A preparation method of Mn-based rod-shaped microscopic composite oxide low-temperature denitration catalyst

A technology of composite oxides and microscopic morphology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of accelerating the deposition of ammonium sulfate species on the catalyst surface, catalyst Shortened service life, poisonous vanadium-containing catalyst, etc., to achieve good water and sulfur resistance, wide denitrification performance at low temperature, and insensitivity to space velocity changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Weigh 9.80g Mn(CH 3 COO) 2 4H 2 O, 17.45g Ni(NO 3 ) 2 ·6H 2 O, 1.20g Cu(CH 3 COO) 2 2H 2 O, 5.48g Ce(NH 4 ) 2 (NO 3 ) 6 and 24.01g CO(NH 2 ) 2 Dissolve in 40ml, 40ml, 10ml, 10ml and 200ml of distilled water respectively, and keep stirring at room temperature until the solution is completely clear. The salt solution and CO(NH 2 ) 2 The solution was mixed well, and distilled water was added to increase the total volume of the mixed solution to 500 ml.

[0024] 2) The mixed solution was placed in an oil bath at 60° C., and the reaction was continued for 5 hours under stirring conditions, and a yellow-green precipitate was obtained after the reaction was completed.

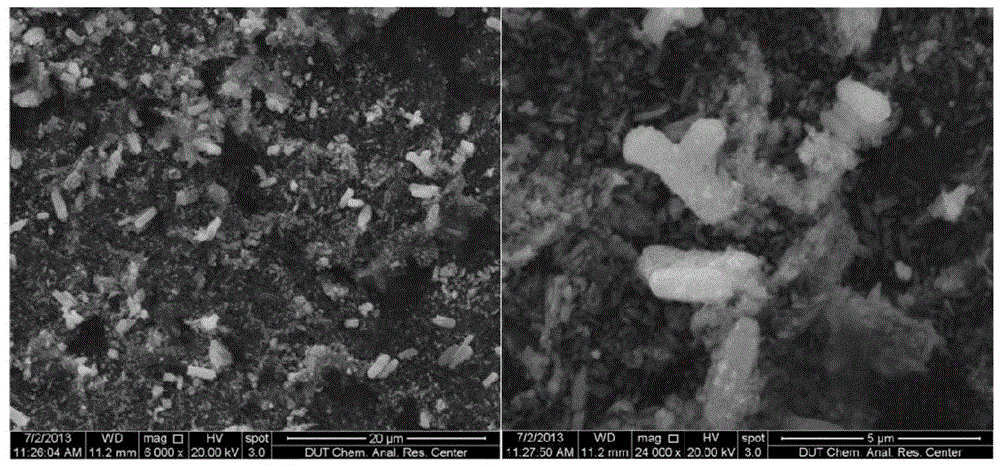

[0025] 3) The obtained sample was washed with water, washed with alcohol, separated, and dried at 70° C. for 12 hours to obtain a Mn-based composite oxide catalyst precursor.

[0026] 4) Put the fully dried sample into a muffle furnace to program the temperature from room temperature to 550°...

Embodiment 2

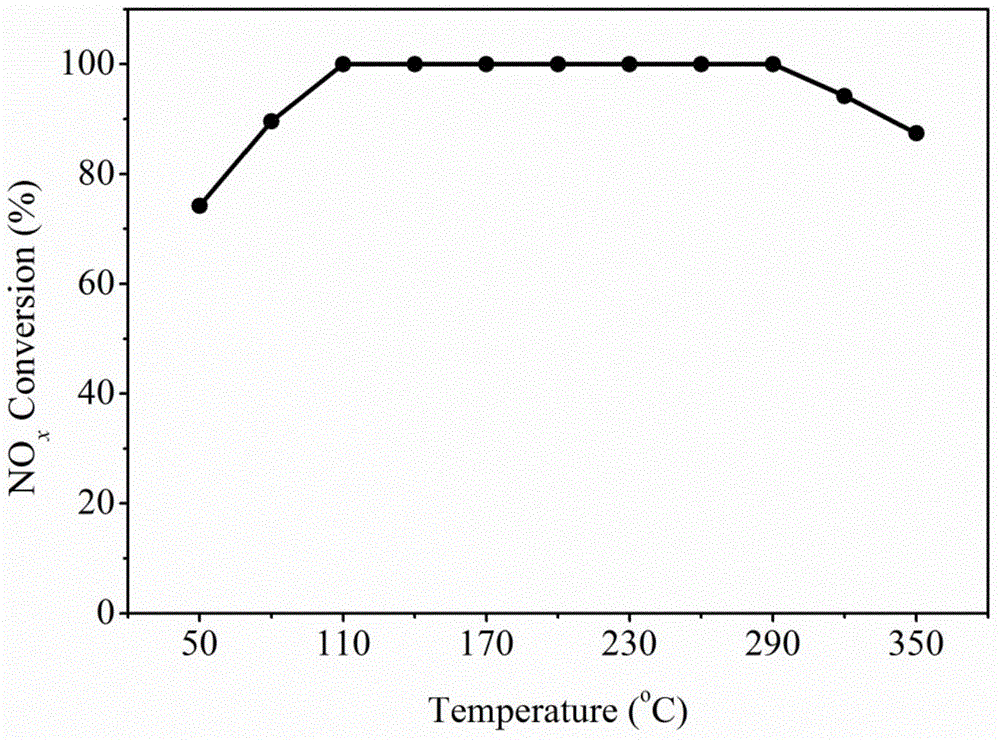

[0028] Put 0.2g of granular Mn-based rod-shaped composite oxide catalyst with a particle size of 40-60 mesh in the flue gas simulation reaction device, and test the NO removal effect of the catalyst under different temperature conditions. The simulated flue gas composition is 500ppm NO , 500ppm NH 3 , 10vol.%O 2 , He is the balance gas, and the air velocity of the simulated flue gas is 30,000h -1 . NO of Mn-based composite oxide catalysts with rod-like micro-morphology x The change curve of conversion rate with temperature is as follows: figure 1 shown.

[0029] The reaction results show that the Mn-based rod-like microscopic composite oxide catalyst has high low-temperature activity. As the reaction temperature increases, the NO of the catalyst x The conversion rate gradually increased. The catalyst has a wide temperature operating window, and its NO x The conversion rate can reach more than 90%, and it can maintain 100% NO in the temperature range of 110-290°C x Conv...

Embodiment 3

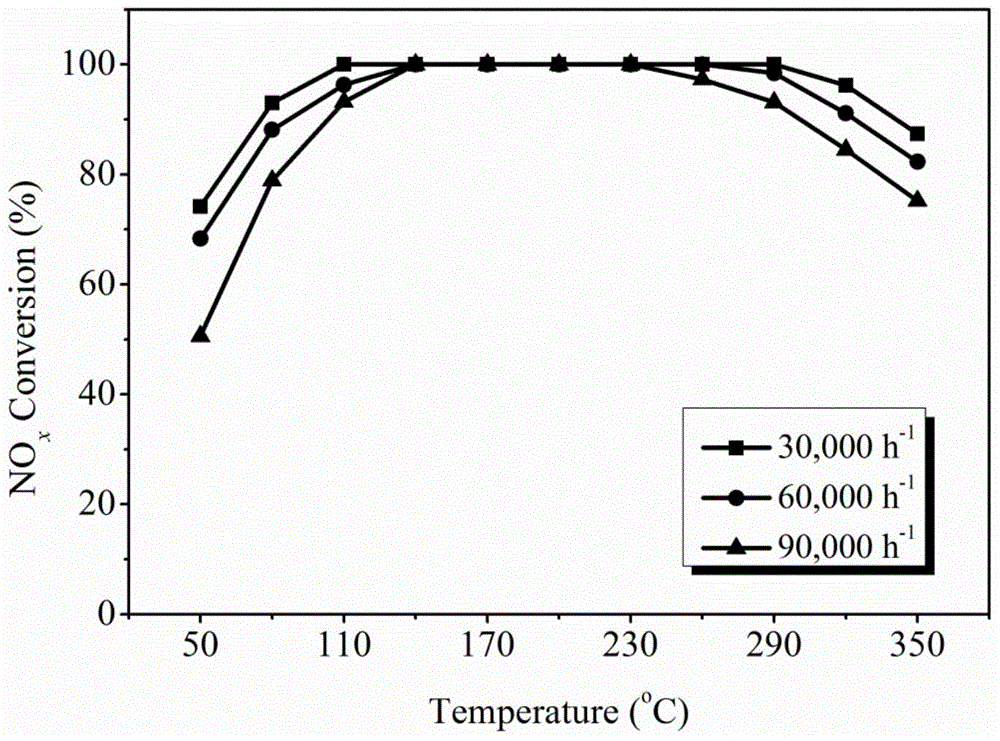

[0030] Example 3: Flue gas space velocity sensitivity test of Mn-based rod-shaped microscopic composite oxide catalyst

[0031] Put 0.2g granular Mn-based rod-shaped composite oxide catalyst with a particle size of 40-60 mesh in the flue gas simulation reaction device, test the effect of simulated flue gas space velocity changes on the denitrification effect of the catalyst, and simulate flue gas composition 500ppm NO, 500ppm NH 3 , 10vol.%O 2 , He is the balance gas, and the air velocity of the simulated flue gas during the test is 30,000h -1 、60,000h -1 and 90,000h -1 . The test results of denitrification performance of Mn-based rod-shaped microscopic composite oxide catalysts under different flue gas space velocities are as follows: image 3 shown.

[0032] The reaction results show that the Mn-based rod-like microscopic composite oxide is not sensitive to the change of reaction space velocity, and has a high prospect of industrial application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com