Lead poisoning resistant Fe-Mn-Ce/titanium-containing blast furnace slag denitration catalyst

A denitrification catalyst, fe-mn-ce technology, applied in the field of low-temperature SCR flue gas denitrification, achieves the effect of low acid consumption, low purification and separation requirements, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

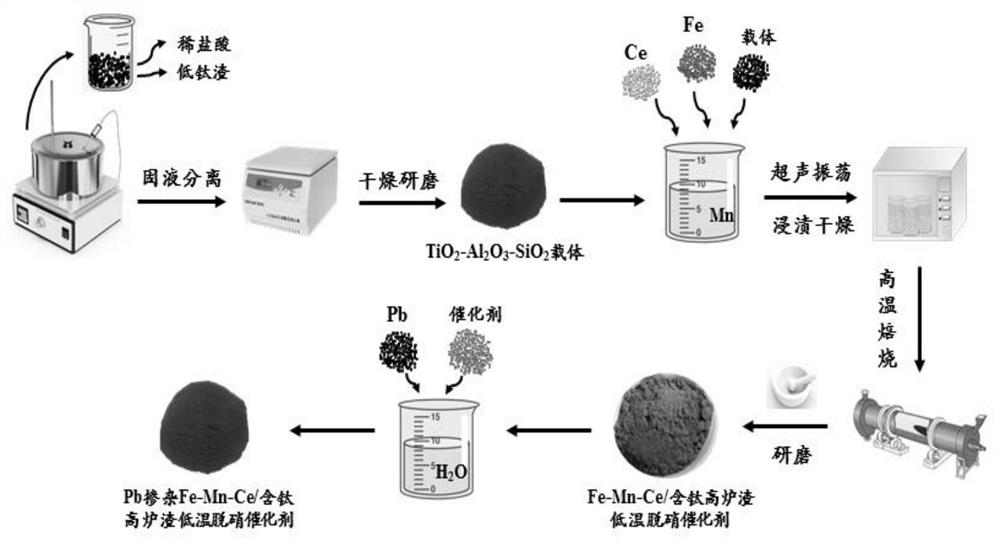

[0024] Low-titanium blast furnace slag (from the Panzhihua Iron and Steel Region in western China) was treated with dilute hydrochloric acid with a concentration of 2 mol / L and a mass fraction of 37 wt%, and fully reacted at a constant temperature of 30°C for 2 hours. Subsequently, a centrifuge at 800r / min was used for solid-liquid separation, and the solid component was repeatedly washed with pure water until it was neutral, then dried at 80°C for 12 hours, and ground to powder. The main chemical components of the original titanium slag and acid leaching residue are shown in Table 1.

[0025] The composition of former titanium slag and acid leaching residue in table 1 embodiment of the present invention

[0026]

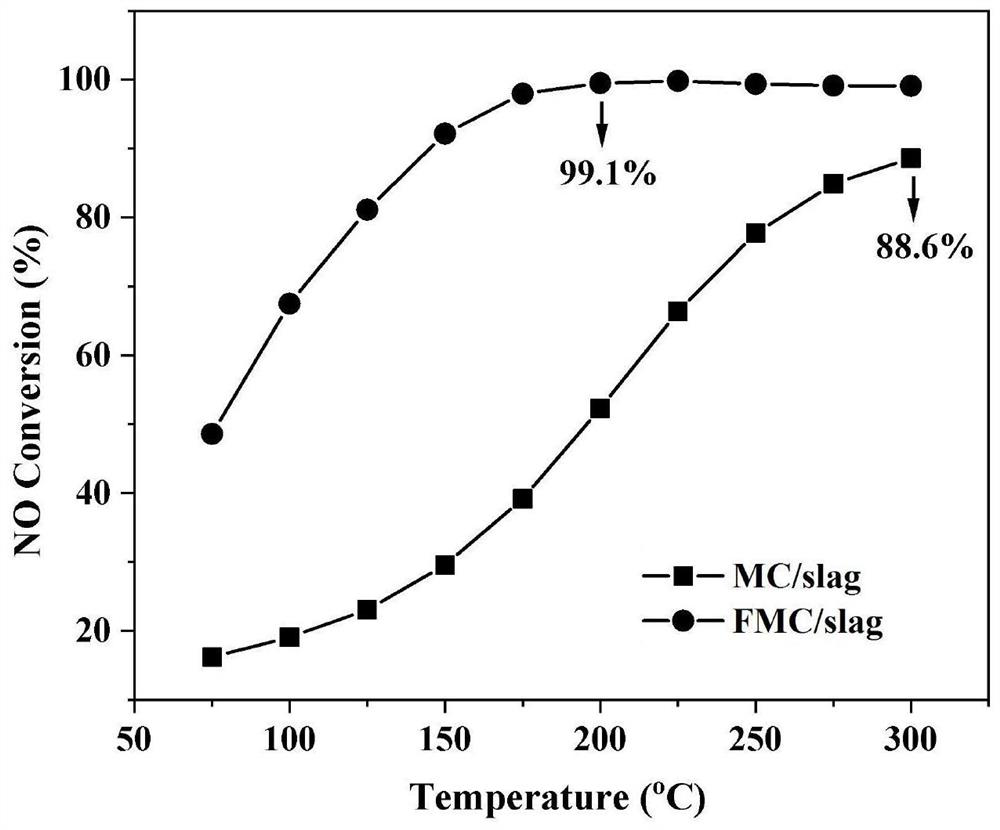

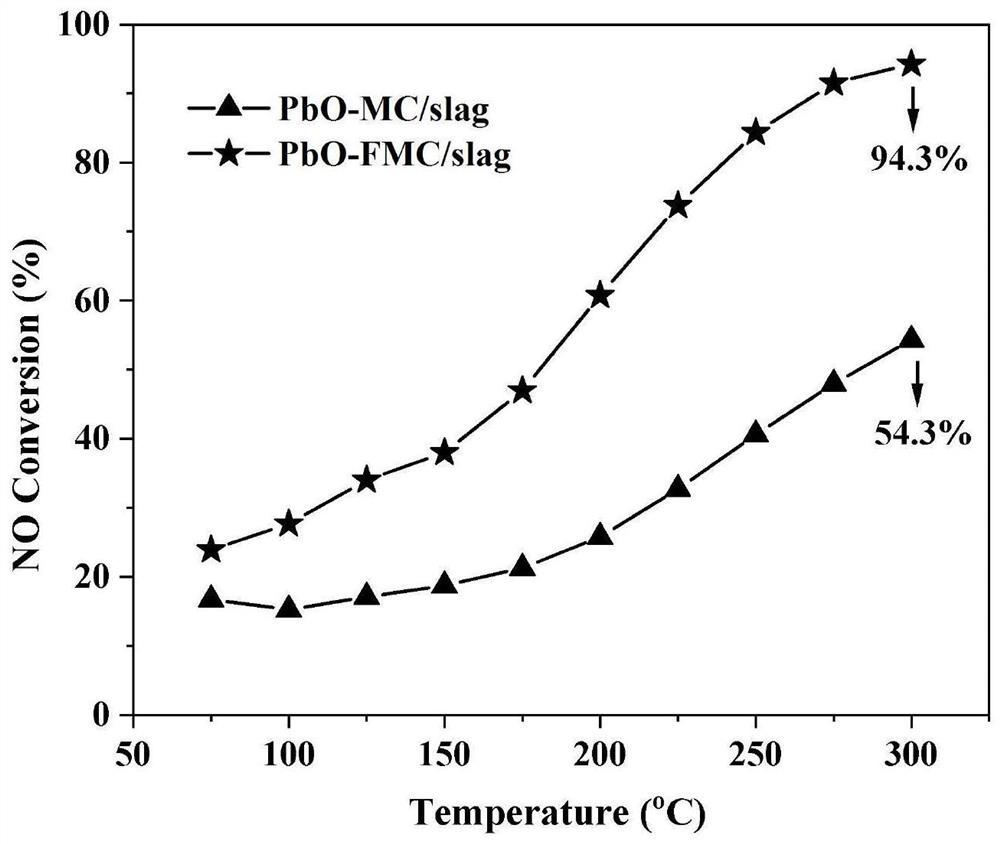

[0027] Preparation of Fe-Mn-Ce / titanium-containing blast furnace slag low-temperature denitrification catalyst by impregnation method. First, account for 15wt% of the carrier according to the total mass of manganese and cerium oxides, weigh 8.08g iron nitrate no...

Embodiment 2

[0030] The preparation method of original titanium slag and acid leaching slag carrier (titanium-containing blast furnace slag composite carrier) is the same as that in Example 1. Preparation of Fe-Mn-Ce / titanium-containing blast furnace slag low-temperature denitrification catalyst by impregnation method. First, account for 15wt% of the carrier according to the total mass of manganese and cerium oxides, weigh 4.04g iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), 2.17g cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O), 4.65mL manganese nitrate solution (Mn(NO 3 ) 2 and 17.33g of acid leaching residue carrier, mixed in 100mL of distilled water and stirred for 10min, then ultrasonically oscillated for 30min. , so that the raw materials used are fully stirred and evenly dispersed in the solution. Then, put it in an 80°C water bath and stir evenly until the water is completely evaporated to dryness, then transfer it to an 80°C drying oven for 24 hours, and finally put the sa...

Embodiment 3

[0033] The preparation method of the carrier (titanium-containing blast furnace slag composite carrier) of the original titanium slag and the acid leaching residue is the same as in Example 1. Preparation of Fe-Mn-Ce / titanium-containing blast furnace slag low-temperature denitrification catalyst by impregnation method. First, account for 20wt% of the carrier according to the total mass of manganese and cerium oxides, weigh 8.08g iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), 2.17g cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O), 4.65mL manganese nitrate solution (Mn(NO 3 ) 2 and 13.01g of acid leaching residue carrier, mixed in 100mL of distilled water and stirred for 10min, then ultrasonically oscillated for 30min. , so that the raw materials used are fully stirred and evenly dispersed in the solution. Then, put it in an 80°C water bath and stir evenly until the water is completely evaporated, then transfer it to an 80°C drying oven for 24 hours, and finally put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com