Nano cerium-zirconium composite oxide and application thereof in catalysis of NOX reduction reaction

A technology of composite oxides and zirconium oxides, applied in the direction of metal/metal oxide/metal hydroxide catalysts, zirconium compounds, catalyst activation/preparation, etc., can solve the problems of catalyst pollutant conversion efficiency, low surface activity, Few active sites, etc., to achieve excellent low-temperature catalytic activity, excellent high-temperature stability, and excellent catalytic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

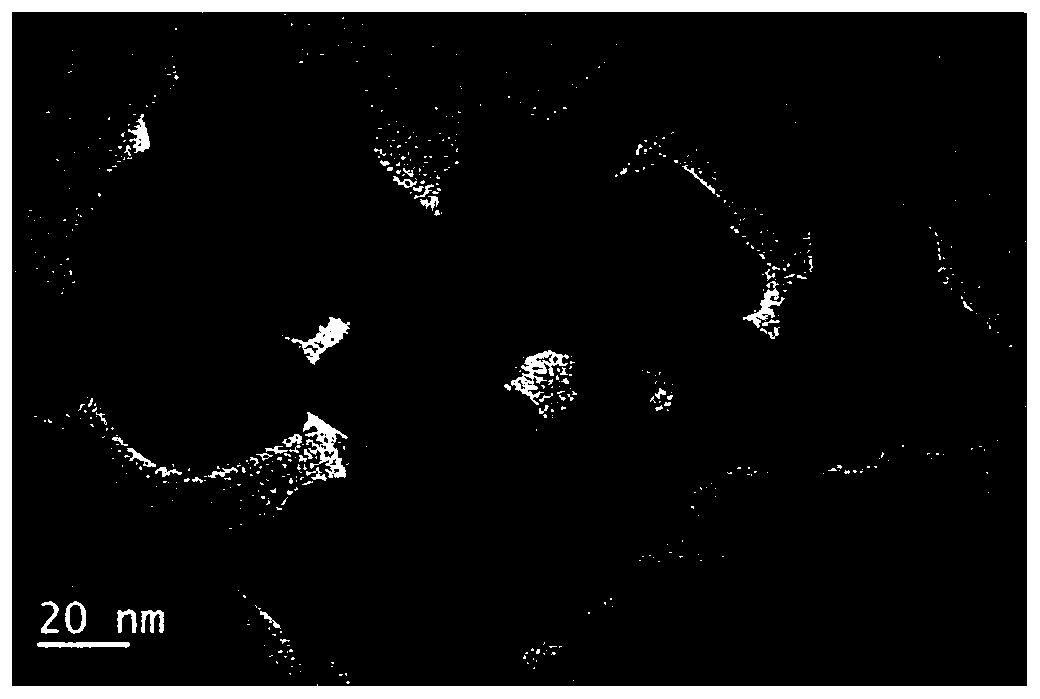

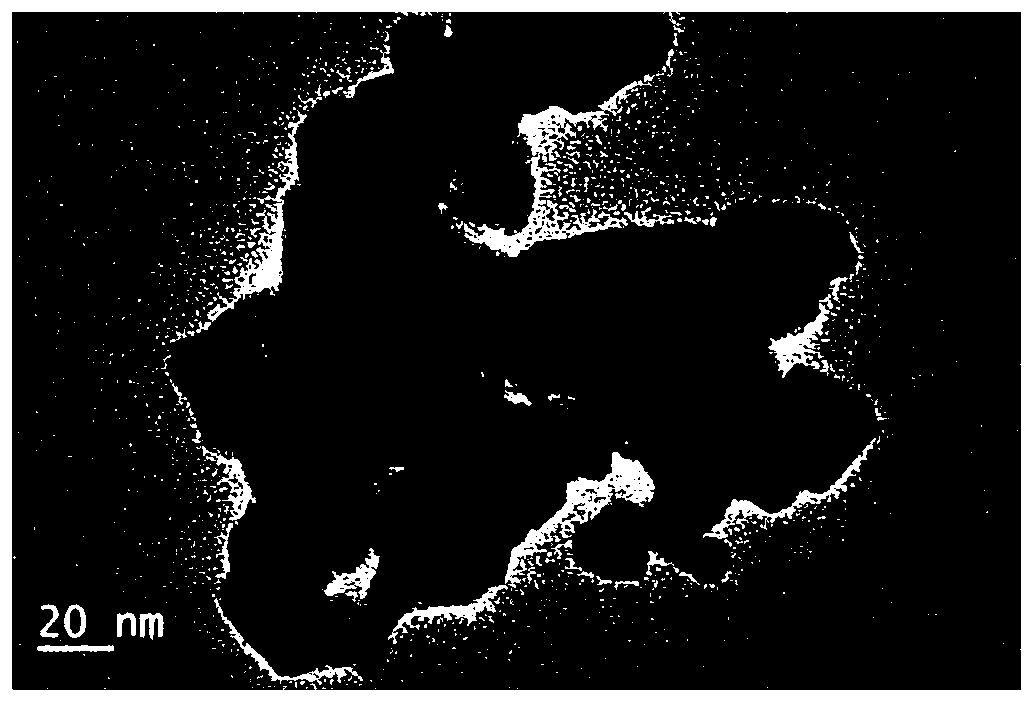

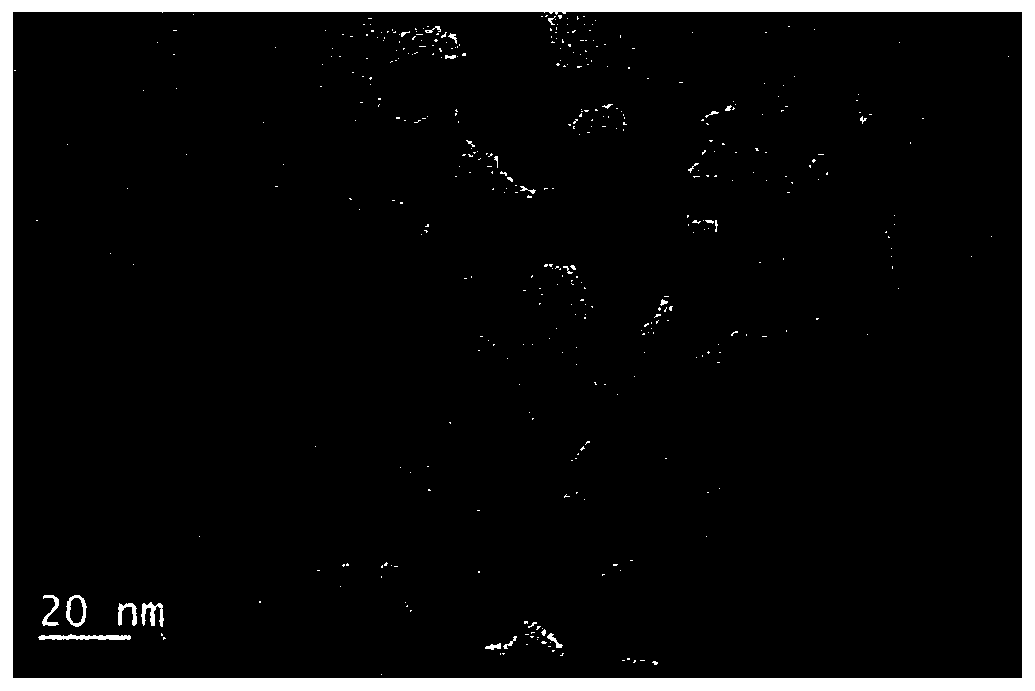

Image

Examples

preparation example Construction

[0051] The embodiment of the present invention provides a preparation method of nano-cerium-zirconium composite oxide, the specific steps include:

[0052] S1, dissolve the salts of cerium, zirconium, lanthanum and praseodymium or yttrium respectively, set the volume to a total concentration of 40-140g / L, stir until clear, and continue to stir at a low speed for 0.5h;

[0053] S2, drop an alkaline precipitant into the above solution, the alkaline precipitant is one or more of ammonia, sodium hydroxide, amines, preferably ammonia, and then adjust the pH of the solution to 1.5- 2;

[0054] S3, introducing the above solution into a high-pressure reactor, and hydrolyzing it at 150° C. for 10-20 hours;

[0055] S4, adding an alkaline precipitant dropwise to the precursor slurry obtained in S3 to adjust the pH to 8-10;

[0056] S5, introducing the precursor slurry obtained in S4 into an autoclave, and performing a hydrothermal reaction at 150° C. for 6-10 hours;

[0057] S6, beat...

Embodiment 1

[0060] Embodiment 1 provides a composition based on cerium oxide, zirconia, lanthanum oxide, and yttrium oxide, and the composition is CeO in proportion by weight of the oxide 2 28%, ZrO 2 62%, La 2 o 3 5%, Y 2 o 3 5%.

[0061] The equipment used in this embodiment is a 10L polytetrafluoro-lined high-pressure reactor, the solution filling degree is 80%, and the total concentration of oxides is 40g / l. Its preparation method is as follows:

[0062] Get 574g of zirconium oxynitrate, 54.2g of yttrium nitrate, dissolve with 2000ml of deionized water until clear to obtain solution A;

[0063] Take 278.5g of ammonium cerium nitrate and 42.7g of lanthanum nitrate into solution A, stir until clear, adjust the pH of solution A to 1.5-1.6 with ammonia water in a water bath at 50°C, set the volume to 8000ml, and introduce In the vinyl fluoride-lined pressure melting bomb, hydrothermal hydrolysis reaction at 150°C for 20 hours, lowered to room temperature and adjusted pH to 9.5-9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com