A kind of preparation method of rare earth compound

A compound, rare earth technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as stability, oxygen storage capacity and insufficient catalytic activity, and achieve low cost and raw material sources. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

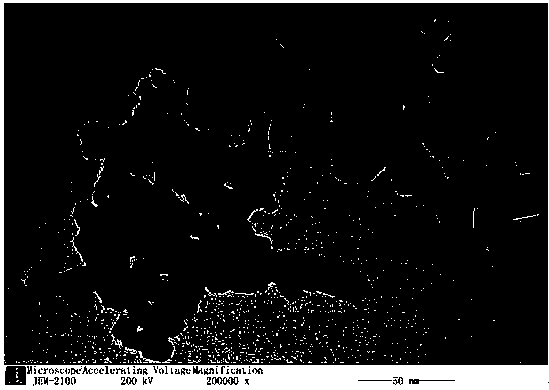

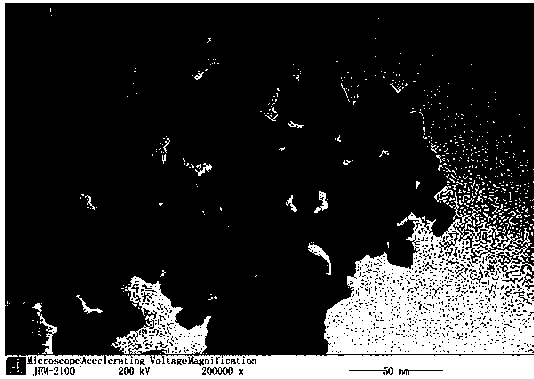

Image

Examples

Embodiment 1

[0031] The present embodiment rare earth complex Ce 0.3 Zr 0.4 La 0.3 o 2 The preparation method specifically comprises the following steps:

[0032] (1) Configure the precursor solution: add 0.3mol of Ce(NO 3 ) 3 ·6H 2 O, 0.4mol of Zr(CH 3 COO) 4 and 0.3molLa(NO 3 ) 3 ·6H 2 O was dissolved in 1 L of water to prepare the precursor solution.

[0033] (2) Adsorption: Add activated carbon (particle size: 400 mesh, specific surface area: 1350㎡ / g) to the precursor solution according to the liquid-solid ratio of 2:1 to adsorb the rare earth ions in the precursor solution, and the adsorption time for 2h.

[0034] (3) Precipitation: Slowly add ammonia water with an ammonia content of 10% to the precursor solution treated in step (2) for precipitation. During the precipitation process, the pH of the solution is controlled to be 8, and the temperature of the solution is 70°C.

[0035] (4) After the precipitation is completed, age at 70°C for 4 hours, then filter, and wash t...

Embodiment 2

[0039] The present embodiment rare earth complex Ce 0.1 Zr 0.5 Yb 0.4 o 2 The preparation method specifically comprises the following steps:

[0040] (1) Configure the precursor solution: add 0.1mol of Ce(NO 3 ) 3 ·6H 2 O, 0.5mol of Zr(CH 3 COO) 4 and 0.4mol of Yb(NO 3 ) 3 ·6H 2 O was dissolved in 1 L of water to prepare the precursor solution.

[0041] (2) Adsorption: Add activated carbon (350 mesh particle size, 1460㎡ / g specific surface area) to the precursor solution at a liquid-solid ratio of 3:1 to adsorb the rare earth ions in the precursor solution, and the adsorption time It is 2.5h.

[0042] (3) Precipitation: Slowly add ammonia water with an ammonia content of 20% to the precursor solution treated in step (2) for precipitation. During the precipitation process, the pH of the solution is controlled to be 10, and the temperature of the solution is 60°C.

[0043] (4) After the precipitation is completed, age at 60°C for 4 hours, then filter, and wash the pr...

Embodiment 3

[0047] The present embodiment rare earth complex Ce 0.4 Zr 0.2 La 0. 2 Yb 0.2 o 2 The preparation method specifically comprises the following steps:

[0048] (1) Configure the precursor solution: add 0.4mol of Ce(NO 3 ) 3 ·6H 2 O, 0.2mol of Zr(CH 3 COO) 4 and 0.2mol of La(NO 3 ) 3 ·6H 2 O 0.2mol of Yb(NO 3 ) 3 ·6H 2 O was dissolved in 1 L of water to prepare the precursor solution.

[0049] (2) Adsorption: Add activated carbon (390 mesh particle size, 1560㎡ / g specific surface area) to the precursor solution at a liquid-solid ratio of 4:1 to adsorb rare earth ions in the precursor solution, and the adsorption time for 3h.

[0050] (3) Precipitation: Slowly add ammonia water with an ammonia content of 25% to the precursor solution treated in step (2) for precipitation. During the precipitation process, the pH of the solution is controlled to be 9, and the temperature of the solution is 65°C.

[0051] (4) After the precipitation is completed, age at 75°C for 3.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com