Patents

Literature

32 results about "Cerium acetylacetonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerium acetylacetonate is a compound with formula Ce(C₅H₇O₂)₃. It is the cerium complex of acetylacetone.

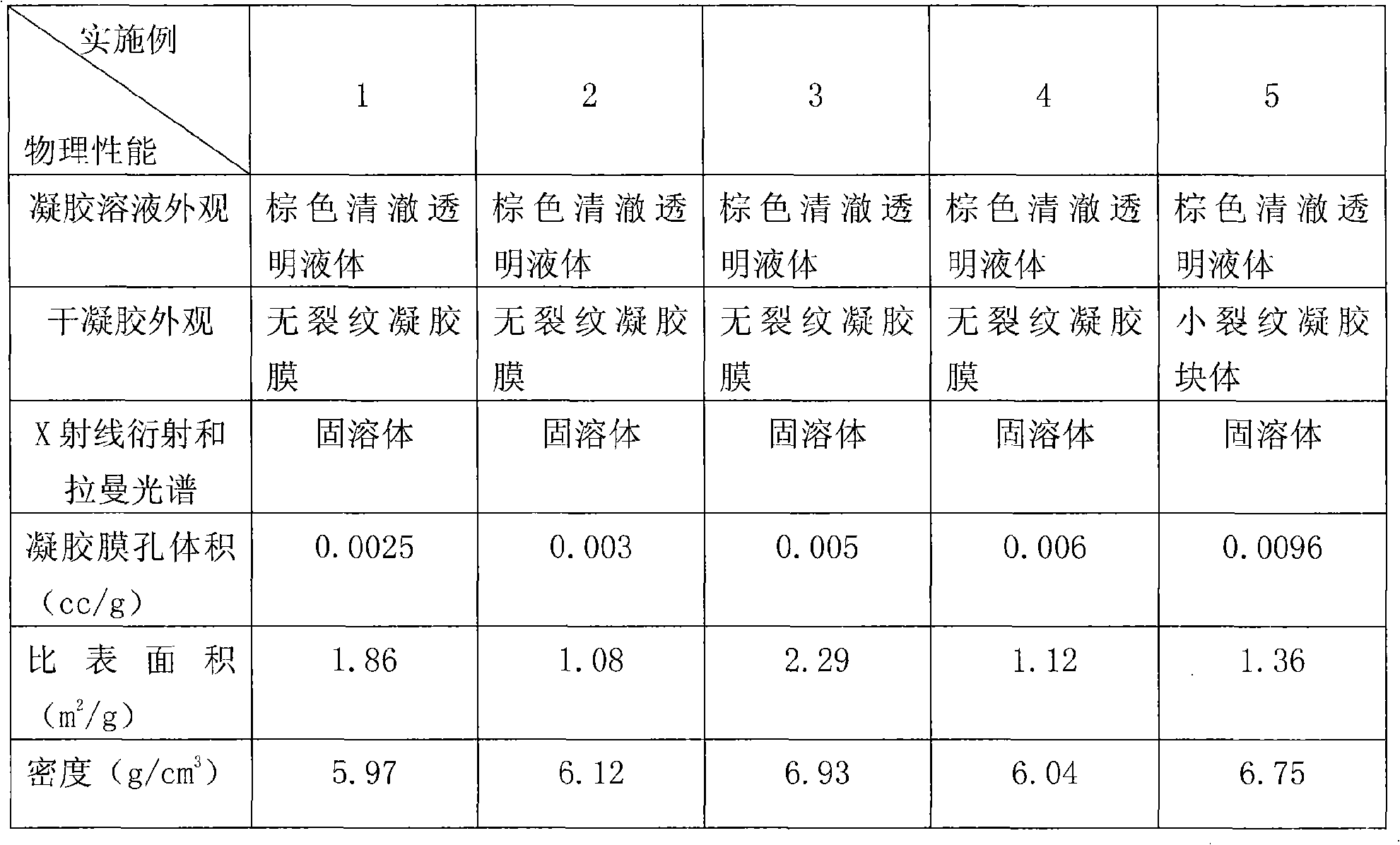

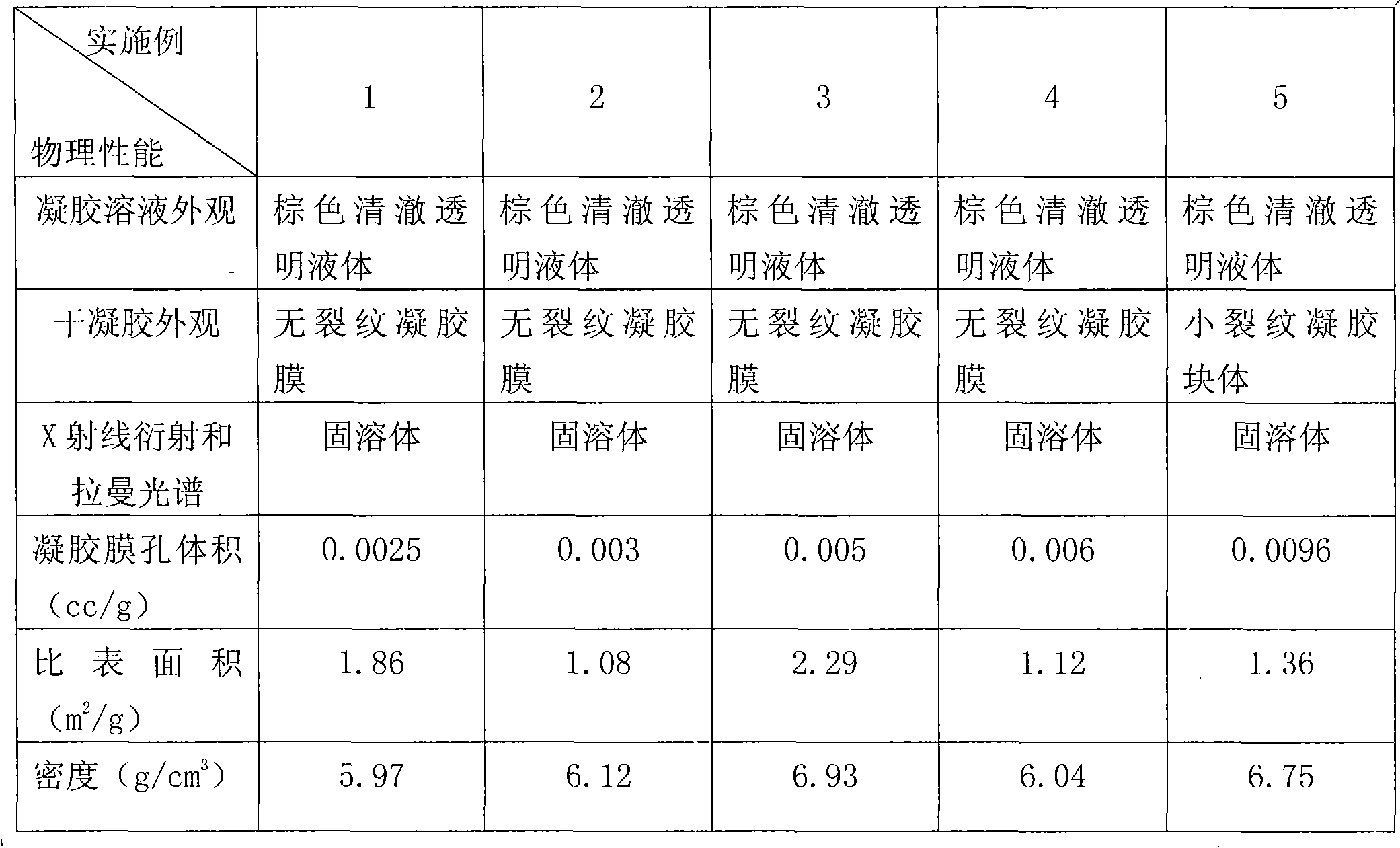

Method for preparing composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide

InactiveCN101552344AHigh sintering activityAvoid secondary film formationFinal product manufactureSolid electrolyte fuel cellsPorosityN dimethylformamide

The present invention relates to a method for preparing composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide. The method has characteristics of including steps as follows: (1) selecting raw material: weighing each raw material by weight part as follows: acetylacetone cerium aqua compound 1.5-2.5, acetylacetone gadolinium aqua compound 0.35-0.45, methanol 20-30, N, N-dimethylformamide 0.3-0.5; (2) mixing in room temperature and stirring 40-60 minutes, obtaining the colloidal solution; (3) gelating the colloidal solution in 45-70 DEG C and dehydrating dealcoholize 8-30 hours; (4) when the colloidal solution becomes viscous, the gelating reaction continues 40-60 minutes for obtaining jelly glue; (5) displacing the jelly glue to a vacuum drying case, vacuum drying 1-2 hours in 130 DEG C, and obtaining the composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide. The product has high denseness and low jelly glue porosity which is benefit for low temperature sintering into a gadolinium oxide adulterating cerium oxide electrolytes film with compact and high density.

Owner:WUHAN UNIV OF TECH

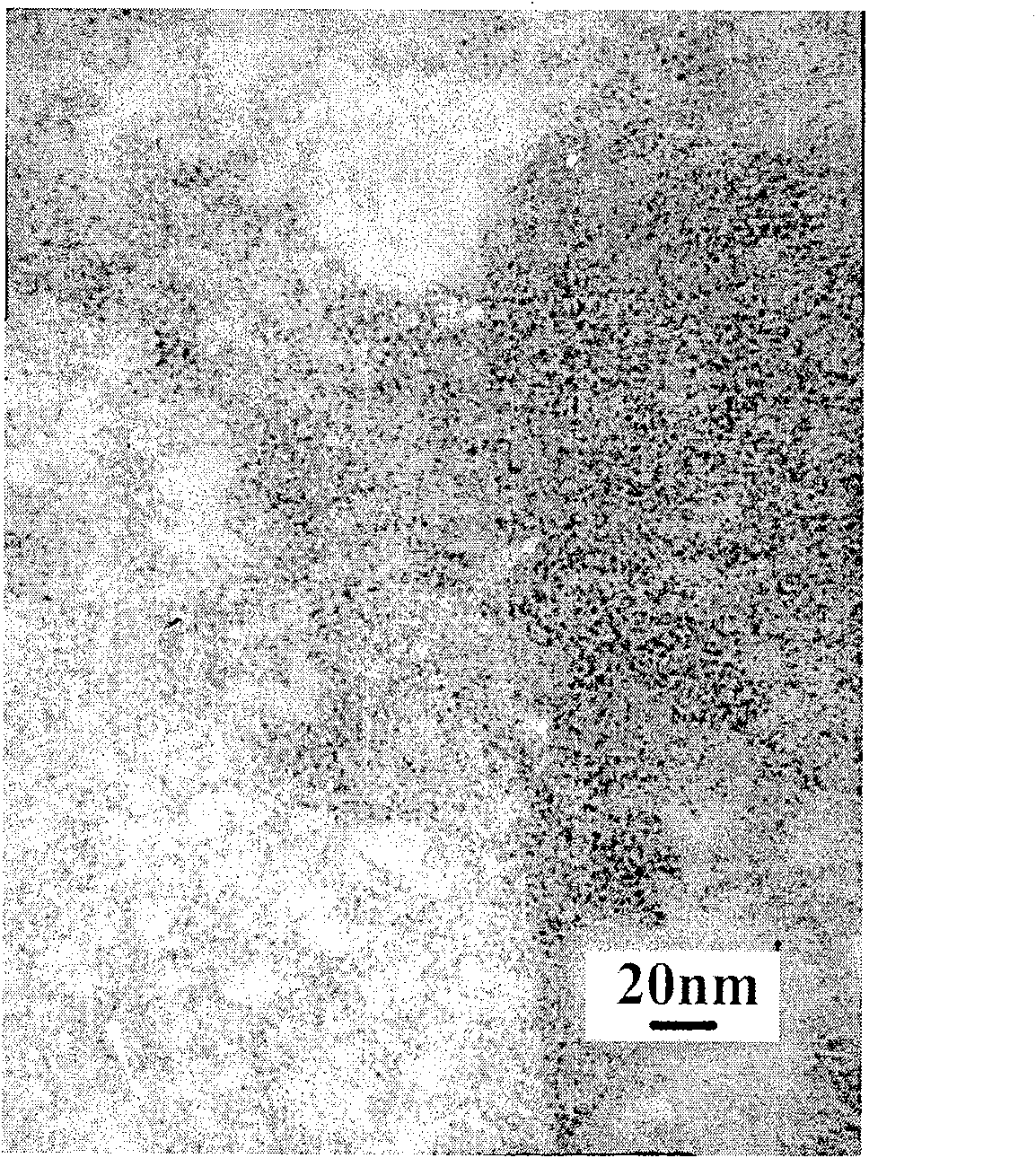

Process for preparing water-soluble ceria nanocrystalline

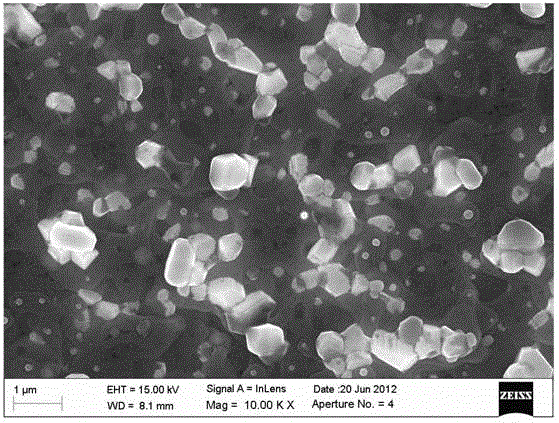

The invention provides a method for preparing a water-soluble ceria nano-crystal, belonging to the nano material technical field. The prior CeO2 nano particles include oil-soluble CeO2 nano particles without surface finishing. A back flow hydrolization method is adopted in the invention. The method of the invention comprises the following steps that: 1. the water-soluble nano particles dispersed in a solution are synthesized; and the back flow hydrolization method is adopted, wherein the cerium source is acetylacetone cerium, and the solvent and the surface finishing agent are 2-pyrrolidone; technical parameters are as follows: the temperature of the back flow hydrolization is between 225 and 240 DEG C, and the time of the back flow is between 60 and 120min; 2. the water-soluble nano particles are separated from the solution; the solution containing the water-soluble nano particles is cooled down to the room temperature and undergoes the steps of deposition by methanol, centrifugal separation, washing by acetone and drying; technical parameters are as follows: the use level of the methanol is between 200 and 300ml, the use level of the acetone is between 50 and 80ml, and the solution is dried by N2 flow for 4h or at a temperature of between 50 and 60 DEG C for 5 to 10h. The water-soluble ceria nano particles finally obtained are ball-shaped and the average particle diameter of which is approximately 5 to 10nm.

Owner:CHANGCHUN UNIV OF SCI & TECH

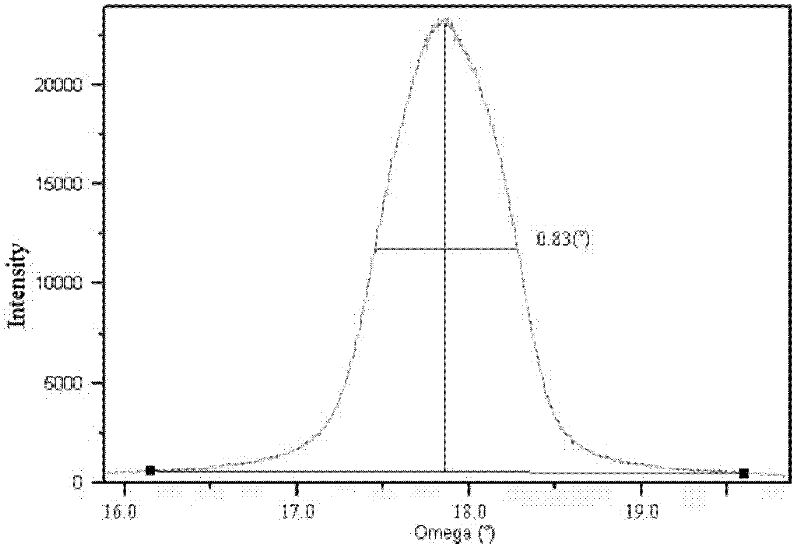

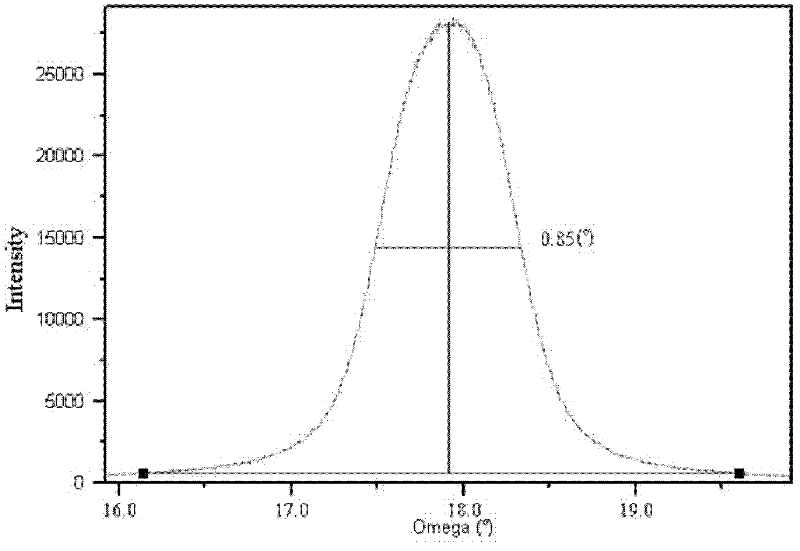

Method for preparing high temperature superconduction coating conductor buffer layer using polymer auxiliary deposition

InactiveCN101281806AImprove textureFlat and dense surfaceSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentElectrical conductorPolyvinyl alcohol

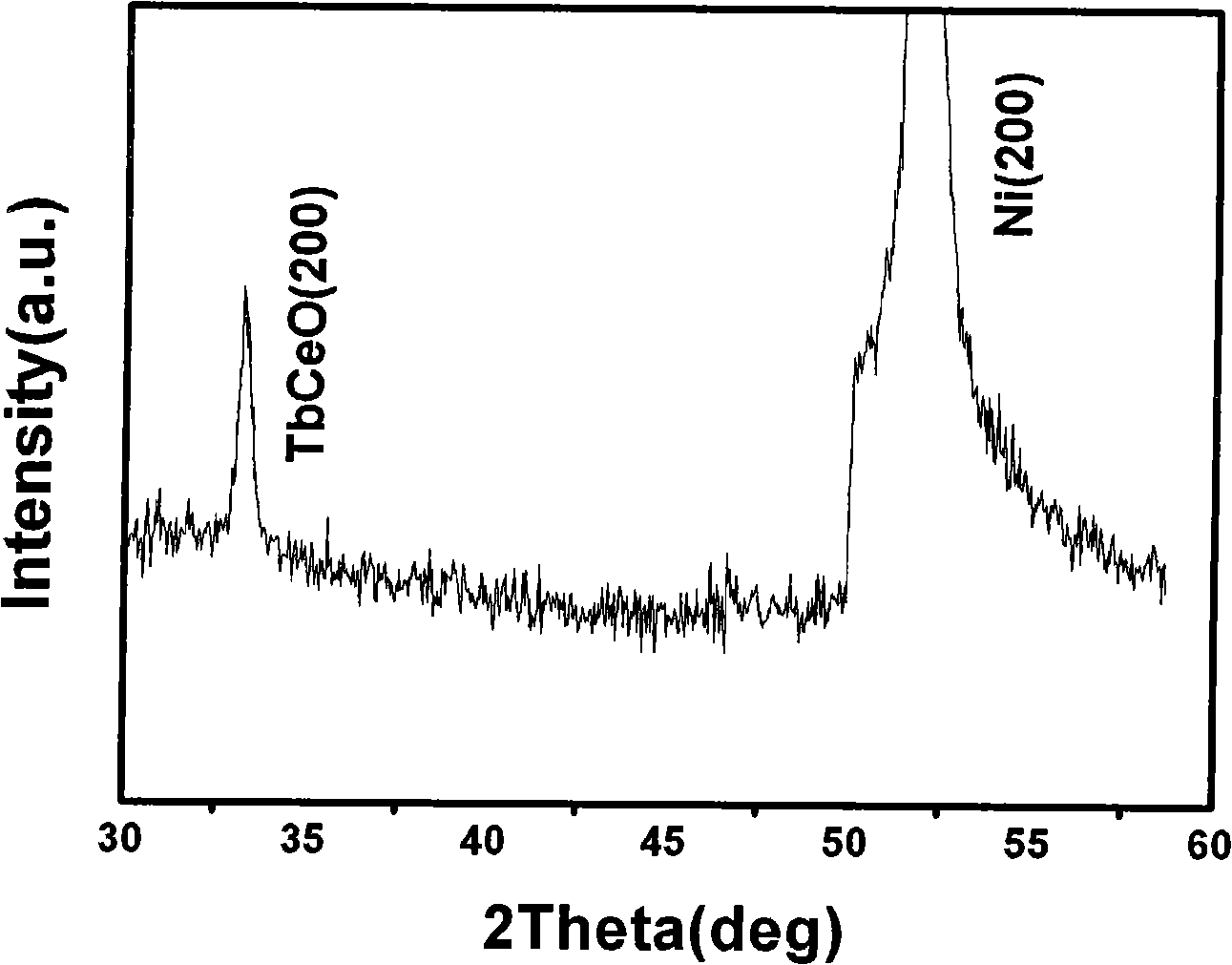

A method for producing the buffer layer of a conductor coated with high temperature superconducting coating by means of macromolecule assisted deposition, which comprises: a. preparing waterless: weigh rare-earth acetate, or rare-earth propoxide, or rare-earth acetylacetonate, or zirconium propoxide, or zirconium n-butoxide and cerium acetylacetonate at an ionic ratio of rare-earth or zirconium: cerium as x:1-x (0.01<=x<=0.5), dissolve the compound in an organic solvent to form a waterless; b. preparing colloid: add polyvinyl butyral, or polyethylene glycol, or polyvinyl pyrrolidone, or polyvinyl alcohol, or polyoxyethylene to the waterless solution to form colloid; c. coating the colloid and drying: coat the colloid on a substrate and then dry the substrate; d. sintering: load the substrate into a sintering oven, heat up to 850-1150 DEG C at 5-100DEG C / min, hold for 0.25-2h, and drop the temperature at 1-2 DEG C / min to room temperature. The method is characterized in simple process, easy operation control, low cost, and free of environment pollution; the single-layer cerium oxide buffer layer obtained can be in critical thickness of 150-200nm.

Owner:SOUTHWEST JIAOTONG UNIV

Low-temperature sintering ceramic medium material

The invention discloses a low-temperature sintering ceramic medium material. The low-temperature sintering ceramic medium material is characterized by comprising, by weight, 31-47 parts of pottery stone, 11-17.9 parts of sodium carbonate, 10-25 parts of polyving akohol, 5.7-13.6 parts of silicon dioxide, 12-34 parts of sericite, 11-54 parts of synthetic rubber, 1-11 parts of acetyl acetone cerium, 4-9 parts of polycarbosilane, 3-15 parts of manganese dioxide, 5.7-18.4 parts of hydrophobic modification nanoscale silicon oxide and 3-14 parts of butyl rubber. The low-temperature sintering ceramic medium material is low in sintering temperature, high in dielectric constant, low in dielectric loss, wide in sintering shrinkage percentage range, and capable of being co-fired with a high-conductivity silver inner electrode .

Owner:QINGDAO XIANGHAI ELECTRONICS

Microporous ceramic

The invention discloses a microporous ceramic, which is characterized by comprising the following raw materials in parts by weight: 50-75 parts of dimethyl sulfoxide, 3-5 parts of copper oxide, 15-45 parts of trichloromethane, 1.8-7.9 parts of silicon oxide, 15-20 parts of cerium acetyl acetonate, 32-44 parts of polycarbosilane, 45-61 parts of porcelain stone, 25-47 parts of magnesite, 3-4.8 parts of wollastonite, 5-18 parts of allophone, 11-15 parts of dimethylaniline, 5-11 parts of hafnium acetylacetonate, 26-49 parts of cresol, 10-19 parts of ferric acetylacetonate, and 5-9 parts of antimony oxide. The microporous ceramic has the beneficial effects that the obtained ceramic belongs to the microporous field, is suitable for a carrier of a catalyst, an adsorbing separation material and the like, and is wide in application prospects; and a foaming agent, a pore production agent and the like are not required, so that the distribution unevenness of pores caused by insufficient mixing of raw materials can be avoided. The microporous ceramic is relatively simple in technology, the cost is lowered to a certain extent, and the application potential can be promoted.

Owner:QINGDAO XIANGHAI ELECTRONICS

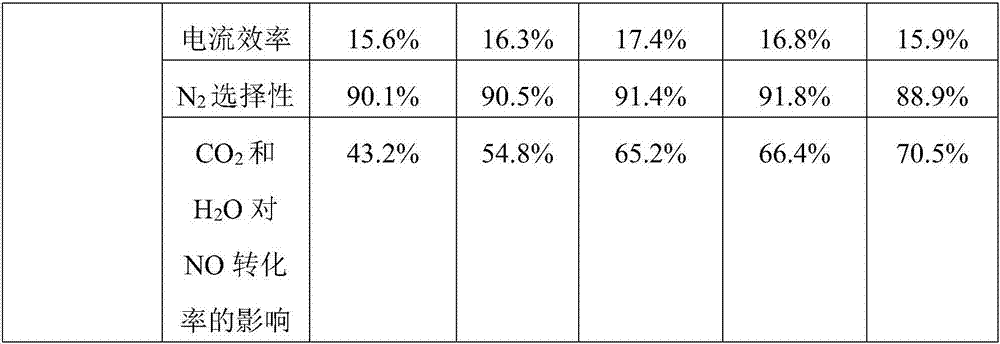

A nitrogen oxide degradation film and its preparation method

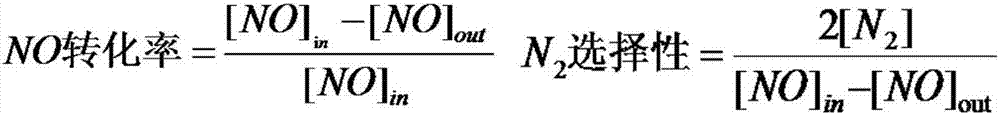

ActiveCN105478152BImprove reduction efficiencyHigh selectivityPhysical/chemical process catalystsDispersed particle separationNitrogen oxidesPotassium fluoride

The present invention provides a nitrogen oxide degradation membrane and a preparation method thereof. The raw material components of the degradation membrane mainly consist of cerium acetylacetonate, barium acetylacetonate, potassium fluoride, melamine and graphene, wherein cerium acetylacetonate and barium acetylacetonate are , potassium fluoride and melamine through a sol-gel method to prepare F and N co-doped BaCeO3, a precursor powder is obtained by mixing graphene with F and N co-doped BaCeO3, and the nitrogen is obtained by a casting film forming method Oxide degradation film. Thus, a non-metal modified inorganic degradation membrane is prepared through the sol-gel method, which has a more efficient and stable current utilization rate and is suitable for highly selective electrocatalytic degradation of nitrogen oxides.

Owner:广州爱科琪盛塑料有限公司

Preparation method of hydrogenated nitrile butadiene rubber

InactiveCN105906743ANovel methodLow costMicroballoon preparationMicrocapsule preparationSilicic acidThermal aging

The invention discloses a preparation method of hydrogenated nitrile butadiene rubber and belongs to the technical field of rubber. The preparation method comprises: adding ortho-silicic acid into ferrous nitrate, magnesium nitrate, urea and cerium acetylacetonate, adjusting pH with ammonia water to obtain mixture, drying and calcining the mixture, introducing high-purity hydrogen, mixing with hydrochloric acid for soaking, adding hydrogen peroxide and nitrile butadiene rubber, filtering after ultraviolet irradiation and hydrogenation, and cooling and drying residue to obtain the hydrogenated nitrile butadiene rubber. Embodiments prove that the process of the invention is simple, production cost is lowered, reaction conditions during preparation are mild, the preparation process is safe and reliable, catalysts are simple to separate and recycle, catalytic activity is improved, the prepared hydrogenated nitrile butadiene rubber has good thermal stability and thermal aging performance and high applicable value and is widely applicable to the fields such as oilfield and automobile industry.

Owner:郭舒洋

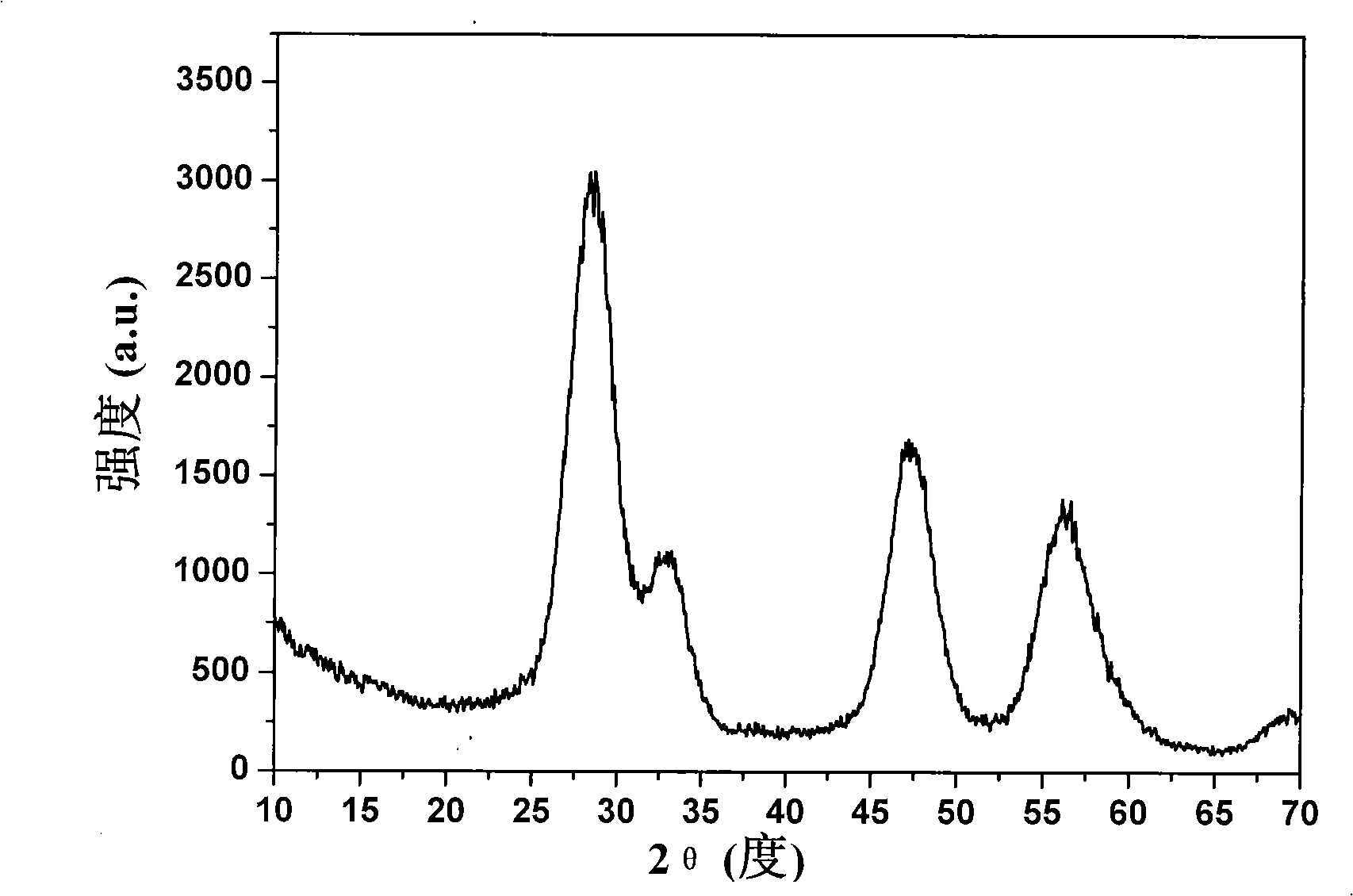

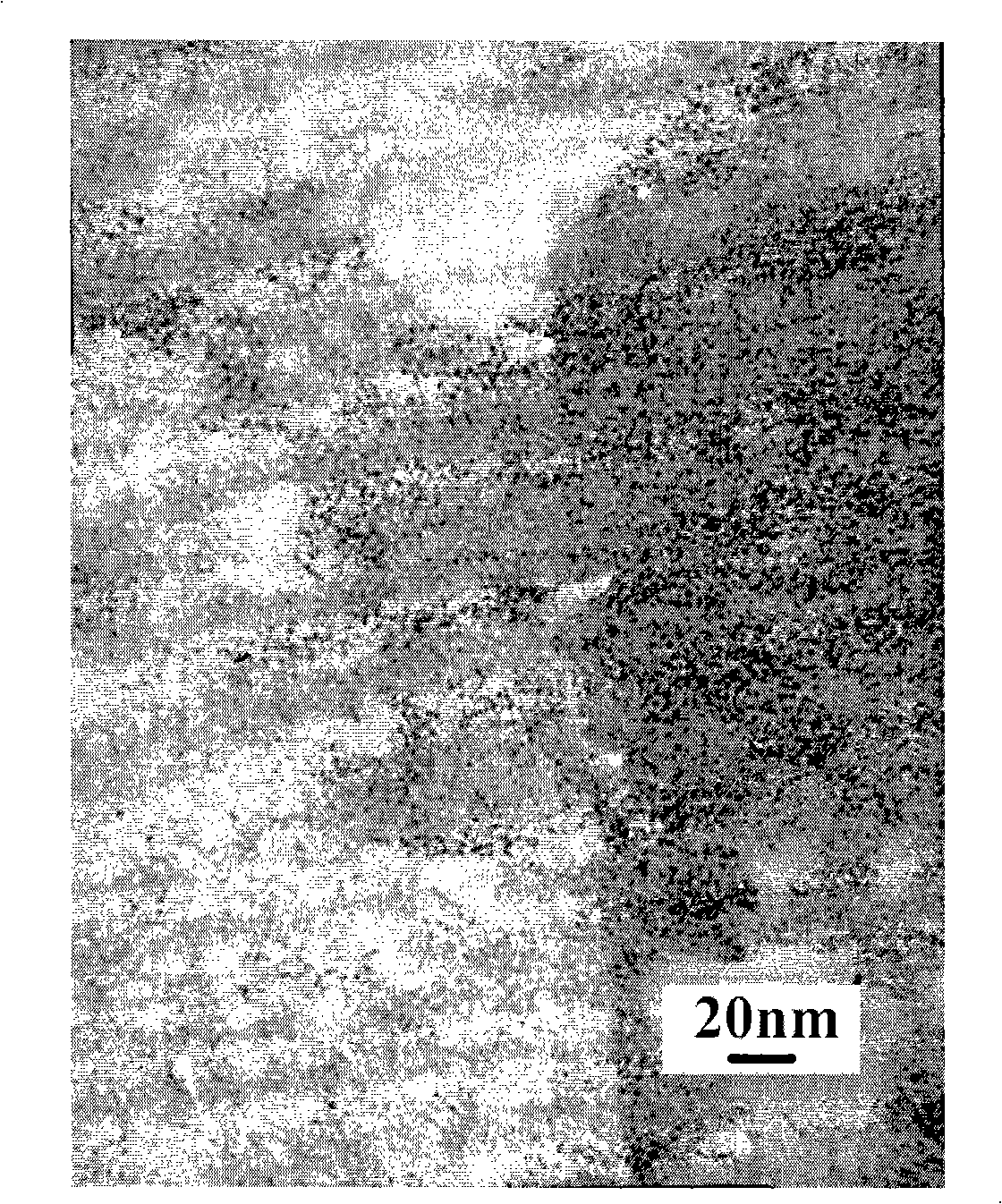

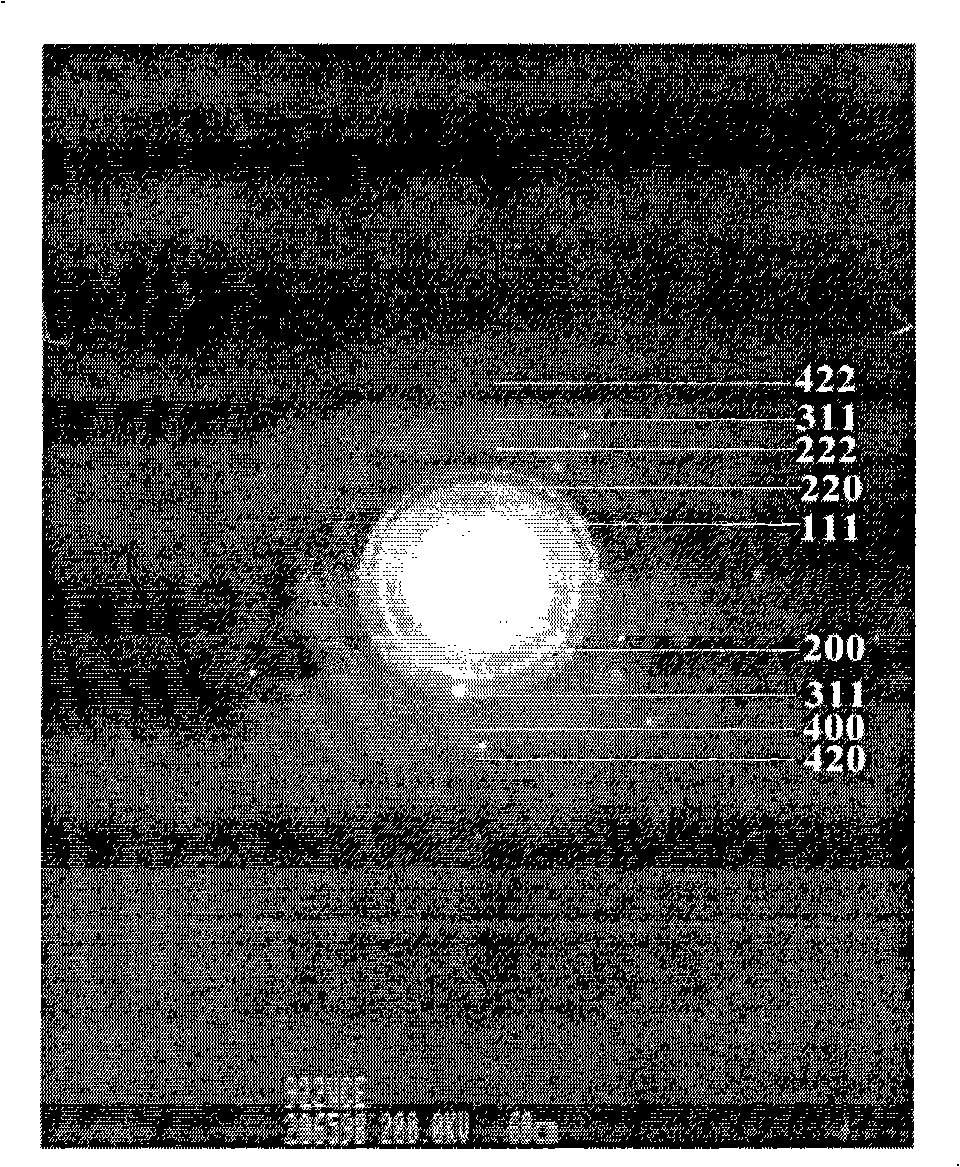

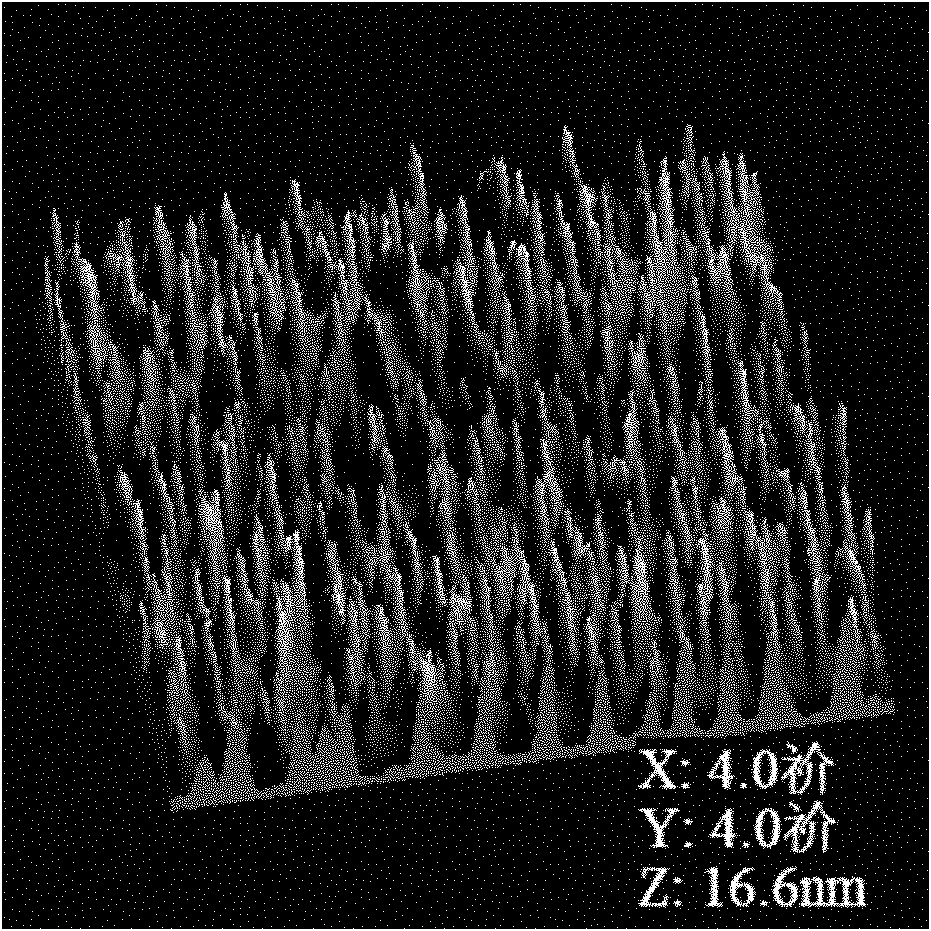

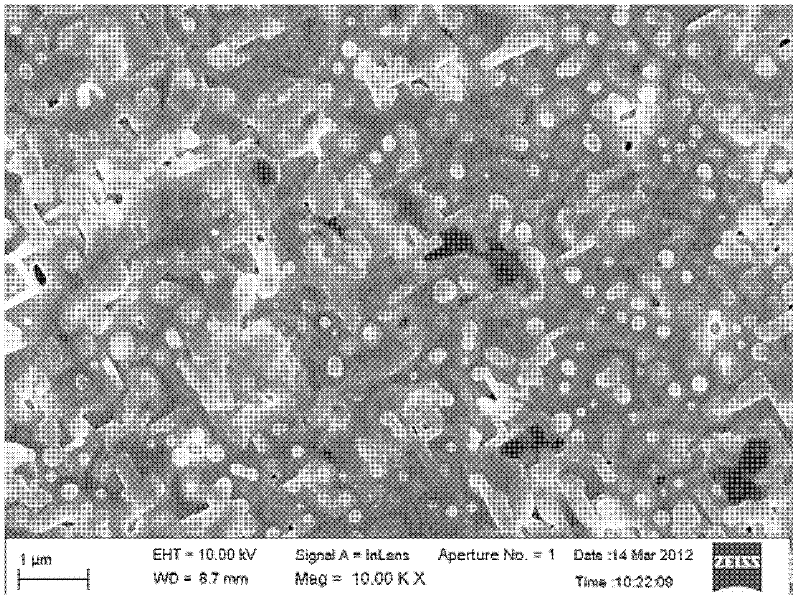

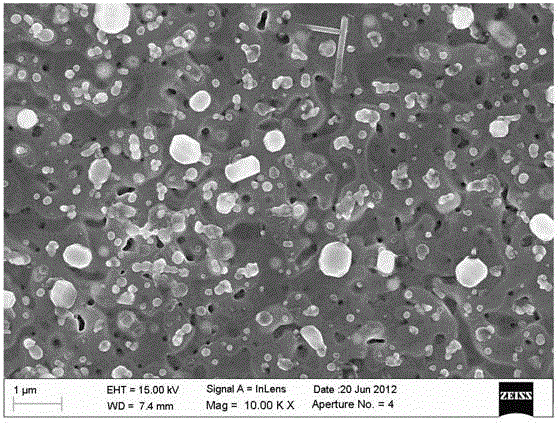

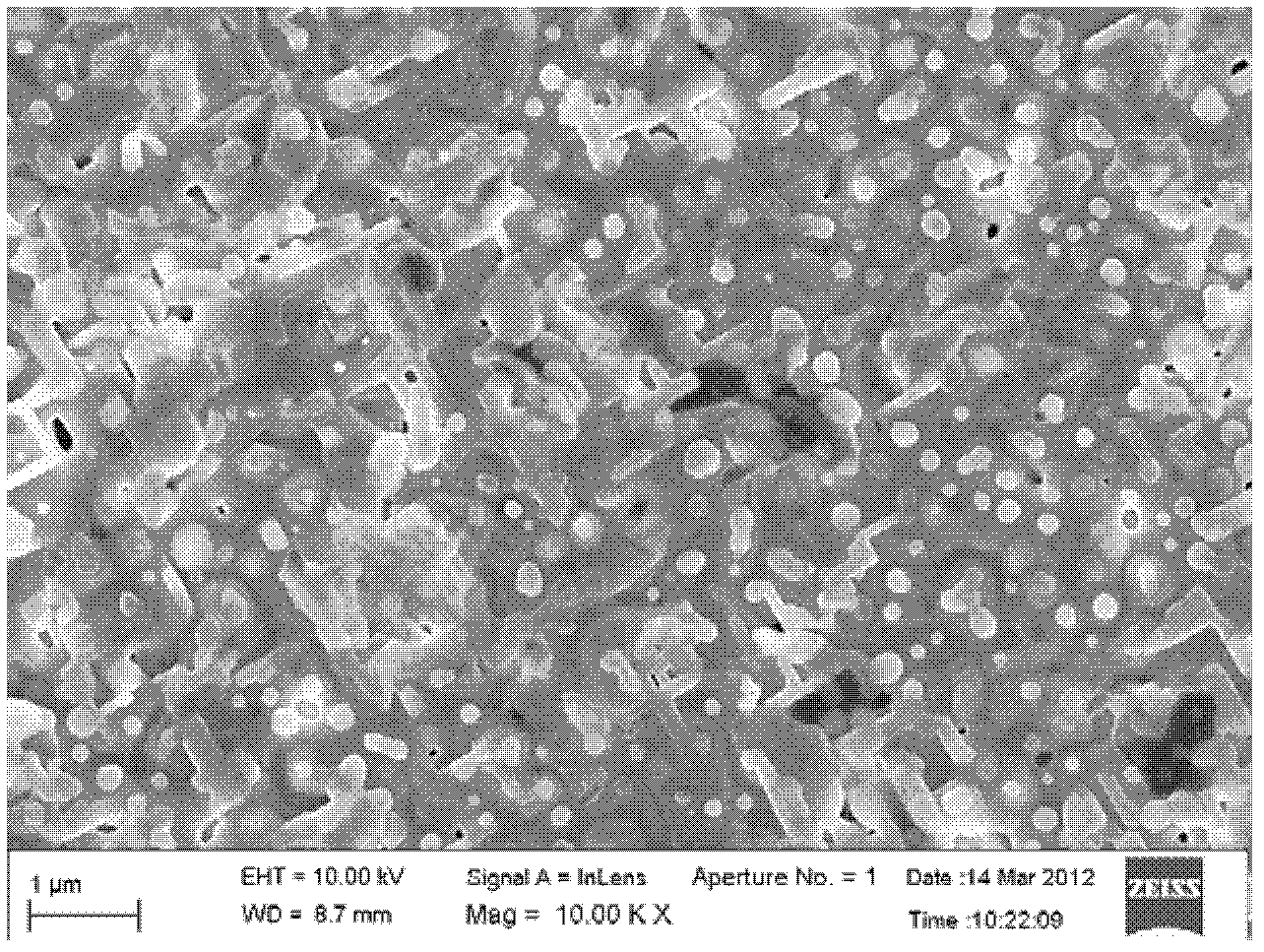

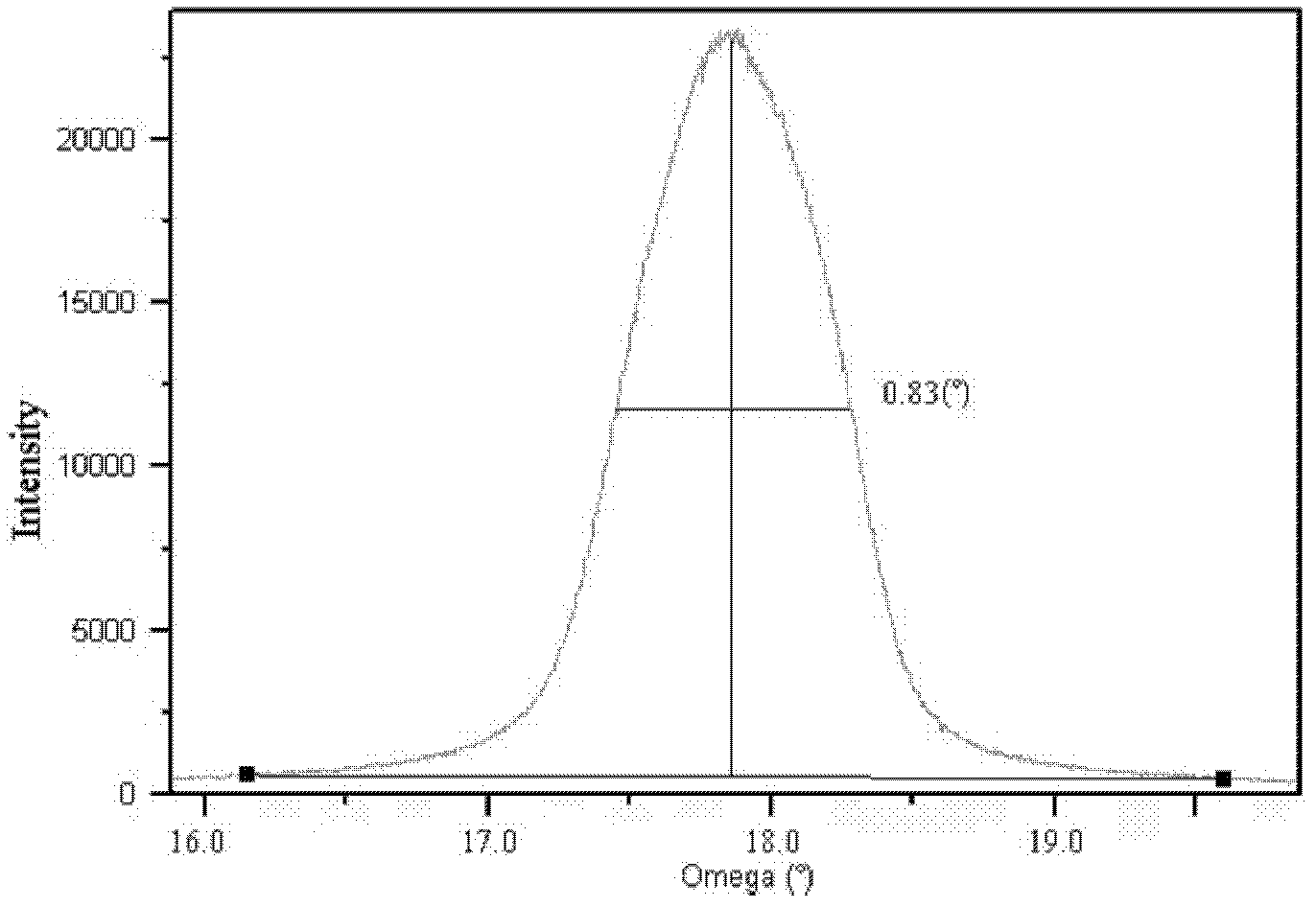

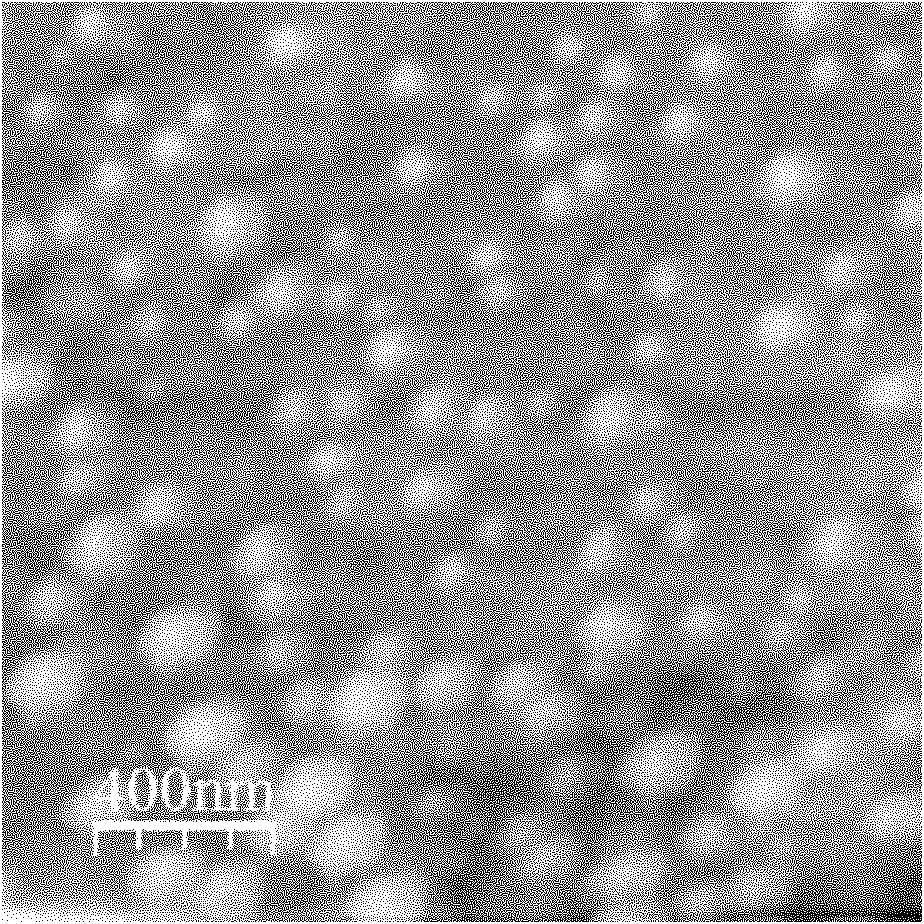

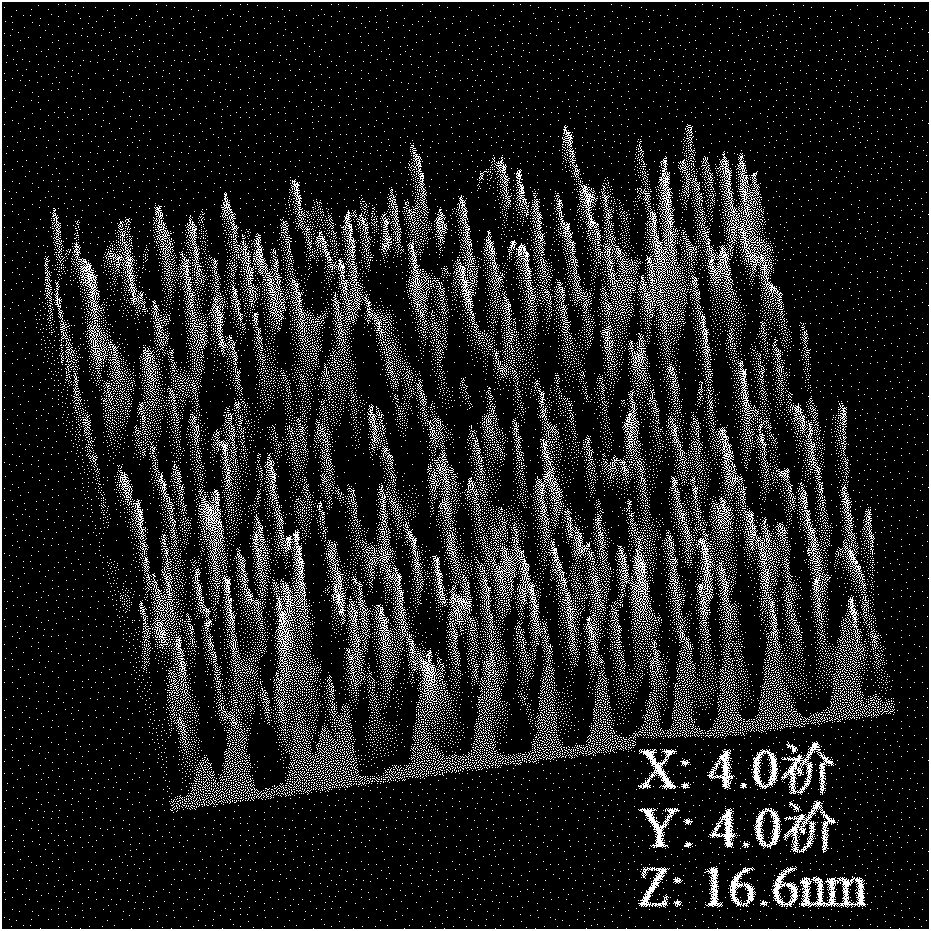

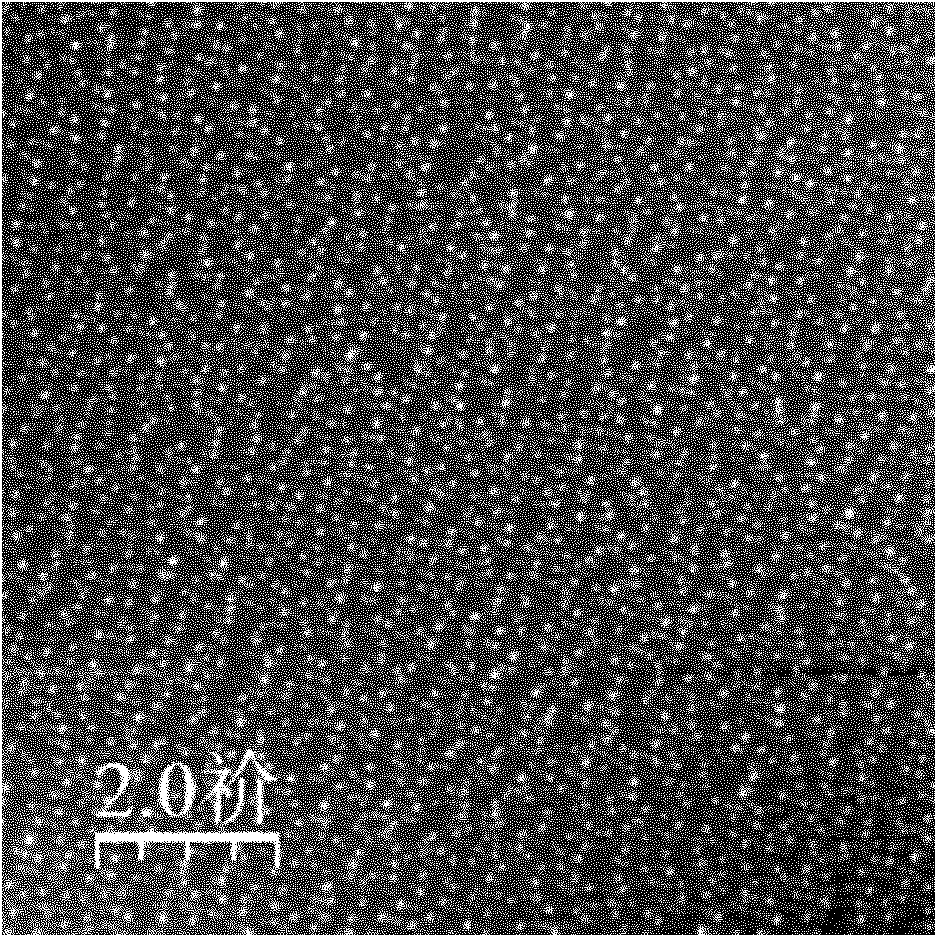

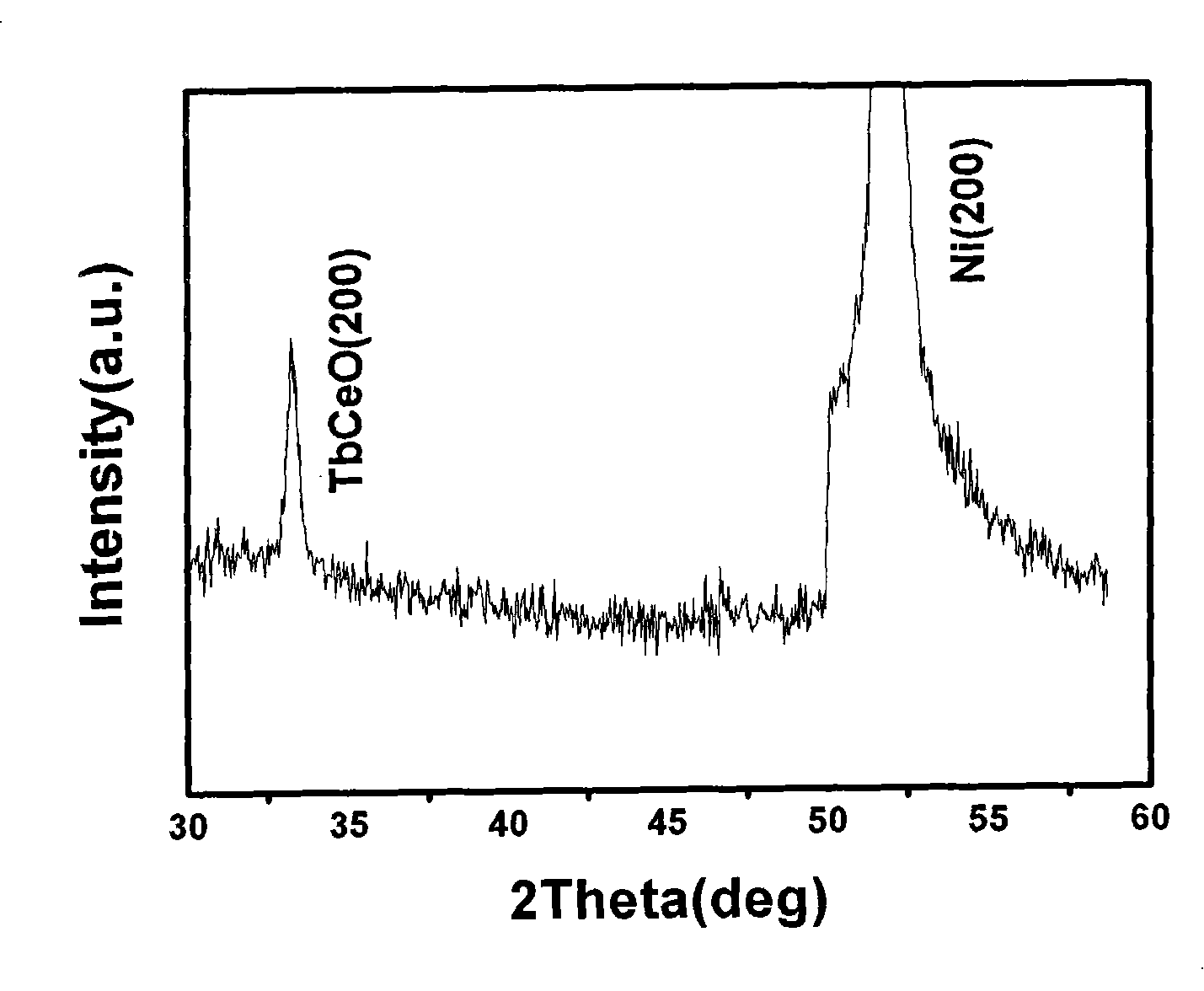

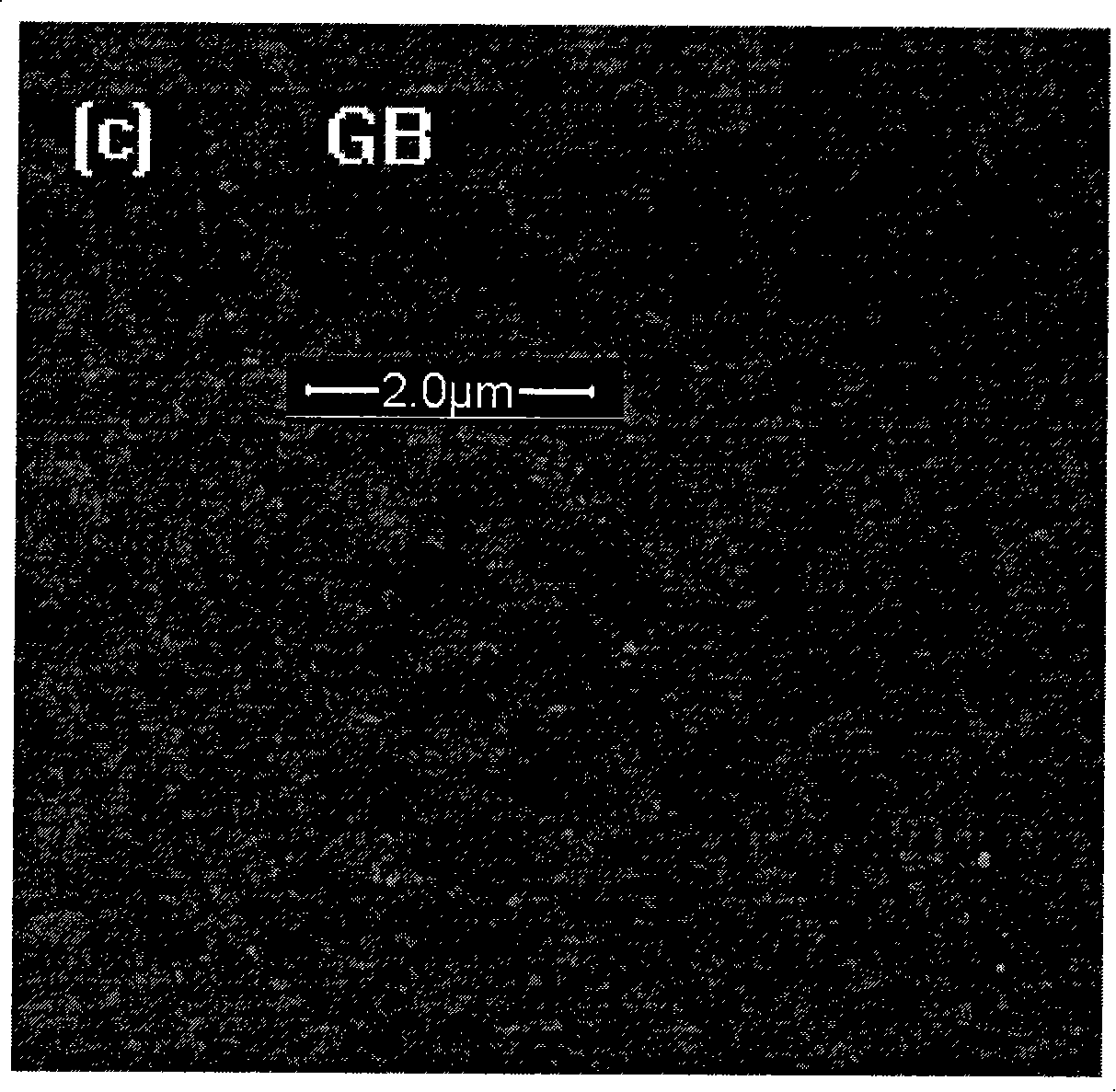

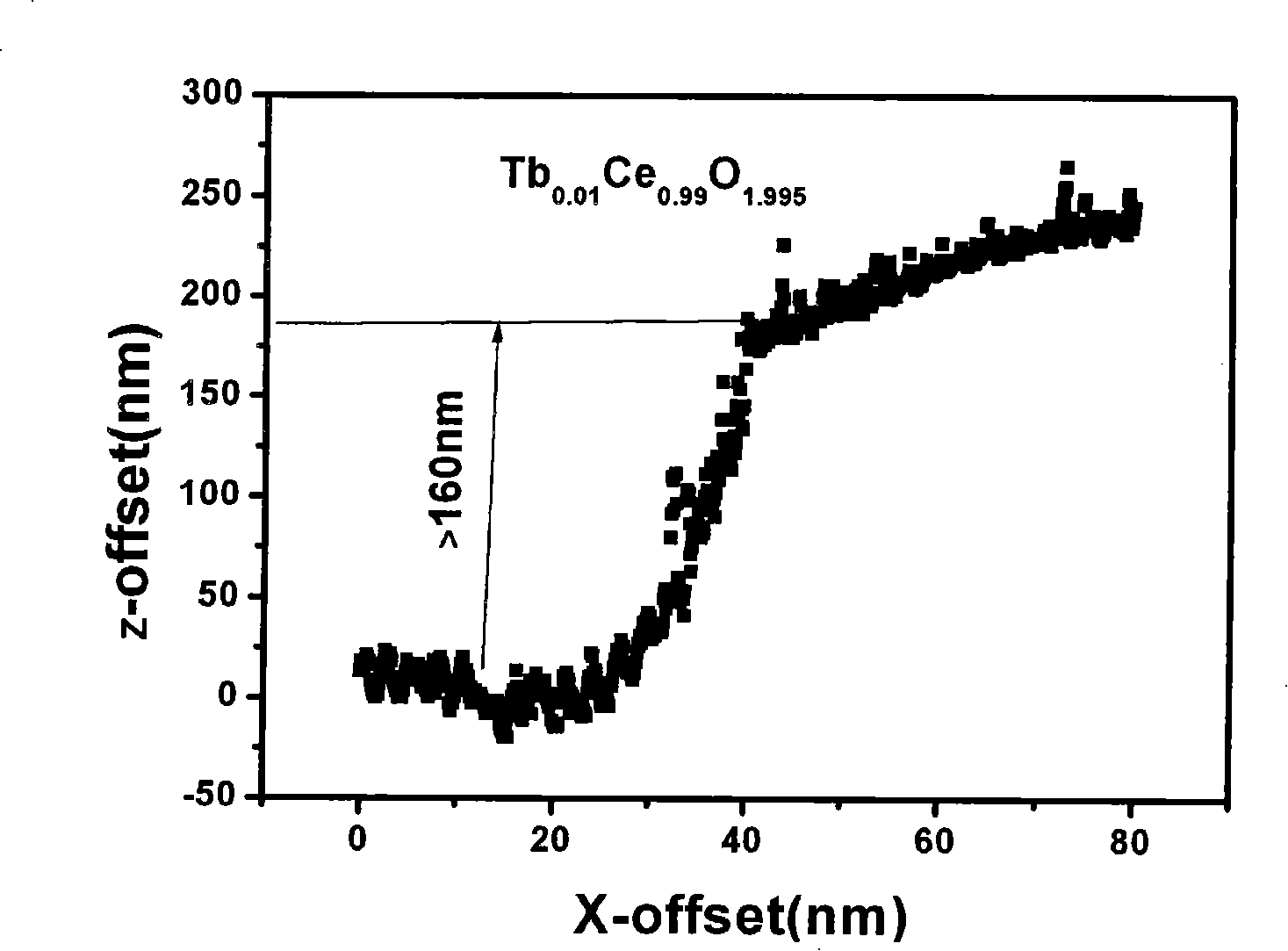

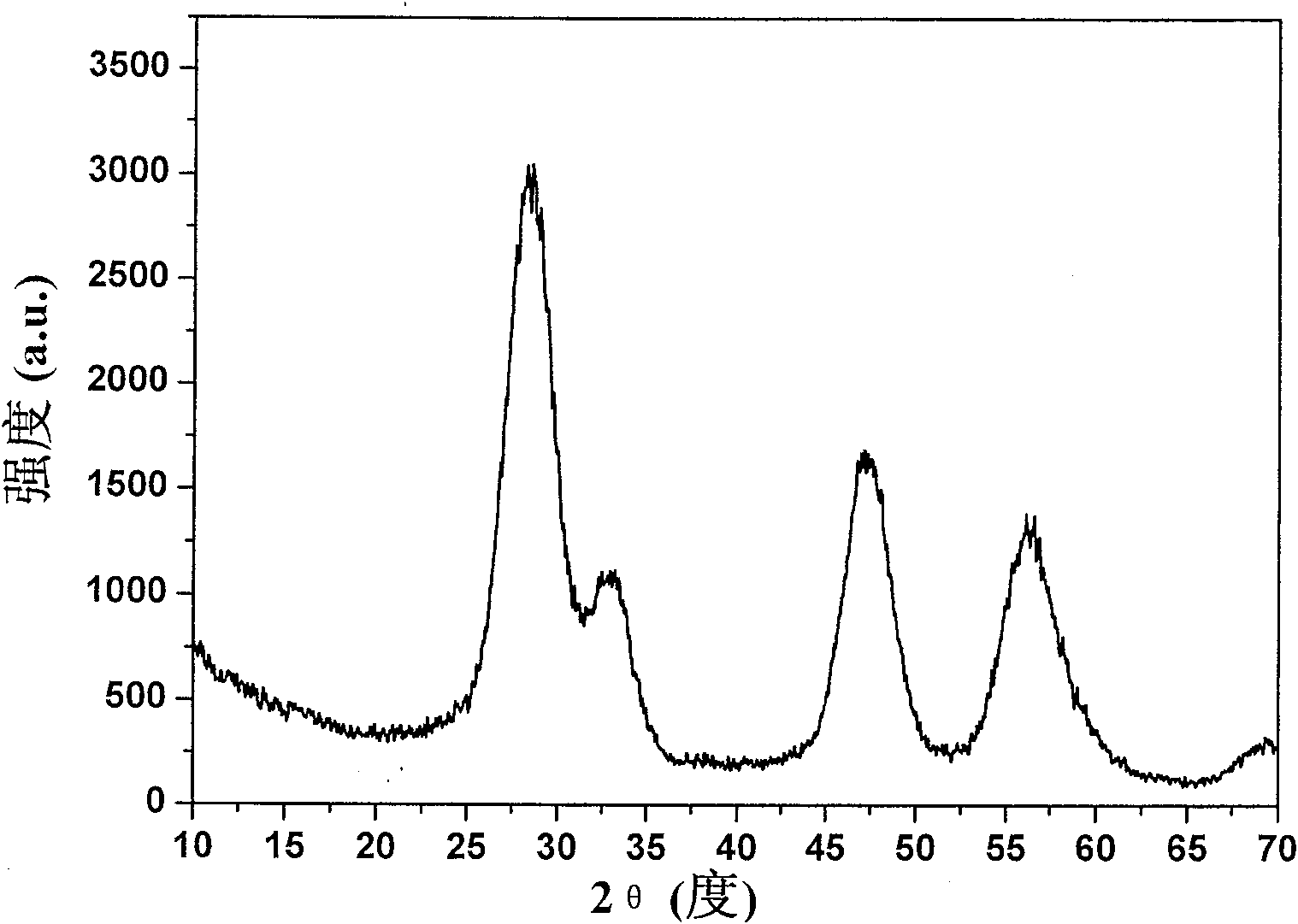

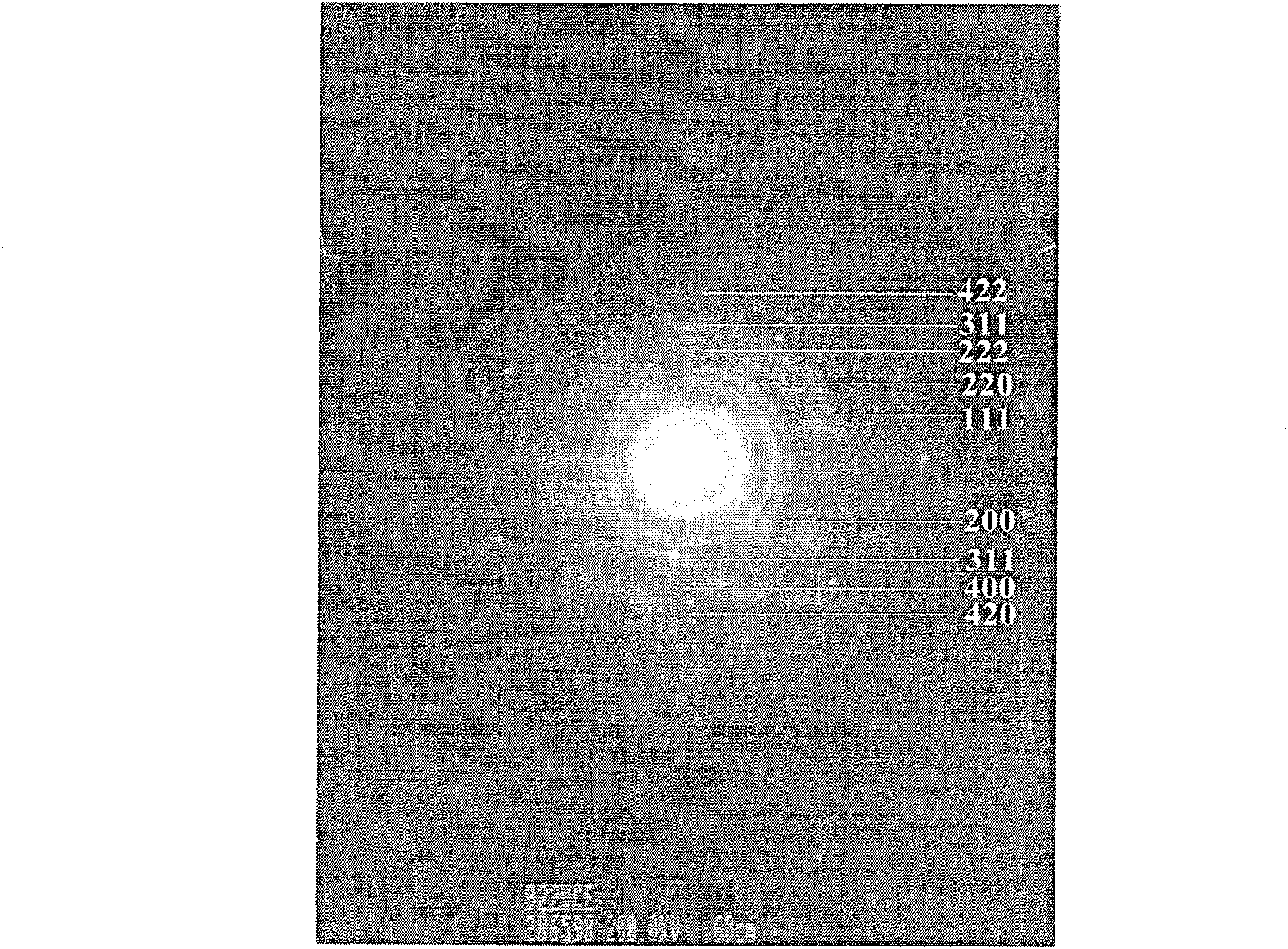

Binary material (Zr,Ce)O2 nanodots, and preparation method and application thereof

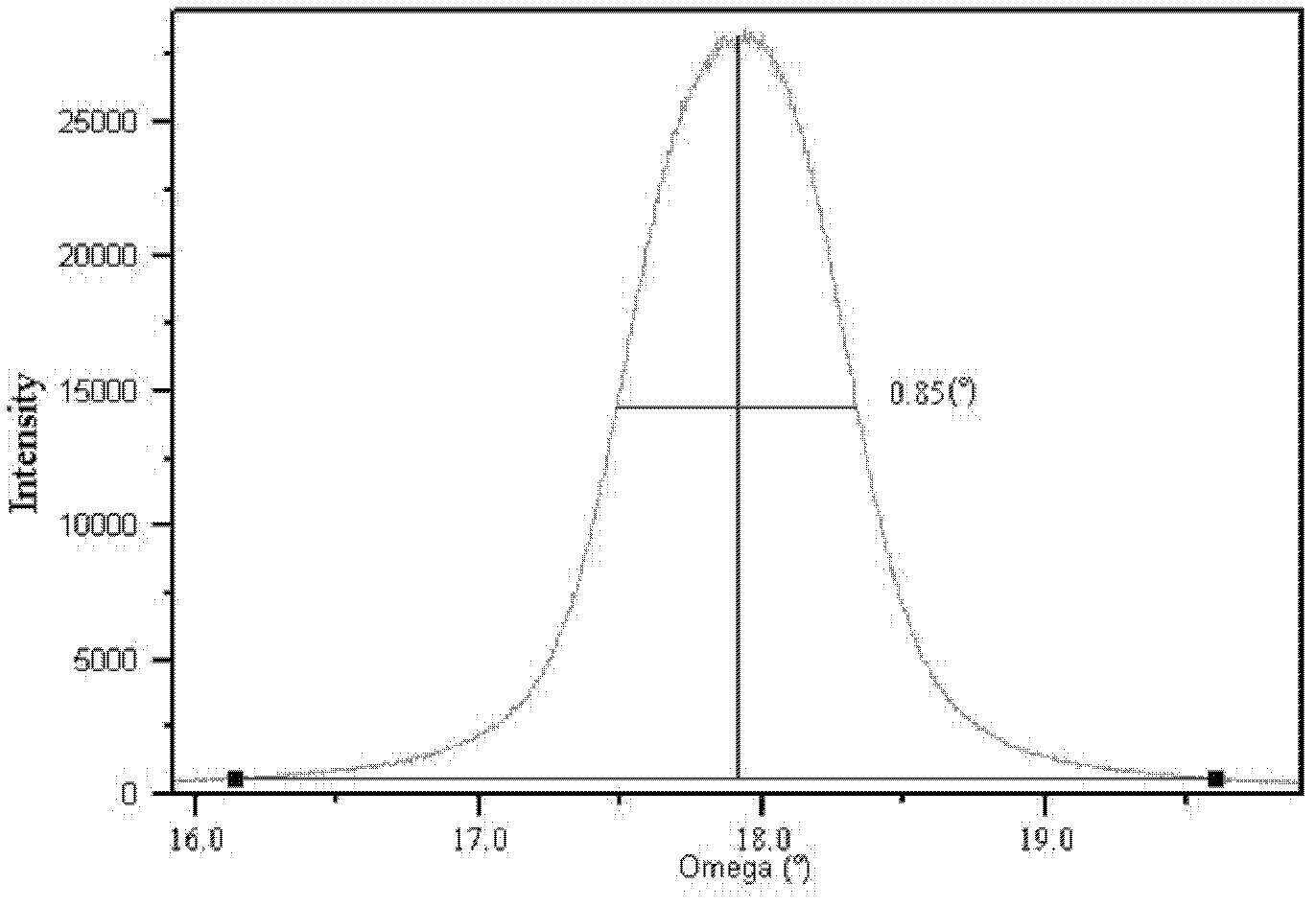

The invention discloses binary material (Zr,Ce)O2 nanodots, and a preparation method and application thereof, belonging to the technical field of high-temperature superconducting materials. The preparation method comprises the following steps: dissolving zirconium acetylacetone and cerium acetylacetone in a zirconium-to-cerium mol ratio of (1-x):x into propanoic acid to obtain a precursor liquid; spreading the precursor liquid onto a monocrystal substrate to obtain a precursor film; in a protective gas atmosphere, sintering the precursor film at 950-1200 DEG C for 10-500 minutes to obtain discontinuous Ce-doped ZrO2 nanodots of which the heights are 5-60nm, the diameters are 20-150nm and the grain density is 10-100 / mu m. A low-fluorine MOD (metal-organic deposition) technique is used for preparing a YBCO (yttrium barium copper oxide) film on a transition layer substrate coated with nanodots to enhance the superconductivity of the YBCO film under the action of an external magnetic field. The shape, number and distribution of the nanodots disclosed by the invention can be effectively controlled in a simple way.

Owner:BEIJING UNIV OF TECH

Biomass fuel having high fuel value, and preparation method thereof

InactiveCN107043646AReduce moisture contentHigh lignin contentBiofuelsSolid fuelsEnvironmental resistanceEngineering

The invention discloses a biomass fuel having a high fuel value, and a preparation method thereof. The biomass fuel comprises, by weight, 40-50 parts of straws, 56-64 parts of Diaphragma juglandis, 11-19 parts of nanometer zinc oxide, 5-12 parts of peroxidase and 8-16 parts of cerium acetylacetonate. The preparation method comprises the following steps: crushing the straws and Diaphragma juglandis, adding water, carrying out heating treatment, adding the peroxidase, sealing and stirring the heated mixture and the peroxidase, mixing obtained mixture with the nanometer zinc oxide and cerium acetylacetonate, cooling the obtained mixture to -5-0 DEG C, carrying out pressurizing heat insulation, heating the obtained mixture to 50-55 DEG C according to a rate of 5 DEG C / 0.5 h, carrying out vacuum pumping during the heat insulation period every 1 h for 10 min, and cooling the mixture to room temperature in order to obtain the biomass fuel. The biomass fuel has the advantages of low water content, high lignin content, high fuel value, long burning time, no smoke or smell in the burning process, cleanness, environmental protection, high forming rate, small size, large specific gravity, high binding capacity of all raw materials, no dust pollution, large density, and wide application range, and can be used in industrial and agricultural production, power generation, heating supply warming, burning boilers, cooking and so on.

Owner:南昌卓尔精诚信息科技有限公司

Method for preparing YBCO superconducting composite film

InactiveCN102690114ARelaxation stressAvoid crackingSuperconductors/hyperconductorsSuperconductor devicesComposite filmSolvent

Disclosed is a method for preparing a YBa2Cu3O7-x (YBCO) superconducting composite film, comprising mixing and dissolving ytterbium acetate <Y(CH3COO)3>, barium acetate <Ba(CH3COO)2>, and cupric acetate <Cu(CH3COO)2> into a water solution of trifluoroacetic acid according to a molar ratio of Y:Ba:Cu of 1.5:2:3; uniformly stirring, and evaporating the above solvent to dryness in vacuum to acquire a gel; adding methanol, uniformly stirring, and evaporating the resulting solvent to dryness to acquire a gel; adding methanol to prepare a precursor liquid in which the total concentration of the three types of metal ions of Y, Ba, and Cu is 1.5-3.0mol / L; coating the precursor liquid on a substrate; allowing the coated film to undergo a process of low-temperature heat treatment to decompose trifluoroacetate; allowing the coated film to undergo a process of high-temperature heat treatment to acquire a YBCO film having a tetragonal phase; coating a precursor liquid of cerium acetylacetonate on the YBCO film and carrying out a high-temperature heat treatment at a temperature ranged from 1000 DEG C to 1100 DEG C; and coating the precursor of Y, Ba, and Cu and the precursor of cerium acetylacetonate in turn repeatedly and carrying out corresponding heat treatment to acquire the YBCO superconducting film having a five-layer structure of YBCO / CeO2 / YBCO / CeO2 / YBCO with a thickness of 1.5 microns.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

Preparation method of yttrium barium copper oxide (YBCO) coating conductor

InactiveCN102751044AActs as flux pinningIncrease the critical current densityCable/conductor manufactureComposite filmElectrical conductor

The invention discloses a preparation method of an yttrium barium copper oxide (YBCO) coating conductor. The method comprises the following steps of: firstly mixing and dissolving yttrium acetate (CH3COO)3, barium acetate Ba (CH3COO)2 and cupric acetate Cu(CH3COO)2 according to the molar rate of Y to Ba to Cu=1.2-1.5 to 2 to 3 into water solution with 10-30 mol percent of trifluoroacetic acid; uniformly stirring the mixture, and drying solvent in vacuum to prepare gel; adding methanol into the mixture for uniformly stirring, and drying the solvent to prepare the gel; subsequently, adding proper amount of methanol and terpinol to prepare a solution of which the total concentration of three metal ions of Y, Ba and Cu is 1.5-3.0mol / L; uniformly stirring the mixture and adding 5-10 percent of acetylacetone having the total ion mol concentration of three metals to prepare a precursor; coating the precursor on a substrate; performing thermal-treatment on the coated film at the low temperature of 300-500 DEG C and decomposing trifluoroacetic acid salt; and finally performing high-temperature thermal treatment at the temperature of 750-850 DEG C and an annealing process at the temperature of 450-550 DEG C to form YBCO superconduction composite film containing nanometer yttrium oxide and nanometer cerium acid barium. The critical current density of the YBCO film prepared by the method reaches 5MA / cm2 (77K, 0T).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Medium-low-temperature denitration catalyst with mesoporous cerium oxide as carrier and preparation method

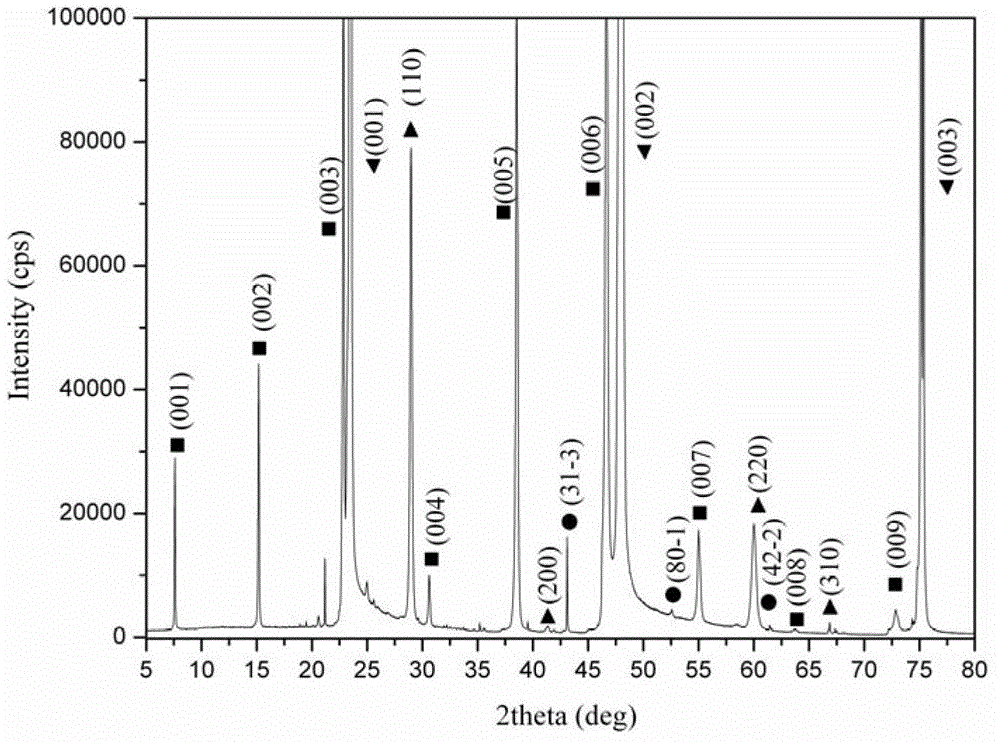

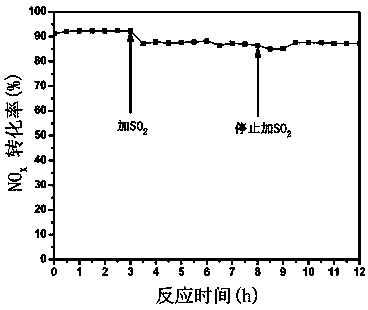

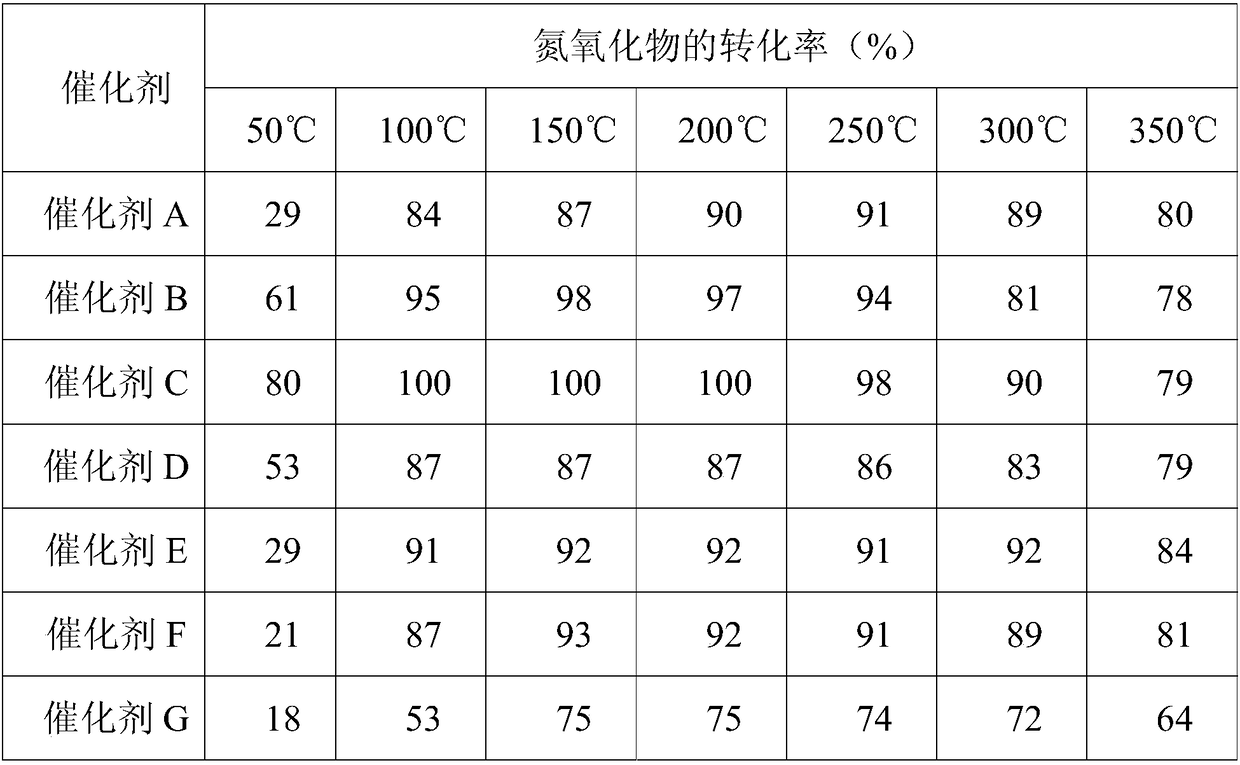

ActiveCN109046324AWon't happenSimple preparation processHeterogenous catalyst chemical elementsDispersed particle separationSulfurSolvent free

The invention discloses a medium-low-temperature denitration catalyst with mesoporous cerium oxide as a carrier and a preparation method. According to the denitration catalyst, the mesoporous cerium oxide is utilized as the carrier, WO3 is utilized as an aid, MnOX is utilized an active ingredient, the mass fraction of the W is 5 to 8%, and the mass fraction of the Mn is 5 to 11%; the catalyst is marked as MnOX-WO3 / CeO2-S-C, wherein the S is equal to a surface active agent, and the C represents organic cerate of cerium acetylacetonate hydrate, cerium isopropoxide, 2-cerium ethylhexoic acid andthe like. According to the medium-low-temperature denitration catalyst disclosed by the invention, the ordered mesoporous aluminum oxide carrier prepared by a solvent-free method has the advantages ofgood ordered mesopores, larger specific surface area, controllable structure, easiness in operation, large-scale production and good application prospect; furthermore, the compound catalyst preparedfrom dipping has a good nitric oxide purifying rate and excellent sulfur resistance in a 100 to 350 DEG C temperature range.

Owner:YANCHENG ENVIRONMENTAL ENG TECH RES & DEV CENT TSINGHUA UNIV

Low-consumption high-strength glass ceramic

Owner:QINGDAO XIANGHAI ELECTRONICS

Microporous ceramic used for processing sewage

InactiveCN106467404AImprove filtering effectExtend the life cycleCeramicwareCeramic sinteringDimethylaniline N-oxide

The invention discloses a microporous ceramic used for processing sewage. The microporous ceramic comprises the following raw materials in parts by weight: 30-42 parts of dimethyl sulfoxide, 5-10 parts of magnesium oxide, 10-18 parts of trichloromethane, 5-10 parts of iron oxide, 11-15 parts of cerium acetylacetonate, 1-4 parts of antimony oxide, 10-22 parts of silicon nitride, 2-5 parts of barium carbonate, 3-10 parts of magnesite, 5-8 parts of dimethylaniline, 20-30 parts of porcelain stone, 1-8 parts of quartz powder, 2-5 parts of allophone, 5-10 parts of aluminum acetylacetonate, 1.5-2.5 parts of polycarbosilane, 2-5 parts of cresol, and 3-5 parts of wollastonite. The microporous ceramic selects a plurality of raw materials with reasonable ratio, the size of the aperture can be controlled in a small scope, the finally produced microporous ceramic has stable and efficient filtering capability. The raw material configuration can uniformly distribute heat during a ceramic sintering process, so that the aperture distribution on the ceramic is more uniform, and the filtering capability stability can be guaranteed.

Owner:郭琳

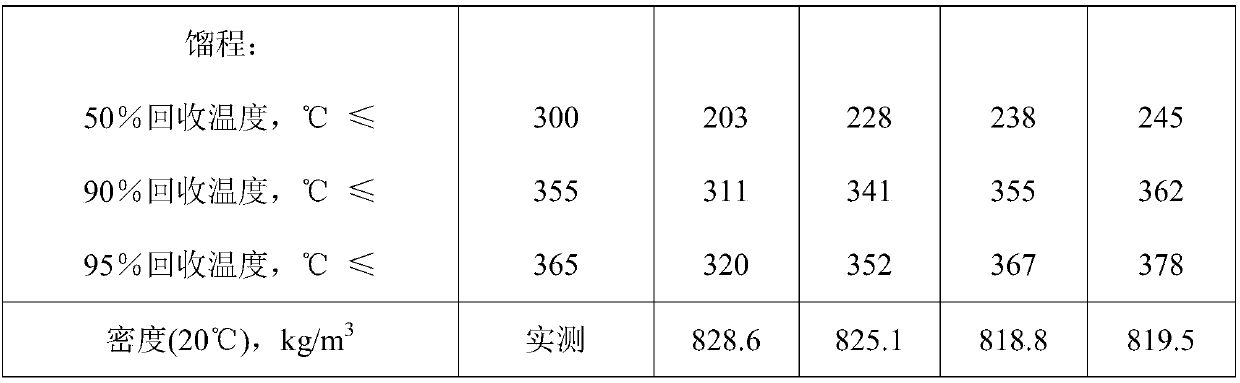

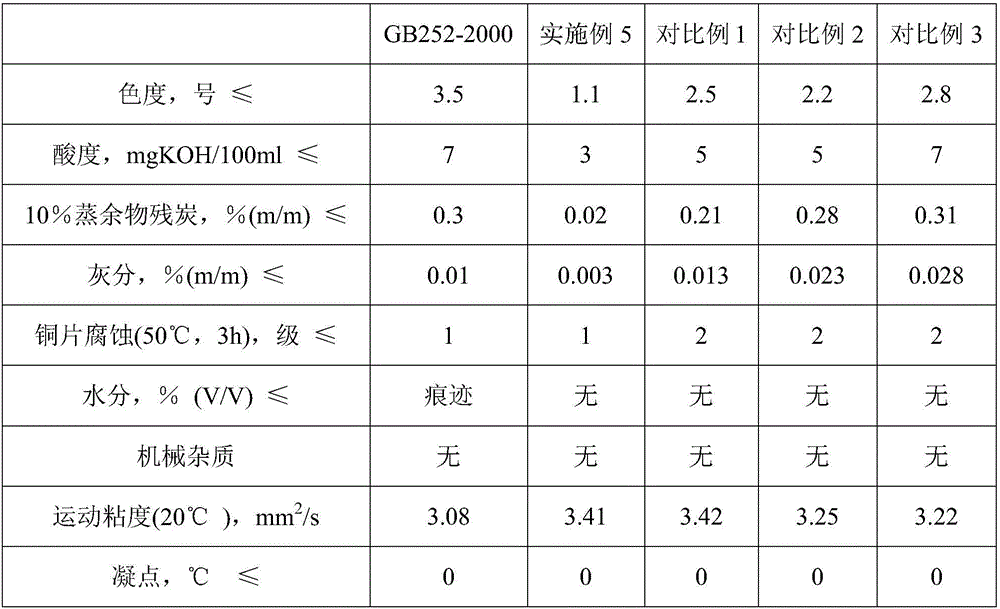

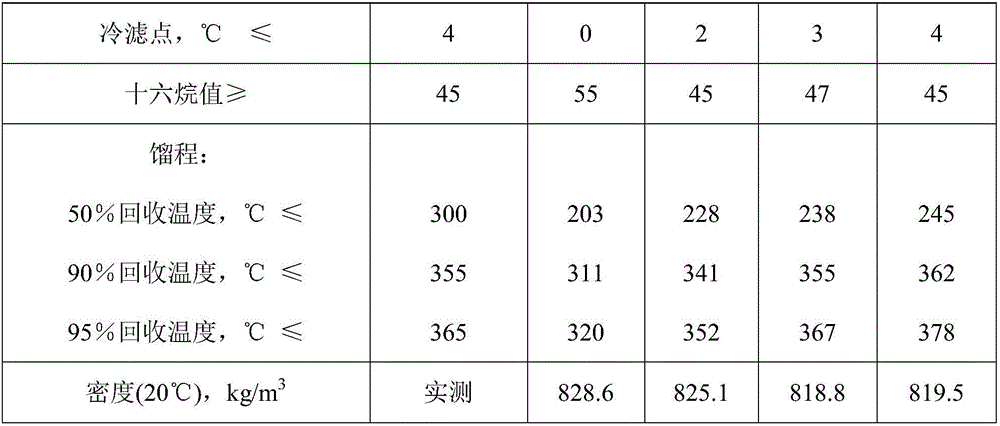

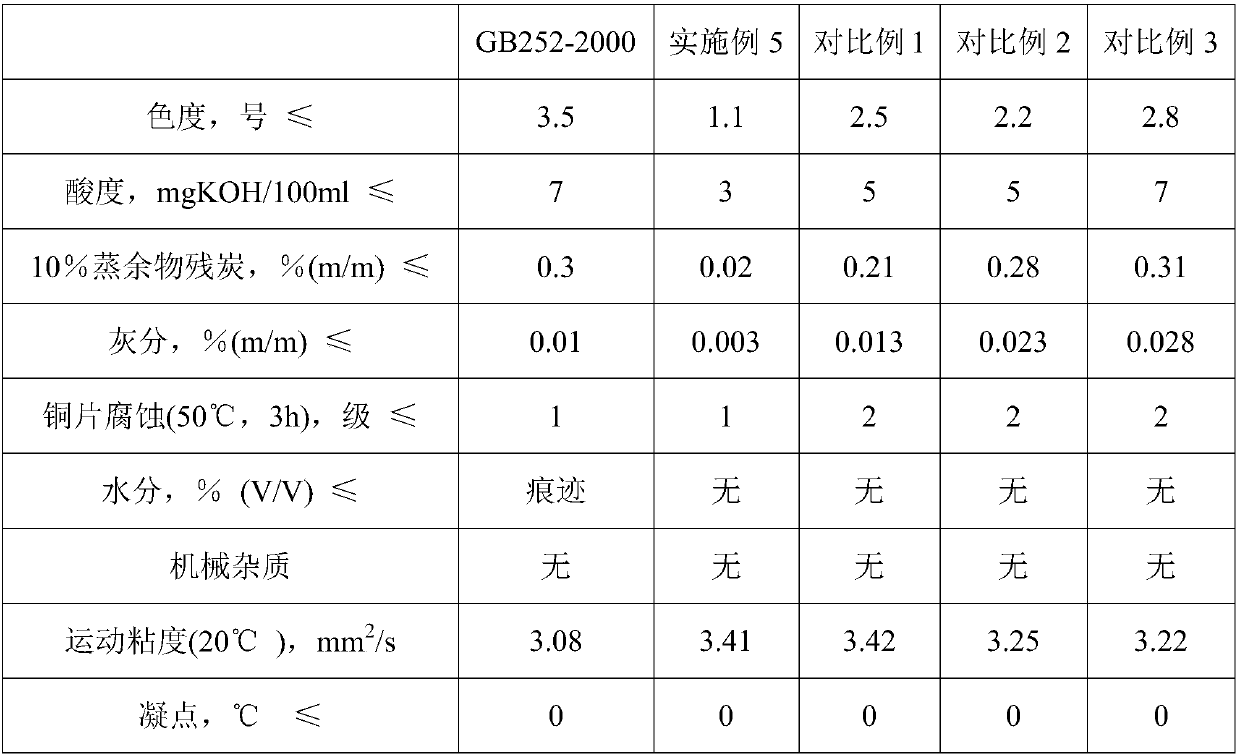

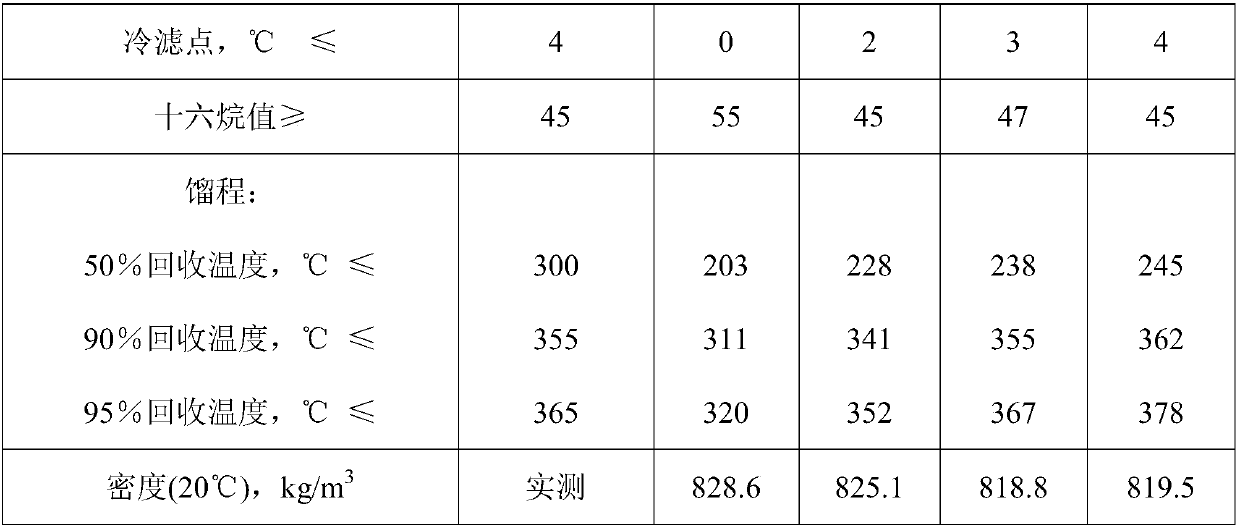

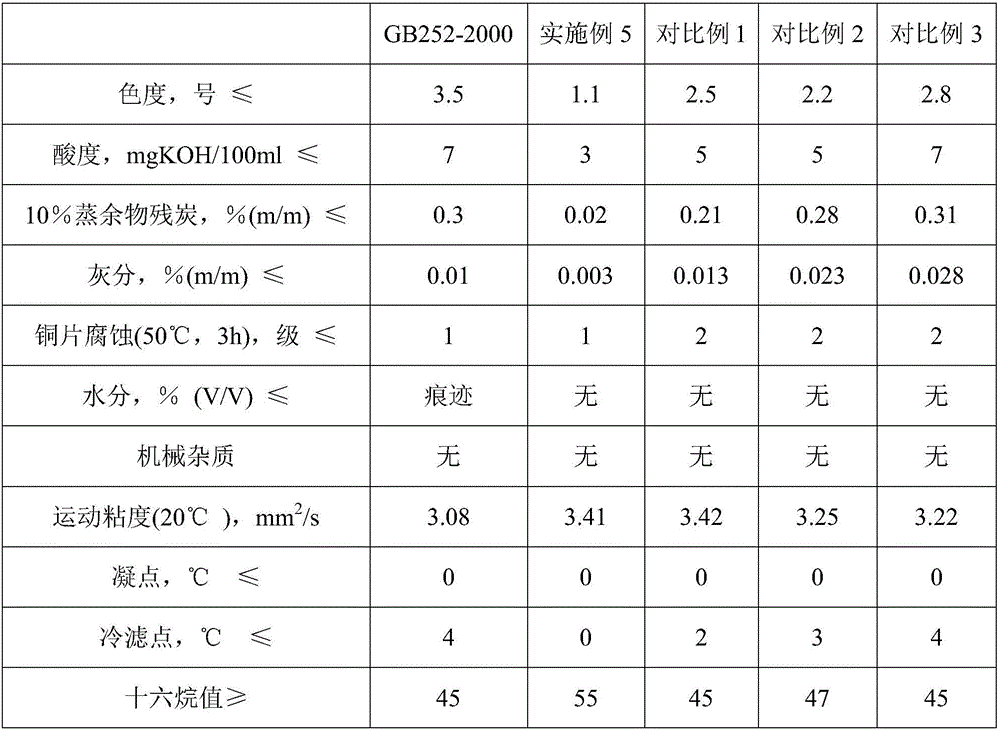

A low-carbon high-clean fuel and its preparation method

ActiveCN106753601BExcellent anticoagulant propertiesReduce manufacturing costLiquid carbonaceous fuelsZno nanoparticlesOxygen

The invention discloses low-carbon and high-cleanness fuel and a preparation method thereof. The fuel is prepared from raw materials in parts by weight as follows: 37-45 parts of methanol, 28-36 parts of diesel, 3-7 parts of tannin, 9-13 parts of cerium acetylacetonate and 2-4 parts of nano-zinc oxide. The preparation method comprises steps as follows: diesel, tannin and cerium acetylacetonate are mixed and are heated and stirred in a sealed manner, and a mixture A is obtained; methanol and nano-zinc oxide are mixed, heated and stirred, and a mixture B is prepared; the mixture A and the mixture B are mixed, heated and ultrasonically processed, and the fuel is prepared. The low-carbon and high-cleanness fuel has a good anticoagulant characteristic, and copper-strip corrosion index is 1. Due to the fact that an oil product contains sufficient oxygen, the fuel is burnt sufficiently, carbon deposition can be effectively reduced, a smoke intensity value is 0.3, purifying rate is 75%, and the fuel has better environmental-friendly performance. According to the low-carbon and high-cleanness fuel and the preparation method thereof, the basic raw materials are widely sourced, few raw materials are adopted, the production process is simple, operation is simple and convenient, production cost is low, and economic benefit and social benefit are remarkable.

Owner:张家界钲浩新能源有限责任公司

Method for preparing composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide

InactiveCN101552344BHigh sintering activityAvoid secondary film formationFinal product manufactureSolid electrolyte fuel cellsPorosityN dimethylformamide

The present invention relates to a method for preparing composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide. The method has characteristics of including steps as follows: (1) selecting raw material: weighing each raw material by weight part as follows: acetylacetone cerium aqua compound 1.5-2.5, acetylacetone gadolinium aqua compound 0.35-0.45, methanol 20-30,N, N-dimethylformamide 0.3-0.5; (2) mixing in room temperature and stirring 40-60 minutes, obtaining the colloidal solution; (3) gelating the colloidal solution in 45-70 DEG C and dehydrating dealcoholize 8-30 hours; (4) when the colloidal solution becomes viscous, the gelating reaction continues 40-60 minutes for obtaining jelly glue; (5) displacing the jelly glue to a vacuum drying case, vacuumdrying 1-2 hours in 130 DEG C, and obtaining the composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide. The product has high denseness and low jelly glue porosity which is benefit for low temperature sintering into a gadolinium oxide adulterating cerium oxide electrolytes film with compact and high density.

Owner:WUHAN UNIV OF TECH

High-dispersity efficient ceramic water reducer

The invention discloses a high-dispersity efficient ceramic water reducer. The high-dispersity efficient ceramic water reducer is characterized by comprising, by weight part, 10-40 parts of magnesite, 15-27 parts of hydroxyethyl cellulose, 3-8 parts of ethylene bis stearamide, 10-14 parts of zirconium oxide, 1.5-3.6 parts of boron nitride, 1.8-7.9 parts of silicon oxide, 25-40 parts of cerium acetylacetonate, 10-21 parts of polycarbosilane, 10-50 parts of polymethylacrylic acid, 15-20 parts of chinastone, 1-8 parts of wollastonite, 5-18 parts of allophane and 15-19 parts of titanate. The high-dispersity efficient ceramic water reducer is higher in water reduction and water dispersity effect, achieves a certain grinding assistance effect for ceramic clay, remarkably reinforces a ceramic biscuit, can reduce the usage of grinding aids and reinforcing agents in the ceramic manufacturing process, and is low in monomer price, easy to prepare and easy to produce industrially.

Owner:QINGDAO XIANGHAI ELECTRONICS

Method for preparing YBCO superconducting composite film

InactiveCN102690114BRelaxation stressAvoid crackingSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentComposite filmTrifluoroacetic acid

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

Low-carbon clean fuel and preparation method thereof

ActiveCN106753602AExcellent anticoagulant propertiesWide variety of sourcesLiquid carbonaceous fuelsOxygenCorrosion

The invention discloses a low-carbon clean fuel and a preparation method thereof. The fuel is prepared from raw materials in parts by weight as follow: 37-45 parts of methanol, 28-36 parts of diesel, 3-7 parts of isinglass, 9-13 parts of cerium acetylacetonate hydrate and 2-4 parts of nano-zinc oxide. The preparation method comprises steps as follows: diesel, fish gelatin and cerium acetylacetonate hydrate are mixed and are heated and stirred in a sealed manner, and a mixture A is prepared; methanol and nano-zinc oxide are mixed, heated and stirred, and a mixture B is prepared; the mixture A and the mixture B are mixed, heated and ultrasonically treated, and the fuel is prepared. The low-carbon clean fuel has a good anticoagulant characteristic, and copper-strip corrosion index is 1. Due to the fact that an oil product contains sufficient oxygen, the fuel is burnt sufficiently, carbon deposition can be effectively reduced, a smoke intensity value is 0.3, purifying rate is 75%, and the fuel has better environmental-friendly performance. According to the low-carbon clean fuel and the preparation method thereof, the basic raw materials are widely sourced, few raw materials are adopted, the production process is simple, operation is simple and convenient, production cost is low, and economic benefit and social benefit are remarkable.

Owner:JIANGSU MORNING ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of magnesium and aluminum doped mesoporous hollow sphere ceria-based oxygen storage material

ActiveCN106082299ASimple preparation stepsHigh specific surface areaRare earth metal compoundsMetal/metal-oxides/metal-hydroxide catalystsSilicic acidCerium

The invention discloses a preparation method of a magnesium and aluminum doped mesoporous hollow sphere ceria-based oxygen storage material and belongs to the technical field of oxygen storage material preparation. The method includes: weighing sodium silicate and water, dropwise adding hydrochloric acid solution, performing ultrasonic dispersion to obtain dispersion liquid, adding magnesium nitrate solution, aluminium nitrate solution, acetone and acetylacetone cerium, enabling the matters to be loaded to the surface of orthosilicic acid sediment under the action of ammonia water titration, performing calcination under nitrogen atmosphere after dehydration, washing with ethyl alcohol, sodium hydroxide solution and deionized water, and filtering to obtain filter residue prior to activation to prepare the magnesium and aluminum doped mesoporous hollow sphere ceria-based oxygen storage material. The preparation method has the advantages that the preparation steps are simple, specific surface area is increased effectively, and oxygen storage capacity is increased by 22-26%; the obtained produce is of a spatial stereostructure, and under the condition of over 1123K, sintering is avoided, and the oxygen storage capacity and the specific surface area are unchanged.

Owner:CHONGQING TONGHUI GAS

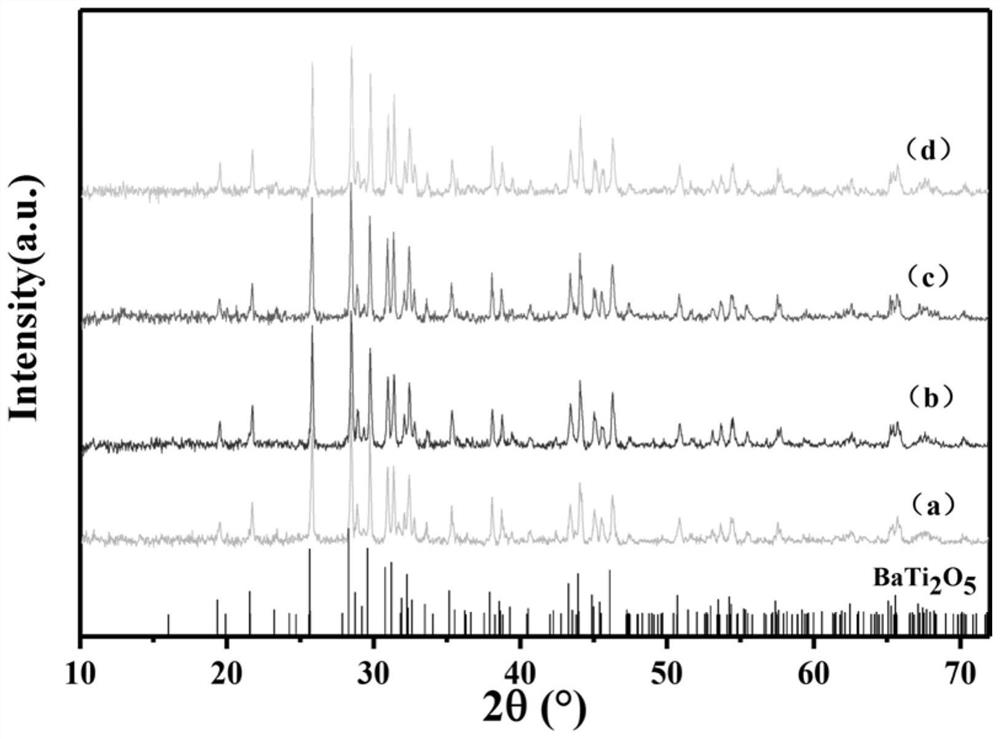

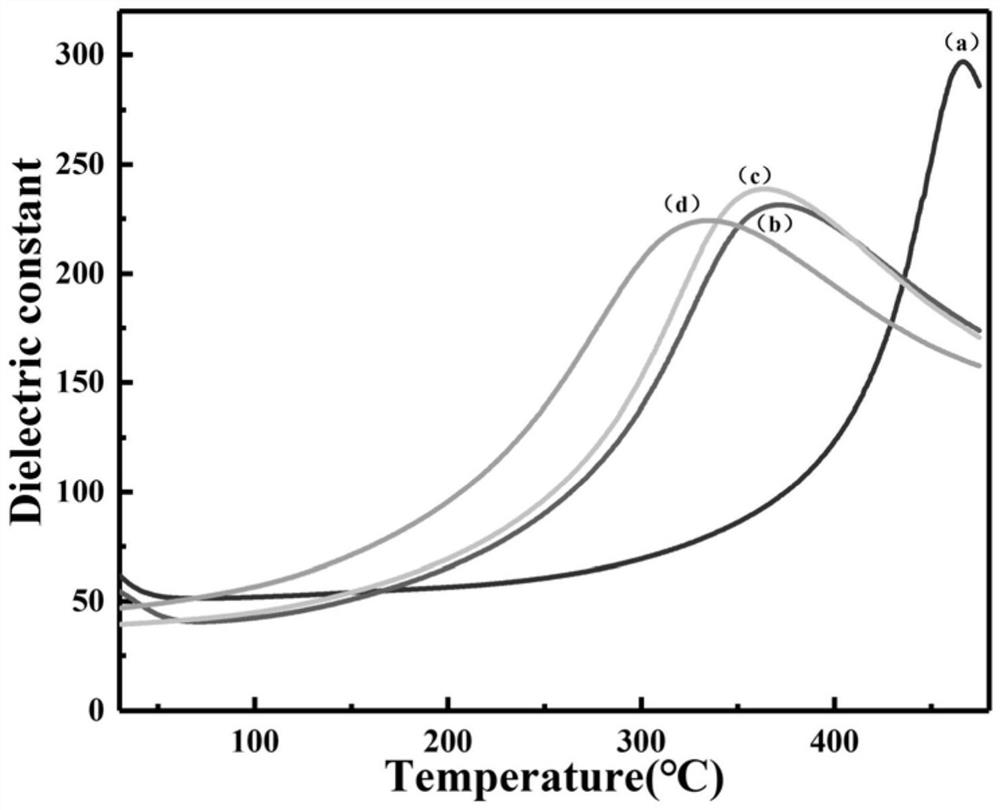

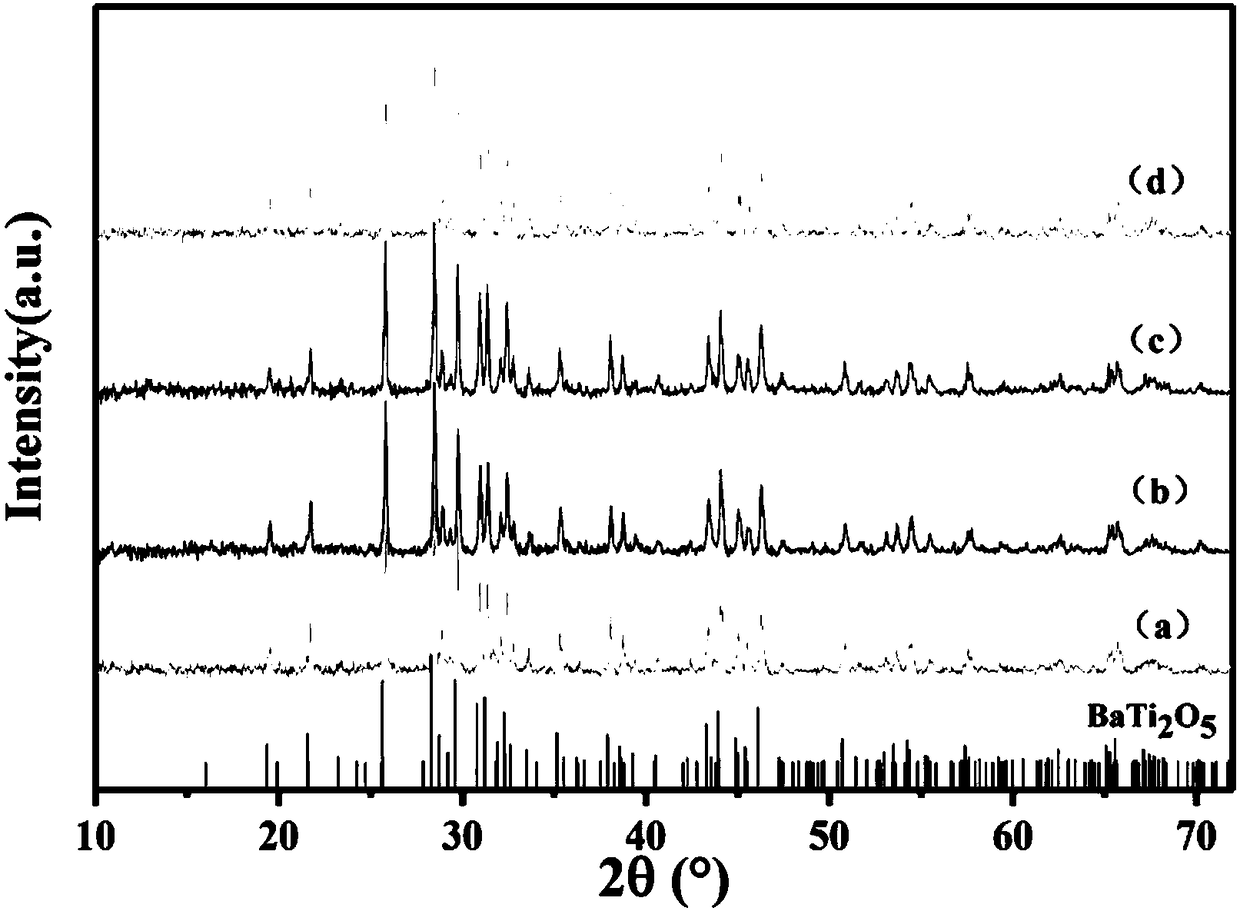

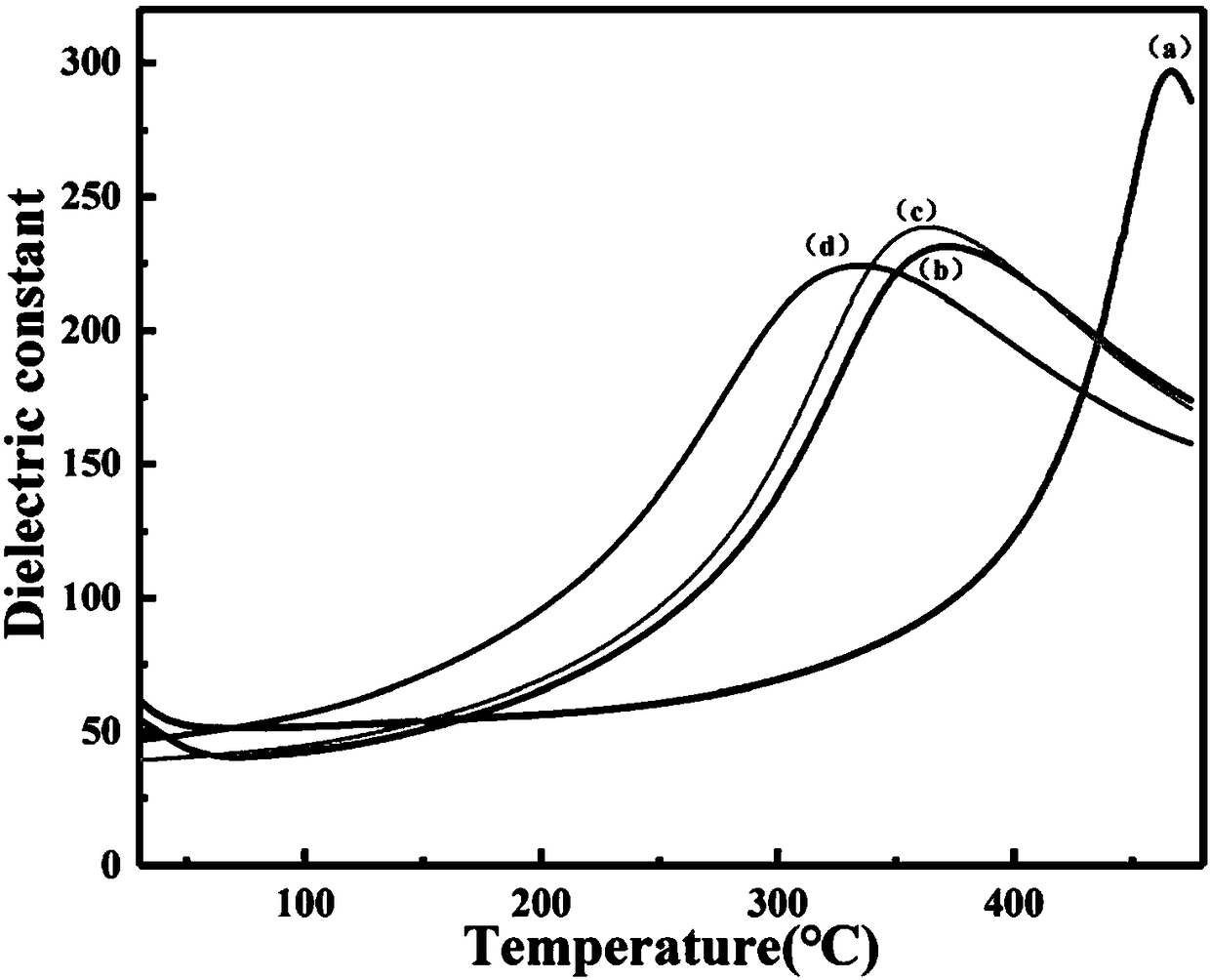

A kind of barium titanate ceramics with wide Curie temperature zone and its preparation method

ActiveCN108314445BMeet the design and use requirementsLower sintering temperatureBarium titanateEuropium

Owner:WUHAN UNIV OF TECH

A kind of low-carbon clean fuel and preparation method thereof

ActiveCN106753602BExcellent anticoagulant propertiesWide variety of sourcesLiquid carbonaceous fuelsZno nanoparticlesOxygen

The invention discloses a low-carbon clean fuel and a preparation method thereof. The fuel is prepared from raw materials in parts by weight as follow: 37-45 parts of methanol, 28-36 parts of diesel, 3-7 parts of isinglass, 9-13 parts of cerium acetylacetonate hydrate and 2-4 parts of nano-zinc oxide. The preparation method comprises steps as follows: diesel, fish gelatin and cerium acetylacetonate hydrate are mixed and are heated and stirred in a sealed manner, and a mixture A is prepared; methanol and nano-zinc oxide are mixed, heated and stirred, and a mixture B is prepared; the mixture A and the mixture B are mixed, heated and ultrasonically treated, and the fuel is prepared. The low-carbon clean fuel has a good anticoagulant characteristic, and copper-strip corrosion index is 1. Due to the fact that an oil product contains sufficient oxygen, the fuel is burnt sufficiently, carbon deposition can be effectively reduced, a smoke intensity value is 0.3, purifying rate is 75%, and the fuel has better environmental-friendly performance. According to the low-carbon clean fuel and the preparation method thereof, the basic raw materials are widely sourced, few raw materials are adopted, the production process is simple, operation is simple and convenient, production cost is low, and economic benefit and social benefit are remarkable.

Owner:JIANGSU MORNING ENVIRONMENTAL PROTECTION TECH CO LTD

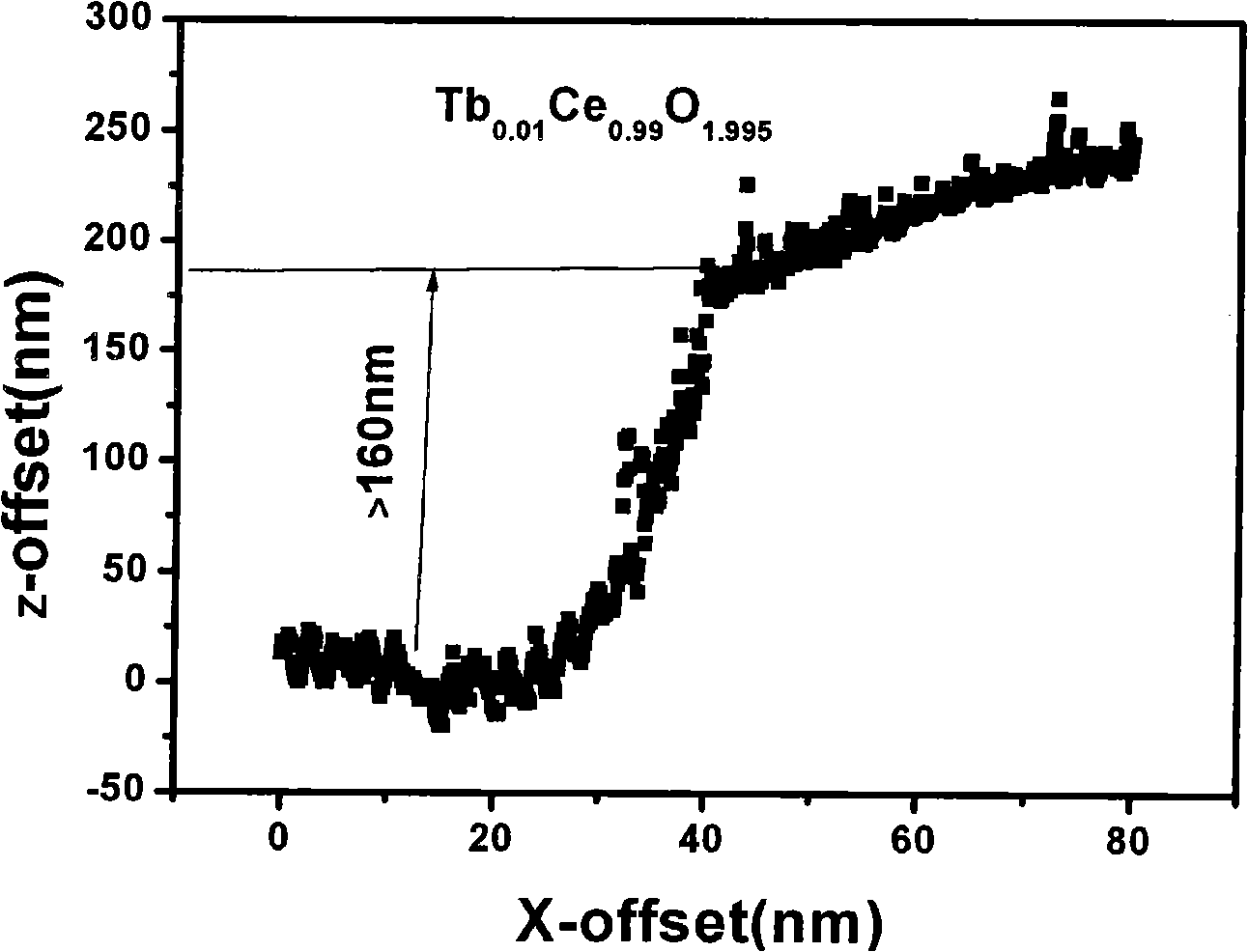

Binary material (Zr,Ce)O2 nanodots, and preparation method and application thereof

The invention discloses binary material (Zr,Ce)O2 nanodots, and a preparation method and application thereof, belonging to the technical field of high-temperature superconducting materials. The preparation method comprises the following steps: dissolving zirconium acetylacetone and cerium acetylacetone in a zirconium-to-cerium mol ratio of (1-x):x into propanoic acid to obtain a precursor liquid;spreading the precursor liquid onto a monocrystal substrate to obtain a precursor film; in a protective gas atmosphere, sintering the precursor film at 950-1200 DEG C for 10-500 minutes to obtain discontinuous Ce-doped ZrO2 nanodots of which the heights are 5-60nm, the diameters are 20-150nm and the grain density is 10-100 / mu m. A low-fluorine MOD (metal-organic deposition) technique is used for preparing a YBCO (yttrium barium copper oxide) film on a transition layer substrate coated with nanodots to enhance the superconductivity of the YBCO film under the action of an external magnetic field. The shape, number and distribution of the nanodots disclosed by the invention can be effectively controlled in a simple way.

Owner:BEIJING UNIV OF TECH

Method for preparing high temperature superconduction coating conductor buffer layer using polymer auxiliary deposition

InactiveCN101281806BEvenly distributedIncrease viscositySuperconductors/hyperconductorsSuperconductor device manufacture/treatmentElectrical conductorPolyvinyl alcohol

A method for producing the buffer layer of a conductor coated with high temperature superconducting coating by means of macromolecule assisted deposition, which comprises: a. preparing waterless: weigh rare-earth acetate, or rare-earth propoxide, or rare-earth acetylacetonate, or zirconium propoxide, or zirconium n-butoxide and cerium acetylacetonate at an ionic ratio of rare-earth or zirconium: cerium as x:1-x (0.01<=x<=0.5), dissolve the compound in an organic solvent to form a waterless; b. preparing colloid: add polyvinyl butyral, or polyethylene glycol, or polyvinyl pyrrolidone, or polyvinyl alcohol, or polyoxyethylene to the waterless solution to form colloid; c. coating the colloid and drying: coat the colloid on a substrate and then dry the substrate; d. sintering: load the substrate into a sintering oven, heat up to 850-1150 DEG C at 5-100DEG C / min, hold for 0.25-2h, and drop the temperature at 1-2 DEG C / min to room temperature. The method is characterized in simple process, easy operation control, low cost, and free of environment pollution; the single-layer cerium oxide buffer layer obtained can be in critical thickness of 150-200nm.

Owner:SOUTHWEST JIAOTONG UNIV

Nitrogen oxide adsorbent as well as preparation method and application thereof

InactiveCN106390917AHigh mechanical strengthExtended service lifeGas treatmentOther chemical processesHigh concentrationGallic acid ester

The invention discloses a nitrogen oxide adsorbent as well as a preparation method and an application thereof. The nitrogen oxide adsorbent is prepared from raw materials in parts by weight as follows: 26-34 parts of nano-attapulgite, 9-17 parts of gallic acid, 5-13 parts of peroxidase and 1-5 parts of cerium acetylacetonate. The adsorbent is prepared from the nano-attapulgite and cerium acetylacetonate through mixed grinding as well as treatment and ultrasonication with gallic acid and peroxidase, so that the adsorbent has higher mechanical strength, the service life of the adsorbent is prolonged, and the replacement frequency is reduced. The adsorbent has quite high treatment efficiency on high-concentration nitrogen oxides and has the advantages of high purification speed, good treatment effect, high adsorption capacity, long replacement period and the like; the adsorbent is harmless to human body, non-corrosive, stable in performance and simple to operate, needs no special equipment and cannot produce secondary pollution in a treatment process. The preparation process is simple, the operation is easy, the cost is low, efficiency and environmental performance are realized, and industrial production is facilitated.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

A preparation method of cerium-based oxygen storage material doped with magnesium and aluminum mesoporous hollow microspheres

ActiveCN106082299BSimple preparation stepsLarge specific surface areaRare earth metal compoundsMetal/metal-oxides/metal-hydroxide catalystsSilicic acidCerium

Owner:CHONGQING TONGHUI GAS

A kind of low-carbon high-clean diesel vehicle fuel and preparation method thereof

ActiveCN108219869BExcellent anticoagulant propertiesPromote environmental protectionLiquid carbonaceous fuelsCombustion chamberInjector nozzle

The invention discloses fuel for a low-carbon and high-cleanness diesel vehicle as well as a preparation method thereof. The fuel consists of the following raw materials in parts by weight: 10 to 20 parts of methanol, 33 to 41 parts of diesel, 5 to 12 parts of sodium formaldehyde sulfoxylate, 11 to 19 parts of itaconic acid, 3 to 7 parts of cerium acetone and 1 to 3 parts of nanometer zinc oxide.The fuel, which is prepared by pretreating diesel by the itaconic acid and the nanometer zinc oxide and then mixing the itaconic acid and the nanometer zinc oxide as well as other raw materials, has excellent anticoagulant characteristic, the copper sheet corrosion index is 1, and the corrosion phenomenon, which is higher than that caused by the diesel for vehicles, on an oil tank, an oil conveying pipe, an oil spraying nozzle and an engine combustion chamber is avoided during use. The oil product contains sufficient oxygen, so that the fuel can be combusted completely, carbon deposition can be effectively reduced, the smoke intensity value is 0.3, the purification rate is 75 percent and more excellent environmental friendliness is achieved. The basic raw materials have diversified sources, the production process is simple and is simple and convenient to operate, the production cost is low, and remarkable economical benefit and social benefit are achieved.

Owner:郝德厚

Process for preparing water-soluble ceria nanocrystalline

A method for preparing water-soluble ceria nanocrystals belongs to the technical field of nanomaterials. Existing CeO2 nanoparticles include non-surface-modified and oil-soluble CeO2 nanoparticles. The present invention adopts reflux hydrolysis method. The steps are: 1. Synthesis of water-soluble CeO2 nanoparticles dispersed in the solution. A reflux hydrolysis method is adopted, the cerium source is cerium acetylacetonate, and 2-pyrrolidone is used as a solvent and a surface modifier. The technical parameters are: reflux hydrolysis temperature: 225-240°C, reflux time: 60-120min. 2. Separation of water-soluble CeO2 nanoparticles from the solution. The solution containing the water-soluble CeO2 nanoparticles was cooled to room temperature, precipitated with methanol, centrifuged, washed with acetone, and dried. The technical parameters are: the amount of methanol used is 200-300ml, the amount of acetone used is 50-80ml, and dried with N2 flow for 4h or at 50-60°C for 5-10h. The final prepared water-soluble CeO2 nanoparticles have an average particle diameter of about 5nm-10nm and are spherical.

Owner:CHANGCHUN UNIV OF SCI & TECH

Barium titanate ceramic with wide curie temperature region and preparation method thereof

ActiveCN108314445AMeet the design and use requirementsLower sintering temperatureBarium titanateCerium

The invention relates to barium titanate ceramic with a wide curie temperature region and a preparation method thereof. The preparation method comprises the following steps: 1) dissolving one of cerium-2,4-pentanedionate hydrate, samarium nitrate hexahydrate and europium nitrate hexahydrate into glacial acetic acid together with barium acetate to obtain a barium-source solution; 2) dissolving tetrabutyl titanate into ethylene glycol monomethyl ether to obtain a titanium-source solution; 3) mixing the barium-source solution with the titanium-source solution, aging and drying obtained sol to obtain xerogel and then presintering, balling and drying to obtain barium titanate powder; 4) sequentially granulating, dry pressing and shaping, discharging sol and pressurelessly sintering the barium titanate to obtain barium titanate ceramic. The barium titanate ceramic disclosed by the invention has a wider curie temperature region, can meet design and use requirements of high-temperature ferroelectric devices and further has the advantage of good single phase.

Owner:WUHAN UNIV OF TECH

Preparation method of low-carbon clean fuel

InactiveCN106635187AExcellent anticoagulant propertiesWide variety of sourcesLiquid carbonaceous fuelsEngineeringOxygen

The invention discloses a preparation method of low-carbon clean fuel. The low-carbon clean fuel is prepared from the following raw materials in parts by weight: 37-45 parts of ethanol, 28-36 parts of diesel oil, 3-7 parts of swimming bladder glue, 9-13 parts of cerium acetylacetonate and 2-4 parts of nano-zinc oxide. The preparation method comprises the following steps: mixing and sealing the diesel oil, the swimming bladder glue and cerium acetylacetonate, heating, and stirring, so as to prepare a mixture A; mixing ethanol with nano-zinc oxide, heating, and stirring, so as to prepare a mixture B; and mixing the mixture A with the mixture B, heating, and carrying out ultrasonic treatment, so as to obtain the low-carbon clean fuel. The low-carbon clean fuel has an excellent anti-freezing property, and a copper corrosion index is 1; an oil product contains sufficient oxygen, so that the fuel can be adequately burnt, and the generation of carbon deposition is effectively reduced; and the smoke intensity value is 0.3, the purifying rate is 75%, and the low-carbon clean fuel has relatively excellent environmental protection performance. The preparation method has the beneficial effects that the sources of the basic raw materials are wide, the adopted raw materials are few, the production process is simple, the operation is simple and convenient, the production cost is low, and the economic and social benefits are remarkable.

Owner:HENAN TIMECLOUD COMM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com