Sliver-based bimetallic catalyst for catalyzing oxidation of volatile organic contaminant, preparation method and application thereof

A bimetallic catalyst, a volatile organic technology, is applied in the field of the preparation of a supported nano-silver-based bimetallic catalyst, and can solve the problems of contacting the human body, high toxicity, human health hazards, etc., and achieves a simple preparation method, stable structure, and cheap raw materials. easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

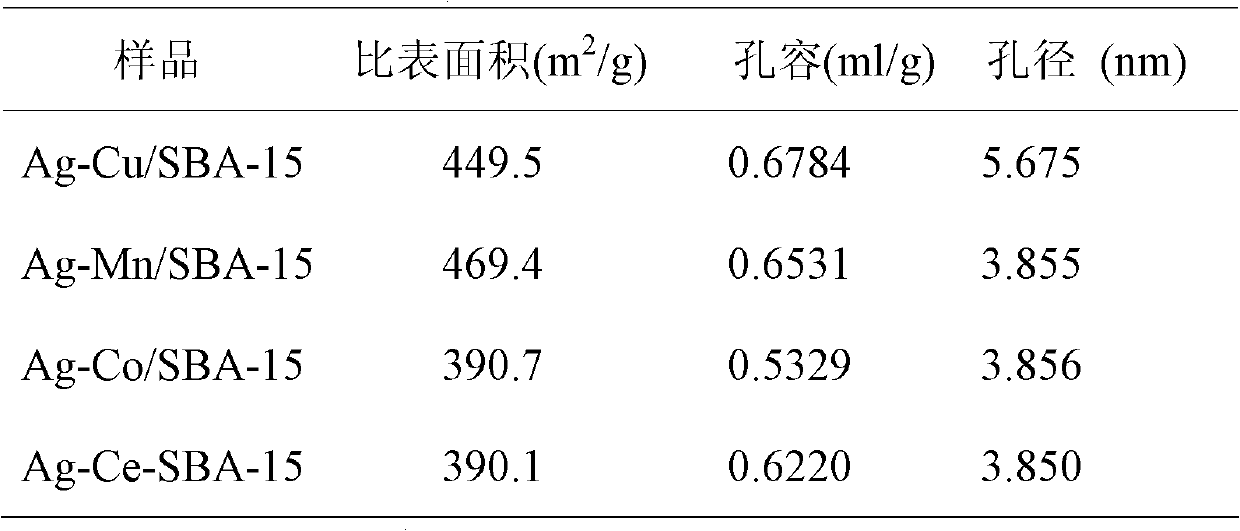

[0031] Taking copper as the second active component and SBA-15 as the carrier as an example, the preparation method is as follows: add 0.0945g of silver nitrate and 0.2281g of copper nitrate into 5ml of deionized water at the same time, and stir to fully dissolve them. Add 1g of SBA-15 into the above mixed solution while stirring, continue to stir for a period of time, then let it stand, and continue to stir after 15 minutes to make the metal distribution as even as possible. The sample was left to stand overnight at room temperature and then dried at 100° C. for 24 hours to obtain a bimetallic catalyst sample with Ag:Cu=1:1. Sieve the dried catalyst into 20-40 mesh size particles for later use.

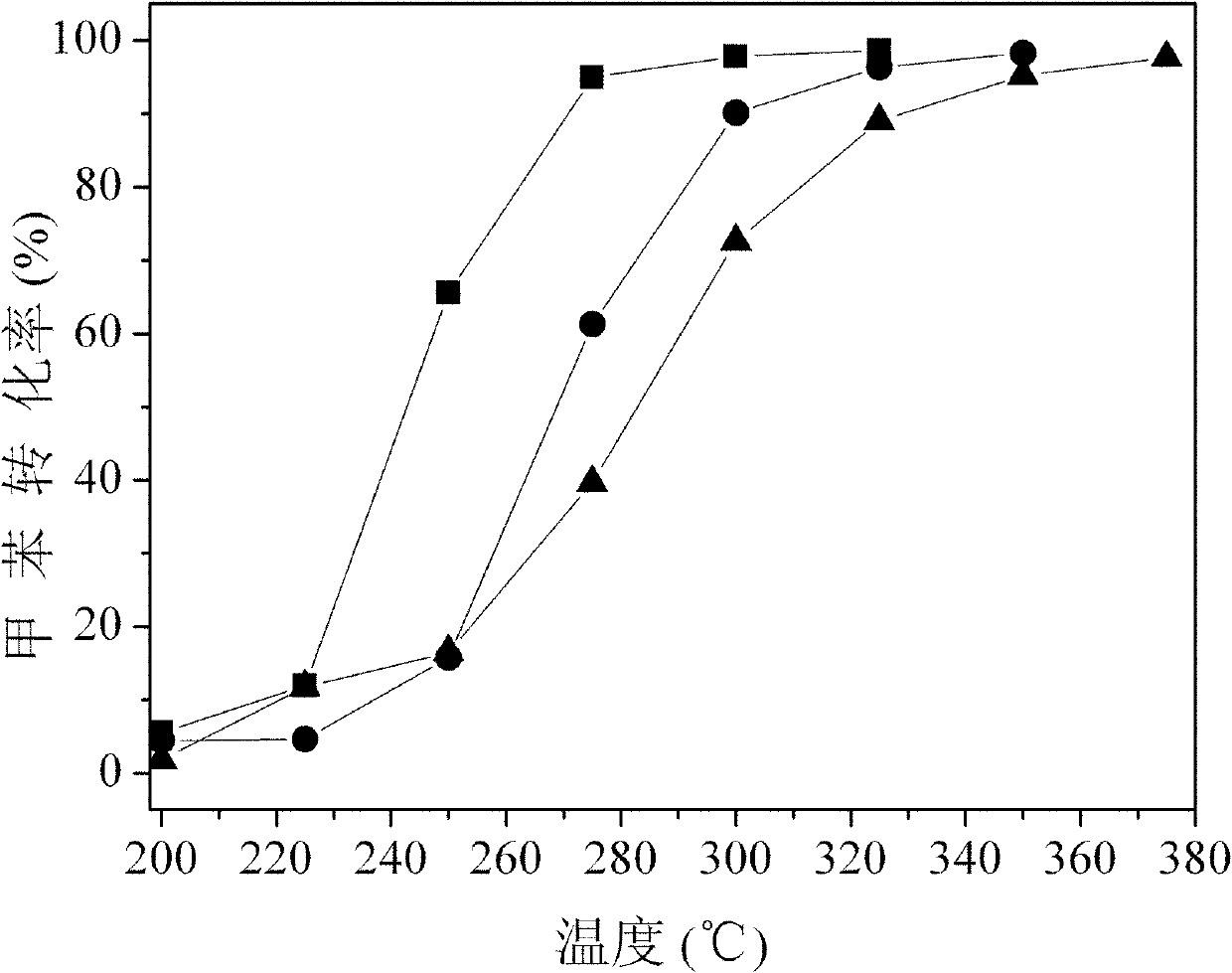

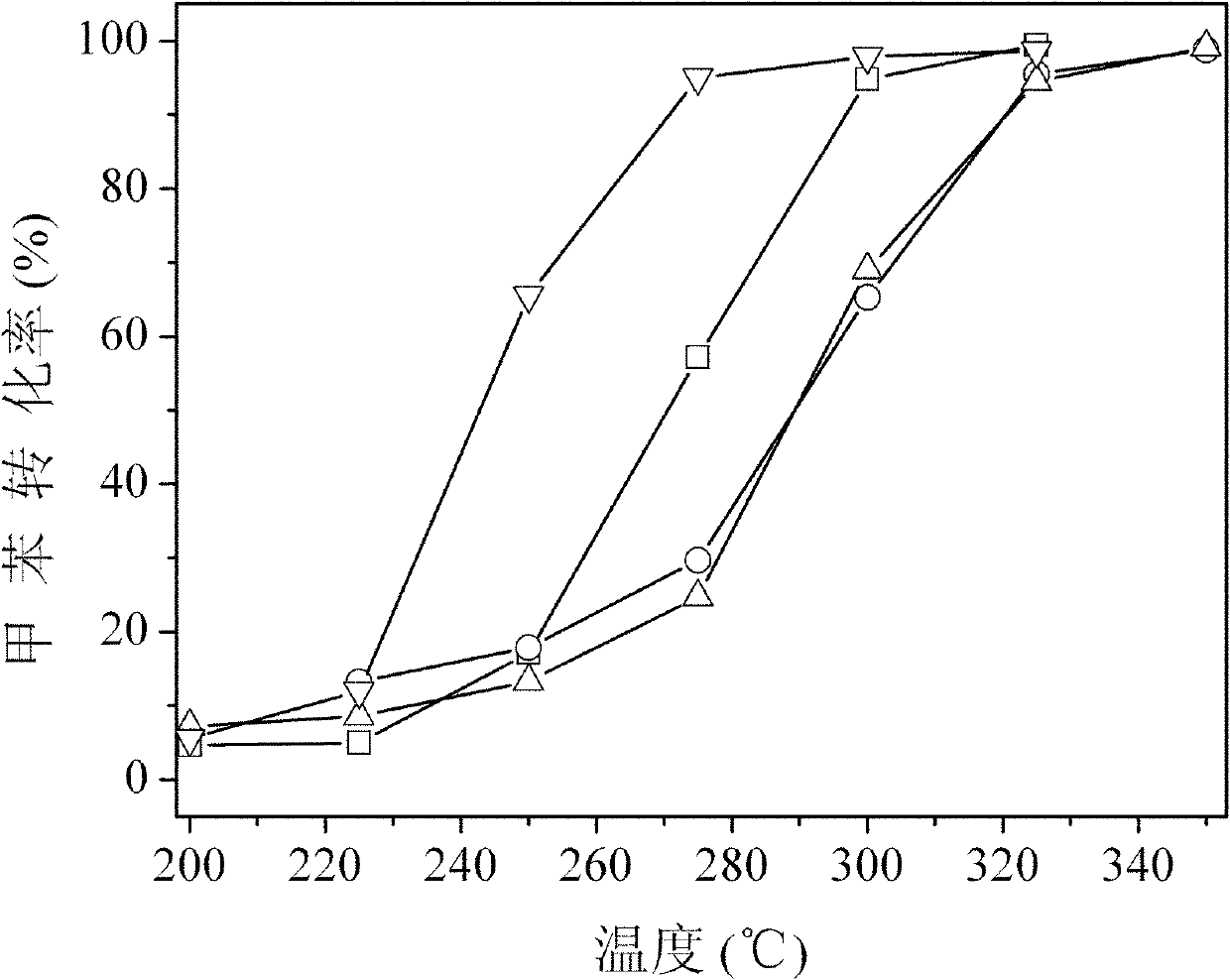

[0032] The activity evaluation of the catalyst was carried out in a U-shaped tubular fixed-bed continuous flow differential reactor. The reactor was a U-shaped quartz reaction tube with an inner diameter of 8 mm. 100-300 mg of catalyst was loaded into the reaction tube and pretreated...

Embodiment 2

[0034] Taking copper as the second active component and SBA-15 as the carrier as an example, the preparation method is as follows: 0.1890g of silver nitrate is added to 5ml of deionized water to obtain a bimetallic catalyst sample of Ag:Cu=1:0. The activity of the catalyst was measured on the device described in the above-mentioned Example 1, and the conversion rate of the catalyst at 290-310° C. to toluene could reach more than 90%.

Embodiment 3

[0036] According to the preparation method of the present invention in Example 1, 0.4563 g of silver nitrate was separately added to 5 ml of deionized water to obtain a Cu / SBA-15 catalyst with Ag:Cu=0:1. The activity of the catalyst was measured on the device described in the above-mentioned Example 1, and the conversion rate of the catalyst at 320-340° C. to toluene could reach more than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com