Low-temperature water-resistant SCR denitration catalyst and preparation method thereof

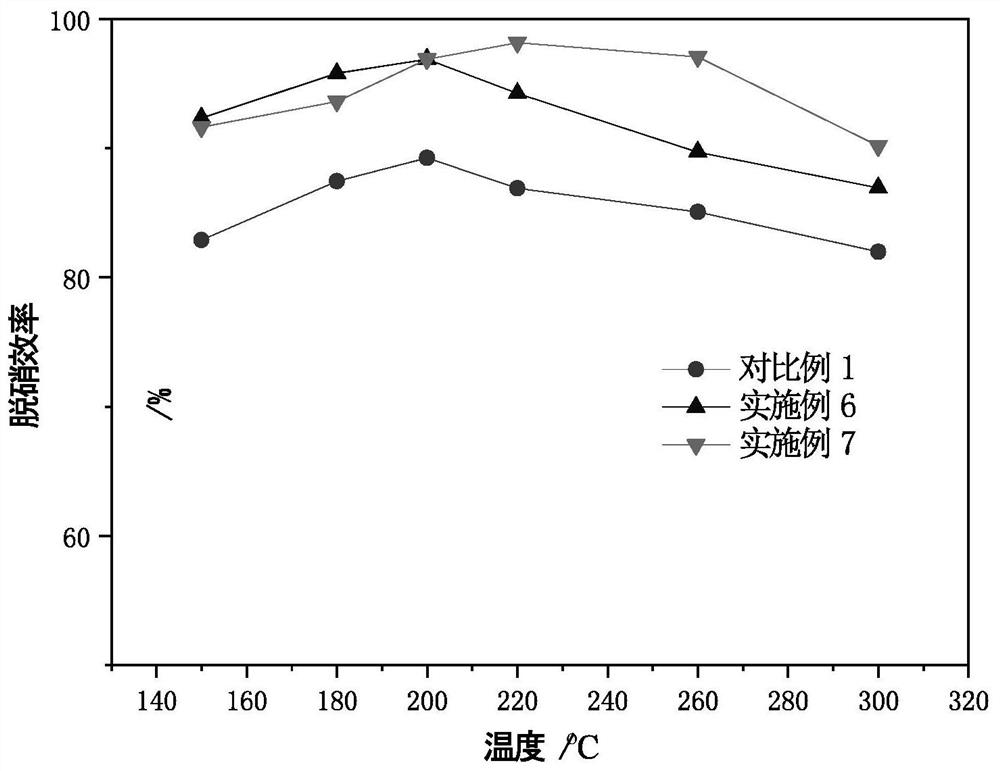

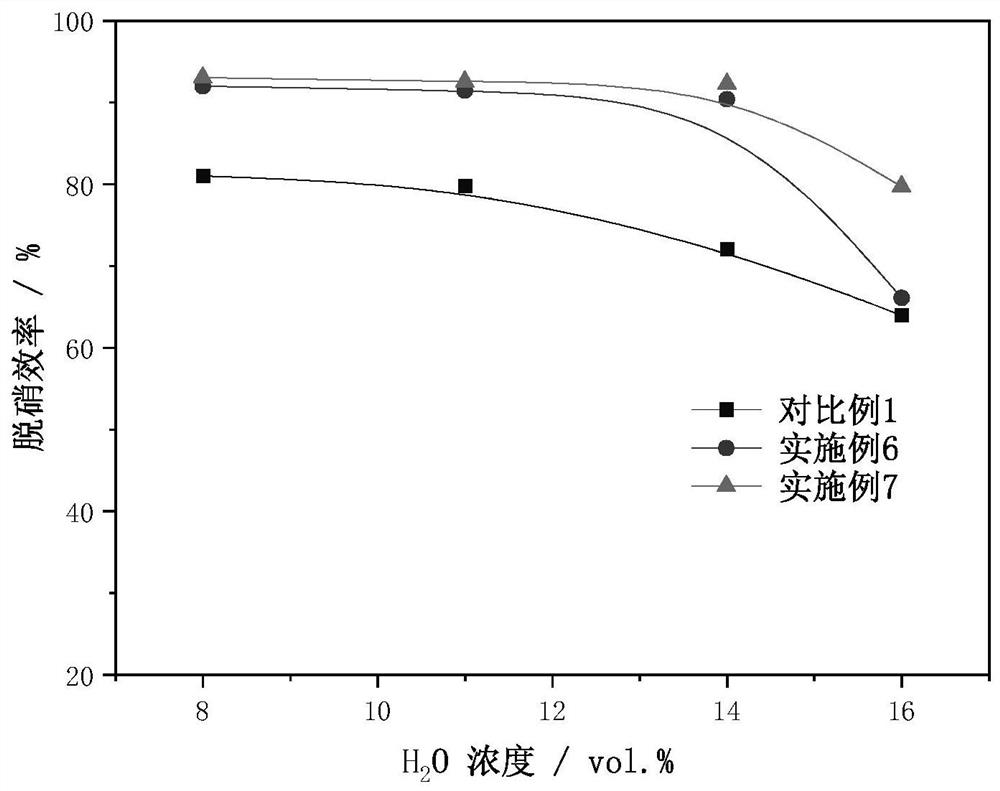

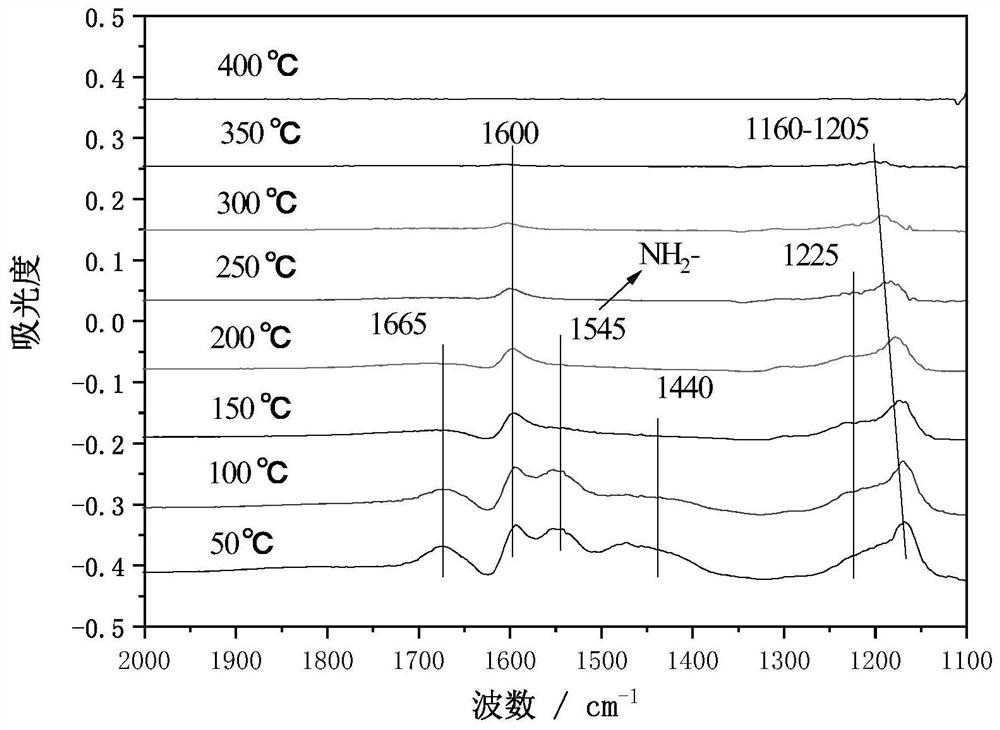

A denitrification catalyst and low-temperature technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of manganese-based catalysts, such as poor sulfur resistance and water resistance, and cannot be truly applied in the field of denitrification treatment. The effect of operation, low activation temperature, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a low-temperature water-resistant SCR denitration catalyst, comprising the following steps:

[0028] (1) Take by weighing 4.5kg titanium dioxide, 0.147kg manganese nitrate, 0.011kg holmium acetate, 0.016kg cerium nitrate, 0.216kg iron nitrate by stoichiometric ratio;

[0029] (2) Add the weighed manganese nitrate, holmium acetate, cerium nitrate, and ferric nitrate into 200mL deionized water, stir at 20°C for 20min at a speed of 40r / min, and then ultrasonically mix at a frequency of 20kHz to obtain activity component mixture;

[0030] (3) Add 1800mL of deionized water to the titanium dioxide and continue to stir. After 1 hour of mixing, a uniform titanium dioxide mud mass is obtained;

[0031] (4) Slowly pour the active component mixture into the titanium dioxide mud mass, stir at a rate of 40r / min for 3h, add glass fiber, kapok, carboxymethyl cellulose, glycerin successively, continue to stir for 0.5h, and let it stand 12h, control the mass rat...

Embodiment 2

[0036] A method for preparing a low-temperature water-resistant SCR denitration catalyst, comprising the following steps:

[0037] (1) Take by weighing 4.5kg titanium dioxide, 5.02kg manganese acetate, 0.267kg holmium nitrate, 0.110kg cerium oxide, 0.419kg cobalt nitrate by stoichiometric ratio;

[0038] (2) Add the weighed manganese acetate, holmium nitrate, cerium oxide, and cobalt nitrate into 600mL deionized water, stir at 30°C for 30min at a speed of 120r / min, and then ultrasonically mix at a frequency of 60kHz to obtain the active group sub-mixture;

[0039] (3) Add 1200mL deionized water to the titanium dioxide and continue to stir. After 3 hours of mixing, a uniform titanium dioxide mud mass is obtained;

[0040] (4) Slowly pour the active component mixture into the titanium dioxide mud mass, stir at a rate of 120r / min for 5h, add glass fiber, kapok, carboxymethyl cellulose, glycerin successively, continue to stir for 2h, then let stand for 24h , control the mass rat...

Embodiment 3

[0045] A method for preparing a low-temperature water-resistant SCR denitration catalyst, comprising the following steps:

[0046] (1) Take by weighing 4.5kg titanium dioxide, 0.937kg manganese monoxide, 0.010kg holmium oxide, 0.028kg cerium nitrate, 0.085kg copper nitrate by stoichiometric ratio;

[0047] (2) Add the weighed manganese monoxide, holmium oxide, cerium nitrate, and copper nitrate into 400mL deionized water, stir at 25°C for 25min at a speed of 80r / min, and then ultrasonically mix at a frequency of 40kHz to obtain activity component mixture;

[0048] (3) Add 1500mL deionized water to the titanium dioxide and continue to stir. After 2 hours of mixing, a uniform titanium dioxide mud mass is obtained;

[0049] (4) Slowly pour the active component mixture into the titanium dioxide mud mass, stir for 4 hours at a rate of 80r / min, add glass fiber, kapok, carboxymethyl cellulose, glycerin successively, continue to stir for 1.2 hours, and let it stand 18h, control the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com