A Novel Photocatalyst Controllable Preparation Method Based on Inorganic Ligand Modification

A photocatalyst and inorganic ligand technology, applied in the field of controllable preparation of new photocatalysts, can solve the problems of hindered reaction and activation, low catalytic activity of perovskite, lack of catalytic activation, etc., to facilitate large-scale industrial production, improve Stability and catalytic activity, effect of improving preparation purity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

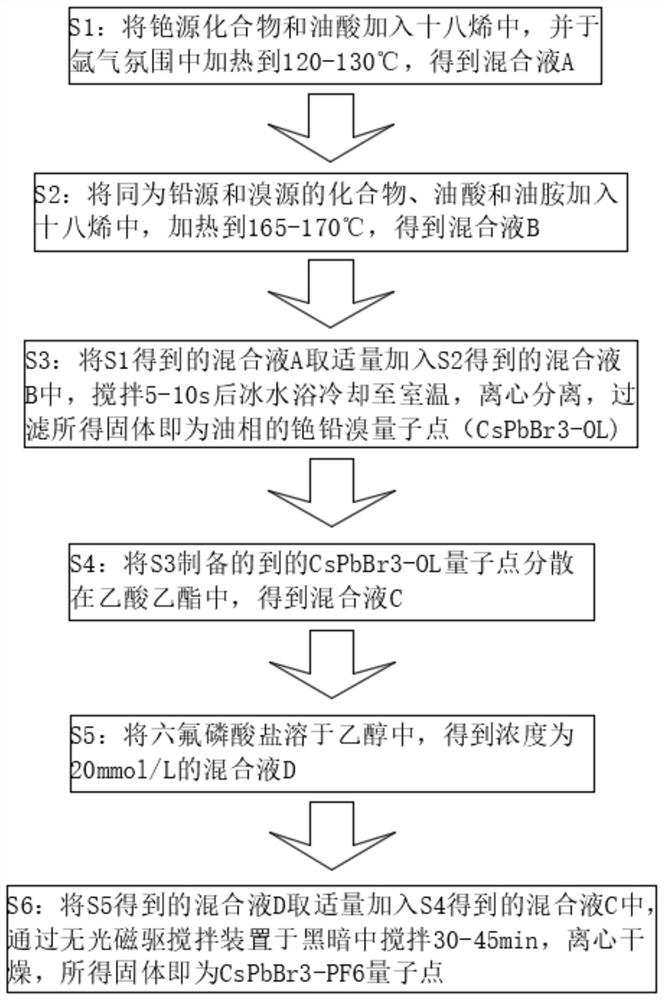

[0049] see figure 1 , add cesium carbonate and oleic acid to octadecene, the ratio is 3.07mmol: 6mL: 40mL, and heat to 120°C in an argon atmosphere to obtain a mixed solution A, take lead bromide, oleic acid and oleylamine and add ten In octacene, the ratio is 1.88mmol: 5mL: 5mL: 50mL, heated to 165°C to obtain mixed solution B, add an appropriate amount of mixed solution A to mixed solution B, stir for 5s, cool to room temperature in an ice-water bath, centrifuge and filter The obtained solid is cesium lead bromine quantum dots (CsPbBr3-OL) in the oil phase. Weigh 5 mg of the prepared oil phase cesium lead bromine quantum dots, disperse them in 5 mL of ethyl acetate, and then add 40 μL, 20 mM ethanol-soluble Ammonium hexafluorophosphate, stirred in the dark for 30 minutes; centrifuged, dried in the air to obtain a yellow solid powder, which is CsPbBr3-PF6 quantum dots.

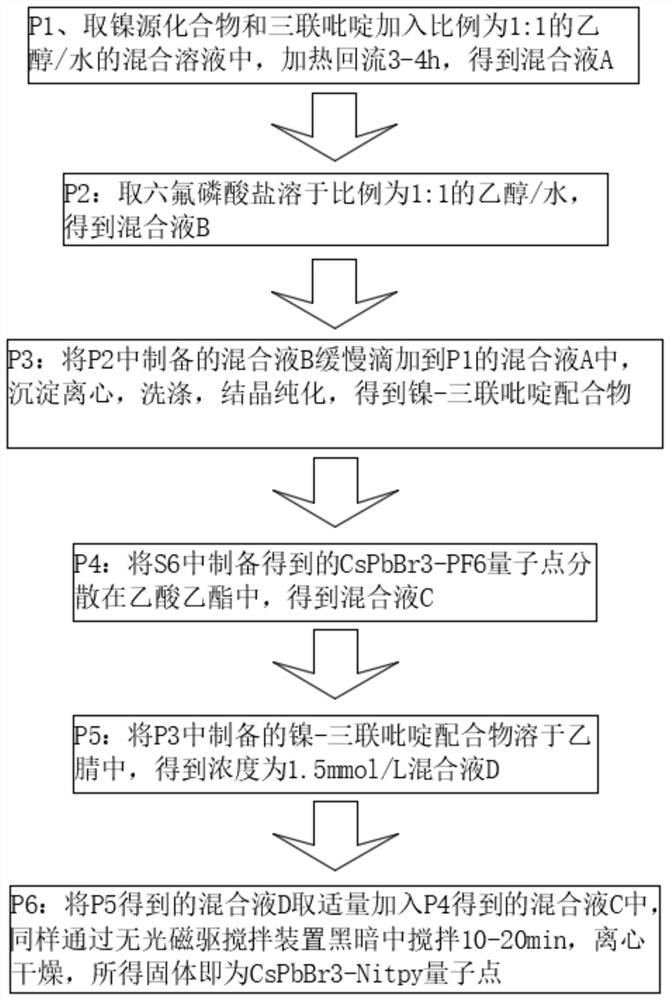

[0050] see figure 2 , take by weighing nickel chloride hexahydrate 30.90mg (0.13mmol), terpyridine 60.6...

Embodiment 2

[0055] CsPbBr3-PF6 quantum dot catalyst for photocatalytic reduction of carbon dioxide:

[0056] Weigh 5 mg of CsPbBr3-PF6 quantum dots prepared in Example 1 and dissolve them in 5 mL of ethyl acetate, add 30 μL of deionized water, transfer them to a 30 mL reactor, use a 300W xenon lamp as the light source, and simulate sunlight for photocatalytic carbon dioxide For the reduction experiment, samples were taken regularly, and the content of carbon monoxide and methane produced was analyzed by gas chromatography.

Embodiment 3

[0058] CsPbBr3-NitPy catalyst for photocatalytic reduction of carbon dioxide:

[0059] Weigh 5 mg of CsPbBr3-NitPy quantum dots prepared in Example 1, dissolve them in 5 mL of ethyl acetate, add 30 μL of deionized water, transfer them to a 30 mL reactor, use a 300W xenon lamp as the light source, and simulate sunlight for photocatalytic carbon dioxide For the reduction experiment, samples were taken regularly, and the content of carbon monoxide and methane produced was analyzed by gas chromatography.

[0060] see Figure 5 , when CsPbBr3-NitPy catalyst is used for photocatalytic reduction of carbon dioxide compared with CsPbBr3-PF6 quantum dots and CsPbBr3, the content of carbon monoxide and methane produced is significantly improved. The improvement and surface reconstruction, that is, the simultaneous realization of inorganic ligand modification and catalyst anchoring, increased the catalytic activity of the obtained composite for photocatalytic reduction of carbon dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com