A nitrogen oxide degradation film and its preparation method

A technology of nitrogen oxides and degradable membranes, which is applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of reduced current efficiency and low removal efficiency, so as to reduce resistance, improve conversion efficiency, and broaden the Effect of Reaction Temperature Window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

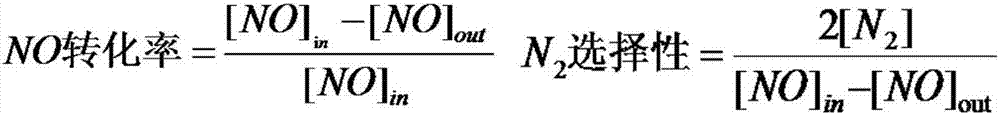

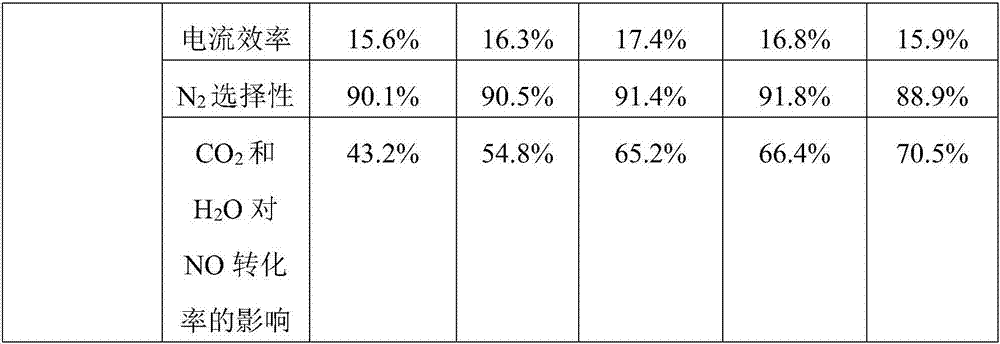

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method for a nitrogen oxide degradation film, comprising the steps of:

[0035] S100 doped F and N into BaCeO formed by the reaction of cerium acetylacetonate and barium acetylacetonate by sol-gel method 3 In, F, N co-doped BaCeO was prepared 3 powdery solid;

[0036] F and N co-doped BaCeO with corresponding mass ratio treated by S200 ball milling 3 powdery solid and graphene, obtain uniform precursor powder after 12-18 hours at room temperature; and

[0037] In S300, the precursor powder is molded by casting, and the formed sheet is calcined in a nitrogen atmosphere at 500° C. for 5 hours to prepare the nitrogen oxide degradation film, which is used for electrocatalytic degradation of nitrogen oxides.

[0038] Wherein, the step S100 includes the steps of:

[0039] S110 Mix and stir cerium acetylacetonate, barium acetylacetonate, acetylacetone and absolute ethanol in the corresponding molar ratio, add potassium fluoride and melamine in the correspondi...

Embodiment 1

[0050] According to the stoichiometric ratio of n(Ba):n(Ce):n(F):n(N)=1:1:0.15:0.02, 0.05mol cerium acetylacetonate, 0.05mol barium acetylacetonate, 0.5mol acetylacetonate Acetone and 0.2mol absolute ethanol were mixed and stirred, and then stoichiometric potassium fluoride and melamine were added to it, stirred at a speed of 250rmp at room temperature for 60min, then converted into a sol, and treated in a water bath at 50°C for 24h to obtain a gel . The obtained gel was first calcined at 200°C for 5h, then heated up to 1000°C at a rate of 2°C / min and kept for 5h, then lowered to room temperature to obtain a powdery solid. The obtained powdery solid and graphene were ball milled at room temperature for 12 hours at a mass ratio of 4:1 to obtain a uniform powder, which was the precursor powder. The obtained precursor powder was cast into a mold, and it was baked at 500° C. for 5 hours under a nitrogen atmosphere to obtain a nitrogen oxide degradation film, wherein the thickness...

Embodiment 2

[0052] According to the stoichiometric ratio of n(Ba):n(Ce):n(F):n(N)=1:1:0.05:0.08, 0.015mol cerium acetylacetonate, 0.015mol barium acetylacetonate, 0.09mol acetylacetonate Mix and stir acetone and 0.03mol absolute ethanol, then add potassium fluoride and melamine in a stoichiometric ratio to it, stir at a speed of 500rmp at room temperature for 30min, then convert it into a sol, and treat it in a water bath at 65°C for 18h to obtain a gel . The obtained gel was first calcined at 200°C for 5h, then heated up to 1000°C at a rate of 5°C / min and kept for 5h, then lowered to room temperature to obtain a powdery solid. The obtained powdery solid and graphene were ball milled at room temperature for 15 hours at a mass ratio of 4:0.5 to obtain a uniform powder, which was the precursor powder. The obtained precursor powder was molded into a mold, and baked at 500° C. for 5 h in a nitrogen atmosphere to obtain a nitrogen oxide degradation film, wherein the thickness of the nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com