Catalyst for preparing 1,2-glycol by epoxy compound through hydration as well as preparation method and application thereof

A technology of epoxy compounds and catalysts, which is applied in the direction of physical/chemical process catalysts, hydrolysis preparation, molecular sieve catalysts, etc., can solve the problems of high energy consumption, high water ratio, etc., and achieve the effect of low cost, simple preparation process and strong acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

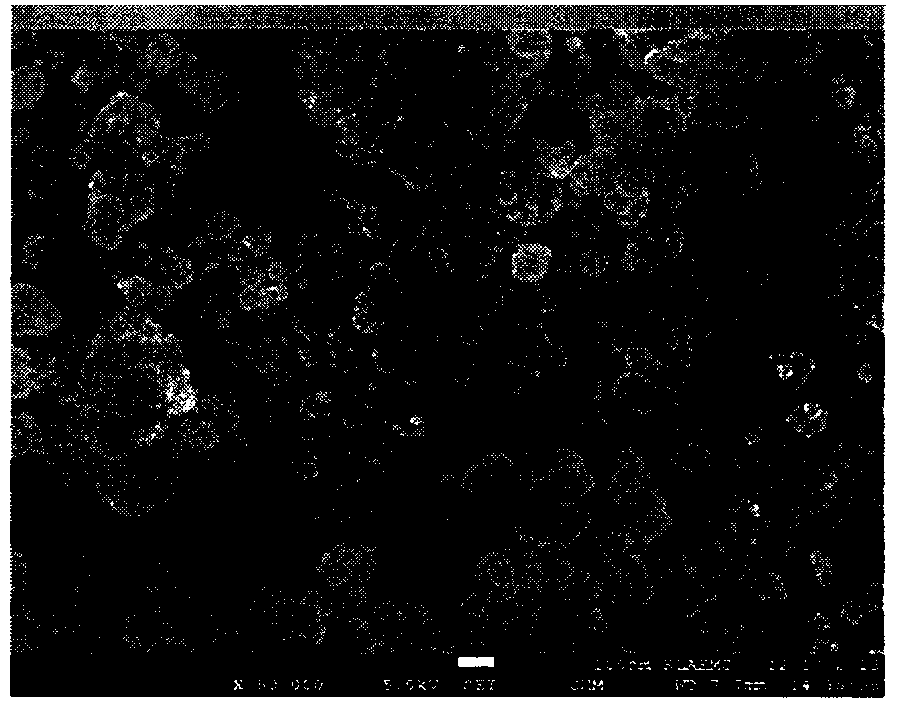

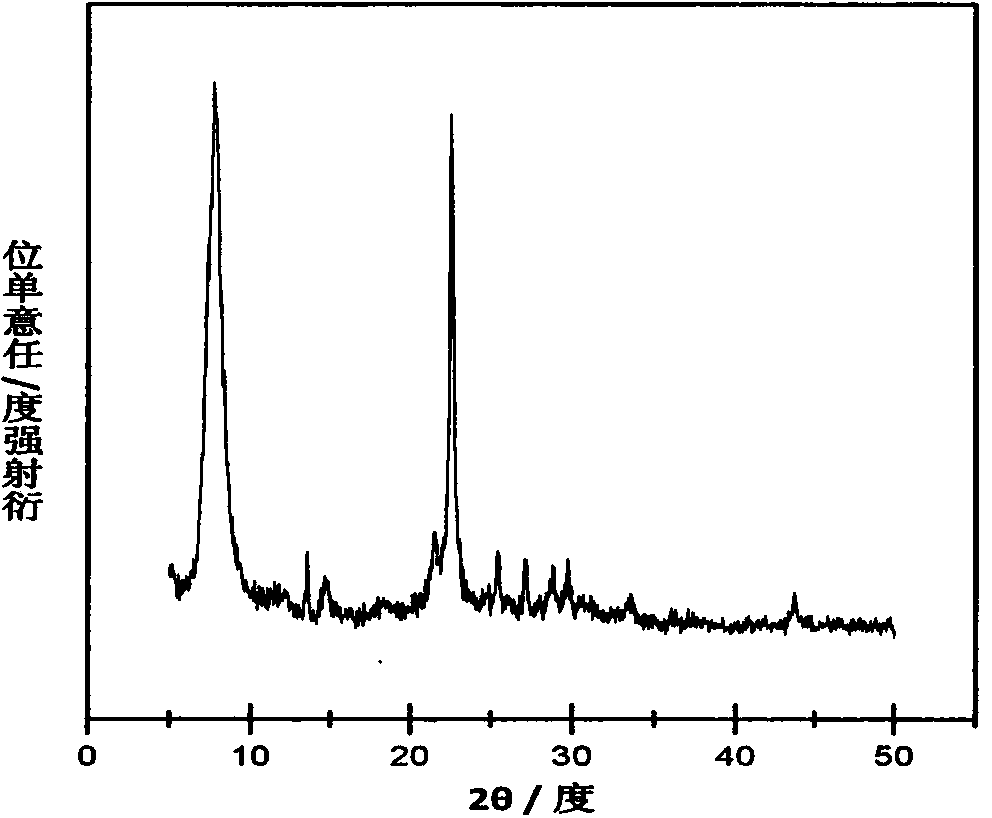

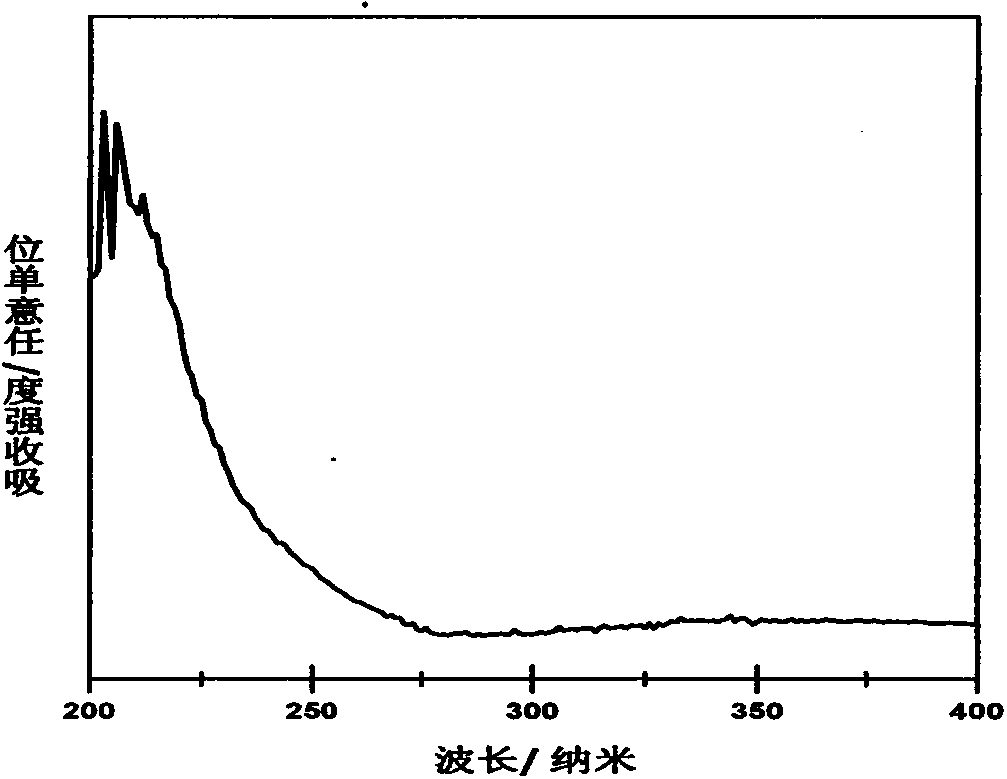

[0025] The preparation process of the 4%Sn-Beta catalyst used in the present embodiment comprises the following steps:

[0026] 1) A certain amount of Beta molecular sieve raw powder (SiO 2 / A 2 o 3 =25) mixed with concentrated nitric acid, concentrated hydrochloric acid or oxalic acid solution in a three-necked flask, heated to reflux and stirred for 20 h in an oil bath reactor at 100°C. Wherein, the feeding ratio of Beta molecular sieve former powder and acid solution is 1: 20 (g / mL);

[0027] 2) After fully cooling the solid-liquid mixture after reflux and stirring, add deionized water to it to dilute to a certain concentration, and after vacuum filtration, wash the obtained filter cake with a large amount of deionized water to neutrality, and then It is placed in a blast drying oven at 100°C for 12 hours at a constant temperature;

[0028] 3) Weigh a certain amount of solid powder in step 2) and the required amount of dimethyl tin dichloride organic precursor in the gl...

Embodiment 2

[0038] In this example, the acid used to treat the raw powder of molecular sieve is nitric acid. The influence of different periods of nitric acid treatment on the hydration performance of 4% Sn-Beta catalyst on the hydration performance of catalytic epoxy cyclohexane under the treatment temperature of 100°C was investigated. The catalytic performance evaluation is shown in Table 2. :

[0039] Table 2 The influence of nitric acid treatment for different time periods on the process of preparing cyclohexanediol by hydration of epoxycyclohexane

[0040]

[0041] The results of catalytic performance evaluation show that: with the increase of nitric acid treatment time, the conversion rate of epoxycyclohexane and the selectivity of the target product are correspondingly improved. When the acid treatment time reaches 20h, the maximum yield of diol is 83.6%. , continue to prolong the acid treatment time, there is no obvious promotion effect on the reaction effect.

Embodiment 3

[0043] This example investigates the influence of different organometallic precursors on the hydration performance of catalytic cyclohexane, and other reaction conditions are the same as those described in Example 2. The catalytic performance evaluation results are shown in Table 3:

[0044] Table 3 Effects of different organometallic precursors on the process of preparing cyclohexanediol by hydration of epoxycyclohexane

[0045]

[0046] The results of catalytic performance evaluation show that different catalytic active centers show obvious differences in the catalytic performance of the reaction. The 4%Sn-Beta catalyst prepared by tin roasting has the best catalytic activity and also exhibits excellent catalytic selectivity.

[0047] Implementation Column 4:

[0048] The purpose of this example is to investigate the influence of the percentage content of tin on the hydration performance of catalytic cyclohexane, and other reaction conditions are the same as those describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com