Nitrogen/sulphur/chlorine co-doped multistage hole carbon catalyst and preparation method thereof

A carbon catalyst and co-doping technology, which can be used in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Harsh and other problems, to achieve the effect of increased yield, simple preparation method, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

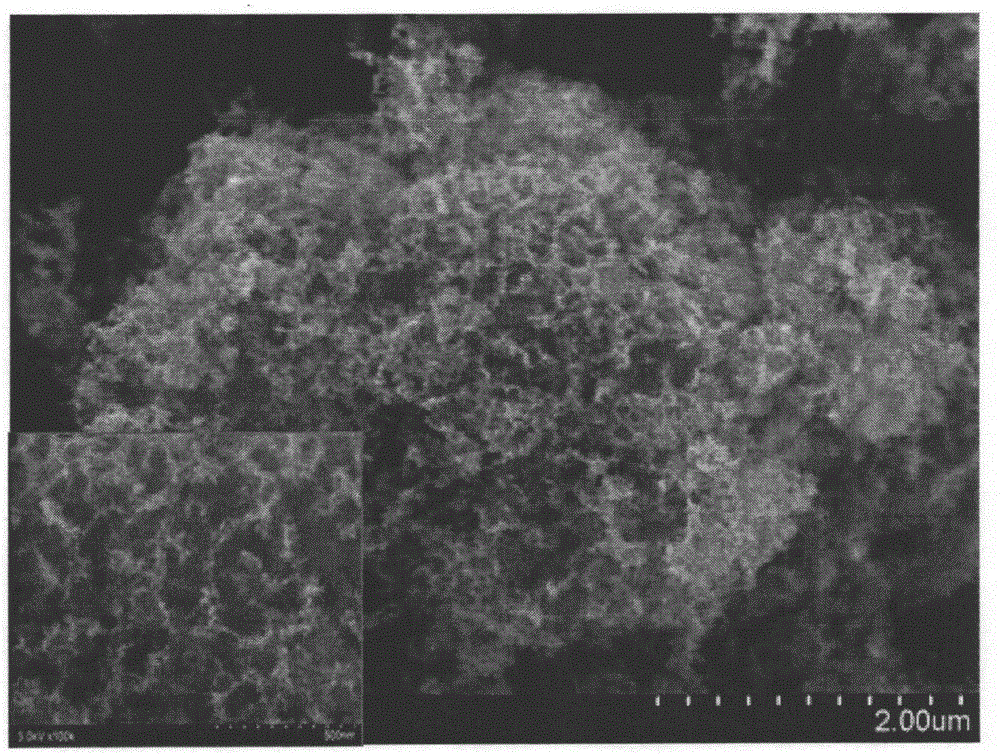

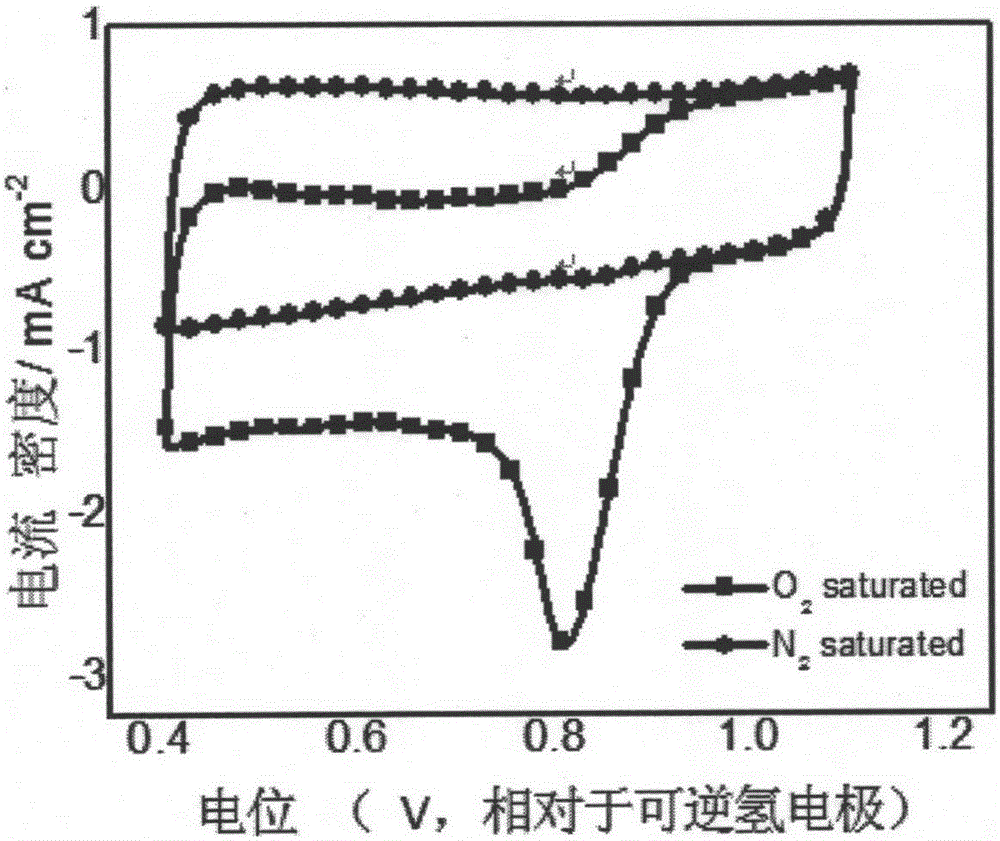

[0037] A nitrogen / sulfur / chlorine co-doped hierarchical porous carbon catalyst obtained by processing a precursor, the precursor comprising 39.6% by mass of silicon dioxide powders with different particle sizes and 21.6% by mass Nitrogen-containing and chlorine-containing high polymer [polyquaternized (bis(2-chloroethyl) ether-alt-1,3-bis[3-(dimethylamino)propyl]urea, referred to as: PQ-2, Sigmaaldrich company] and mass content are the transition metal salt ferrous sulfate of 38.8%.Above-mentioned mass content is based on the total mass of precursor.Described processing comprises roasting reduction treatment for the first time, alkali cleaning treatment, pickling treatment and The second roasting reduction treatment.

[0038] The preparation of the nitrogen / sulfur / chlorine co-doped hierarchical porous carbon catalyst is: PQ-2, the particle size is 15nm, 100nm, 500nm silicon dioxide powder and FeSO4 7H 2 O is configured with 1 mole per liter of hydrochloric acid to form a PQ-2...

Embodiment 2

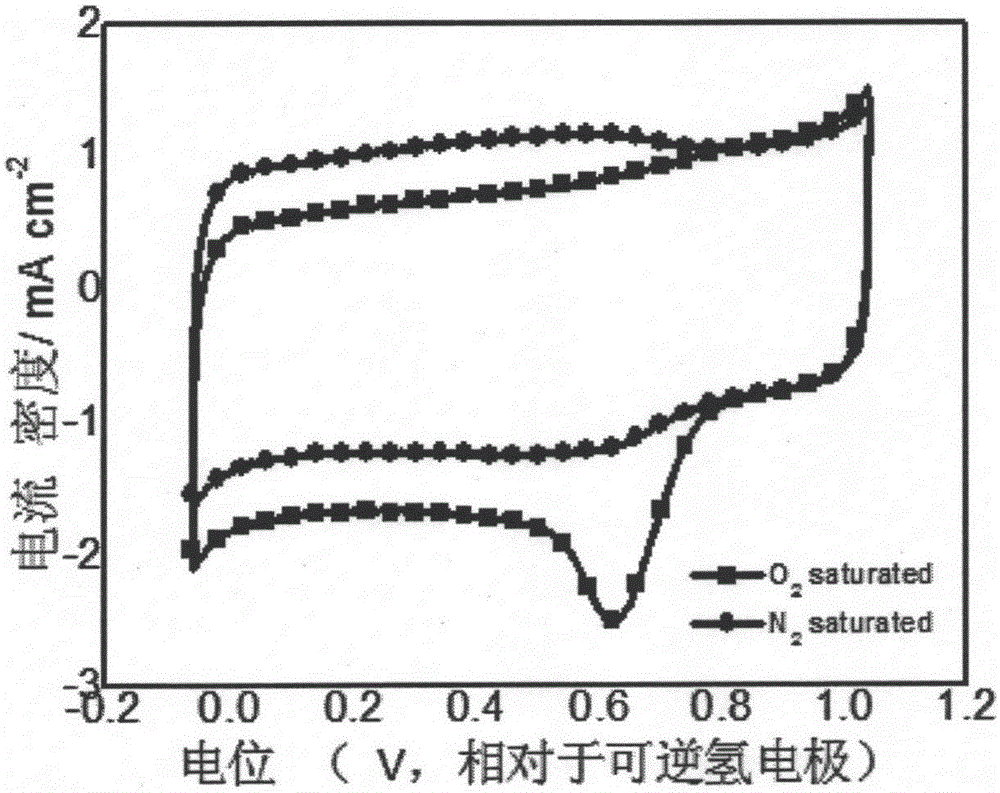

[0041] A nitrogen / sulfur / chlorine co-doped hierarchical porous carbon catalyst obtained by processing a precursor, the precursor comprising a mass content of 39.6% and a particle size of 500nm silicon dioxide powder, a mass content of 21.6% % nitrogen-containing, chlorine-containing high polymer [polymer of chlorinated-1-vinyl-3-methyl-1H-imidazole and 1-vinyl-2-pyrrolidone, referred to as: LFC, Sigmaaldrich company] and mass content 38.8 % transition metal salt ferrous sulfate. The above mass content is based on the total mass of the precursor. The treatment includes the first roasting reduction treatment, alkali washing treatment, pickling treatment and the second roasting reduction treatment.

[0042] The preparation of the nitrogen / sulfur / chlorine co-doped hierarchical porous carbon catalyst is as follows: LFC, silica powder and FeSO 4 ·7H 2 O is respectively configured with 1 mole per liter of hydrochloric acid to form LFC solution with mass fraction of 5%, SiO with 14...

Embodiment 3

[0045] A nitrogen / sulfur / chlorine co-doped hierarchical porous carbon catalyst obtained by processing a precursor, the precursor comprising 39.6% by mass content and a diameter of 500nm silicon dioxide powder, with a mass content of 21.6% The nitrogen-containing, chlorine high polymer [poly(diallyl dimethyl ammonium chloride, referred to as: PDC, Sigmaaldrich company)] and the transition metal salt ferrous sulfate with a mass content of 38.8%. The above mass content is based on the total mass of the precursor. The treatment includes the first roasting reduction treatment, alkali washing treatment, pickling treatment and the second roasting reduction treatment.

[0046] The preparation of the nitrogen-sulfur / chlorine co-doped hierarchical porous carbon catalyst is as follows: PDC with a particle size of 500nm silica powder and FeSO 4 ·7H 2 O is respectively configured with 1 mole per liter of hydrochloric acid to form 5% PDC solution and 14% SiO 2 solution and 30% ferrous su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com