A kind of barium titanate ceramics with wide Curie temperature zone and its preparation method

A technology of barium titanate and ceramics, applied in the field of barium titanate ceramics and its preparation, can solve the problems of low powder purity, high sintering temperature, poor phase stability, etc., and achieve easy control of doping amount and low sintering temperature , The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

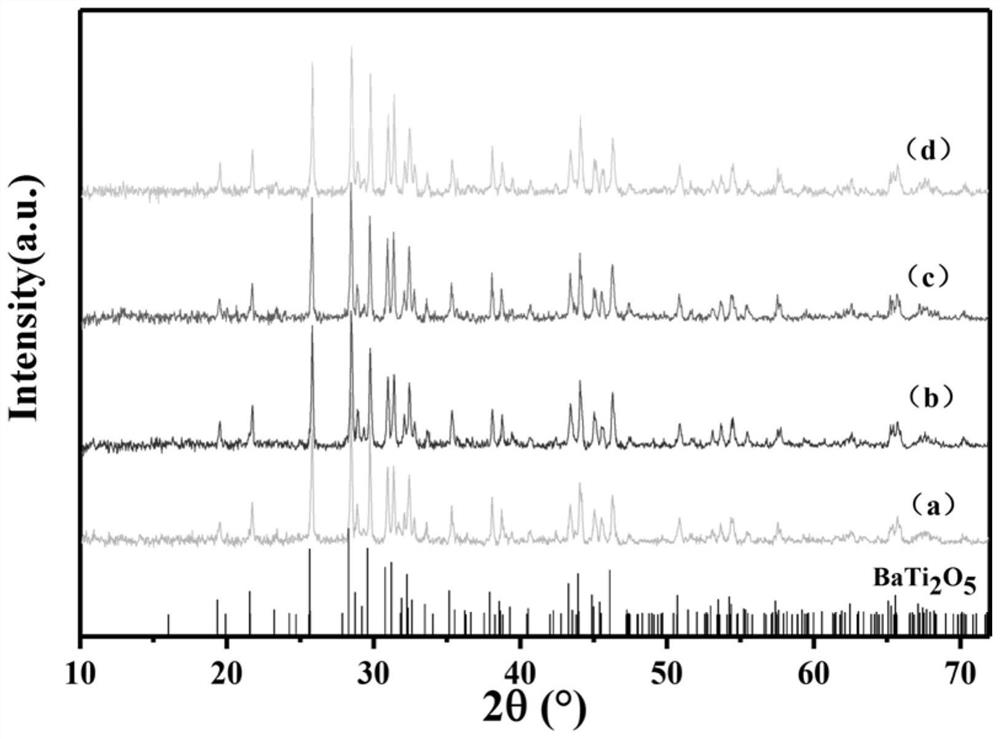

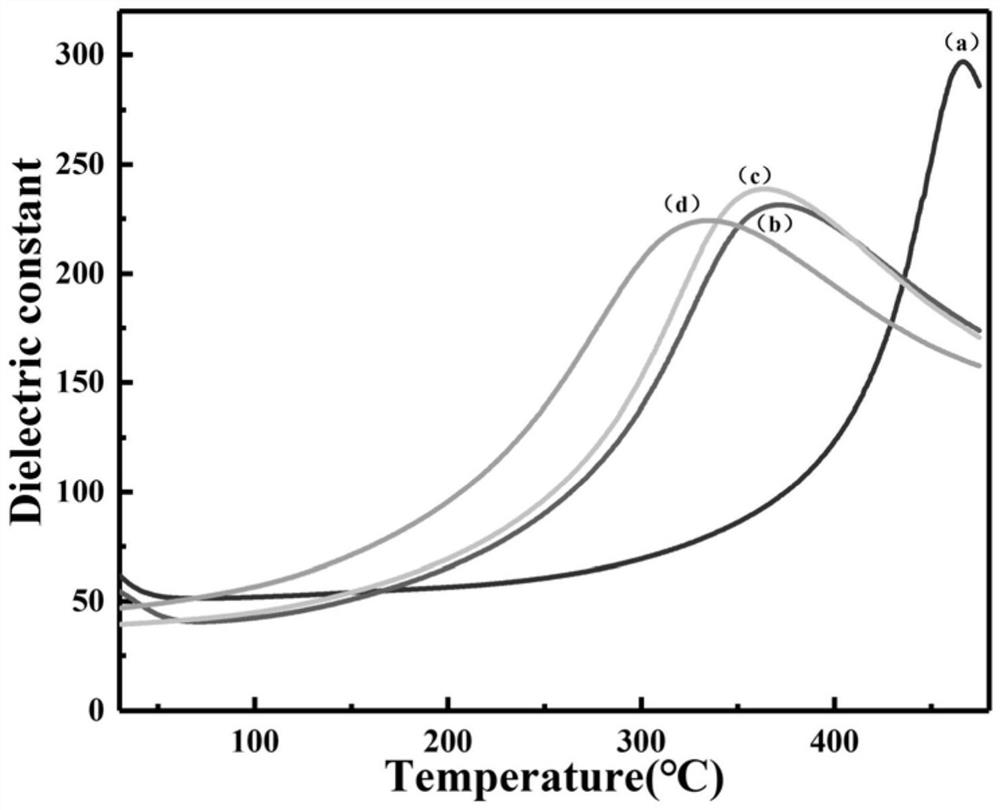

[0039] To prepare barium titanate ceramics with a wide Curie temperature zone, the specific steps are as follows:

[0040] Dissolve 7.740g of barium acetate and 0.040g of samarium nitrate hexahydrate in 25mL of glacial acetic acid to obtain a barium source solution, dissolve 20.838g of tetrabutyl titanate in 20mL of ethylene glycol methyl ether to obtain a titanium source solution, and then dissolve the barium The source solution and the titanium source solution were mixed (molar ratio Ba:Ti:Sm=1:2:0.003), stirred for 12 hours to obtain a barium dititanate precursor sol, and the resulting sol was aged in air for 4 hours, and then placed at 120°C Dry in an electric blast drying oven for 24 hours to obtain barium dititanate precursor xerogels, grind the xerogels and pre-calcine them, and heat them up to 850°C at room temperature for 3 hours at a rate of 4°C / min to obtain the two Barium titanate powder, the powder is ball milled for 10h (the speed of the ball mill is 540 rpm), th...

Embodiment 2

[0044] To prepare barium titanate ceramics with a wide Curie temperature zone, the specific steps are as follows:

[0045] Dissolve 7.740g of barium acetate and 0.054g of europium nitrate hexahydrate in 25mL of glacial acetic acid to obtain a barium source solution, dissolve 20.838g of tetrabutyl titanate in 20mL of ethylene glycol methyl ether to obtain a titanium source solution, and then dissolve the barium The source solution and the titanium source solution were mixed (molar ratio Ba:Ti:Eu=1:2:0.004), stirred for 12 hours to obtain a barium titanate precursor sol, and the obtained sol was aged in air for 4 hours, and then placed in 120°C Dry in an electric blast drying oven for 24 hours to obtain barium dititanate precursor xerogels, grind the xerogels and pre-calcine them, and heat them up to 850°C at room temperature for 3 hours at a rate of 4°C / min to obtain the two For barium titanate powder, ball mill the powder for 10 hours, then dry the ball-milled slurry, add 5 wt...

Embodiment 3

[0049] To prepare barium titanate ceramics with a wide Curie temperature zone, the specific steps are as follows:

[0050] 7.740g of barium acetate and 0.052g of cerium acetylacetonate (III) hydrate were dissolved in 25mL of glacial acetic acid to obtain a barium source solution, 20.838g of tetrabutyl titanate was dissolved in 20mL of ethylene glycol methyl ether to obtain a titanium source solution, and then Mix the barium source solution and the titanium source solution at room temperature (molar ratio Ba:Ti:Ce=1:2:0.004), stir for 12 hours to obtain a barium dititanate precursor sol, place the obtained sol in air and age it for 4 hours, Put it in a 120°C electric blast drying oven and dry it for 24 hours to obtain the dry gel of barium titanate precursor. After the dry gel is ground, it is pre-calcined. At room temperature, the temperature is raised to 900°C at a rate of 4°C / min. 5h, to obtain the barium titanate powder, ball mill the powder for 10h, then dry the ball-mille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com