out; drying and grinding are carried out; trifluoromethanesulfonic acid is added to the product, and the mixture is well mixed; and drying is carried out, such that the cerium oxide is obtained. The raw materials are cheap, and the process procedure of the method is simple. With the method, a doping defect caused by doping in a cerium oxide carrier is overcome. Also, performance indexes such as thermal stability, aging specific surface area, oxygen storage capacity, and the like of the carrier catalyst are greatly improved.

Owner:淄博加华新材料有限公司

Praseodymium-doped cerium-zirconium carrier catalyst and preparation method thereof

ActiveCN104148087BOvercome doping defectsImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCeriumManganese oxide

The invention relates to a solid solution carrier catalyst, in particular to a praseodymium-doped cerium-zirconium carrier catalyst. The chemical composition and weight content are: 30-50 parts of ceria, 30-50 parts of zirconia, 1-5 parts of praseodymium Transition metal oxide: 1-5 parts; wherein, the transition metal oxide is a mixture of vanadium oxide, chromium oxide, manganese oxide, iron oxide, cobalt oxide and copper oxide. The invention also provides a preparation method thereof. All raw materials are mixed, a surfactant is added, and the pH is adjusted to 8-10 to obtain a colloidal precipitate, and the product is obtained after roasting. The invention overcomes the doping defects caused by doping in the cerium-zirconium carrier, and at the same time greatly improves the thermal stability, aging specific surface area, oxygen storage capacity and other performance indicators of the carrier catalyst; the invention also provides its preparation method, raw material price Inexpensive, simple process, and conducive to large-scale industrial production.

Owner:淄博加华新材料有限公司

Cerium-zirconium composite oxide as well as preparation method and application thereof

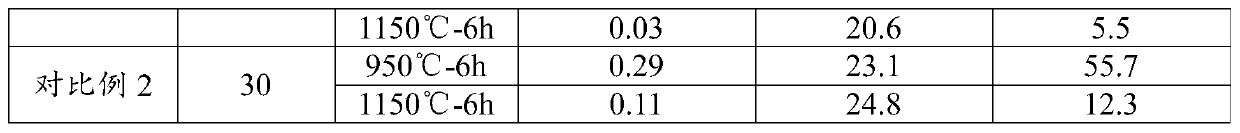

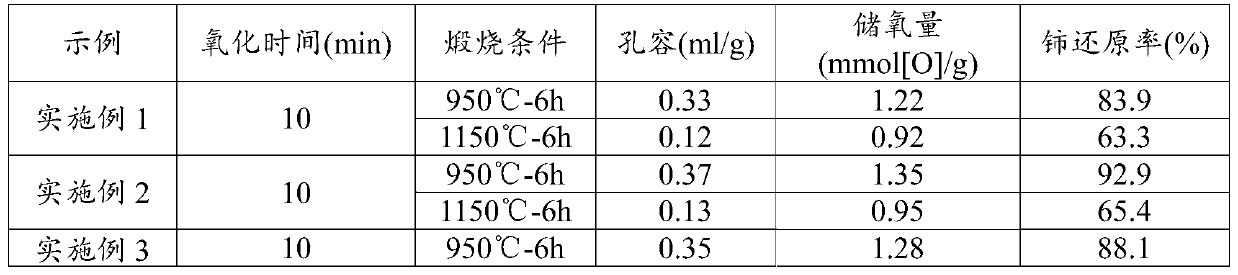

ActiveCN110026178AHigh oxygen storage performanceLarge Pore StructureDispersed particle separationCatalyst activation/preparationRare earthCerium

The invention provides a cerium-zirconium composite oxide which comprises a cerium-containing oxide, a zirconium-containing oxide and at least one oxide, wherein the oxide is selected from rare-earthmetallic elements except cerium; the content of the oxide which is selected from rare-earth metallic elements except cerium is 10-20wt%; after 4-8 hours of thermal treatment at 950 DEG C, the composite oxide has a pore volume of 0.30-0.60ml / g, a specific surface area of 58-100m<2> / g and an oxygen storage amount of 1.00mmol[O] / g at least. The cerium-zirconium composite oxide provided by the invention has a large pore volume structure, has a remarkable oxygen storage capability, and has a very good oxygen storage effect after high-temperature aging.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Novel motorcycle catalyst and preparation method thereof

InactiveCN107649127AImprove firm performanceImprove conversion rateHeterogenous catalyst chemical elementsDispersed particle separationCeriumSlurry

The invention discloses a novel motorcycle catalyst. The catalyst comprises a carrier, and an inner layer slurry and an outer layer slurry which are coated on the carrier; the inner layer slurry comprises, by mass, 20-50% of Al2O3, 30-60% of CeZrO2, 2-10% of a cerium precursor (by CeO2), 2-10% of a zirconium precursor (by ZrO2) and 2-10% of a vanadium precursor (by BaO); and the outer layer slurrycomprises, by mass, 30-60% of Al2O3, 30-50% of a CeZrO2 complex oxide, 2-10% of the cerium precursor (by CeO2), 2-10% of the zirconium precursor (by ZrO2) and 2-10% of the vanadium precursor (by BaO). The novel motorcycle catalyst can effectively reduce the content of motor emissions, prevent the pollution of the motor emissions to the environment and improve the air quality of the environment.

Owner:艾科卡特催化器丹阳有限公司

Core-shell oxide material, method for producing the same, and catalyst and method for purification of exhaust gas using the core-shell oxide material

ActiveUS20170282123A1Excellent oxygen storage/release capacityHigh rateHeterogenous catalyst chemical elementsDispersed particle separationExhaust gasOxide

Owner:TOYOTA JIDOSHA KK

Multi-component doped cerium-zirconium carrier catalyst and preparation method thereof

ActiveCN104117363BOvercome doping defectsImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCeriumCopper oxide

The invention relates to a solid solution carrier catalyst and particularly relates to a multi-doped cerium-zirconium carrier catalyst. The chemical components of the catalyst in parts by weight are as follows: 30-40 parts of cerium oxide, 30-40 part of zirconia, 1-20 parts of other rare earth oxides and 1-5 parts of transition metal oxides, wherein the other rare earth oxides are lanthanum oxide, praseodymium oxide, neodymium oxide, yttrium oxide and samarium oxide and the transition metal oxides are vanadium oxide, chromium oxide, manganese oxide, ferric oxide, cobaltosic oxide and copper oxide. The invention further provides a preparation method of the catalyst. The preparation method comprises the following steps: mixing all the raw materials with a surfactant, adjusting the pH to 8-10 to obtain a gel-like deposition and calcining to obtain the product. According to the method, the doping defect caused during cerium-zirconium carrier doping is overcome; meanwhile, the thermal stability, aging specific area and oxygen storage amount of the carrier catalyst are improved; the invention also provides the preparation method which is simple in technique process and is favorable for large-scale industrial production.

Owner:淄博加华新材料有限公司

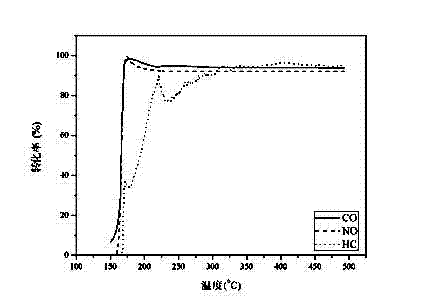

Nano cerium-zirconium composite oxide and application thereof in catalysis of NOX reduction reaction

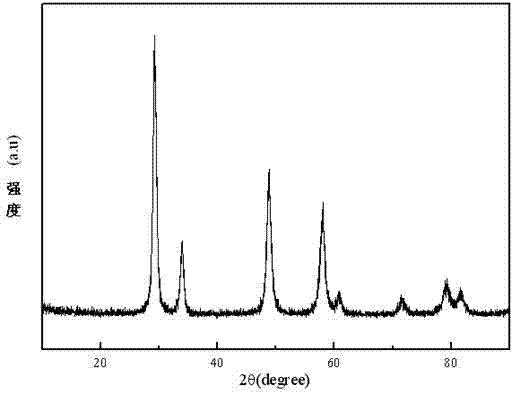

ActiveCN110526290AAppropriate micro-nano particle sizeHigh oxygen storageMaterial nanotechnologyGas treatmentCeriumCalcination

The invention provides a nano cerium-zirconium composite oxide. The nano cerium-zirconium composite oxide comprises ceria, zirconia and at least one of rare-earth metal oxides except for cerium oxides, wherein a mass percent ratio of a cerium oxide to a zirconium oxide in the composite oxide is smaller than 1; and after heat treatment of 4 to 8 hours at the temperature of 750 DEG C, the compositeoxide has the particle size of 5nm to 20nm and the oxygen storage capacity of at least 1.10mmol[O] / g. The nano cerium-zirconium composite oxide provided by the invention has a proper microscopic nanoparticle size and relatively high oxygen storage capacity. Shown by experiments, after 4 hours of calcination of the nano cerium-zirconium composite oxide provided by the invention at the temperatureof 750 DEG C, T50 and T90 are about 150 DEG C and 200 DEG C separately, after 4 hours of high-temperature aging at the temperature of 1,100 DEG C, the T50 and the T90 are about 170 DEG C and 220 DEG Cseparately, and thus, excellent low-temperature catalytic activity and antiaging activity are shown.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Ternary-cerium-based oxygen storage material and preparation method thereof

ActiveCN102258995BLow ignition temperatureLarge specific surface areaInternal combustion piston enginesMetal/metal-oxides/metal-hydroxide catalystsPolyvinyl alcoholCerium

Owner:HUBEI HANGTE TECH CO LTD

A kind of cerium zirconium composite oxide and preparation method thereof

ActiveCN110385120BUniform distribution of dopingLarge specific surface areaHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsMischmetalNitrogen oxides

The present invention provides a cerium-zirconium composite oxide, comprising cerium oxide, zirconium oxide and at least one oxide of rare earth metal elements other than cerium. The pore size of the double pore group distribution, wherein the diameter of the first pore group is concentrated in 2-10 nm, and the diameter of the second pore group is concentrated in 15-80 nm. The cerium-zirconium composite oxide provided by the invention has remarkable low-temperature catalytic activity, and can be used to catalyze hydrocarbons, carbon oxides and / or nitrogen oxides in the exhaust gas of the mobile source. The invention also provides a preparation method of cerium-zirconium composite oxide, which can prepare and obtain cerium-zirconium composite oxide with more uniform element lattice doping distribution and no phase separation, and can treat and purify mobile source exhaust gas containing cerium-zirconium composite oxide The study of the drug is of great significance.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

A kind of preparation method of palladium-doped cerium-zirconium composite oxide

ActiveCN104307518BSmall particle sizeLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsFiltrationMass ratio

Owner:JIANGSU LONGCHANG CHEM

Cubic phase cerium and zirconium based composite oxide with high specific surface area and preparation method thereof

ActiveCN102247826BReaction is easy to controlSave raw materialsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementCerium

The invention discloses a cubic phase cerium-zirconium-based composite oxide with high specific surface area. Rare earth elements are doped into the cerium-zirconium composite oxide, and the rare earth elements are two or three of Pr, Nd and La, wherein The molar ratio of Zr to Ce is 1.8~2.5:1, the molar ratio of Pr to Ce is 0~0.32:1, the molar ratio of Nd to Ce is 0~0.32:1, and the molar ratio of La to Ce is 0~0.16: 1. The cerium-zirconium-based composite oxide exists in the form of cerium-zirconium solid solution. The invention also discloses its preparation method. The present invention prepares composite oxides through different precursor precipitation and drying methods. The reaction process is simple and the requirements for drying equipment are low. The obtained cerium-zirconium-based composite oxides have high specific surface area, high thermal stability and high oxygen storage and release capacity. After 1000 After calcination at ℃ for 12 hours, the specific surface area is higher than 35m2 / g, more particularly higher than 60m2 / g.

Owner:UNIV OF JINAN

A kind of preparation method of rare earth compound

InactiveCN105214641BWide variety of sourcesLow costMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsActivated carbonChemical industry

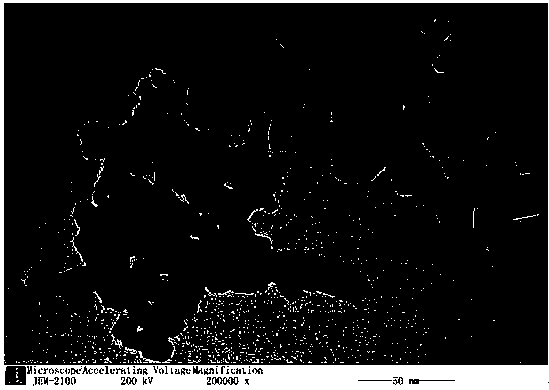

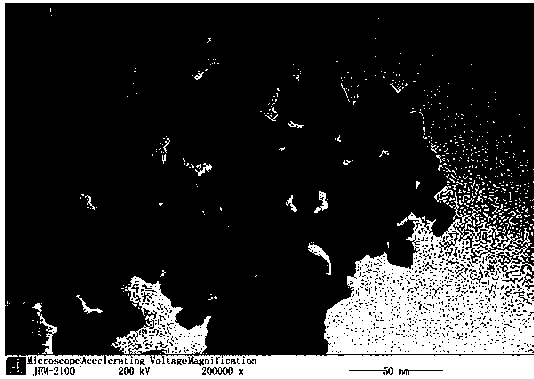

The invention discloses a preparing method for rare earth compounds and belongs to the technical field of preparation of inorganic composite materials. The method comprises the steps that Ce, Zr, La, Pr, Nd, Yb and other compounds are selected as precursors, and a ternary rare earth compound, a quaternary rare earth compound and a polynary rare earth compound are prepared respectively; powdery porous activated carbon is arranged in corresponding precursor solutions, then stirring is carried out, a precipitator is added after adsorption is conducted for a certain time to precipitate the mixture, the pH value is adjusted to be proper, aging is conducted after complete precipitation, and the mixture is filtered, washed, dried and them roasted at a high temperature. The rare earth compounds prepared through the method have the advantages of being large in specific surface area, high in OSC and the like; TEM representation shows that the compounds are nanoparticles with the particle size ranging from 9 nm to 20 nm. The compounds prepared through the method can be widely applied to the fields of petroleum, chemical industry, environmental protection and the like.

Owner:云南铑熠金属材料有限公司 +1

A kind of preparation method of high oxygen storage cerium zirconium composite oxide

ActiveCN110327909BHigh oxygen storageLarge structureRare earth metal oxides/hydroxidesHeterogenous catalyst chemical elementsMischmetalCerium

The invention provides a method for preparing a high oxygen storage cerium-zirconium composite oxide, wherein the cerium-zirconium composite oxide includes cerium oxide, zirconium oxide and at least one oxide of rare earth metal elements other than cerium, the method It includes the step of pretreating the salts of cerium, zirconium and rare earth metals in the process of preparing the cerium-zirconium composite oxide by hydrothermal method, and the pretreatment is oxidation treatment. Using the preparation method provided by the present invention, the cerium-zirconium composite oxide with high oxygen storage capacity can be obtained, and the cerium-zirconium composite oxide has a large pore volume structure and specific surface area, has a significant oxygen storage capacity, and remains It can maintain a good oxygen storage effect.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

A kind of cerium-zirconium solid solution with high oxygen storage capacity prepared by using tobacco plant as a template and its preparation method

ActiveCN105013457BLarge specific surface areaImprove oxygen storage capacityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNano structuringFiltration

The present invention relates to a cerium-zirconium solid solution whose microstructure is morphologically replicated from that of tobacco plant tissue. The present invention also relates to the preparation method of the cerium-zirconium solid solution, which comprises the following steps: (1) soaking the tobacco plants with hydrochloric acid and then filtering and dehydrating to obtain a tobacco plant template; The tobacco plant template is soaked with a precursor solution, wherein the precursor solution is an aqueous solution or an ethanol solution containing a cerium source, a zirconium source, a complexing agent (or a precipitation agent); (3) filtering the mixture in step (2), and retaining a solid and drying it to obtain an initial solid product; (4) calcining the solid product obtained in step (3) to obtain a cerium-zirconium solid solution. The cerium-zirconium solid solution prepared by the invention has nano fine structure, large specific surface area and high oxygen storage capacity. The preparation method of the cerium-zirconium solid solution has simple process, convenient operation, low reaction conditions, low production cost and high production benefit, and has good industrialized production prospects.

Owner:CHINA TOBACCO YUNNAN IND

A kind of cerium-zirconium composite oxide with high specific surface area and its preparation method and application

ActiveCN110252275BUniform distribution of dopingLarge specific surface areaGas treatmentHeterogenous catalyst chemical elementsCeriumComposite oxide

The present invention provides a high specific surface area cerium-zirconium composite oxide, comprising cerium oxide, zirconium oxide and at least one oxide of rare earth metal elements other than cerium, and the composite oxide is heat-treated at 850°C for 4-8 hours After, having at least 80m 2 / g specific surface area, 0.50~0.60mL / g pore volume, 500~1200μmol O 2 Oxygen storage capacity per gram, and the pore diameter showing a distribution of two pore groups, wherein the diameter of the first pore group is concentrated in the range of 1-8nm, and the diameter of the second pore group is concentrated in the range of 20-60nm. The cerium-zirconium composite oxide provided by the invention has a higher specific surface area and pore volume distribution than the composite oxide prepared by the existing method, shows better low-temperature catalytic activity, and can be used to catalyze hydrocarbons, Carbon oxides and / or nitrogen oxides. The present invention also provides a method for preparing cerium-zirconium composite oxides, which can prepare and obtain composite oxides with more uniform element lattice doping distribution and no phase separation. Research is of great significance.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Low-cost high-performance carrier catalyst and its preparation method

ActiveCN104128173BOvercome doping defectsImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCeriumRare earth

The invention relates to a solid solution, namely a supported catalyst and in particular relates to a low-cost high-performance supported catalyst. The supported catalyst comprises the following chemical components in parts by weight: 10-30 parts of cerium oxide, 10-30 parts of zirconium oxide, 30-50 parts of aluminium oxide and 1-20 parts of other rare earth oxides, wherein other rare earth oxides are mixtures of lanthanum oxide, praseodymium oxide, neodymium oxide, yttrium oxide and samarium oxide. The invention also provides a preparation method of the supported catalyst. The preparation method comprises the steps of mixing all the raw materials, adding surfactants, then adjusting the pH value to 8-10 to obtain a colloidal precipitate, and roasting to obtain the product. The supported catalyst and the preparation method have the advantages that doping defects caused by doping in cerium-zirconium supports are overcome; meanwhile, the performance indexes of the supported catalyst, such as heat stability, aging specific surface area, oxygen storage capacity and the like are greatly improved; the preparation method is low in raw material price and simple in process and is beneficial to large-scale industrial production.

Owner:淄博加华新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com