Liquid-phase CO2 methanation catalyst, preparation method and application of catalyst

A methanation catalyst, CO2 technology, applied in the direction of physical/chemical process catalysts, catalytic reactions, chemical instruments and methods, etc., can solve the problems of catalyst strength decline, catalyst layer erosion, large energy consumption, etc., to prevent aggregation and avoid Easy to fall off at high temperature, realize the effect of recovery and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

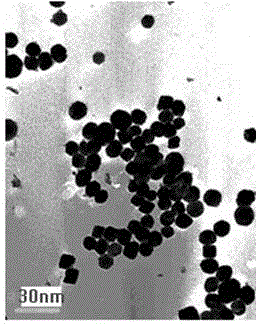

[0028] Mix and disperse nickel nitrate, magnesium nitrate and 1-16 alkyl-3-methylimidazole hydrochloride ionic liquid in the liquid medium water at a molar ratio of 1:0.2:20 at room temperature to obtain a mixed system solution. The concentration of nickel nitrate in the system solution is 2.79×10 -4 mol / L, then add ammonia water to adjust the pH value of the system to 9.0, continue to stir and react for 3h, then transfer the reaction solution to the reactor at 150 o C. Pass H under 3.0MPa 2 Reduction for 2 hours, finally centrifuged, filtered, washed with water, washed with ethanol, and dried. Tested by TEM, see figure 1 . Depend on figure 1 It can be seen that the liquid phase CO 2 The average particle size of the metal active component nanoparticles in the methanation catalyst is 11.8nm, and the particle size distribution is narrow and uniform.

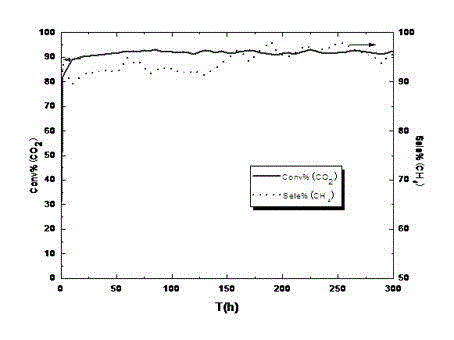

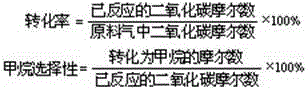

[0029] Using the above catalysts for CO 2 The methanation reaction is specifically: take an appropriate amount of the abov...

Embodiment 2

[0031]At room temperature, nickel acetate, lanthanum nitrate and 1-18 alkyl-3-methylimidazolium hexafluorophosphate ionic liquid were mixed and dispersed in the liquid medium ethanol at a molar ratio of 1:0.15:20 to obtain a mixed system solution. The molar concentration of nickel acetate is 3.61×10 -4 mol / L, then add triethylamine to adjust the pH value of the system to 8.0, continue to stir and react for 2h, then transfer the reaction solution to the reactor at 100 o C. Inject H under 3.0MPa pressure 2 Reduction for 1.5h, finally centrifuged, filtered, washed with water, washed with ethanol, and dried.

[0032] Using the above catalysts for CO 2 The methanation reaction is specifically: take an appropriate amount of the above-mentioned catalyst and add it to the reactor, then add an appropriate amount of solvent water, and control the concentration of the catalyst in the reaction system to be 0.005mol / L. According to nH 2 : nCO 2 =4, pass into CO 2 and H 2 , then heate...

Embodiment 3

[0034] Nickel nitrate, cerium nitrate and amphiphilic ionic liquid N-dodecylpyridinium tetrafluoroborate (C 12 PyB 4 ) in a molar ratio of 1:0.15:18 and mixed and dispersed in liquid medium acetonitrile to obtain a mixed system solution, the concentration of nickel nitrate in the mixed system being 1.32×10 -3 mol / L, then add diisopropyl tert-butylamine to adjust the pH value of the system to 10.0, continue to stir and react for 3h, then transfer the reaction solution to the reactor at 150 o C. Inject H under 3.0MPa pressure 2 Reduction for 1.5h, finally centrifuged, filtered, washed and dried.

[0035] Using the above catalysts for CO 2 The methanation reaction is specifically: take an appropriate amount of the above-mentioned catalyst and add it to the reaction kettle, then add an appropriate amount of solvent acetonitrile, and control the concentration of the catalyst in the reaction system to be 0.005mol / L, according to nH 2 : nCO 2 =4, pass into CO 2 and H 2 , then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com