Patents

Literature

73 results about "Batio3 ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Utilization of poly(ethylene terephthalate) plastic and composition-modified barium titanate powders in a matrix that allows polarization and the use of integrated-circuit technologies for the production of lightweight ultrahigh electrical energy storage units (EESU)

InactiveUS7466536B1Low costLower sintering temperatureCell electrodesFixed capacitor dielectricManufacturing technologyBarium titanate

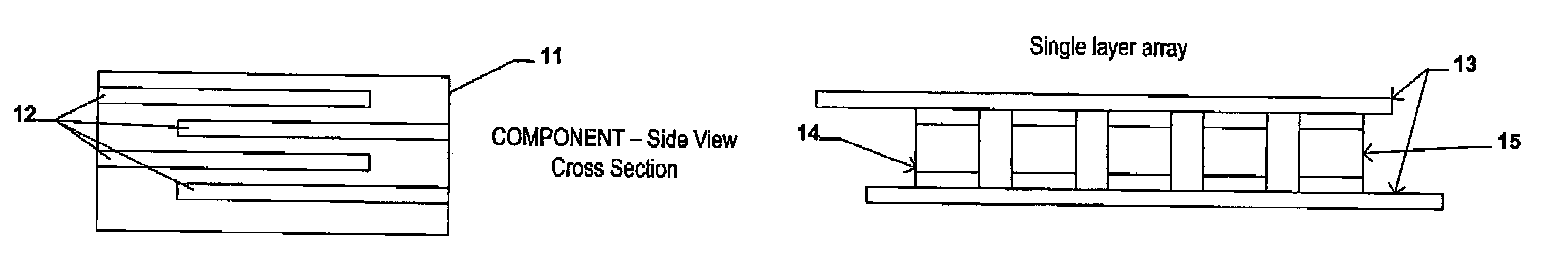

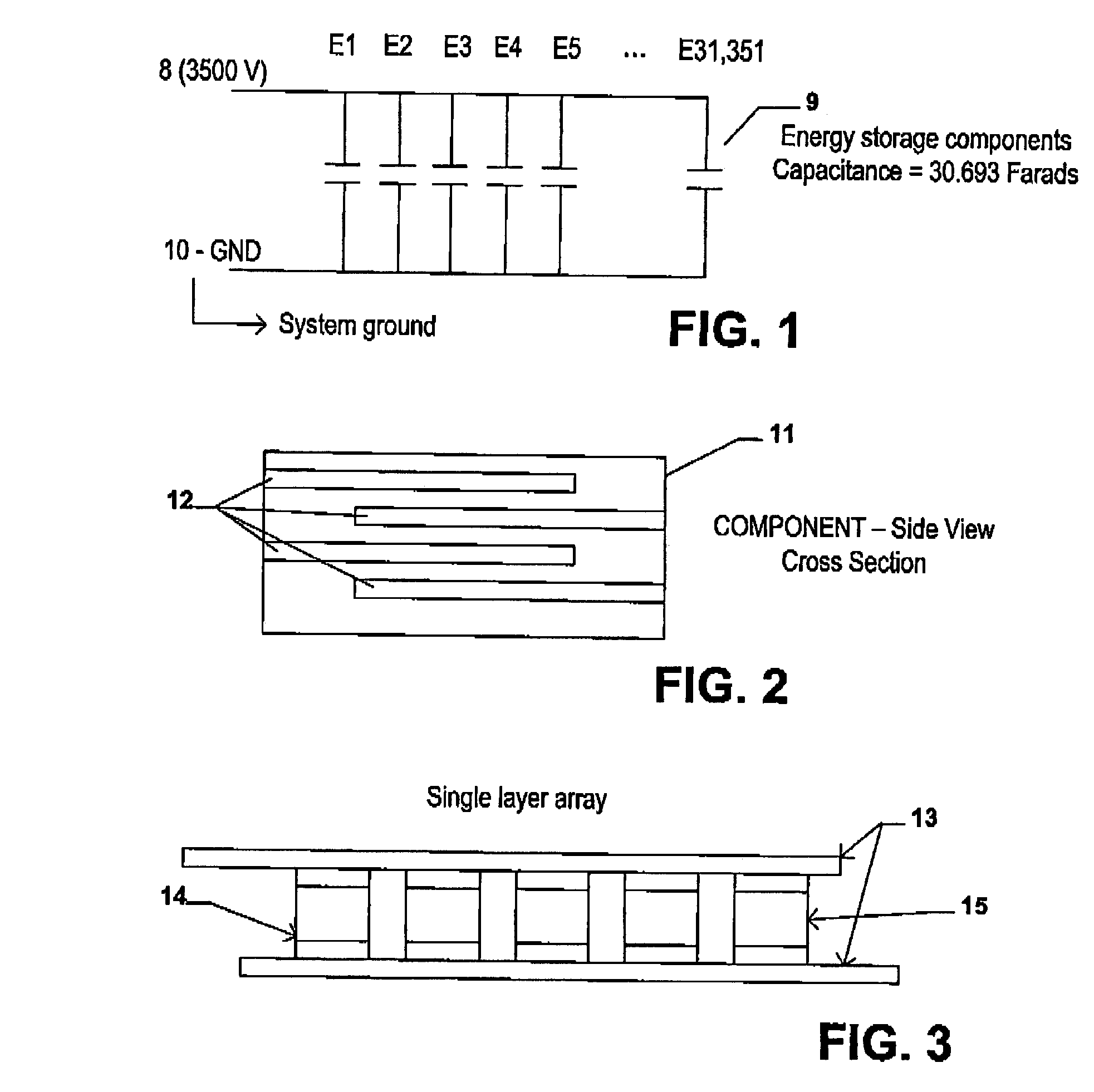

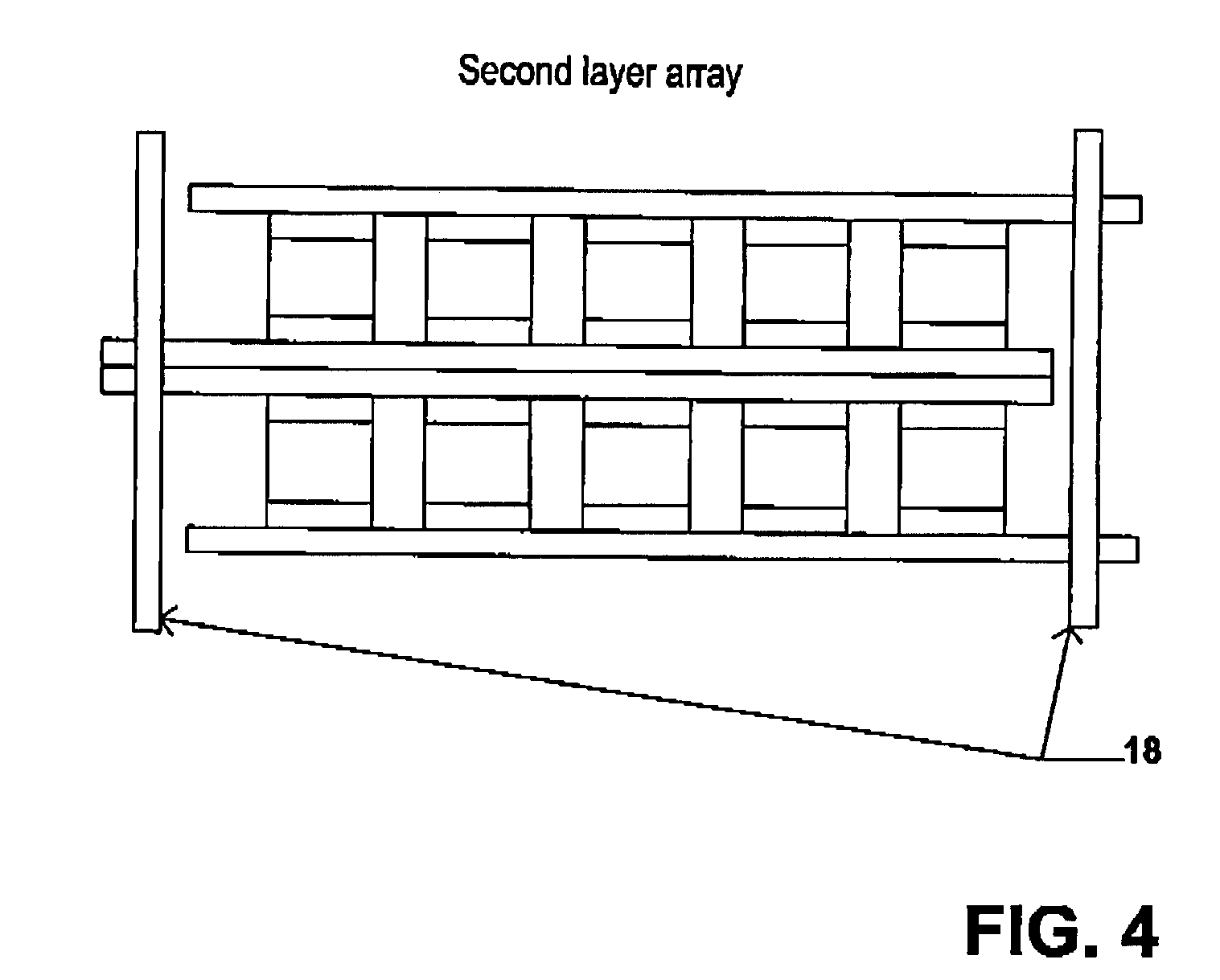

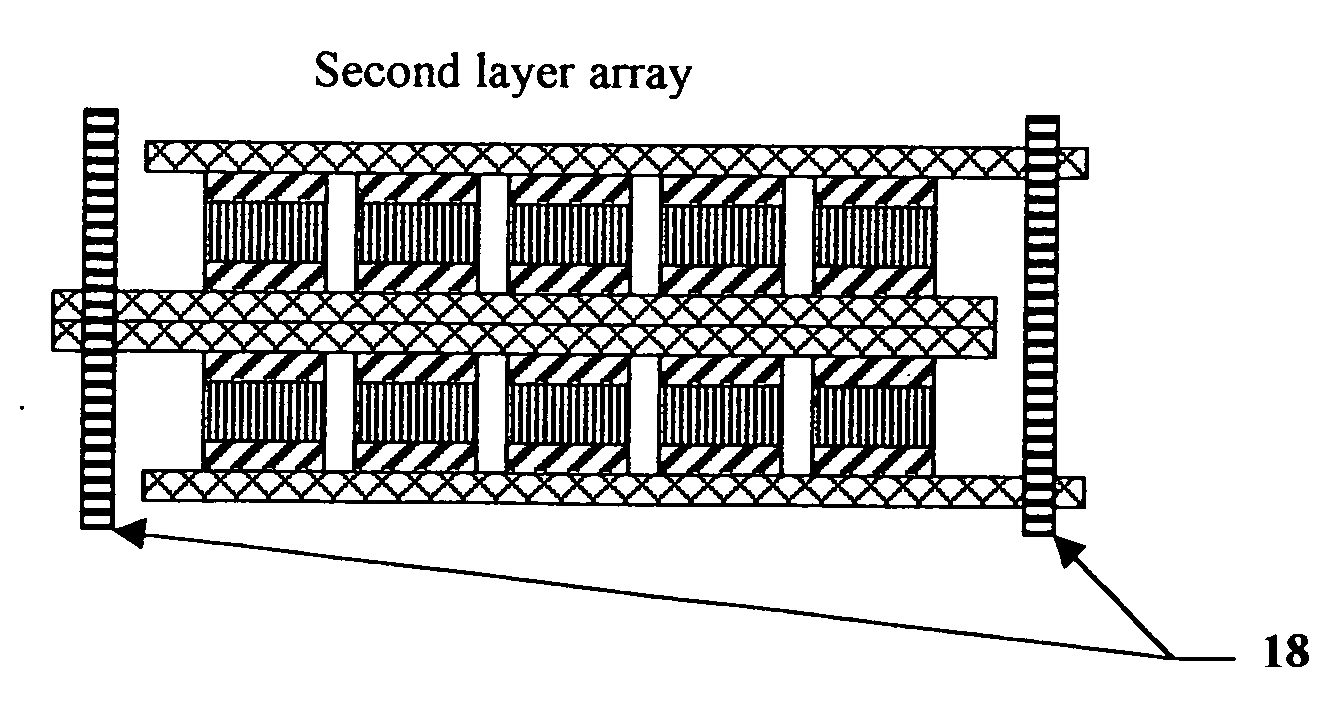

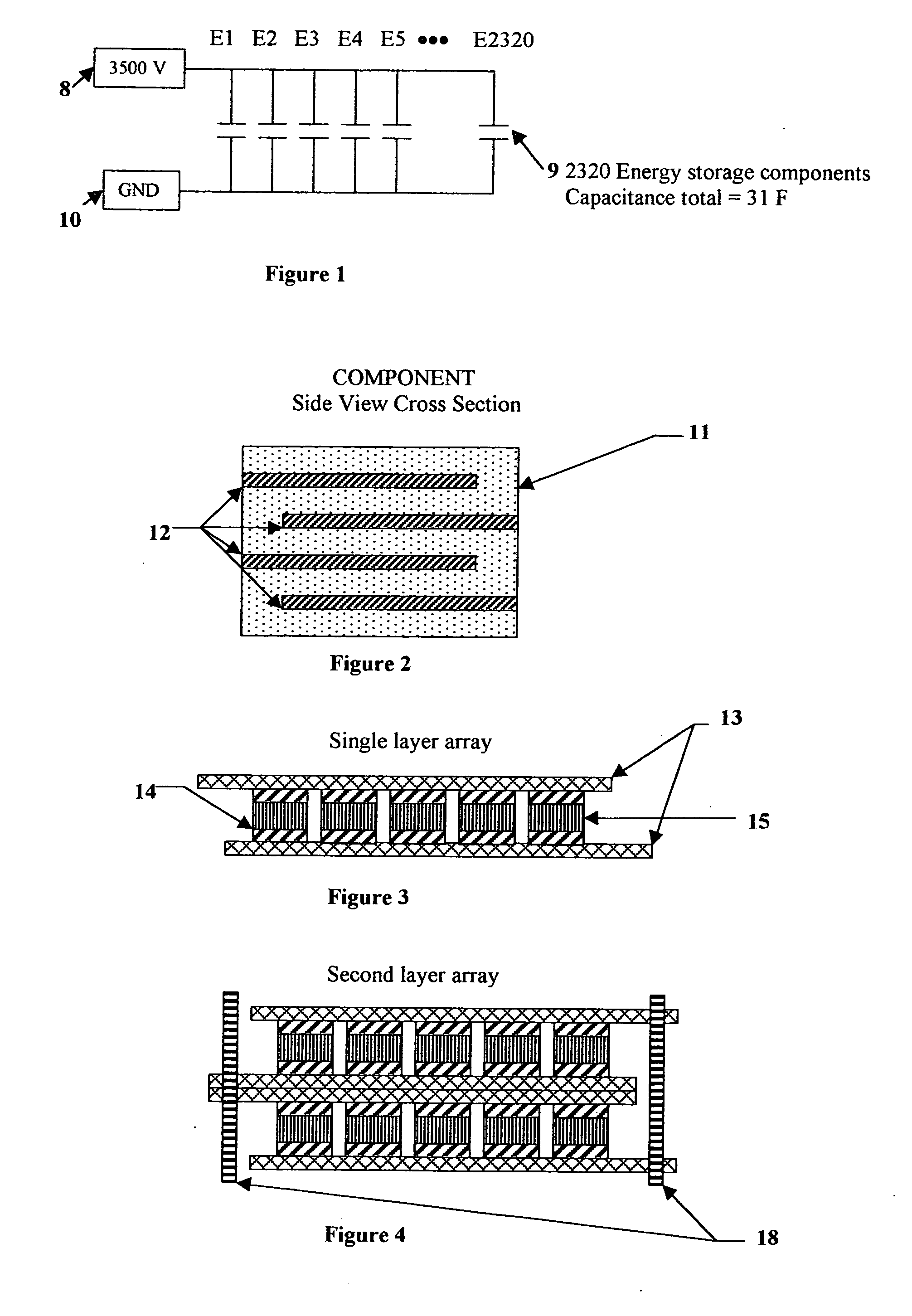

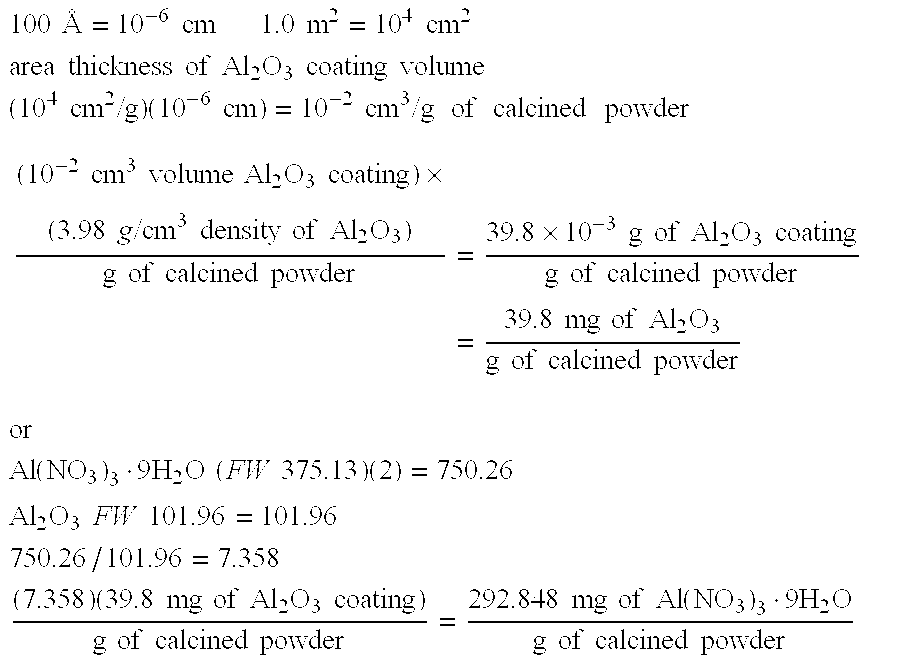

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is single coated with aluminum oxide and then immersed in a matrix of poly(ethylene terephthalate) (PET) plastic for use in screen-printing systems. The ink that is used to process the powders via screen-printing is based on a nitrocellulose resin that provide a binder burnout, sintering, and hot isostatic pressing temperatures that are allowed by the PET plastic. These lower temperatures that are in the range of 40° C. to 150° C. also allows aluminum powder to be used for the electrode material. The components of the EESU are manufactured with the use of conventional ceramic and plastic fabrication techniques which include screen printing alternating multilayers of aluminum electrodes and high-permittivity composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The 31,351 components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store at least 52.22 kW·h of electrical energy. The total weight of an EESU with this amount of electrical energy storage is 281.56 pounds including the box, connectors, and associated hardware.

Owner:EESTOR

Piezoelectric ceramic fibers having metallic cores

ActiveUS20050274176A1Simple structureReduce the voltage rangePiezoelectric/electrostriction/magnetostriction machinesTyre measurementsMicrocontrollerFiber

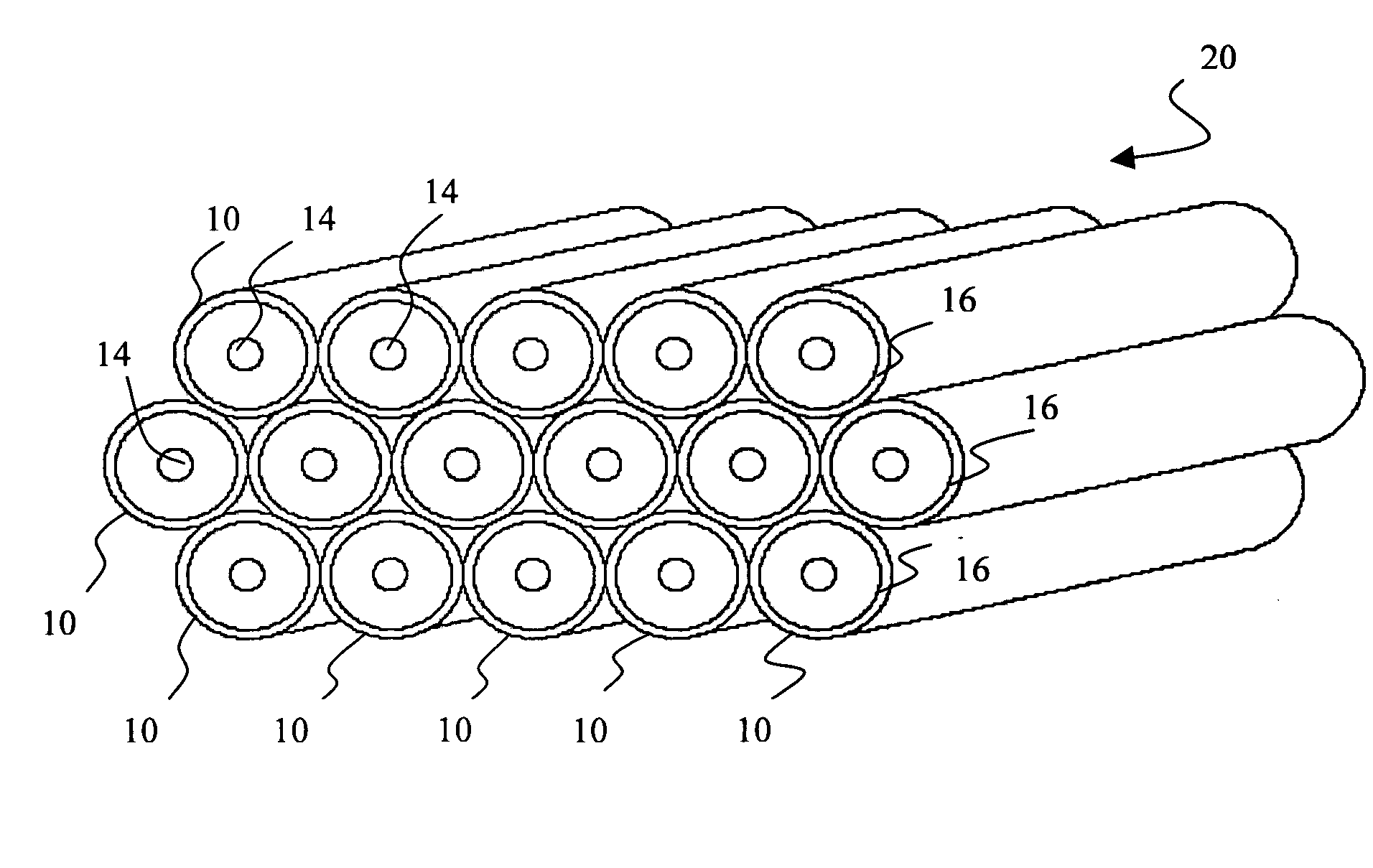

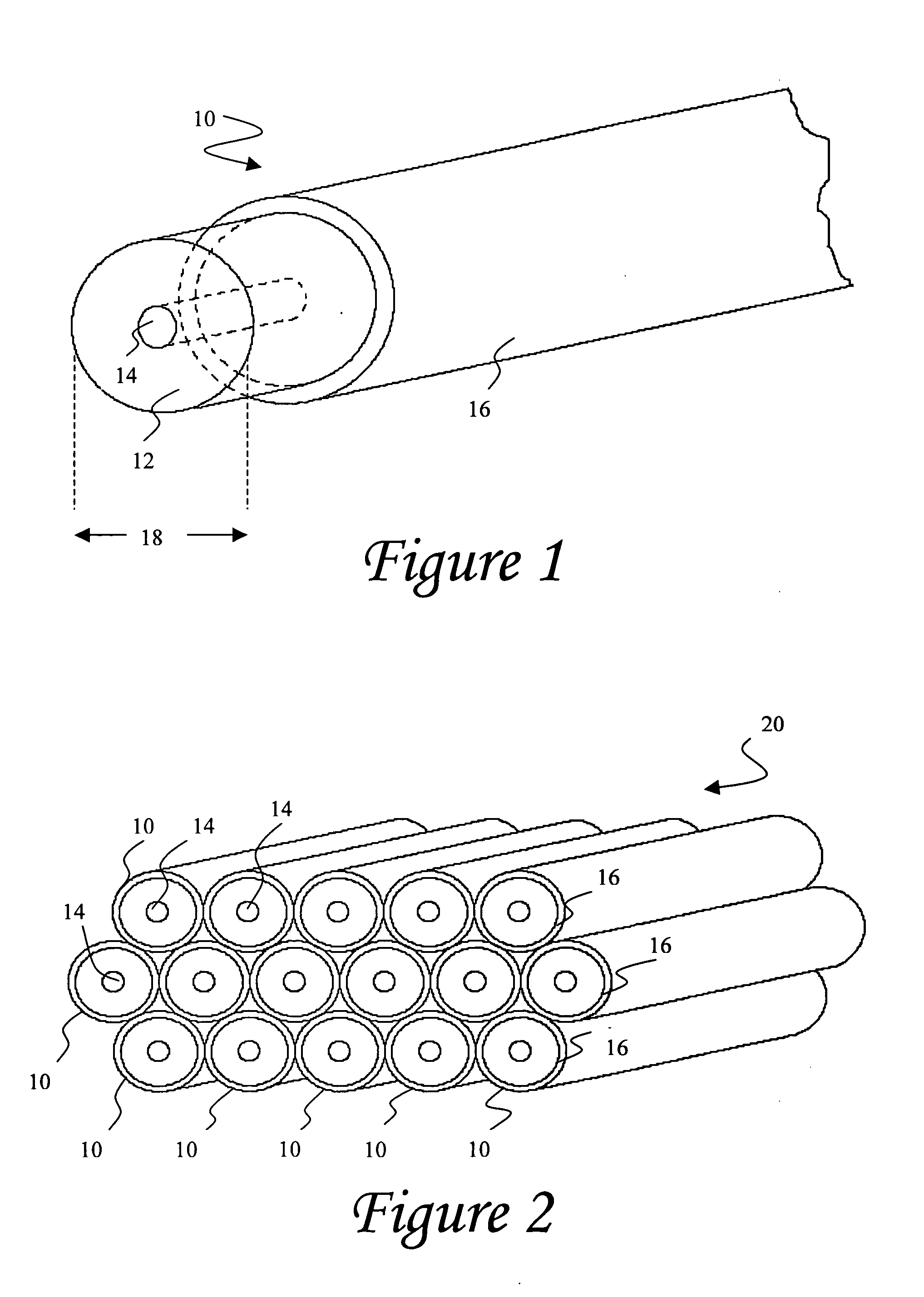

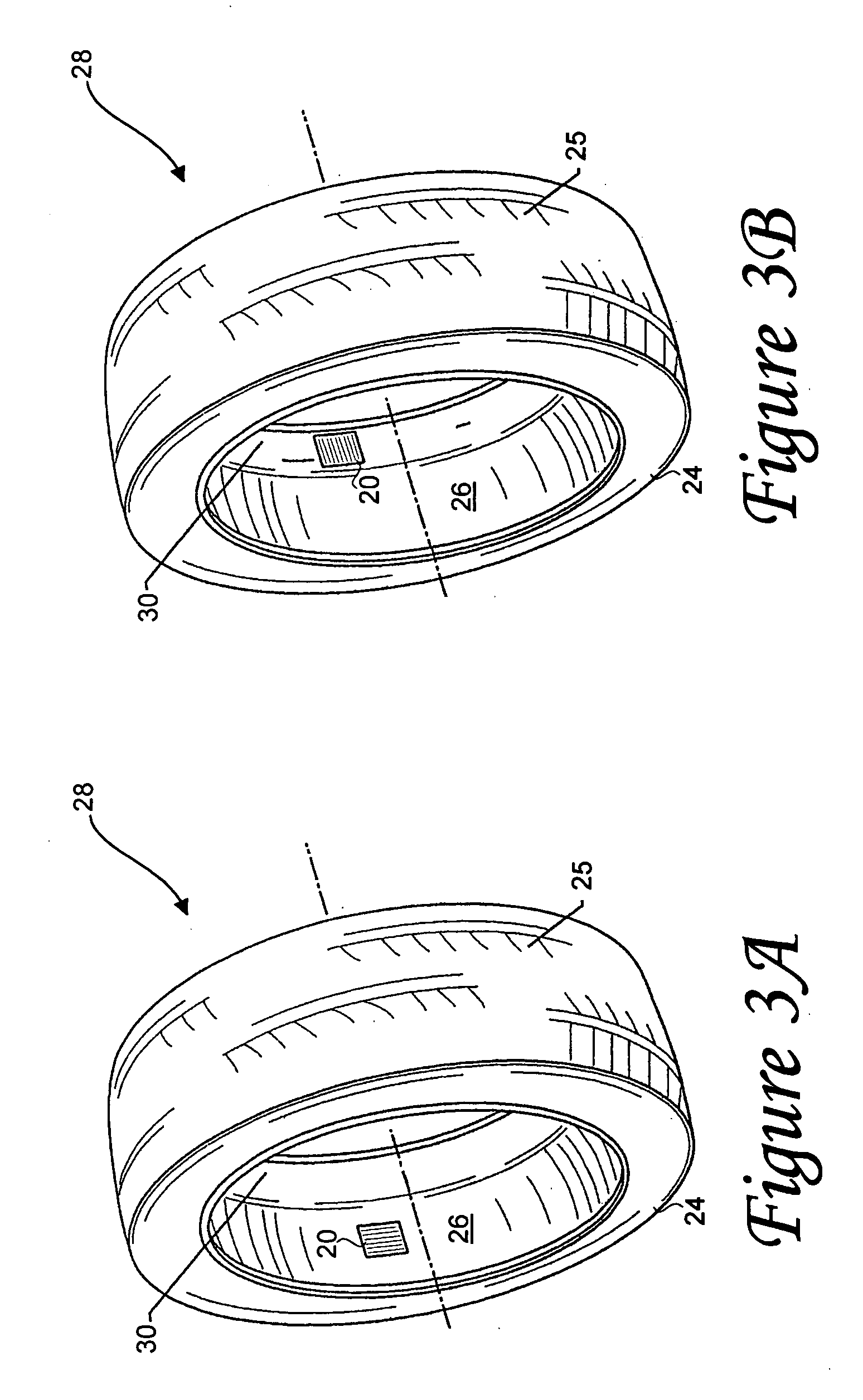

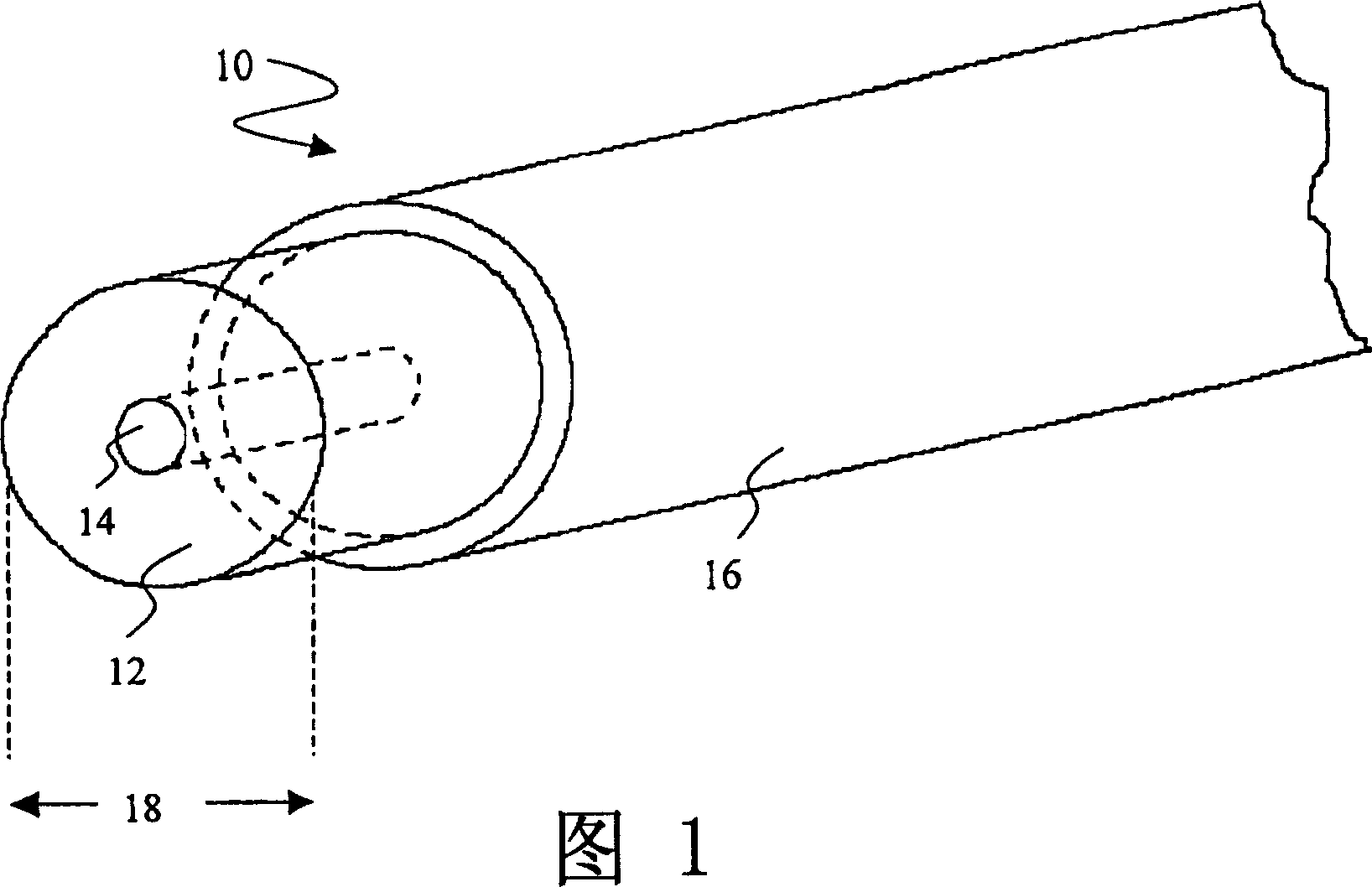

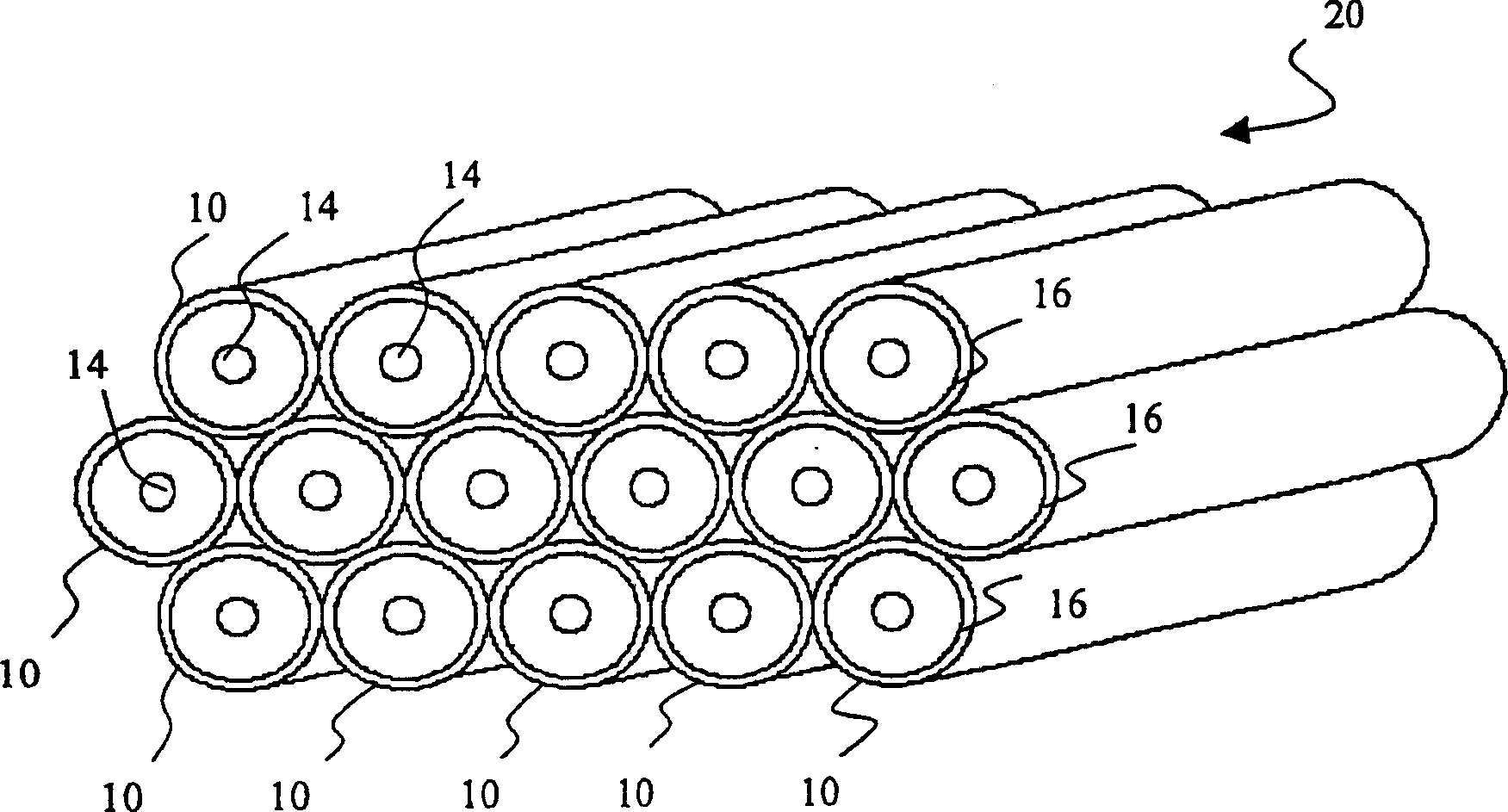

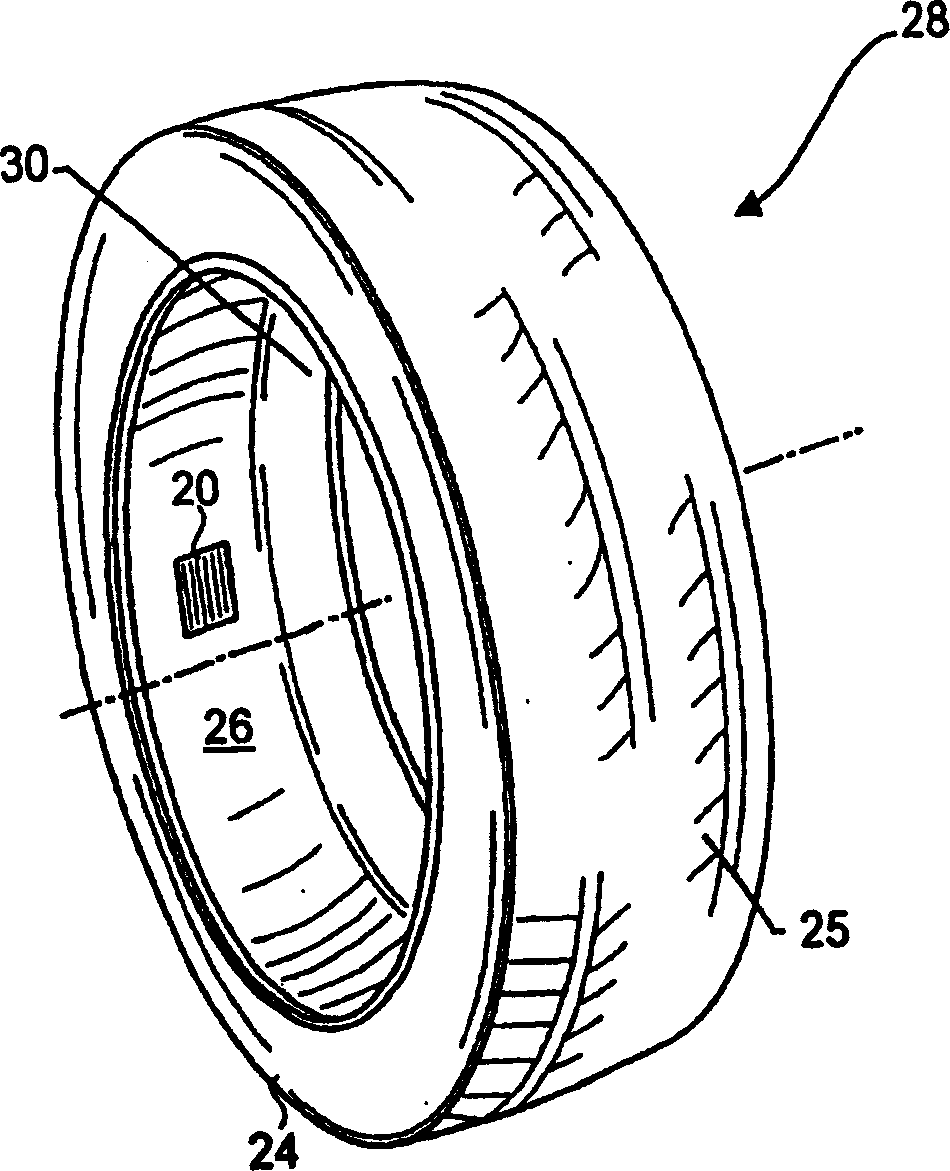

An enhanced piezoelectric wire structure includes an elongated portion of piezoelectric material, a metallic core, and an outer conductive sheath. The metallic core is substantially surrounded by the elongated portion of piezoelectric material and configured to function as a first electrode for the piezoelectric structure. The conductive outer sheath preferably covers selected areas of the elongated portion of piezoelectric material and functions as a second electrode for the structure. The piezoelectric material may correspond to barium titanate ceramic fibers, such that a lead-free structure is effected, however other piezoelectric materials may also be utilized. The disclosed structure can be poled with a reduced poling voltage and lower temperature level, and also requires a reduced voltage potential level required for mechanical actuation. A collection of such piezoelectric structures can be provided together in a modular patch assembly that may be formed in a variety of customized configurations for integration with various environments, and can function as a mechanical actuator device, a condition-responsive device (e.g., a sensor) and / or as a power generation device. When utilized as a power generation device, the subject piezoelectric assembly can power tire electronics components such as a revolution counter, a sensor, a rechargeable battery, a flashing light assembly, a microcontroller, a global positioning system (GPS), and a radio frequency (RF) device.

Owner:MICHELIN RECH & TECH SA

Electrical-energy-storage unit (EESU) utilizing ceramic and integrated-circuit technologies for replacement of electrochemical batteries

InactiveUS20060210779A1Fast chargingSolution to short lifeStacked capacitorsPrimary cellsBarium titanateElectrical battery

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is double coated with the first coating being aluminum oxide and the second coating calcium magnesium aluminosilicate glass. The components of the EESU are manufactured with the use of classical ceramic fabrication techniques which include screen printing alternating multilayers of nickel electrodes and high-permittivitiy composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store electrical energy in the range of 52 kW·h. The total weight of an EESU with this range of electrical energy storage is about 336 pounds.

Owner:EESTOR

Piezoelectric ceramic fibers having metallic cores

ActiveCN1707934AEasy to combinePromote reductionPiezoelectric/electrostriction/magnetostriction machinesTyre measurementsFiberBarium titanate

The improved piezoelectric wire structure includes an elongated portion of the piezoelectric portion, a metallic core, and an outer conductive layer. The metal core is substantially surrounded by the elongated portion of piezoelectric material and is provided as a first electrode of the piezoelectric structure. The outer conductive layer preferably covers selected areas of the elongated portion of piezoelectric material and serves as the second electrode of the structure. The piezoelectric material may be barium titanate ceramic fibers, allowing for an effective lead-free construction, however, other materials may also be used. The disclosed structures can be restored with reduced reduction voltages and lower temperatures, and also require reduced voltage levels required for mechanical actuation. Such collections of piezoelectric structures can also be provided together in modular patch assemblies that can be formed in a variety of specialized structures for combination with a variety of environments and can be used as mechanical actuators, conditions respond to devices (e.g. sensors) and / or act as power generating devices.

Owner:MICHELIN & CO (CIE GEN DES ESTAB MICHELIN)

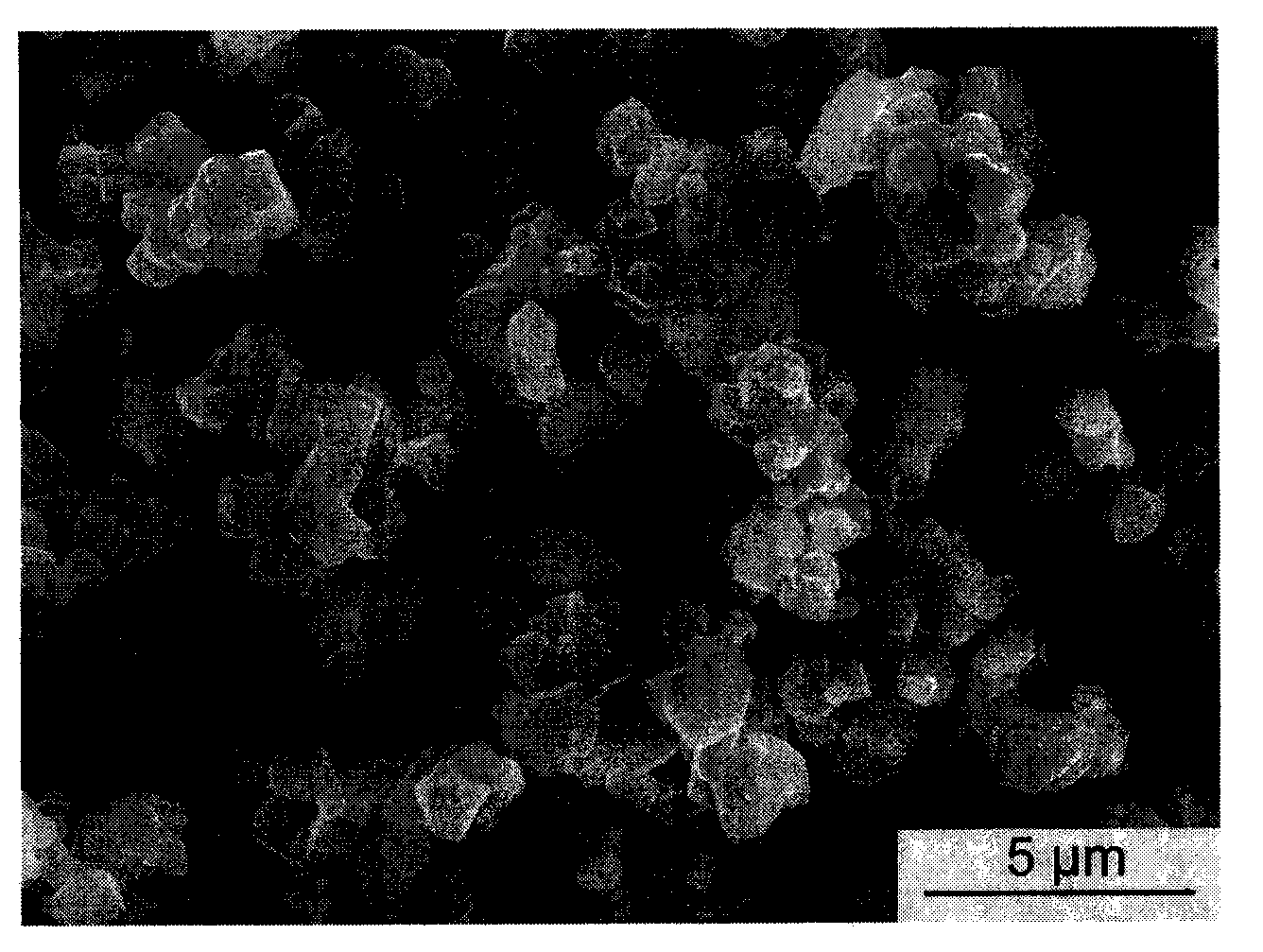

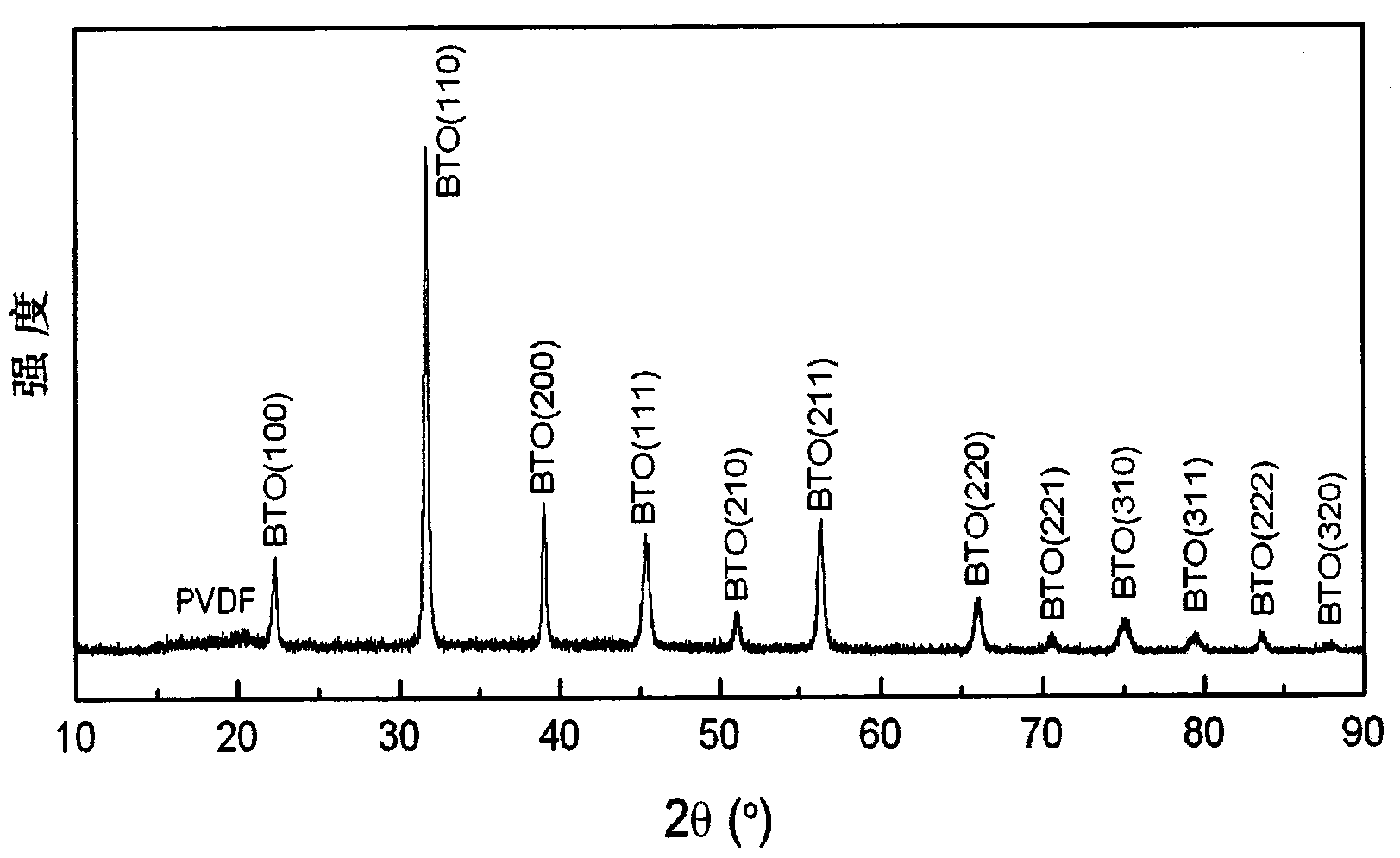

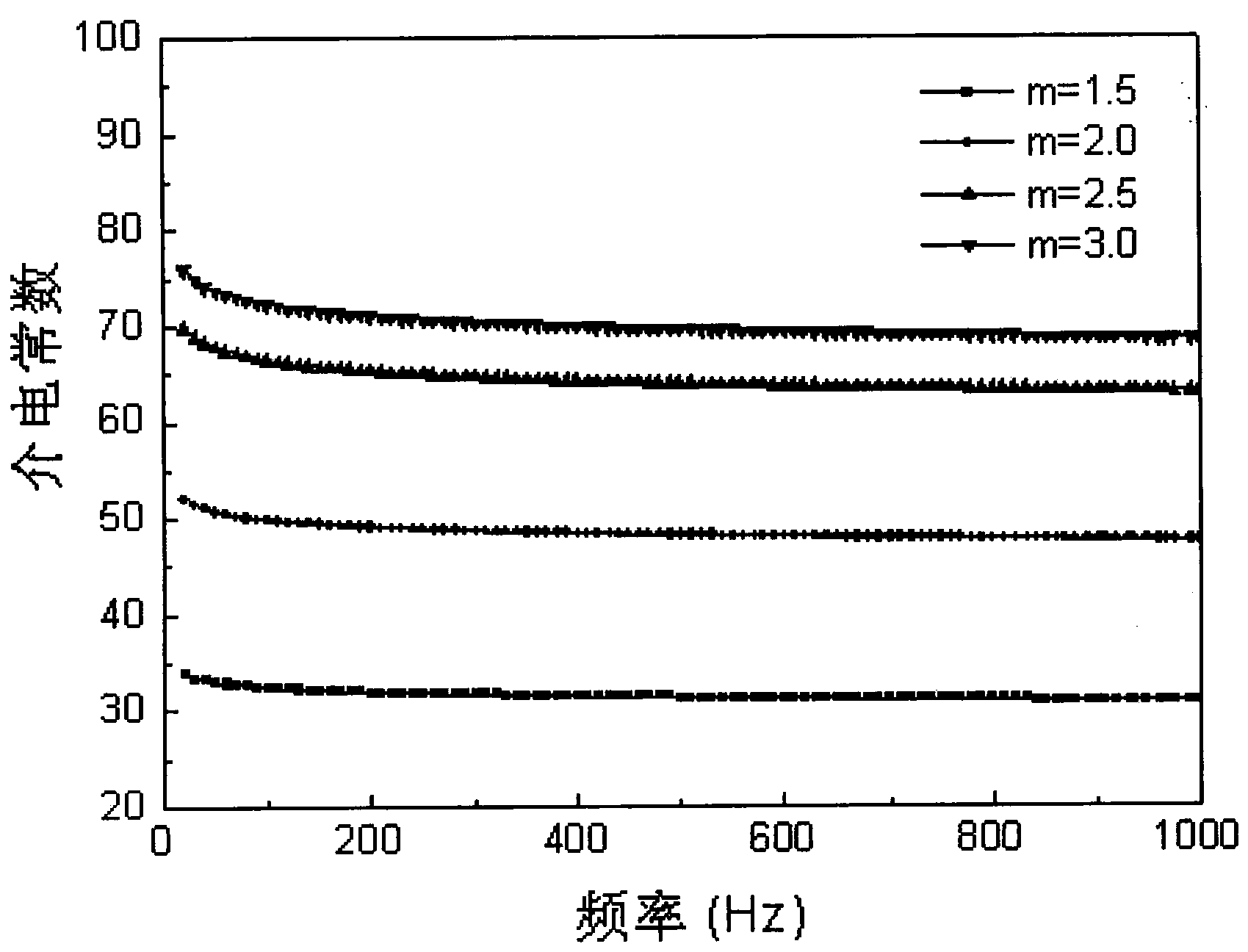

Barium titanate/polyvinylidene fluoride composite dielectric film and preparation method thereof

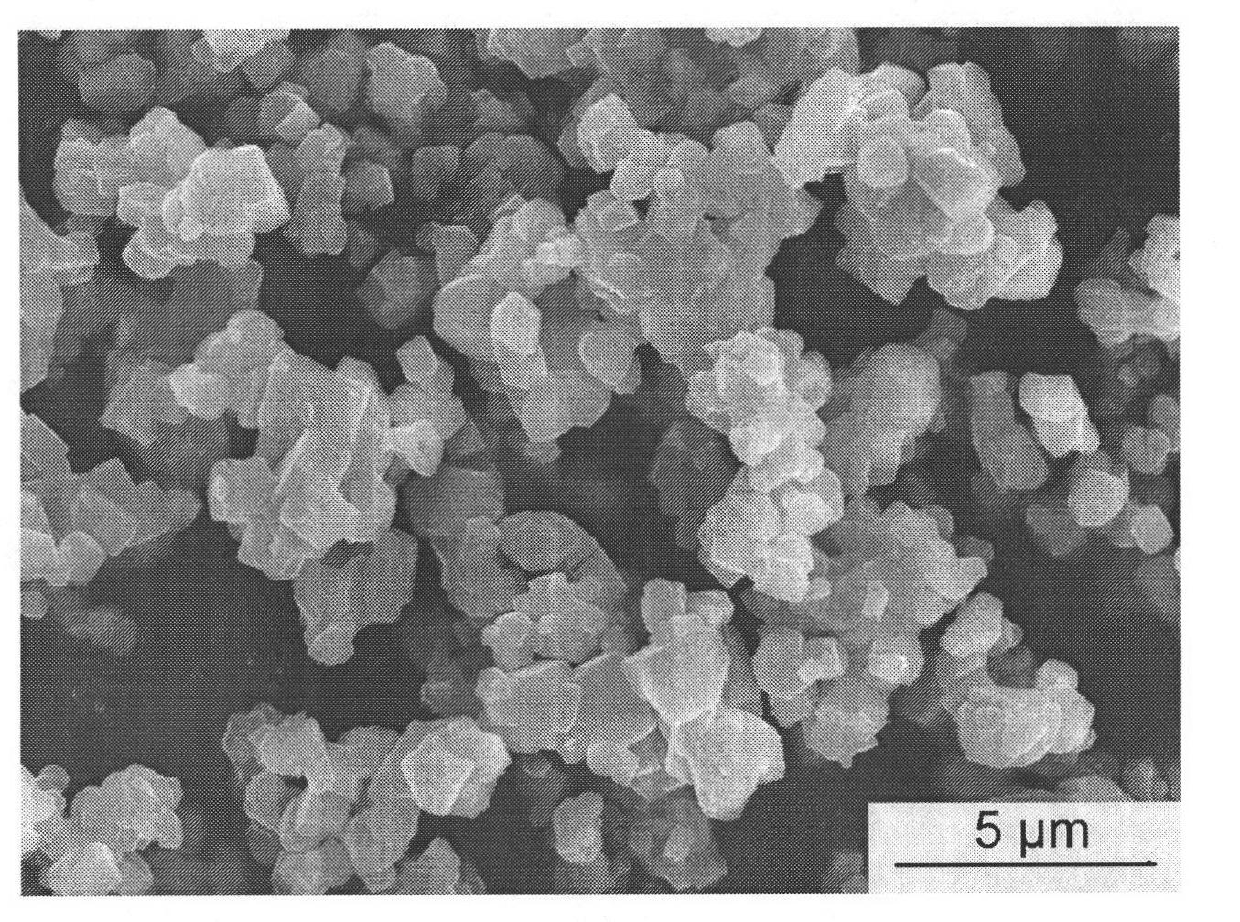

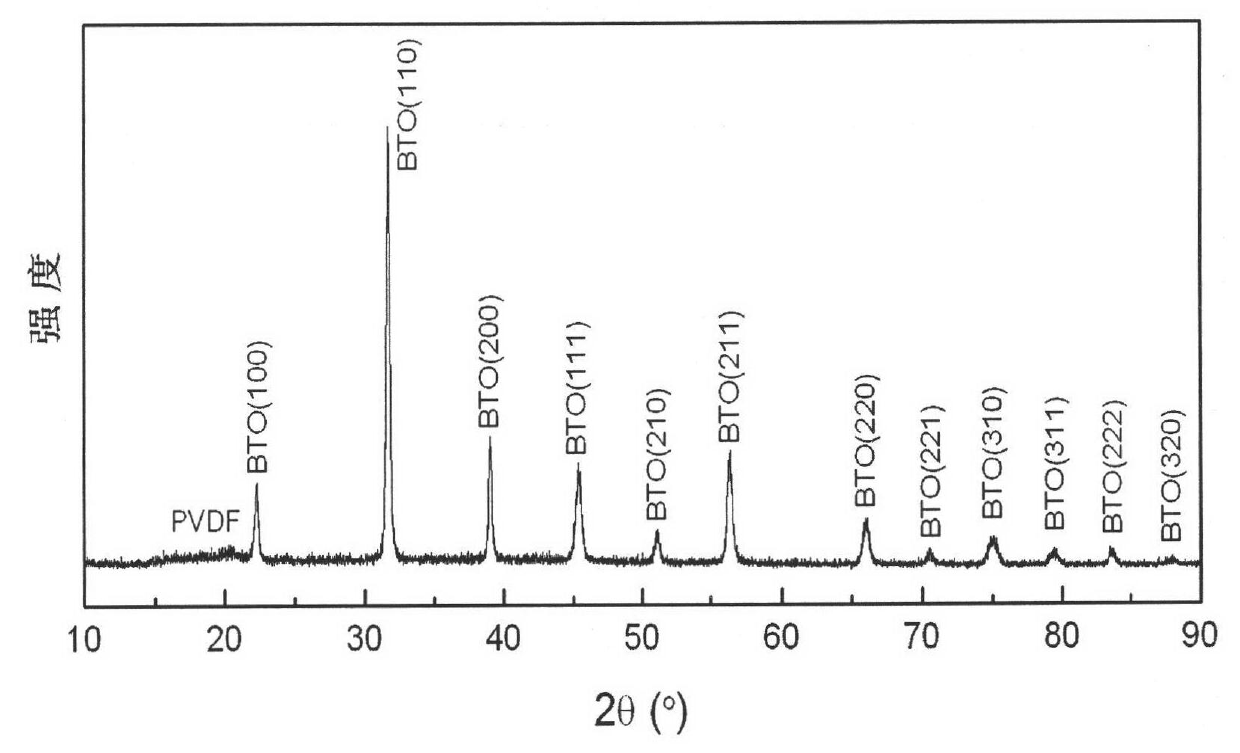

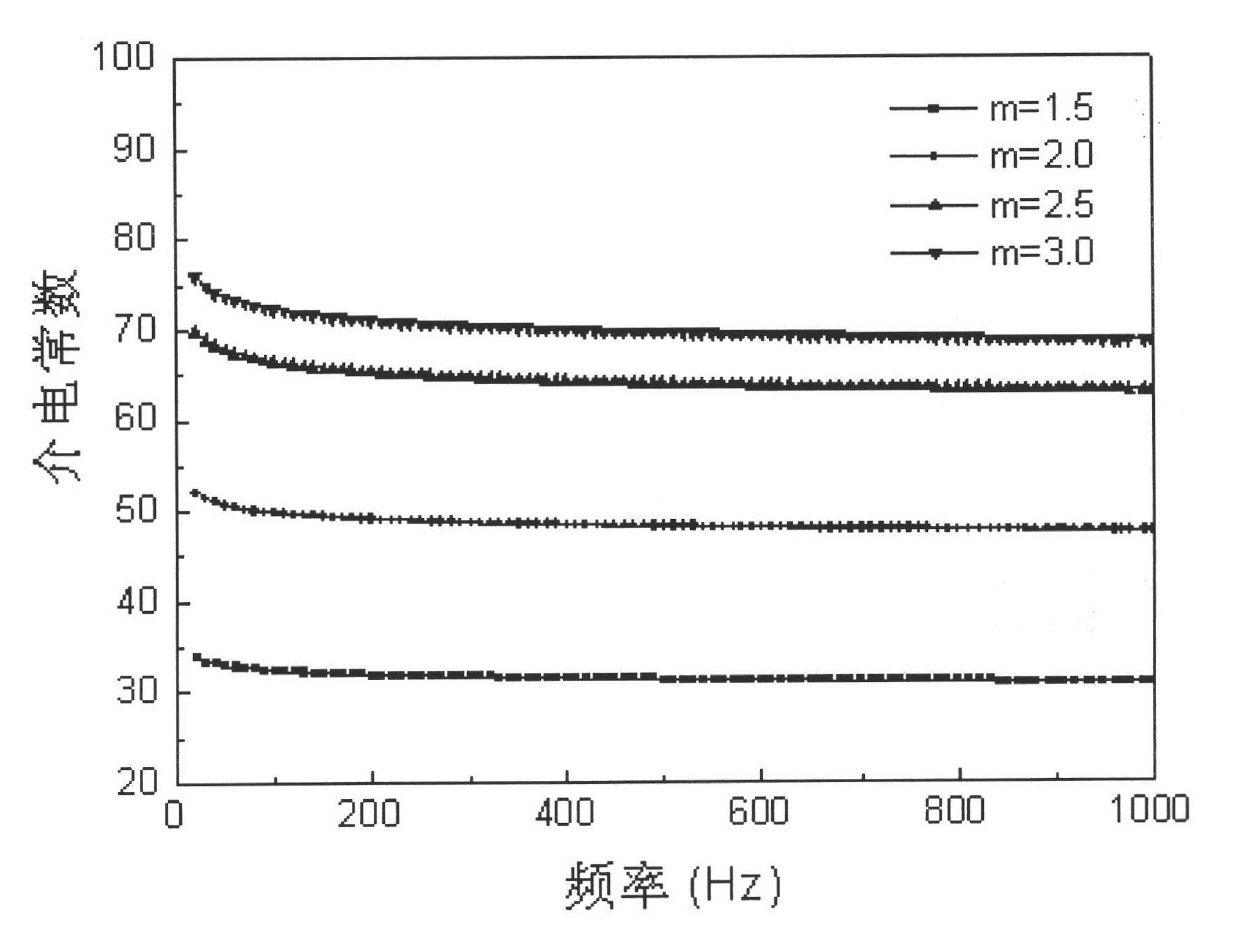

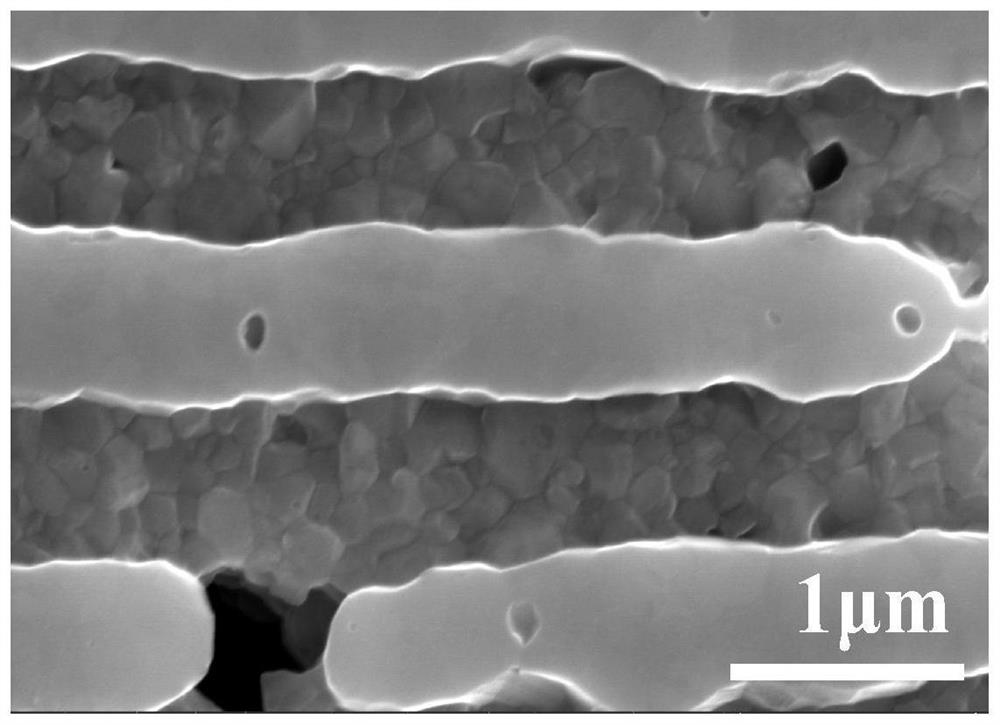

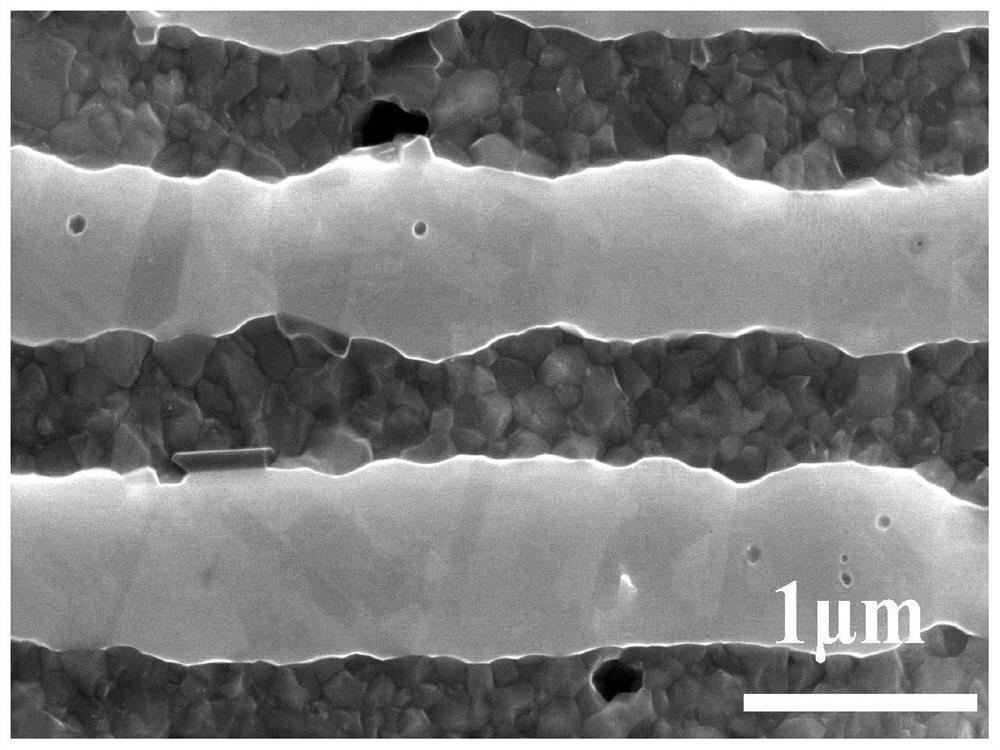

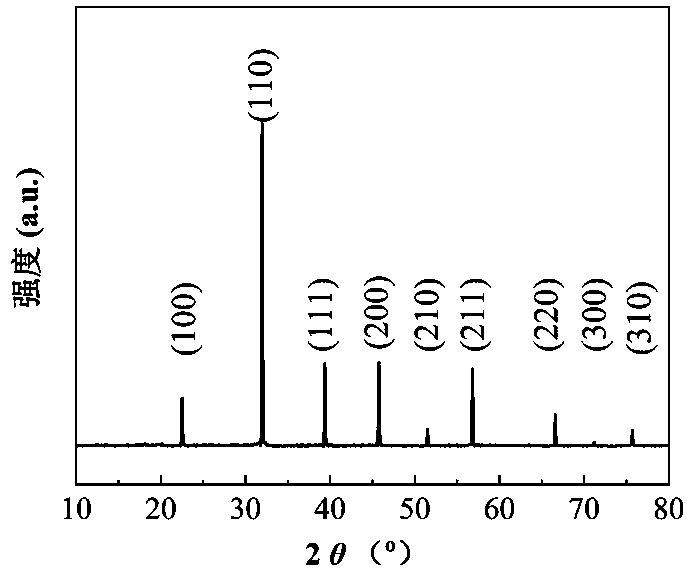

ActiveCN102558718AImproved rheological propertiesIncrease BTO contentBarium titanateSolid state reaction method

The invention provides a barium titanate / polyvinylidene fluoride composite dielectric film and a preparation method thereof. The film comprises barium titanate and polyvinylidene fluoride with the weight ratio of 1.5-5.0:1, and the thickness of the film is less than 50 mu m. In the frequency range of 100 Hz-1 MHz, the relative dielectric constant of the film can reach more than 70, and the dielectric loss is lower than 5*10<-2>. By compounding BaTiO3 ceramic and PVDF polymer, the dielectric film material with high dielectric constant and low dielectric loss is prepared. According to the invention, the barium titanate / polyvinylidene fluoride composite dielectric film with uniform distribution of ceramic particles, controllable thickness, high dielectric constant and low dielectric loss is prepared by preparing barium titanate ceramic powder through solid phase reaction or chemical coprecipitation and then using high temperature drying gel method or solvent induced phase separation gel method. The dielectric film is especially suitable for capacitor, ferroelectric memory, and other electronic devices.

Owner:GRIMAT ENG INST CO LTD

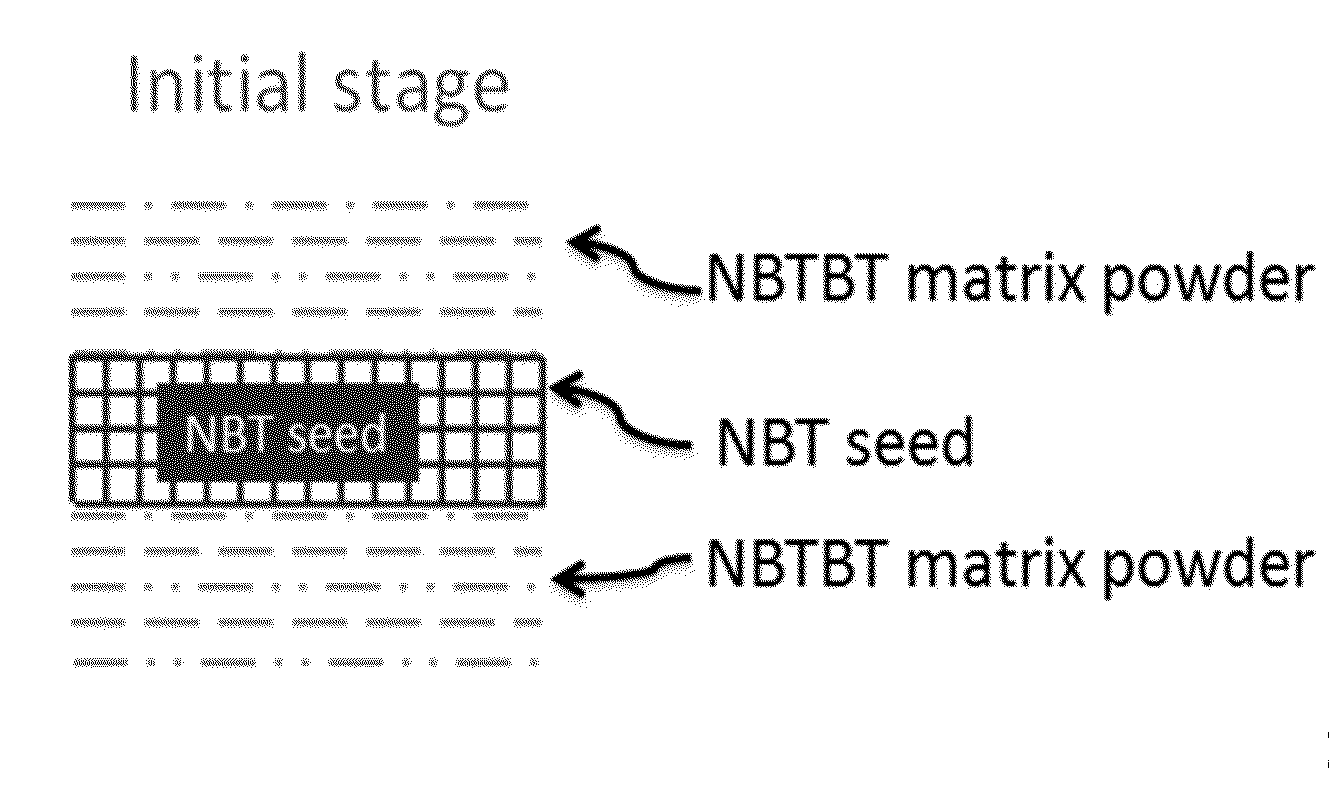

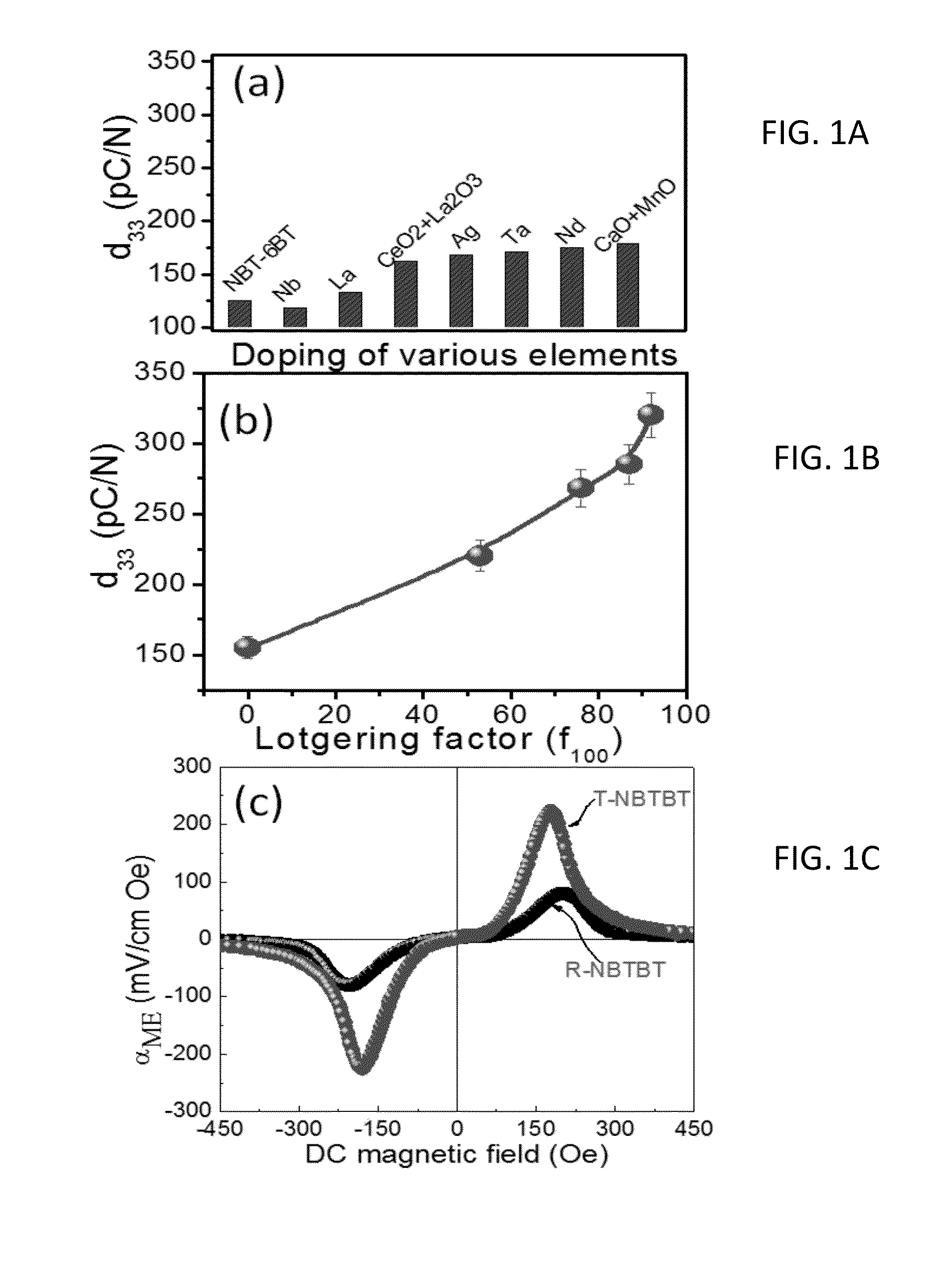

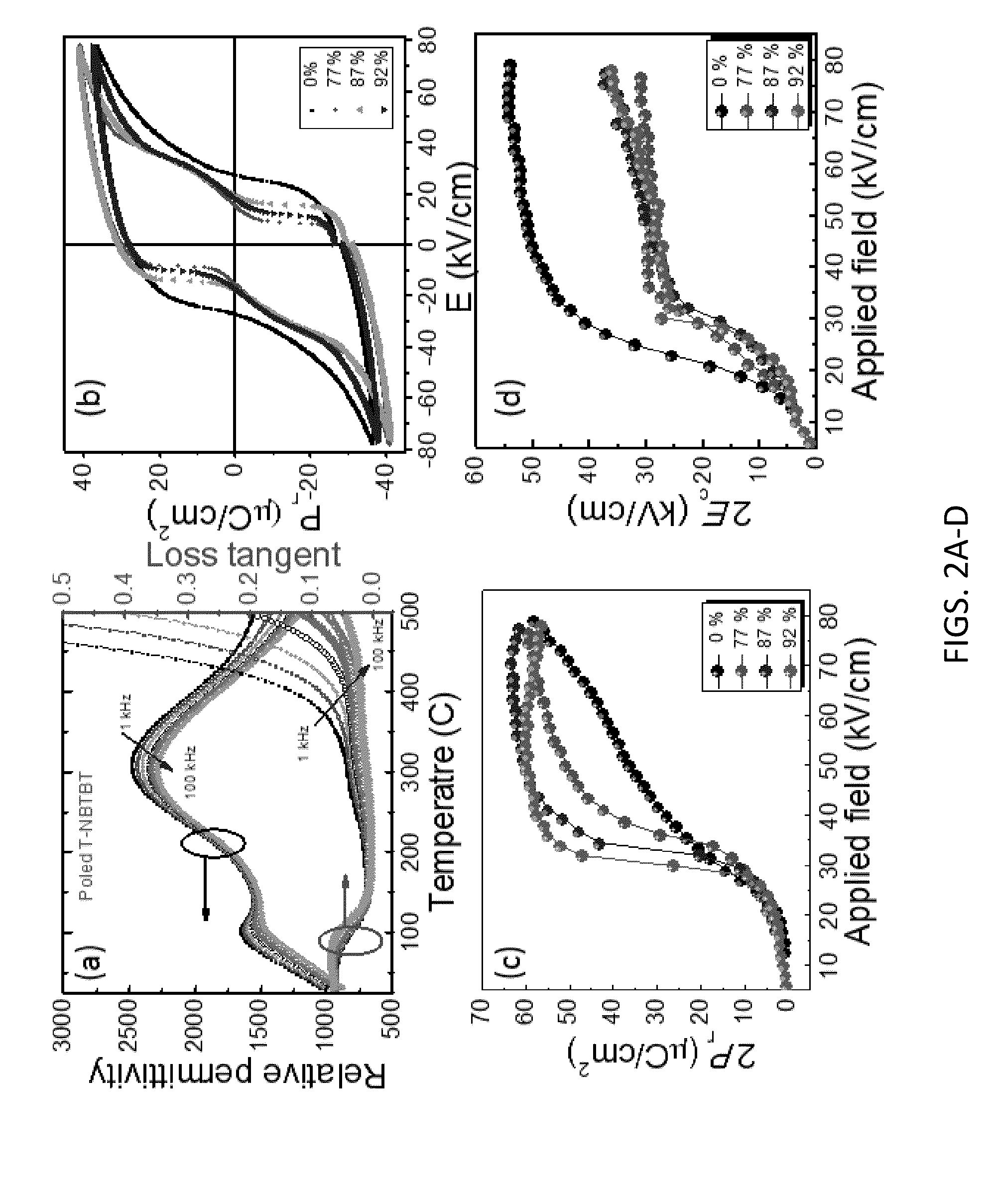

NEW PROCESSING METHOD FOR GRAIN-ORIENTED LEAD-FREE PIEZOELECTRIC Na0.5Bi0.5TiO3-BaTiO3 CERAMICS EXHIBITING GIANT PERFORMANCE

InactiveUS20140239774A1High aspect ratioImprove propertiesPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive material selectionElectricityCoupling

Textured ceramic compositions having improved piezoelectric characteristics as compared with their random counterparts are provided. Methods of making the compositions and devices using them are also included. More particularly, compositions comprising textured ceramic Na0.5Bi0.5TiO3—BaTiO3(NBT-BT) materials synthesized from high aspect ratio NBT seeds exhibit improved characteristics, including an increased longitudinal piezoelectric constant (d33) and magnetoelectric coupling coefficient over randomly oriented NBT-BT. Additionally provided are compositions comprising of nanostructured Na0.5B0.5TiO3—BaTiO3 ferroelectric whiskers having a high aspect ratio. Nanostructured whiskers can be used to improve the piezoelectric properties of the bulk ceramics. The inventive materials are useful in microelectronic devices, with some finding particular application as multilayer actuators and transducers.

Owner:VIRGINIA TECH INTPROP INC

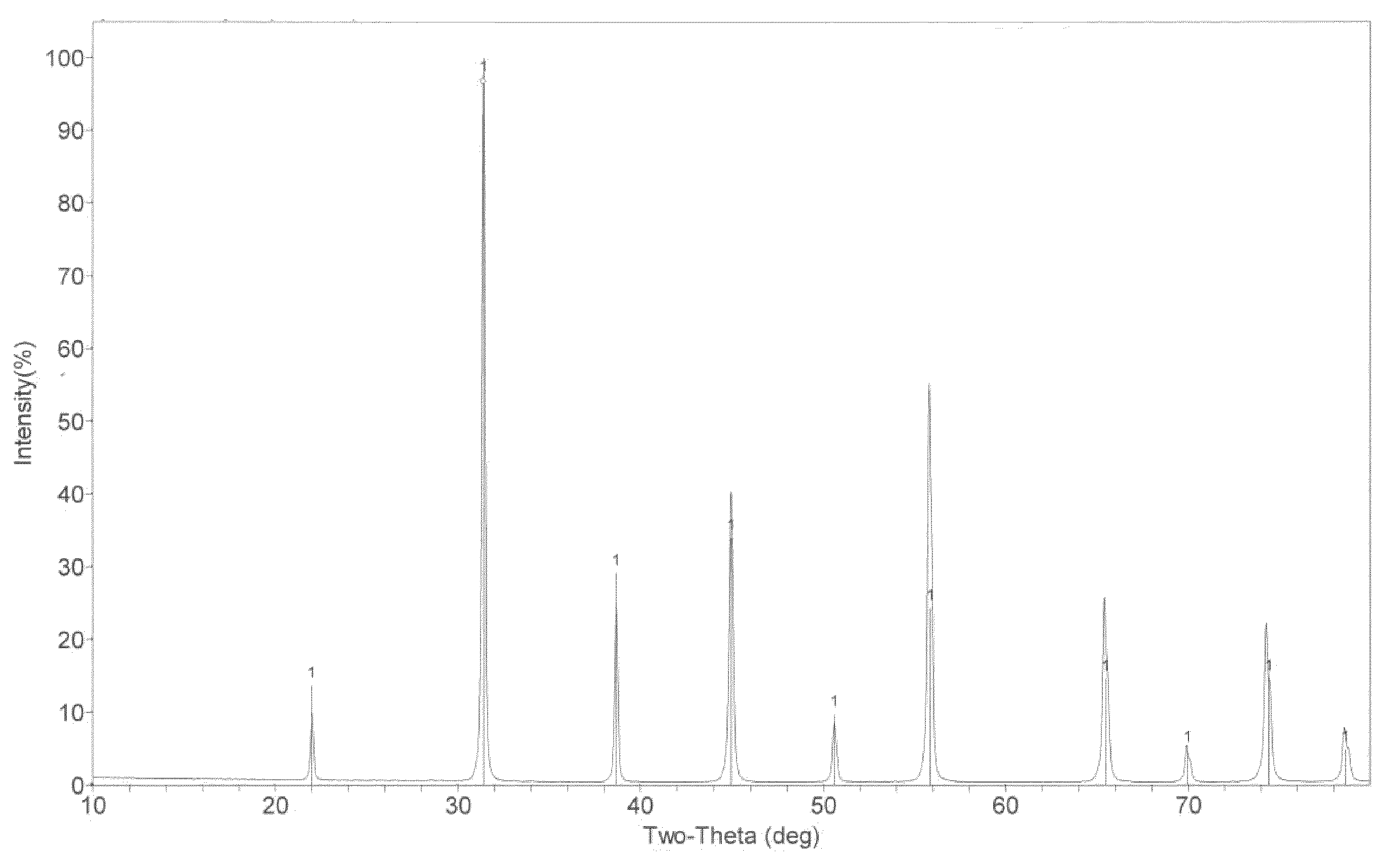

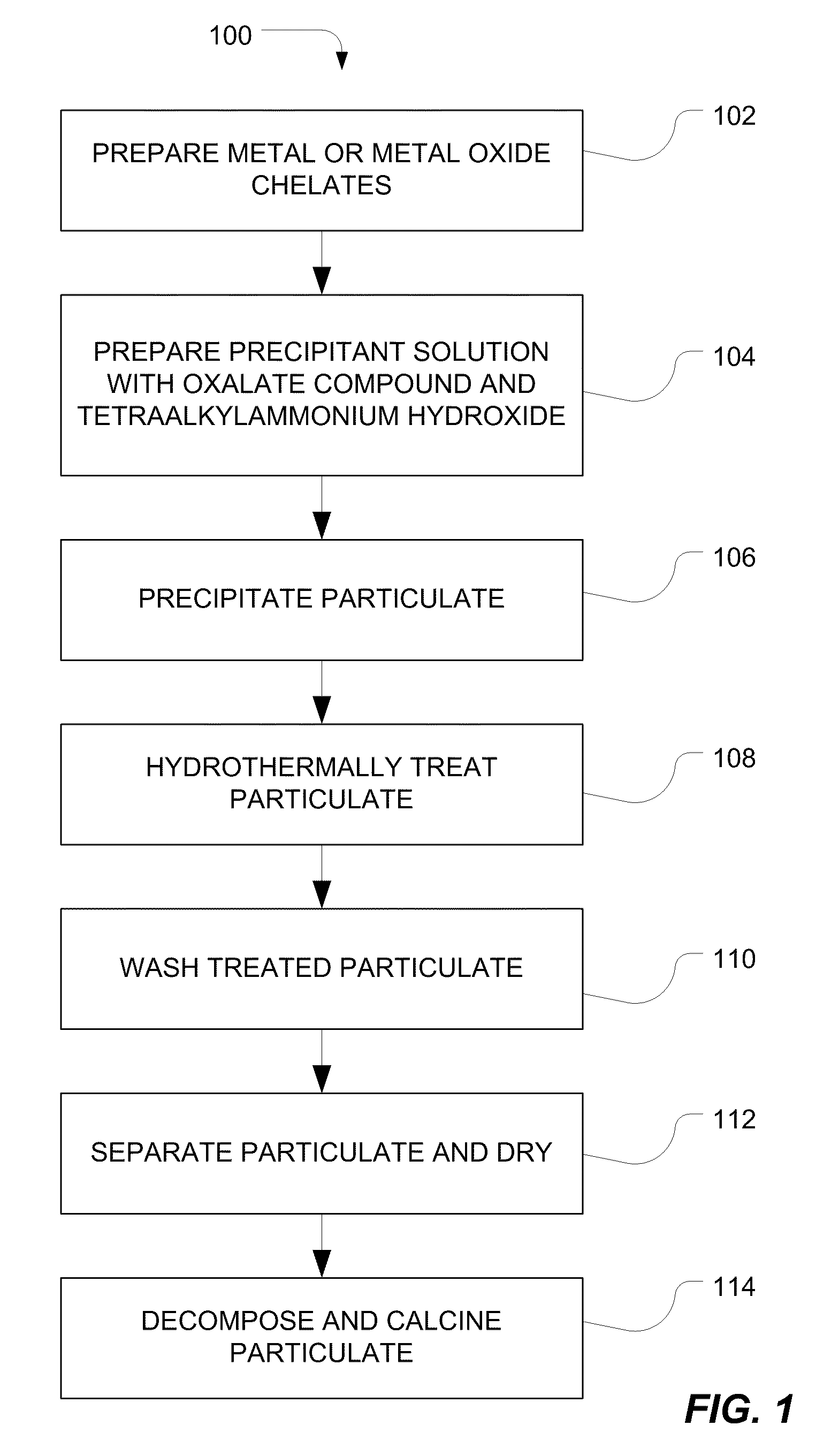

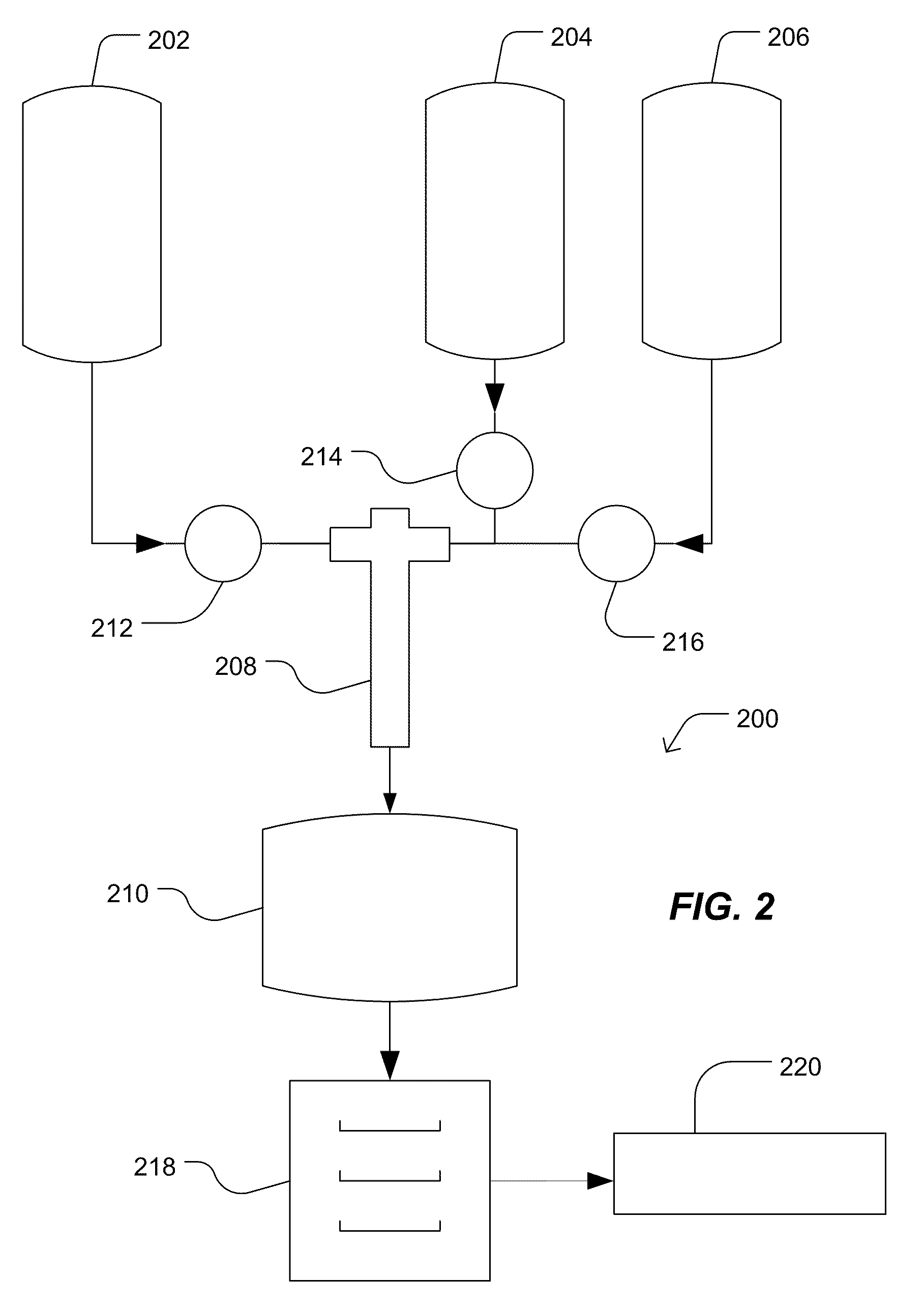

Method of Preparing Ceramic Powders

A method of forming composition-modified barium titanate ceramic particulate includes mixing a plurality of precursor materials and a precipitant solution to form an aqueous suspension. The plurality of precursors include barium nitrate, titanium chelate, and a metal or oxometal chelate. The precipitant solution includes tetraalkylammonium hydroxide and tetraalkylammonium oxalate. The method further includes treating the aqueous suspension at a temperature of at least 150° C. and a pressure of at least 200 psi, and separating particulate from the aqueous suspension after treating.

Owner:EESTOR

Barium titanate/polyvinylidene fluoride composite dielectric film and preparation method thereof

ActiveCN102558718BImproved rheological propertiesIncrease BTO contentBarium titanateSolid state reaction method

The invention provides a barium titanate / polyvinylidene fluoride composite dielectric film and a preparation method thereof. The film comprises barium titanate and polyvinylidene fluoride with the weight ratio of 1.5-5.0:1, and the thickness of the film is less than 50 mu m. In the frequency range of 100 Hz-1 MHz, the relative dielectric constant of the film can reach more than 70, and the dielectric loss is lower than 5*10<-2>. By compounding BaTiO3 ceramic and PVDF polymer, the dielectric film material with high dielectric constant and low dielectric loss is prepared. According to the invention, the barium titanate / polyvinylidene fluoride composite dielectric film with uniform distribution of ceramic particles, controllable thickness, high dielectric constant and low dielectric loss is prepared by preparing barium titanate ceramic powder through solid phase reaction or chemical coprecipitation and then using high temperature drying gel method or solvent induced phase separation gel method. The dielectric film is especially suitable for capacitor, ferroelectric memory, and other electronic devices.

Owner:GRIMAT ENG INST CO LTD

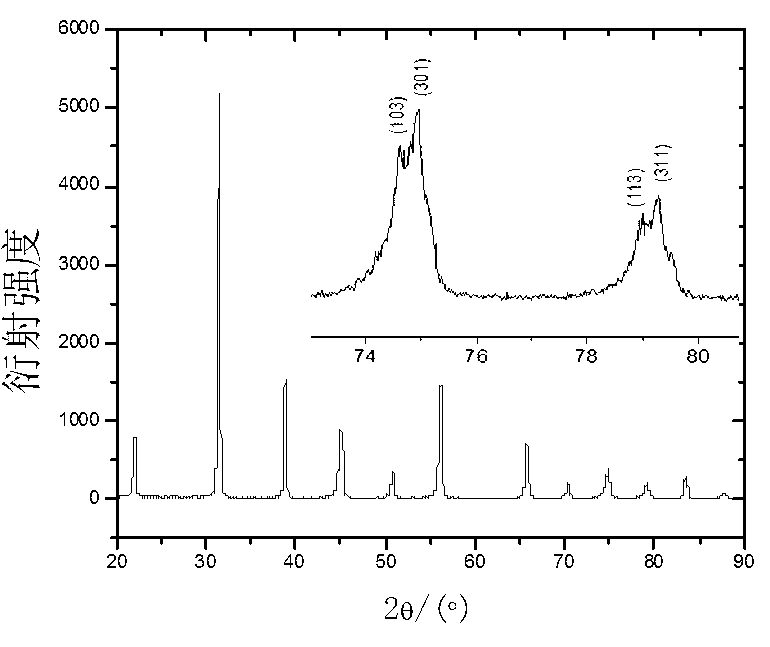

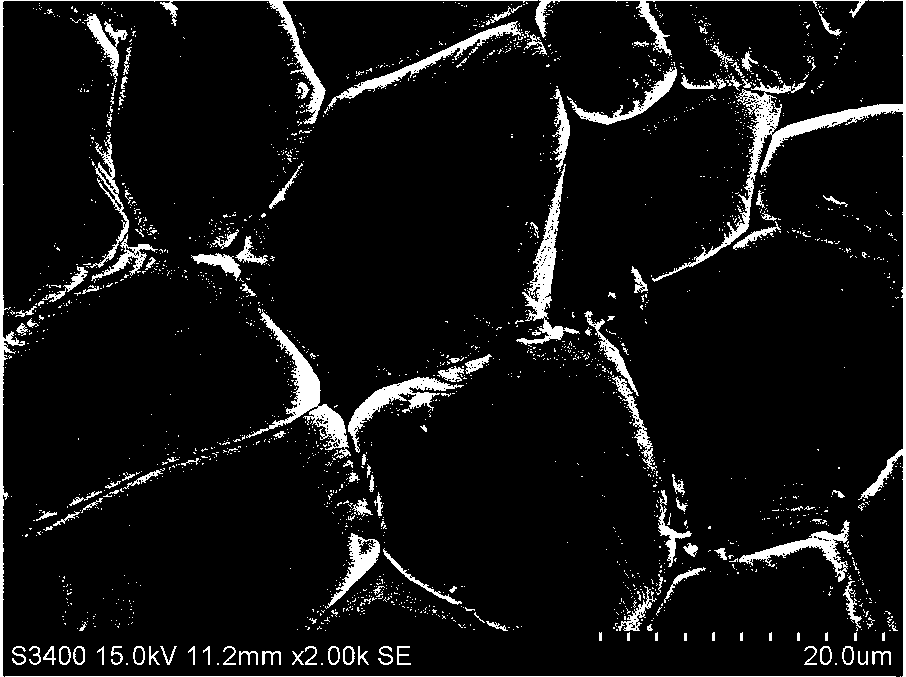

Preparation method of giant-dielectric-constant barium titanate ceramic

InactiveCN103214237AHigh dielectric constantImprove compactnessCeramicsCompression moldingBarium titanate

The invention relates to a preparation method of giant-dielectric-constant barium titanate ceramic, belonging to the technical field of ceramic materials. The giant-dielectric-constant barium titanate ceramic is sintered by using a self-propagating high-temperature quick pressurizing technology, wherein a self-propagating high-temperature system adopts a thermit system. The method comprises the following steps of: performing compression molding on barium titanate powder under the pressure of 200 MPa; placing into a self-propagating system; and after a self-propagating reaction is finished, applying axial pressure of 100 to 200 MPa, so that the barium titanate ceramic is compact. The barium titanate ceramic prepared by the method has the advantages of high dielectric constant, low dielectric loss and high heat stability. The self-propagating high-temperature quick pressurizing technology is low in energy consumption; the process is simple; the required materials are low in price; the sintering time is extremely short; and great value is achieved on industrial application.

Owner:WUHAN UNIV OF TECH

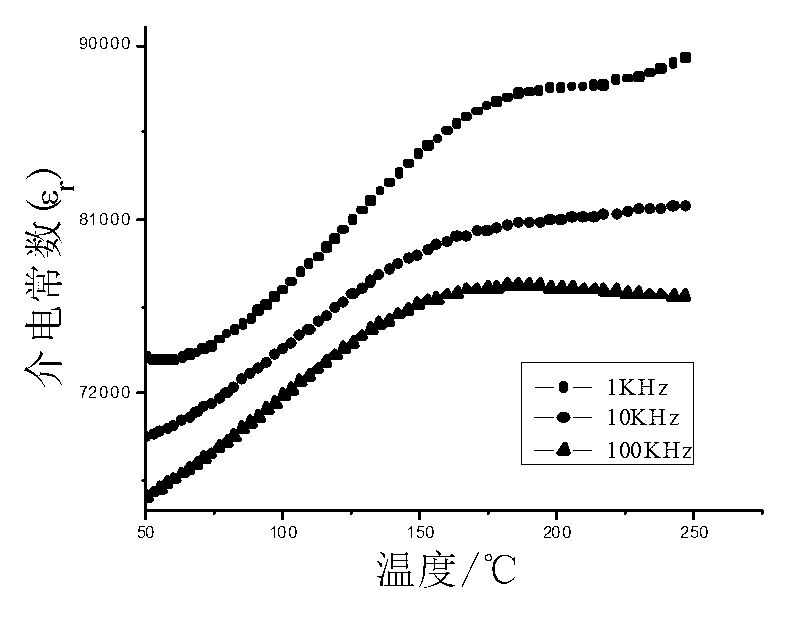

(Na1/2Bi1/2) TiO3/BaTiO3 ceramic dielectric material and preparation of capacitor thereof

InactiveCN101798214AHigh dielectric constantSmall dielectric lossFixed capacitor dielectricSilver electrodeDielectric loss

The invention relates to a (Na1 / 2Bi1 / 2) TiO3 / BaTiO3 ceramic dielectric material and a preparation of a capacitor thereof. The ceramic dielectric material contains the following components of BaCO3, SrCO3, Bi2O3, SnO2, TiO2, (Na1 / 2Bi1 / 2) TiO3, Y2O3, ZnO and MnO2, and the sum of the mole percents of the components is 100%. The method for preparing the capacitor by using the material comprises the following steps of synthesizing the (Na1 / 2Bi1 / 2) TiO3; preparing a pre-synthesizing material by using the BaCO3, the SrCO3, the Bi2O3, the SnO2 and the TiO2, (Na1 / 2Bi1 / 2) TiO3; preparing a dry grinding material by using the Y2O3, the ZnO, MnO2and the pre-synthesizing material; adding a polyvinyl alcohol solution in the dry grinding material, and then pelleting, screening, pressing and sintering and preparing a silver electrode to obtain the capacitor. The ceramic dielectric material has the characteristics of high dielectric constant, low dielectric loss and low temperature change rate of the dielectric constant. The prepared capacitor has good performance parameters.

Owner:TIANJIN UNIV

Low-temperature cold sintering preparation method of barium titanate ferroelectric ceramic

The invention provides a low-temperature cold sintering preparation method of barium titanate ferroelectric ceramic. The preparation method comprises the following steps: 1, dissolving Ba(OH)2 and TiO2 into deionized water; 2, adding BaTiO3 nano-level powder and BaTiO3 submicron-level powder into 25 percent of Ba(OH)2 / TiO2 suspension by weight prepared in the step 1 according to the mass ratio of 1 to 1, and carrying out grinding in a grinding bowl for 0.5 to 1 hour; 3, pouring BaTiO3 mixed slurry into a mold, carrying out cold pressing on an electric heating press in an environment with room temperature till the pressure is 450 to 500 MPa, preserving the pressure for 10 to 20 min, then under a condition of not changing the pressure, heating to 180 to 200 DEG C at the heating rate of 5 to 10 DEG C per minute, and preserving the temperature for 3 hours; 4, drying a BaTiO3 ceramic prefabricated blank at 200 DEG C for 12 to 18 hours; and 5, sintering the dried BaTiO3 ceramic prefabricated blank at 850 to 950 DEG C. The process is simple, environment-friendly and extremely low in energy consumption; the preparation method can be an ideal preparation method of the BaTiO3 ferroelectric ceramic for an underwater acoustic transducer, and has a wide industrial application prospect.

Owner:HARBIN ENG UNIV

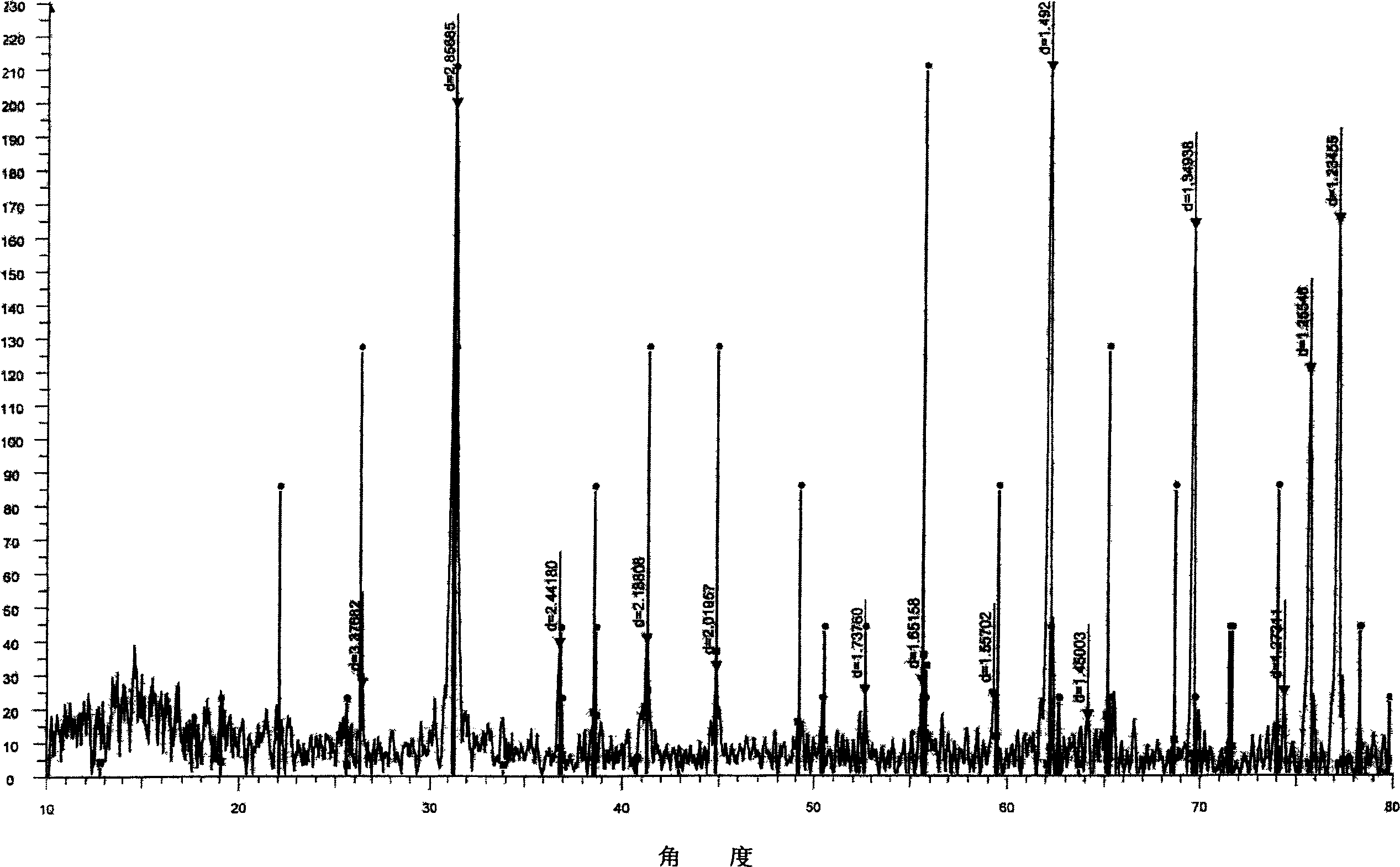

Graphite paper and barium titanate ceramic film capacitor and preparation method thereof

ActiveCN103346014AHigh dielectric constantReduce leakage currentThin/thick film capacitorFixed capacitor electrodesOxide ceramicBarium titanate

The invention provides a graphite paper and barium titanate ceramic film capacitor. The graphite paper and barium titanate ceramic film capacitor comprises one or more layers of inner electrodes, ceramic dielectric layers among the inner electrodes, insulating layers between the dielectric layers and the inner electrodes, and end electrodes at the two ends. The graphite paper and barium titanate ceramic film capacitor is characterized in that the inner electrodes are made of graphite paper materials, the dielectric layers are barium titanate ceramic film, the end electrodes are formed by coating conductive aquadag in a dried mode, the insulating layers are aluminum oxide ceramic film, and the outermost layer of the graphite paper and barium titanate ceramic film capacitor is wrapped and packaged by barium titanate ceramic. A preparation method for the graphite paper and barium titanate ceramic film capacitor comprises the steps of (1) using graphite paper as the inner electrodes, (2) carrying out film pulling forming in aluminum oxide ethanol dispersion liquid, (3) carrying out film pulling forming and lamination in barium titanate ethanol dispersion liquid after drying, (4) using barium titanate powder to carry out packaging, and (5) carrying out integral pressure forming and vacuum hot pressing sintering to form the graphite paper and barium titanate ceramic film capacitor. The graphite paper and barium titanate ceramic film capacitor prepared through the preparation method has the advantages of being excellent in performance, high in dielectric constant, low in cost, simple in production technology and controllable in structure, and facilitating commercial production.

Owner:OCEAN UNIV OF CHINA

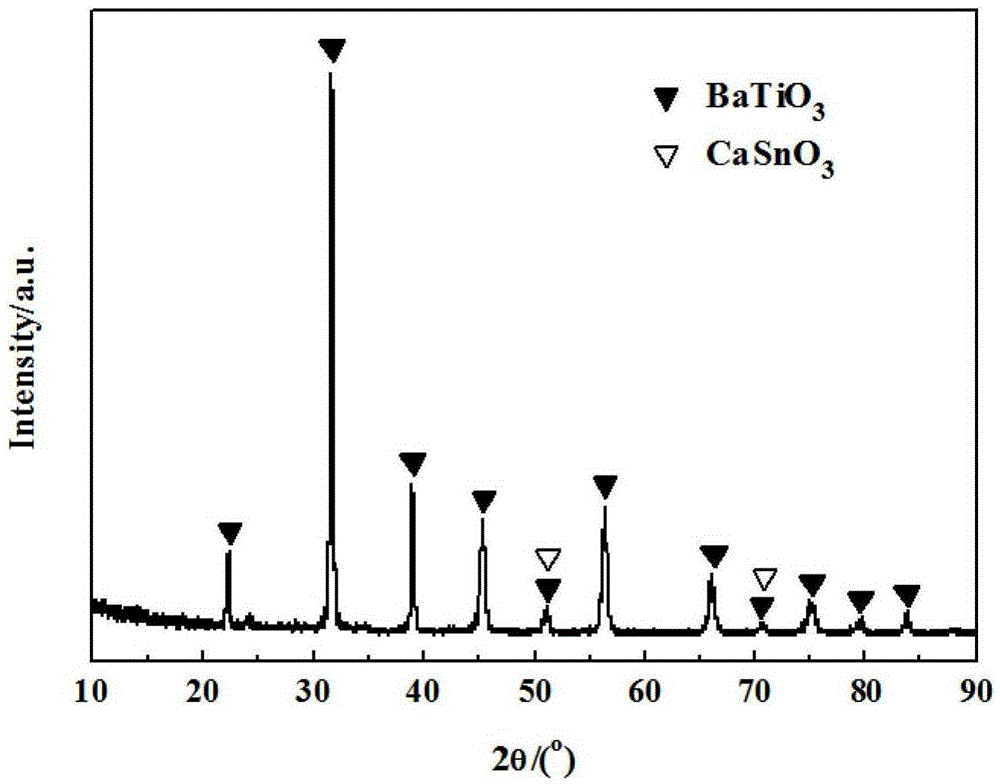

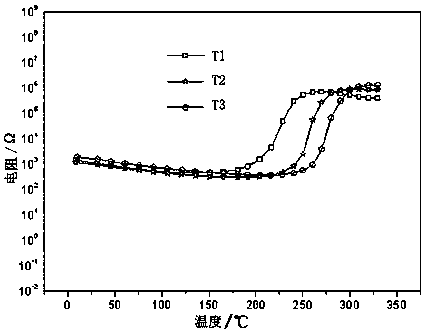

Preparation method for modified barium titanate ceramics

The invention discloses a preparation method for modified barium titanate ceramics suitable for a super capacitor, wherein the preparation method comprises the following steps: step a, auxiliary material preparation: selecting SnO2, CaCO3, BaCO3 and TiO2 and mixing evenly in proportion to obtain an auxiliary material mixture, putting the auxiliary material mixture in a muffle furnace, sintering for a first time, taking out the material, and crushing the material to obtain an auxiliary material, wherein the granularity of the auxiliary material is 3-5 [mu]m; step b, raw material preparation: selecting BaCO3 and TiO2 and mixing, then putting the mixture into the muffle furnace, sintering for a second time, and crushing the product after sintering to obtain a fine powder material; and step c, raw material modification: selecting the auxiliary material and the fine powder material and mixing, putting the mixture into the muffle furnace, sintering for a third time, and crushing the product after sintering for the third time to obtain a finished product. The method has the beneficial effects that the process is simple, the cost is saved, fluctuation of the dielectric coefficient is smooth along with temperature variation, the granularity is relatively fine, and the stable composite material is convenient to synthesize.

Owner:ZHEJIANG JIUKANG ELECTRIC +1

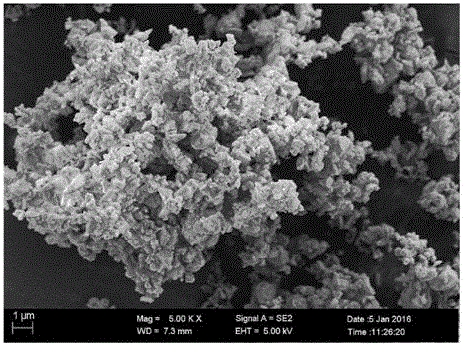

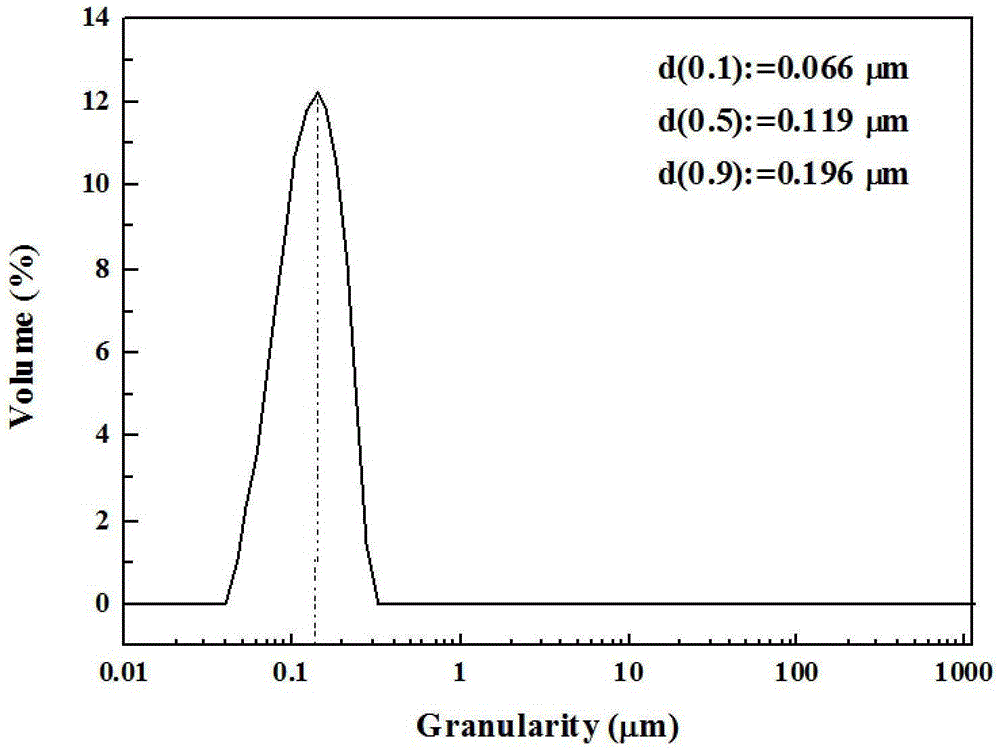

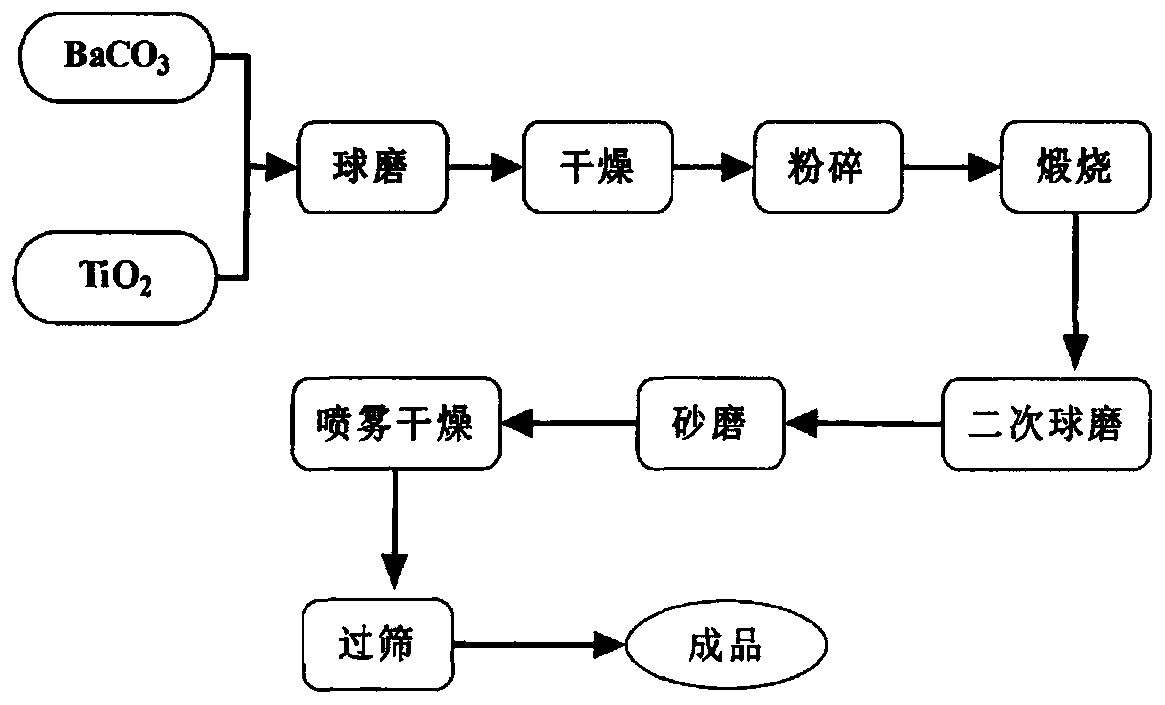

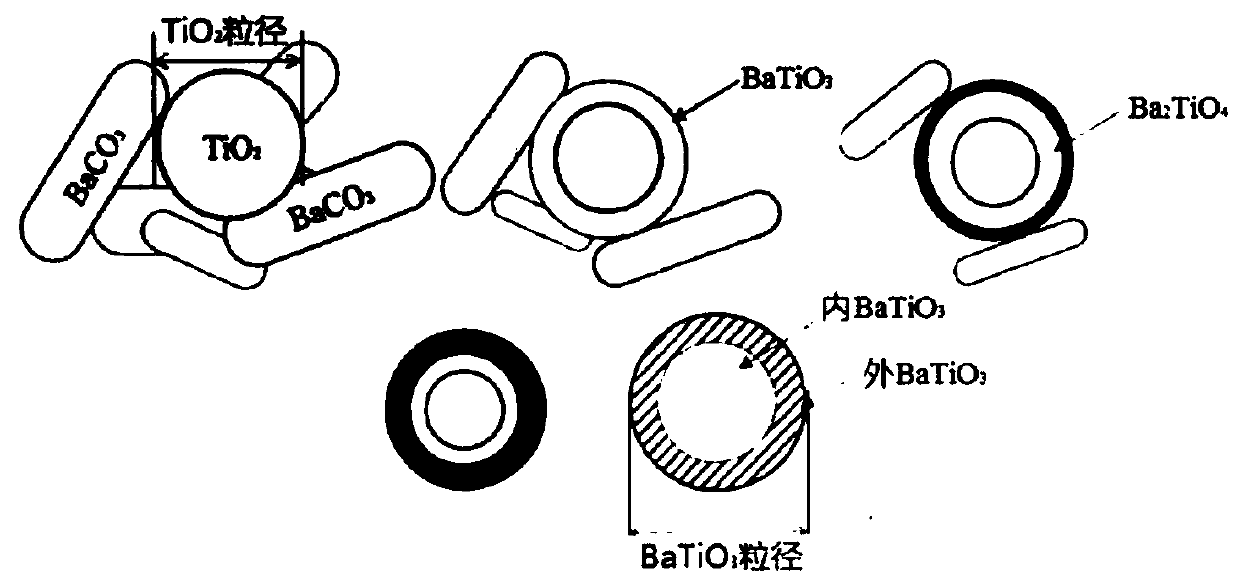

Nanocrystalline barium titanate ceramic and preparation method thereof

The invention belongs to the technical field of capacitor dielectric materials, and particularly relates to nanocrystalline barium titanate ceramic and a preparation method thereof. The preparation method of the nanocrystalline barium titanate ceramic comprises the following steps of: mixing barium carbonate and titanium dioxide, and carrying out ball milling, sanding, drying, sieving and calcining to obtain the barium titanate ceramic. The preparation method of the nanocrystalline barium titanate ceramic comprises the following steps of: mixing and ball-milling barium carbonate and titanium dioxide to increase the sintering activity of barium carbonate and titanium dioxide; carrying out solid-phase synthesis by using a sanding method to obtain barium titanate nano-powder with relatively small particle size and high tetragonality; the barium titanate nano-powder is subjected to calcination treatment, and the obtained nanocrystalline barium titanate ceramic has a small grain size and ahigh dielectric constant and can meet the requirement that a capacitor contains 5-6 ceramic grains in each single dielectric medium when being used as a ceramic capacitor material.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

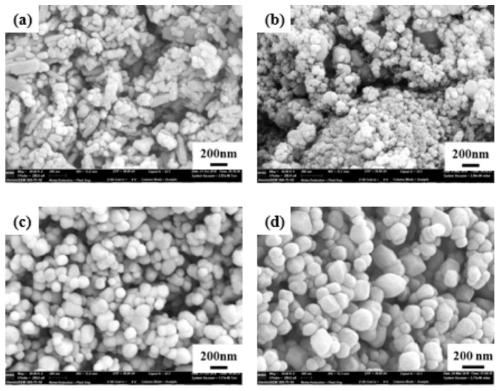

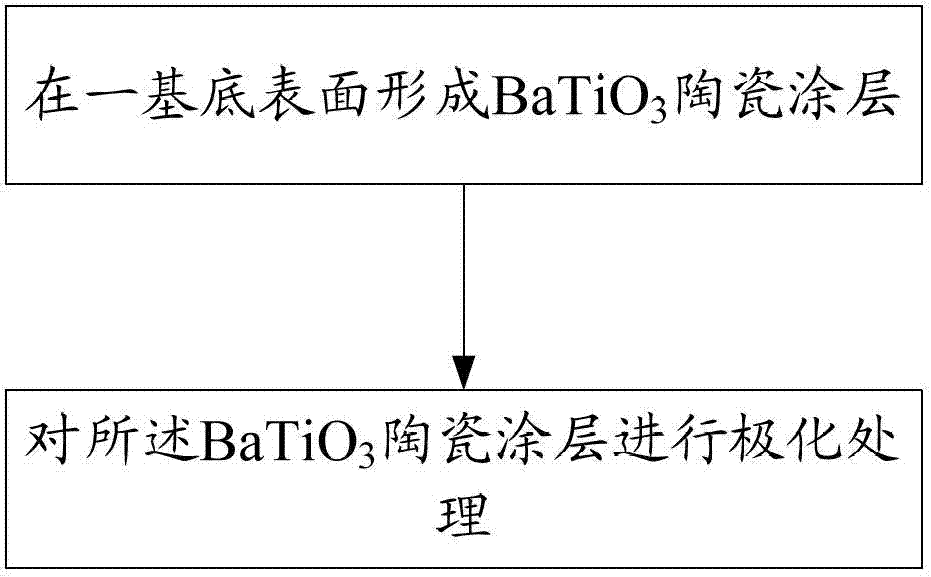

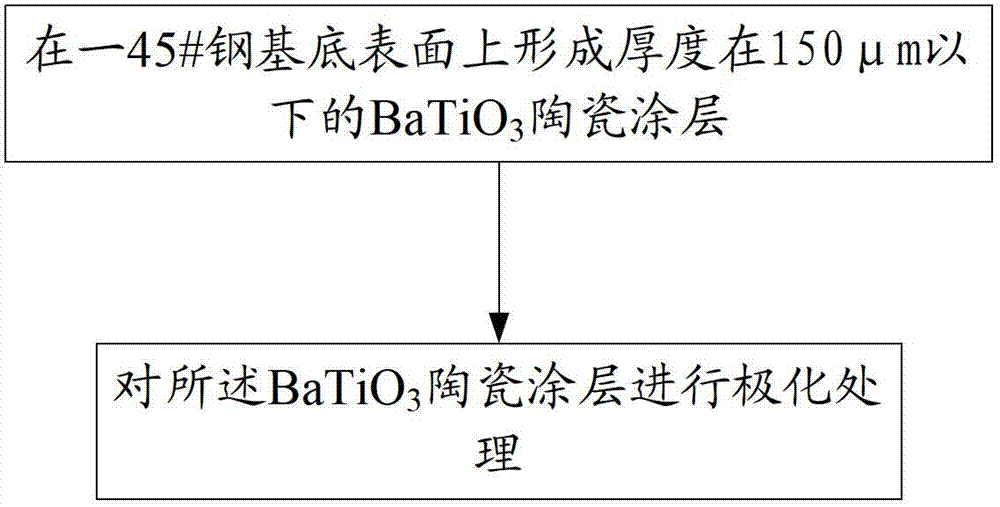

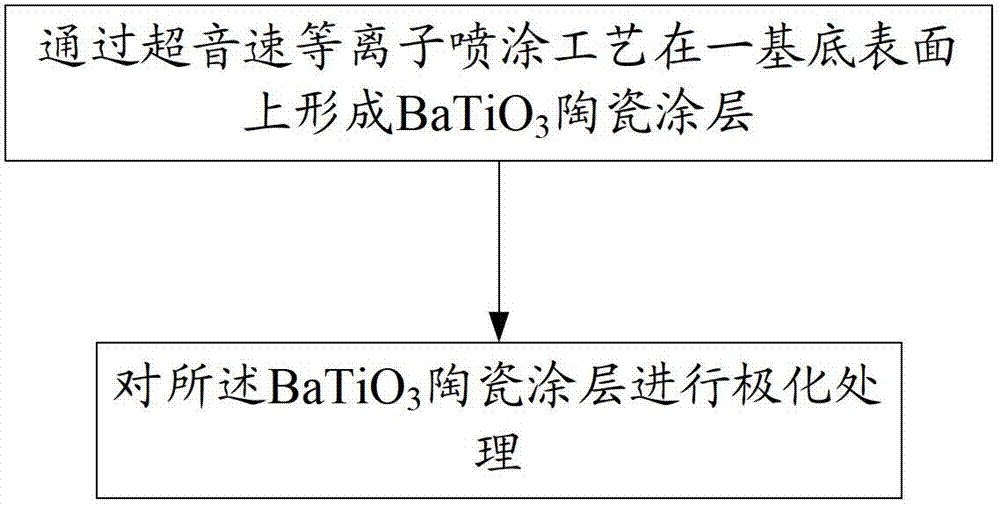

Intelligent BaTiO3 coating and preparation method thereof

ActiveCN102888579AImprove adhesionImprove wear resistancePiezoelectric/electrostrictive device manufacture/assemblyMolten spray coatingCeramic coatingPiezoelectric coefficient

The embodiment of the invention discloses a preparation method of the intelligent BaTiO3 coating. The preparation method comprises the following steps of forming a BaTiO3 ceramic coating on the surface of a substrate; and carrying out a polarization treatment on the BaTiO3 ceramic coating so that the BaTiO3 ceramic coating is of a piezoelectric effect. The obtained intelligent BaTiO3 coating has functions of a piezoelectric sensor and the self abrasion state of the intelligent BaTiO3 coating is monitored and fed back in real time so that a sensor does not need to be adhered. Compared with a sensor and a substrate combined by adhesion in the prior art, the preparation method of the intelligent BaTiO3 coating, disclosed by the invention, can prevent a problem of poor adhesion between the sensor and the substrate.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

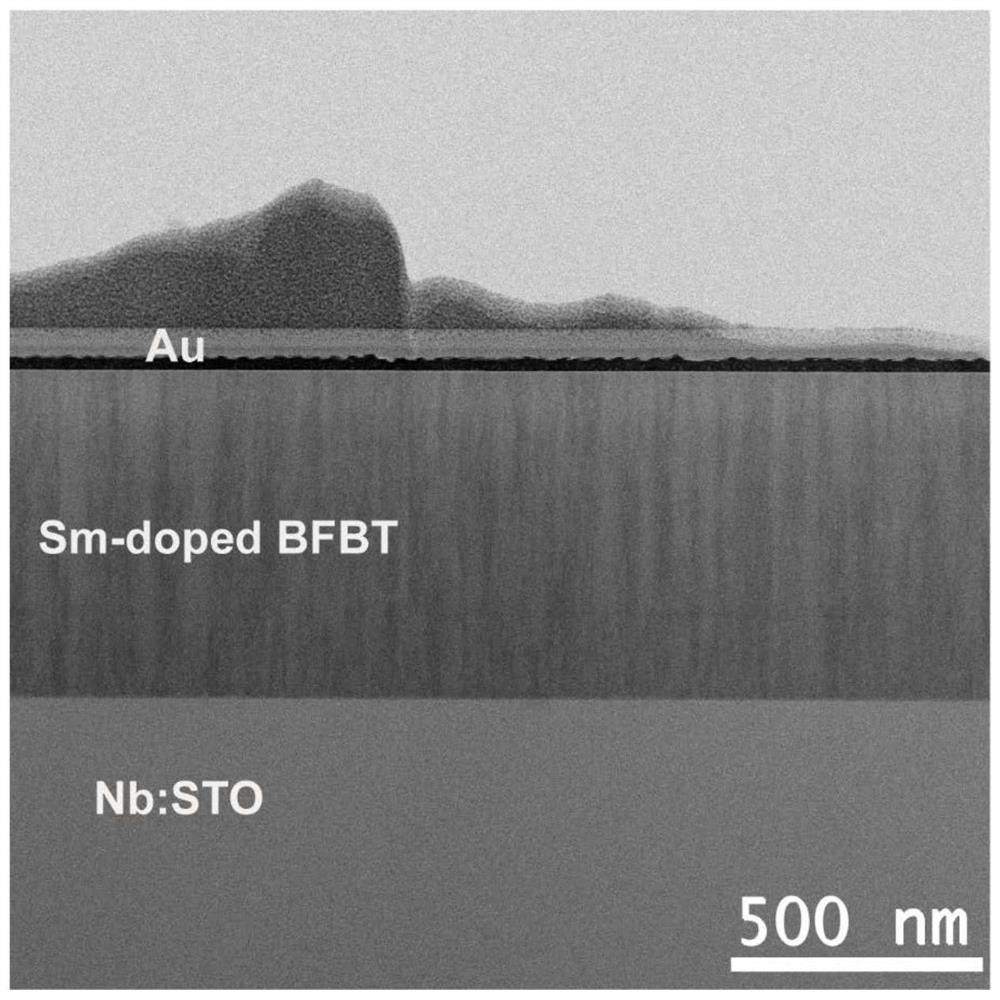

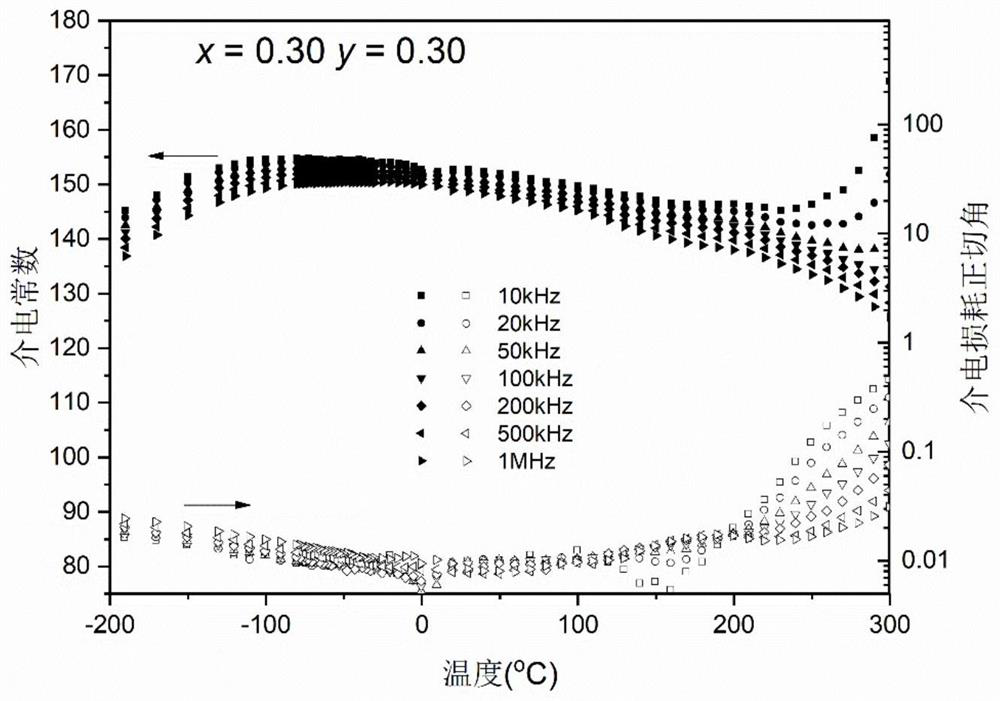

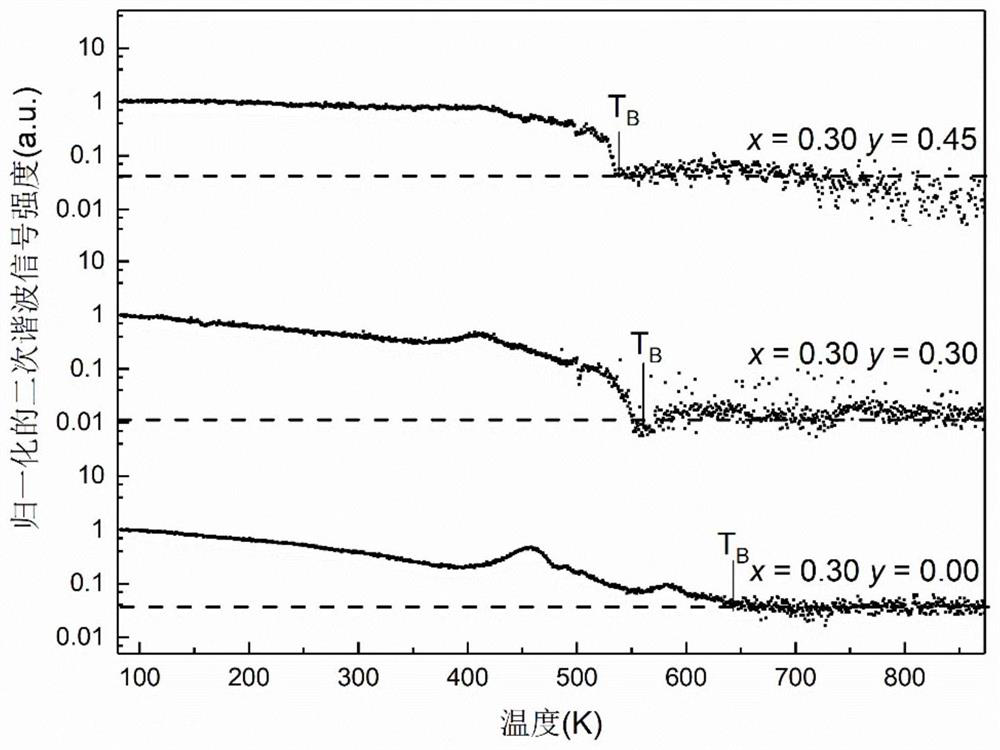

Samarium-doped bismuth ferrite-barium titanate ceramic film as well as preparation method and application thereof

The invention discloses a samarium-doped bismuth ferrite-barium titanate ceramic film as well as a preparation method and application thereof, and belongs to the technical field of dielectric materials. The chemical general formula of the film is x (Bi1-yScy) FeO3-(1-x) (Ba1-yScy) TiO3, wherein x and y are mole fractions, x is more than 0 and less than 1, and y is more than 0 and less than 1. The preparation method comprises the following steps of: mixing Bi2O3, Fe2O3, BaCO3, TiO2 and Sm2O3 according to a selected stoichiometric ratio to obtain raw material powder; pre-sintering the raw material powder to obtain a ceramic blank; carrying out buried sintering to obtain a ceramic target material; and bombarding the target material by using pulse laser, and carrying out annealing treatment to obtain the ceramic film. Experiments prove that the breakdown field strength of the film can reach 4-5.3 MV / cm, the energy storage density can reach 152 J / cm < 3 >, and the energy storage efficiency is about 78%; and the film is a novel dielectric material which has high breakdown field strength and high energy storage density and is environment-friendly.

Owner:TSINGHUA UNIV

Barium titanate ceramic dielectric material and capacitor prepared using barium titanate ceramic dielectric material

InactiveCN105218089AUniform particle size distributionGood dispersionFixed capacitor dielectricStacked capacitorsBarium titanateNickel electrode

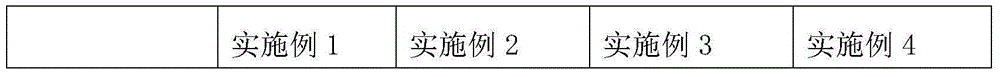

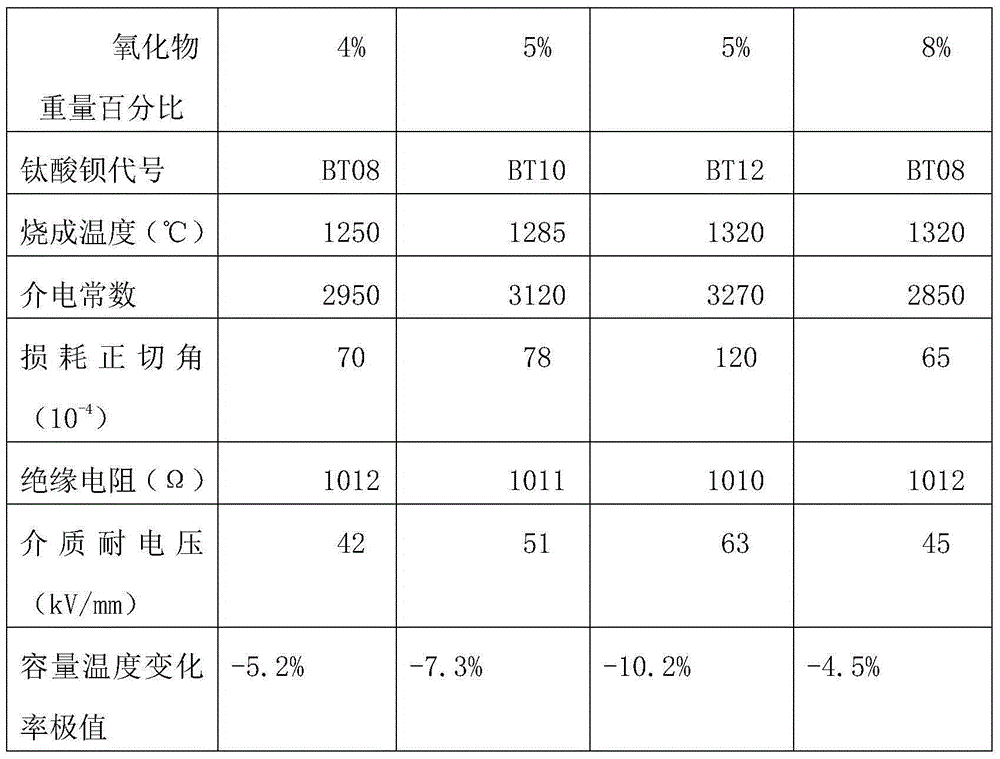

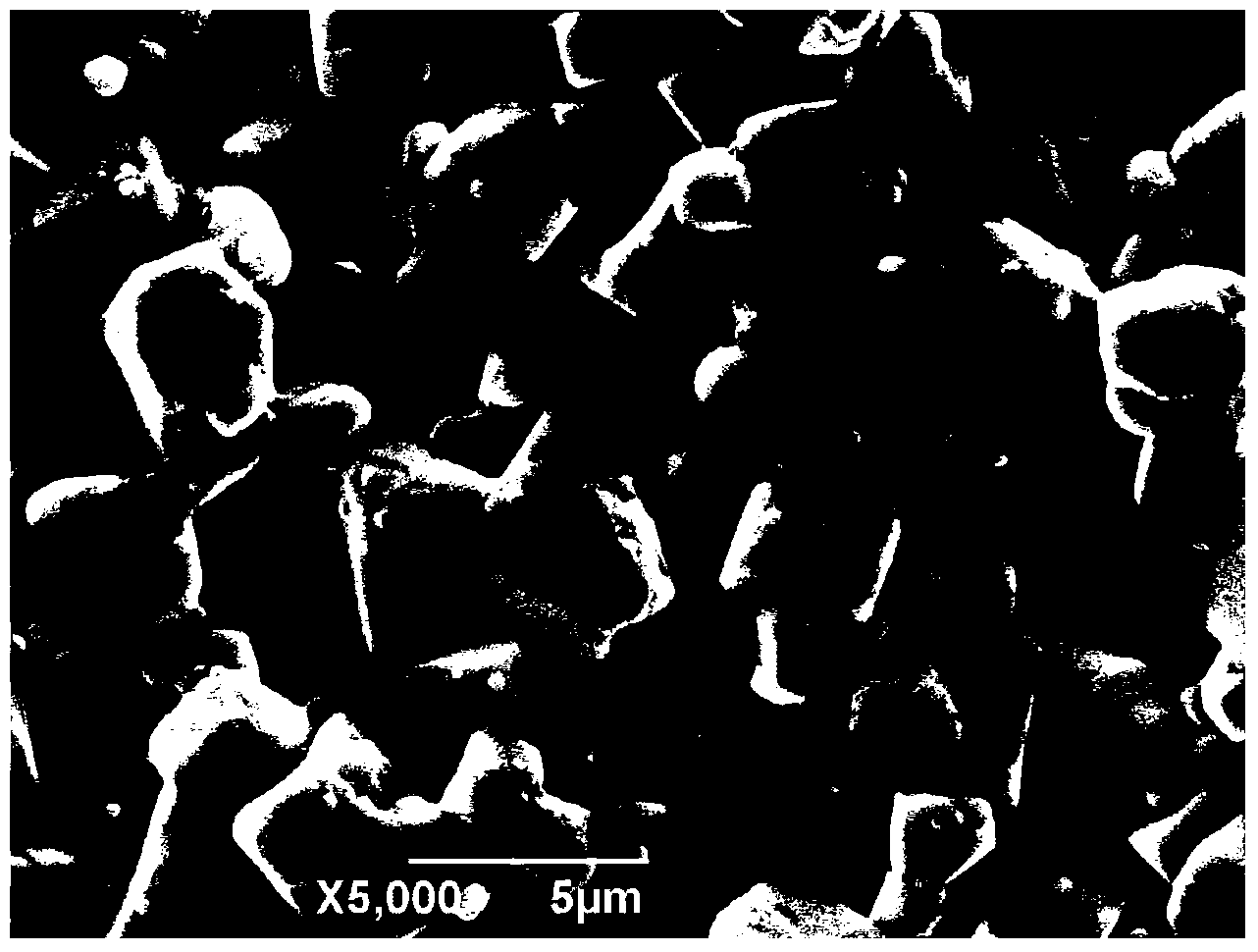

The invention relates to the technical field of ceramic dielectric materials and components and parts prepared using the ceramic dielectric materials, in particular to a barium titanate ceramic dielectric material and a high voltage chip-type multilayer capacitor prepared using the barium titanate ceramic dielectric material, wherein the barium titanate ceramic dielectric material is prepared through the following method steps: A, calcining: calcining BaTiO3 powder with the initial particle size D50 being equal to 0.1-0.3 [mu]m for 2-3 hours at the temperature of 1100-1200 DEG C, the particle size D50 of calcined BaTiO3 powder is controlled to be equal to 0.8-1.5 [mu]m; B, doping, doping powder in the step A with oxide, the weight of oxide accounts for 4-8% of the total weight of powder in the step A; C, performing mixed dispersion on the powder in the step B through wet ball grinding, and further drying. The multilayer capacitor prepared using the barium titanate ceramic dielectric material has a nominal voltage of 10000V, uses a nickel electrode as the inner electrode, can realize low-cost base metallization of high voltage products, and can be extensively applied to civilian electronic products with low cost requirements.

Owner:广州创天电子科技有限公司

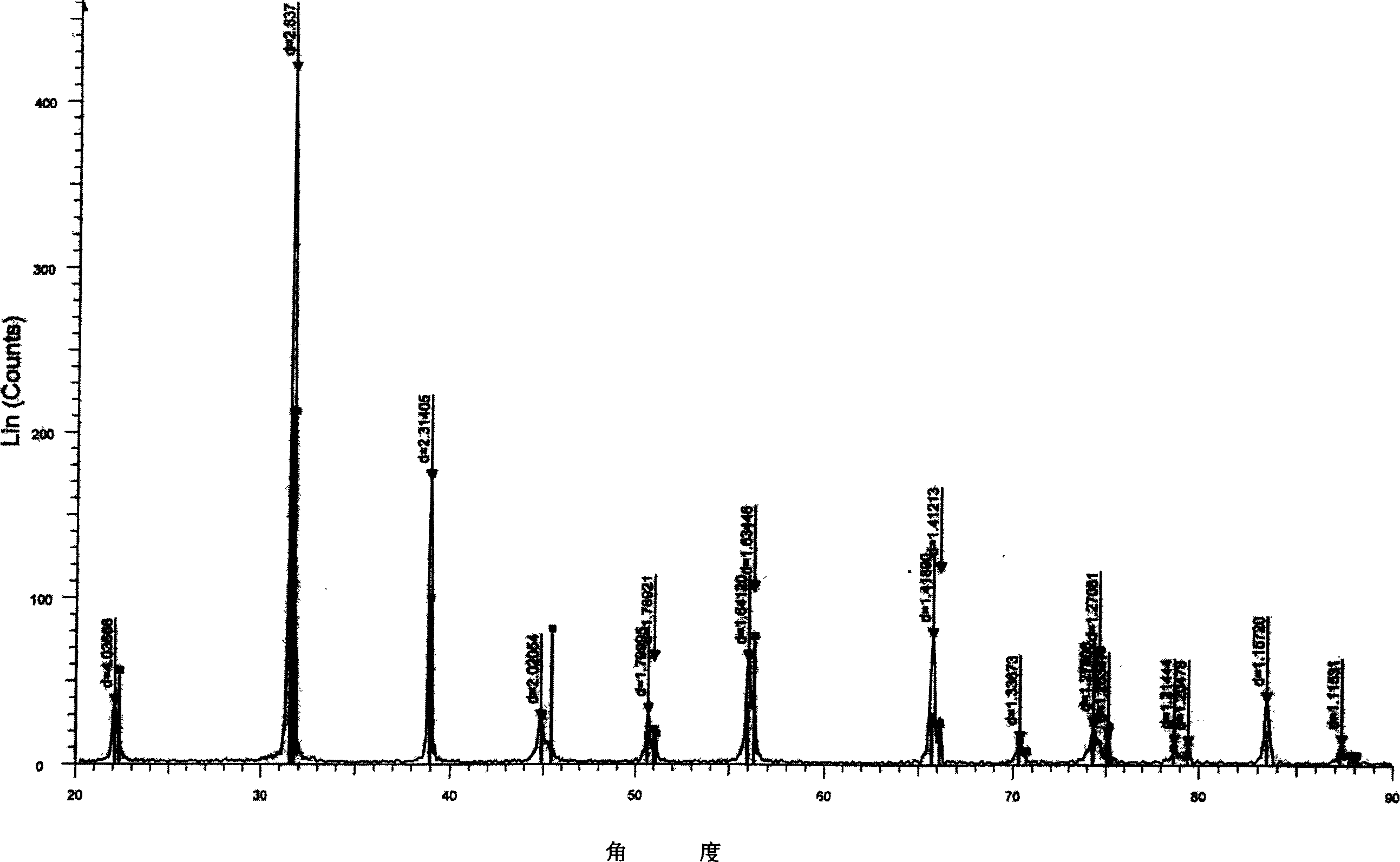

Method for preparing binderless BaTiO3 ceramic through microwave-assisted method

The invention discloses a method for preparing a binderless BaTiO3 ceramic through a microwave-assisted method. The method comprises the following steps: dissolving BaCl2.H2O and TiCl4 into deionized water, adding mineralizer NaOH, and uniformly stirring to obtain a coprecipitation precursor A; pouring the coprecipitation precursor A into the lining of a microwave hydrothermal reaction kettle, then placing the lining into the microwave hydrothermal reaction kettle for reaction, taking a reactant out after furnace temperature is naturally cooled to room temperature, washing, and drying to obtain nanometer BaTiO3 powder; briquetting the obtained BaTiO3 powder, and then screening and granulating obtained BaTiO3 powder blocks through a mesh screen to obtain powder with the granularity of 75-48 micrometers; and forming the obtained powder, sintering a formed billet to obtain the BaTiO3 ceramic after furnace cooling. The method disclosed by the invention omits the step of bonding agent addition in a preparation process, has the advantages of low preparation cost, easiness for operation, short reaction period, low sintering temperature, good ceramic density and excellent dielectric property of a product and achieves the dielectric constant up to 3000 and the dielectric loss less than 0.1 at the room temperature of a sample.

Owner:JIANGSU SHUSHI LIGHTING CO LTD

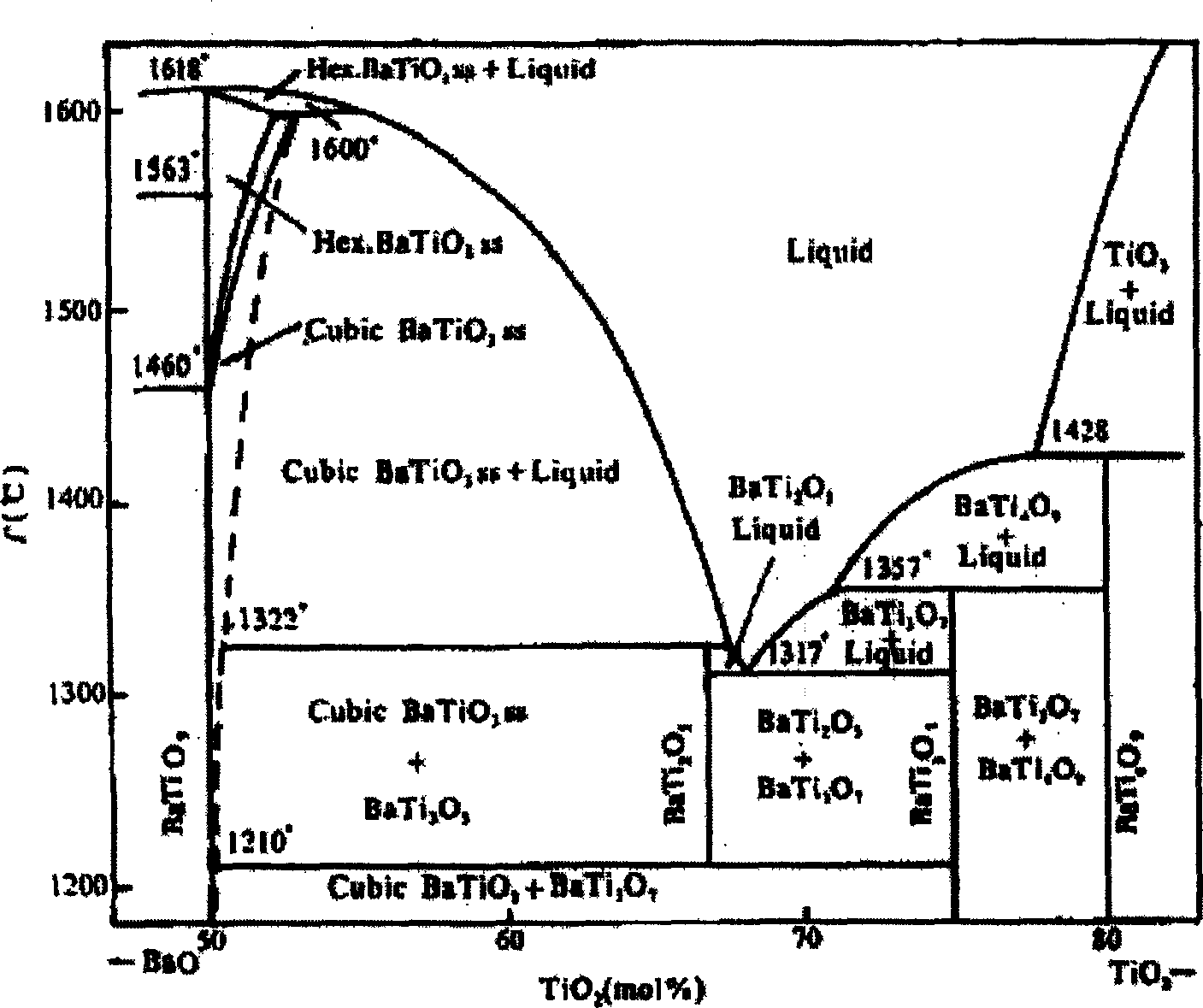

Process for laser preparation of hexagonal phase barium titanate ceramic

The present invention is laser preparation process of hexagonal barium titanate ceramic and belongs to the field of ceramic preparing technology. The preparation process includes the following steps: preparing barium titanate ceramic biscuit via traditional solid reaction process; irradiating the ceramic biscuit directly with great power laser in scanning mode through raising the laser power density from 0 to 466-777 W / sq cm in 10-60 sec, sintering for 20-60 sec and lowering laser power density continuously in 10-60 sec; and cooling to form the hexagonal barium titanate ceramic. The preparation process has short time and easy control, and can realize no-contamination sintering.

Owner:CHENGDU 3D CHANGE TECH

Co-doped barium titanate ceramic dielectric material as well as preparation method and application thereof

PendingCN114014649AHigh dielectric constantImprove reliabilityFixed capacitor dielectricBarium titanateCeramic capacitor

The invention discloses a co-doped barium titanate ceramic dielectric material, a preparation method and application of the co-doped barium titanate ceramic dielectric material in preparation of an electronic component. The co-doped barium titanate ceramic dielectric material takes 93-97 mol% of BaTiO3 as a main body material, and takes 3-7 mol% of a glass phase material, an anti-reducing agent, an alkali metal compound and a rare earth oxide as doping materials. The invention also discloses a multilayer ceramic capacitor prepared from the co-doped barium titanate ceramic dielectric material, the dielectric constant of the multilayer ceramic capacitor is between 2800 and 3900, the thickness of the dielectric layer is between 650 and 850nm, the room temperature resistivity can reach 8G omega.m, and the reliability meets the requirement of a life test. The co-doped barium titanate ceramic dielectric material and the capacitor provided by the invention are simple in preparation process, free of toxic substances, well matched with base metal inner electrodes such as nickel, compact in ceramic body, small in crystal grain, few in defect and wide in application prospect.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

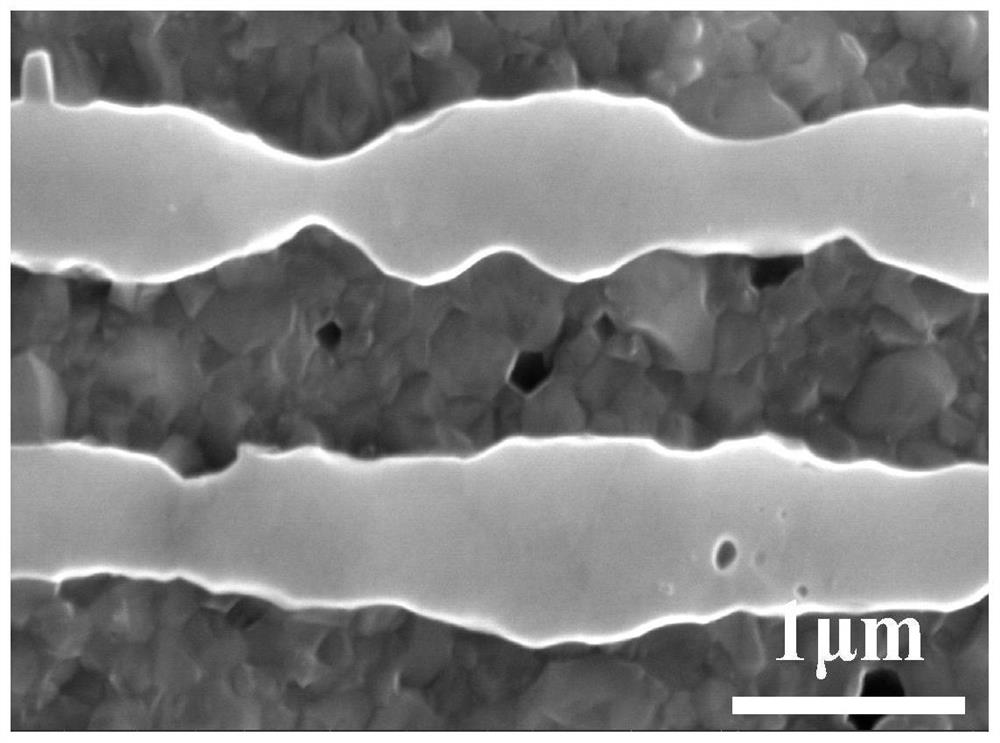

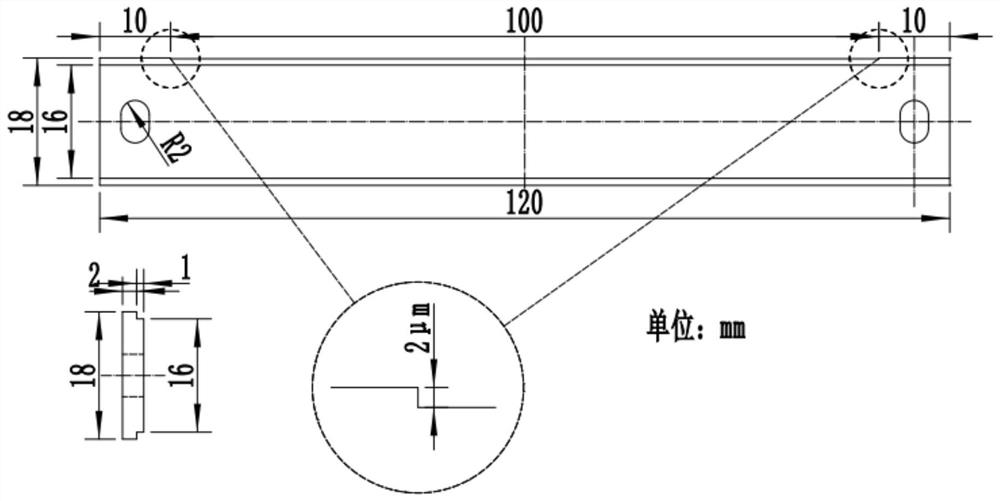

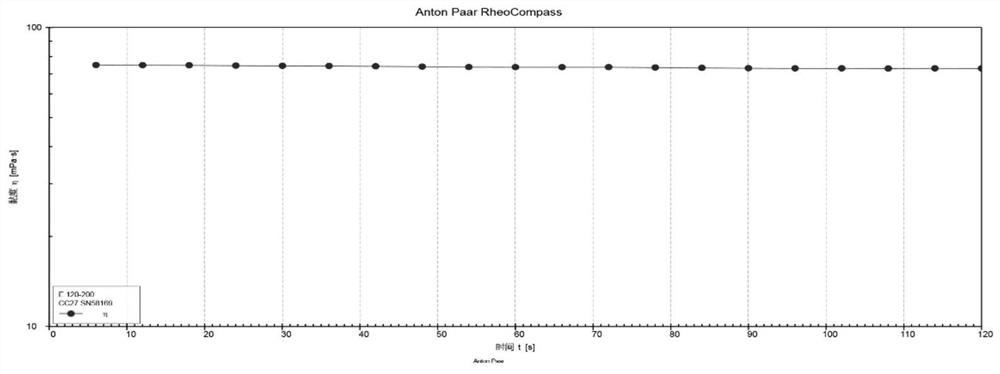

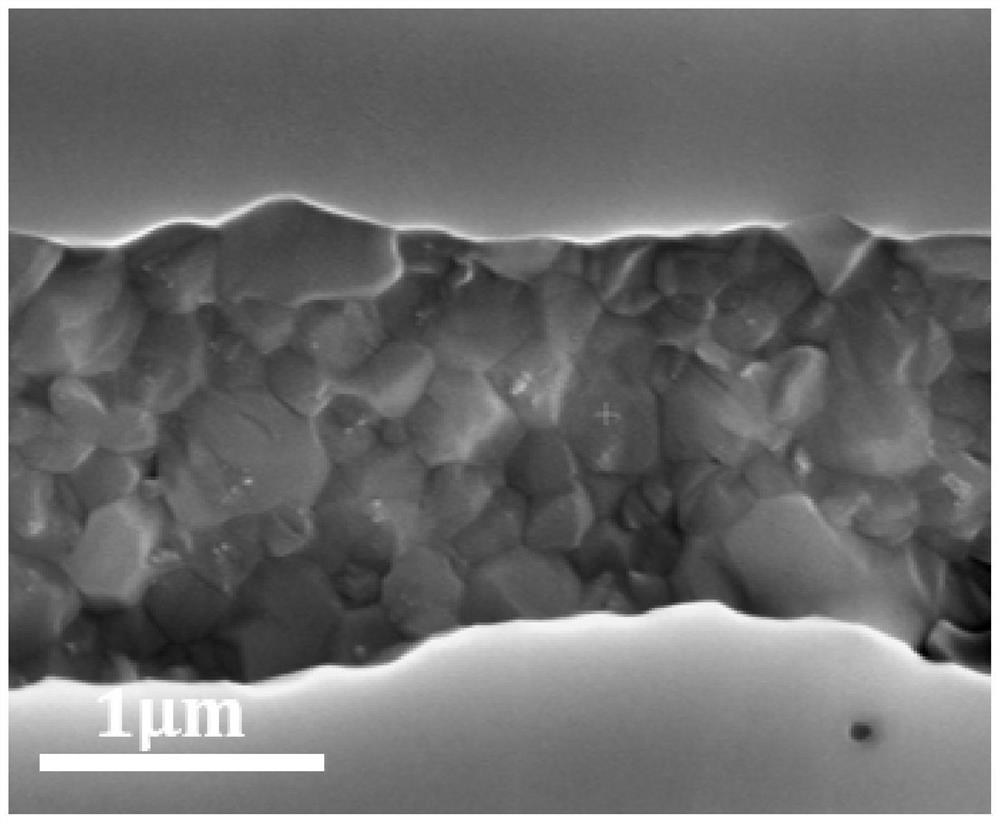

Ceramic ultrafine powder tape casting ultrathin dielectric paste and ceramic film formed by ceramic ultrafine powder tape casting ultrathin dielectric paste

ActiveCN113314340AImprove uniformityHigh strengthFixed capacitor dielectricStacked capacitorsBarium titanateAdhesive

The invention belongs to the technical field of inorganic materials, particularly relates to barium titanate ceramic ultrafine powder tape casting ultrathin dielectric paste, and further discloses a tape casting method of the barium titanate ceramic ultrafine powder tape casting ultrathin dielectric paste, and a ceramic film and an MLCC device which are formed by tape casting of the barium titanate ceramic ultrafine powder tape casting ultrathin dielectric paste. The ceramic ultrafine powder casting ultrathin dielectric paste is developed based on deep processing of the barium titanate ultrafine powder, a paste system with excellent dispersity and casting stability is formed by selecting proper organic solvent, dispersing agent, surfactant, plasticizer, defoaming agent and adhesive, the paste viscosity is very stable, and the performance requirements of casting high-quality ultra-thin dielectric diaphragms of 2 microns and below and corresponding chip multilayer ceramic capacitors can be met.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

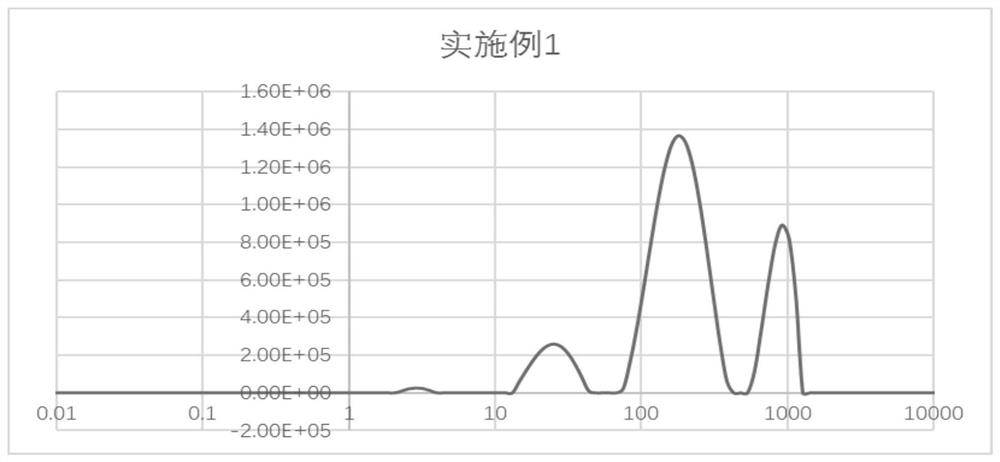

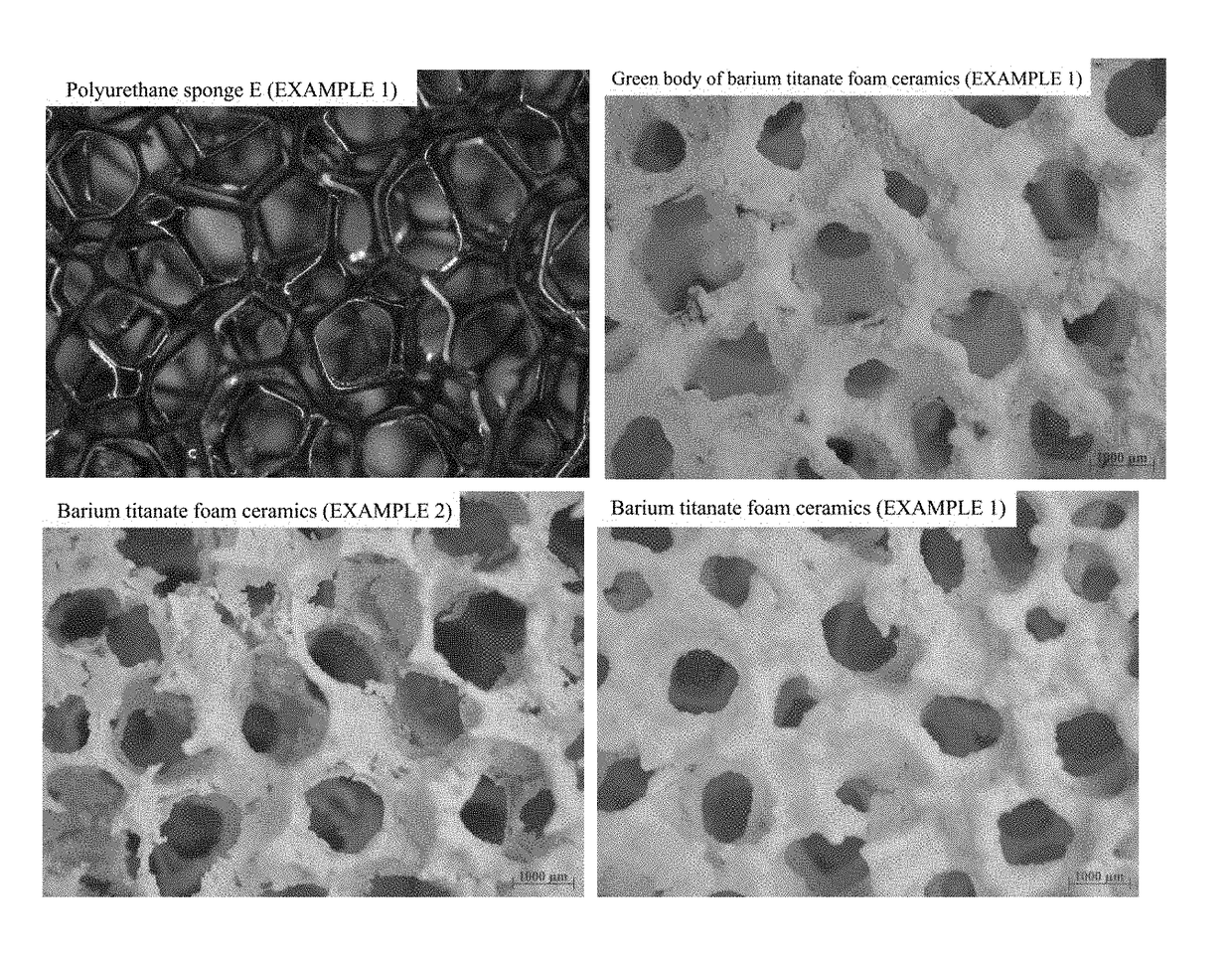

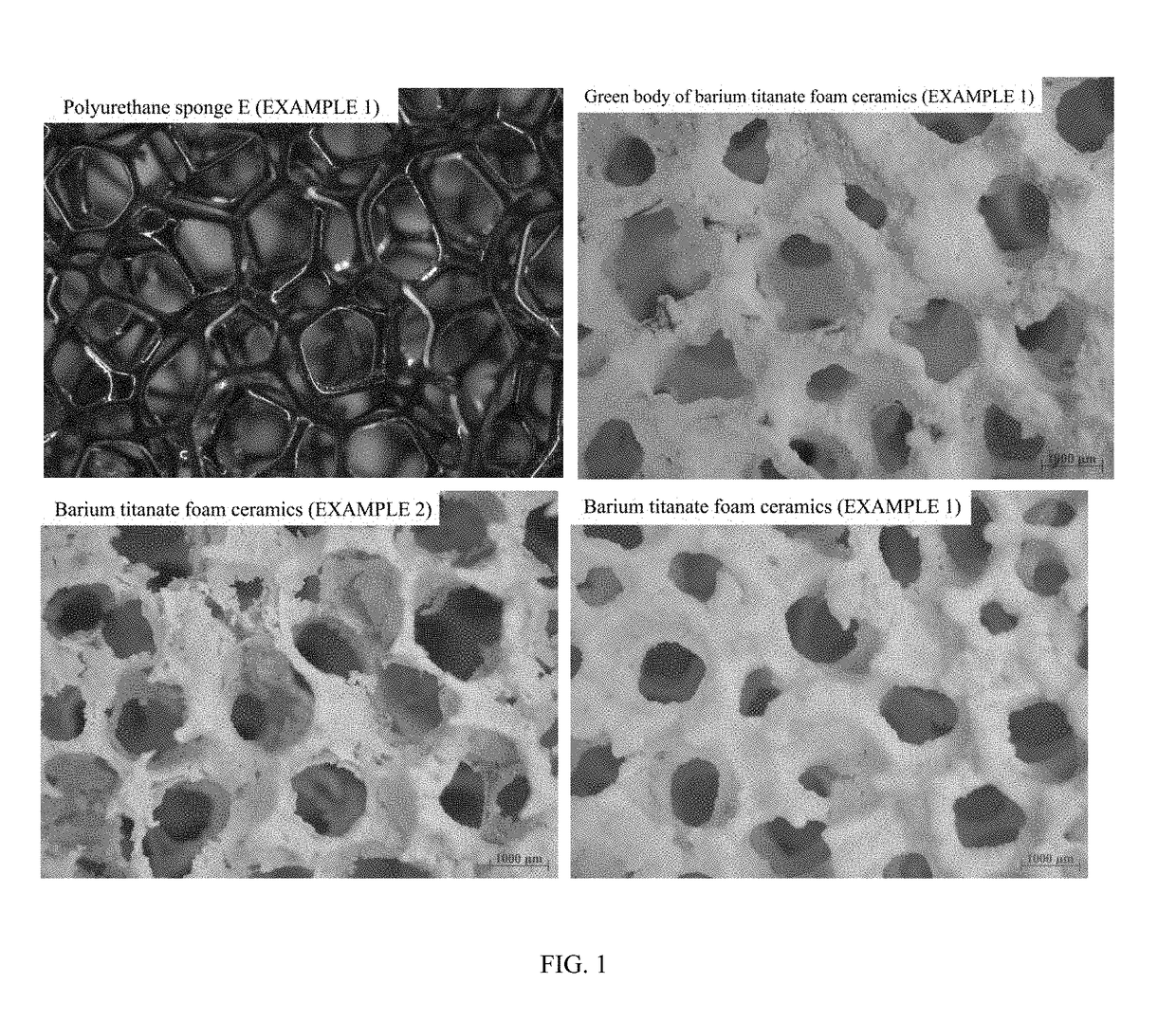

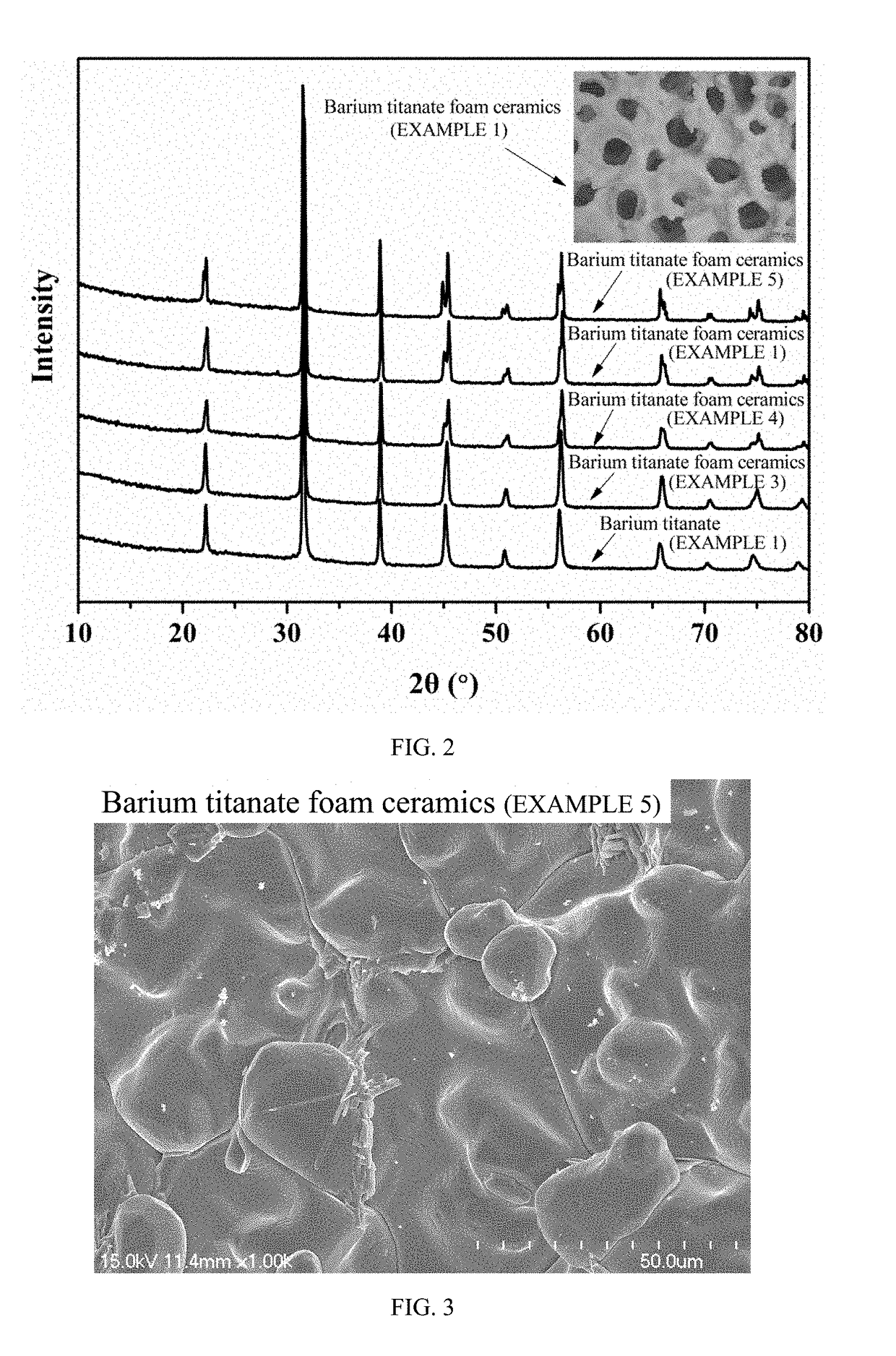

Barium titanate foam ceramics and preparation method thereof

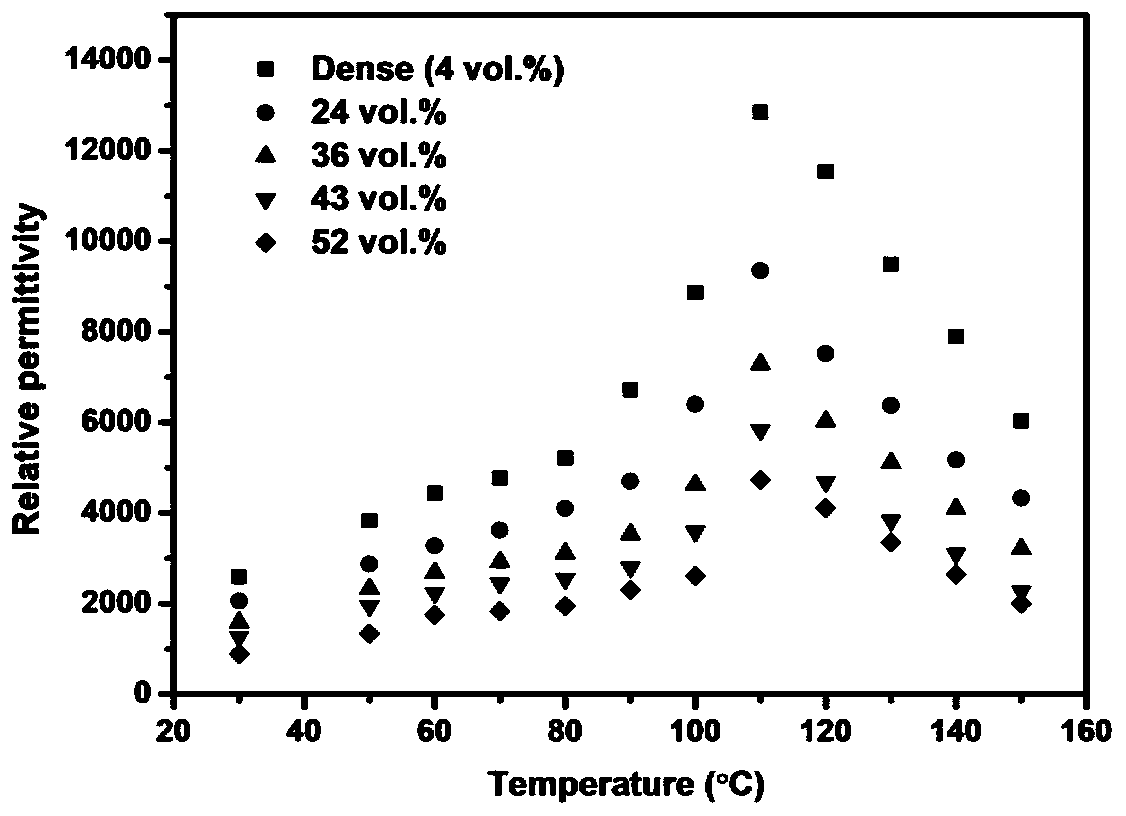

InactiveUS20180194692A1High strengthHigh dielectric constantCeramicwareChemical compositionBarium titanate

Barium titanate foam ceramics and a preparation method thereof are disclosed. An organic binder, an organic rheological agent and an organic dispersing agent are used as auxiliaries; deionized water is used as a solvent; nanometer barium titanate is used as a ceramic raw material; and all of same are mixed and ground so as to form a slurry with a certain solid content. A pretreated polymer sponge is impregnated into the slurry for slurry coating treatment and then dried to obtain a barium titanatefoam ceramic blank with an ideal slurry coating and without blocking holes, and same is then sintered so as to obtain a barium titanate foam ceramic. The foam ceramic has a three-dimensional network skeleton structure, and the skeleton of the foam ceramic is composed of pure barium titanate ceramic of a single chemical composition.

Owner:SUZHOU UNIV

Surface treatment method of BaTiO3 ceramic substrate used for single-layer capacitor

ActiveCN105070545AIntegrity guaranteedImprove thickness uniformityCapacitor manufactureAlcoholMetallurgy

The invention discloses a surface treatment method of a BaTiO3 ceramic substrate used for a single-layer capacitor. The surface treatment method comprises the steps of: (1) selecting a grinding disc; (2) selecting a grinding liquid; (3) selecting a planetary frame; (4) polishing the substrate after grinding, wherein a grinding rate is controlled to range from 8 to 10mu m / min, a polishing rate is controlled to range from 3 to 4mu m / min, is controlled to range from 3 to 5 kg, and the grinding time is controlled to be within 30min; (5) mixing one or more of deionized water, alcohol, acetone and a cleaning agent evenly, and carrying out ultrasonic cleaning for 30 min at the temperature ranging from 40 to 50 DEG C within a power range from 250 to 300W; (6) and carrying out thermal treatment on the substrate after surface treatment under the conditions of temperature ranging from 500 to 600 DEG C and heat preservation time of 2 hr. By adopting the surface treatment method, the recycling type cutting machine can protect the factory environment, and prevents cutting fluid from contaminating the field.

Owner:GUANGZHOU AURORA TECHNOLOGIES CO LTD

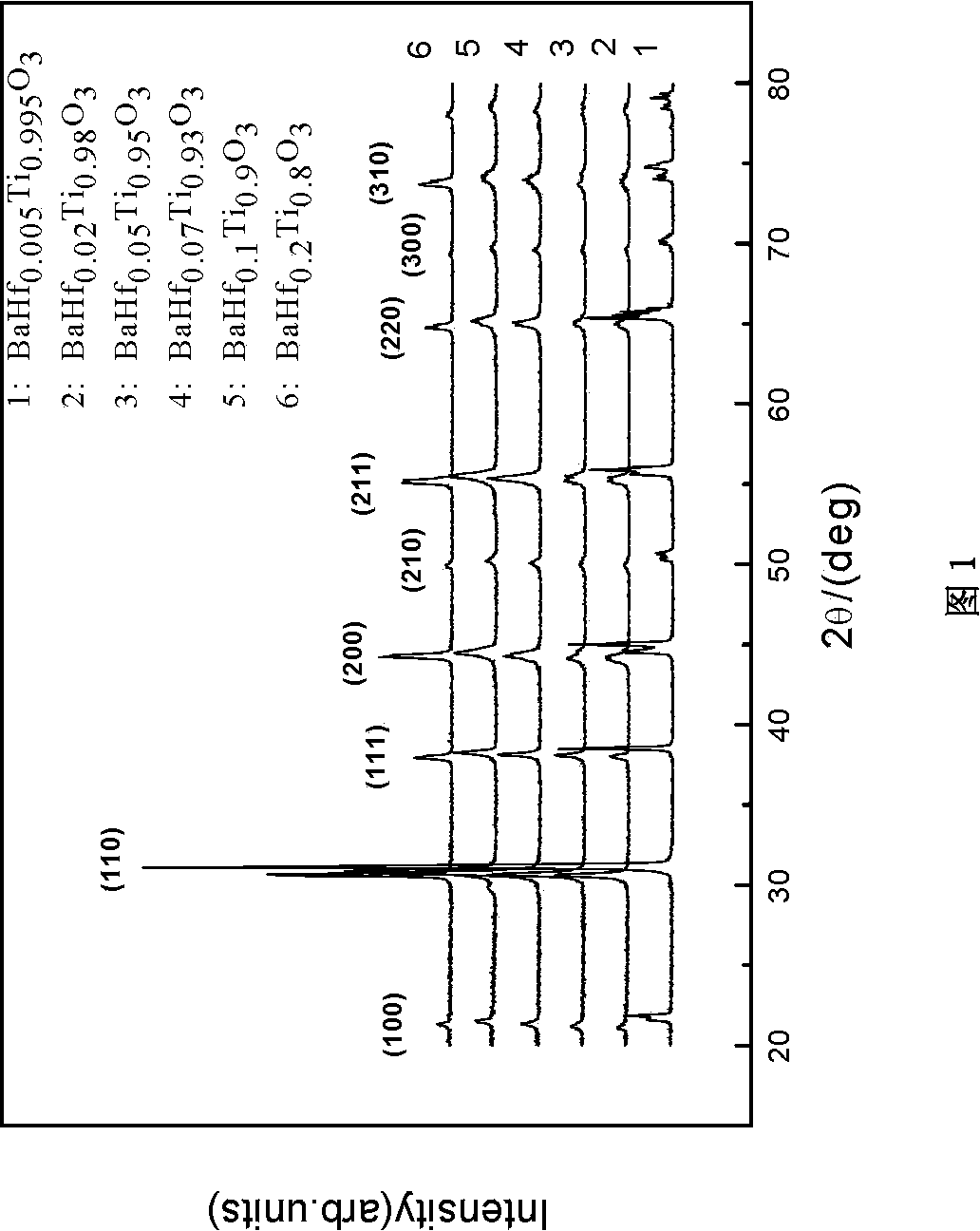

Barium hafnium titanate leadless piezoelectric ceramic with high piezoelectric coefficient and preparation method of leadless piezoelectric ceramic

InactiveCN103467085AHigh piezoelectric coefficientRaise the sintering temperatureCeramic sinteringBarium titanate

The invention relates to the technical field of piezoelectric ceramics, in particular to barium hafnium titanate leadless piezoelectric ceramic with a high piezoelectric coefficient and a preparation method of the leadless piezoelectric ceramic. The preparation method of the barium hafnium titanate leadless piezoelectric ceramic with the high piezoelectric coefficient comprises the steps of uniformly mixing BaCO3, TiO2 and HfO2 at a ratio of 1:(1-x):x into a mixed material. Compared with barium titanate ceramic, under the condition that the sintering temperature of the barium hafnium titanate leadless piezoelectric ceramic is slightly lower than that of the barium titanate ceramic, the piezoelectric coefficient of the barium hafnium titanate leadless piezoelectric ceramic is 2-3 times that of the barium titanate ceramic; compared with zircon barium titanate ceramic, under the condition that the sintering temperature of the barium hafnium titanate leadless piezoelectric ceramic is much lower than that of the zircon barium titanate ceramic, the piezoelectric coefficient of the barium hafnium titanate leadless piezoelectric ceramic is much higher than that of the zircon barium titanate ceramic; the sintering temperature of a material is reduced on the basis of increasing the piezoelectric coefficient of the material; the production cost is saved; and in addition, the preparation technology is simple and is applicable to industrial production and popularization.

Owner:YILI NORMAL UNIV

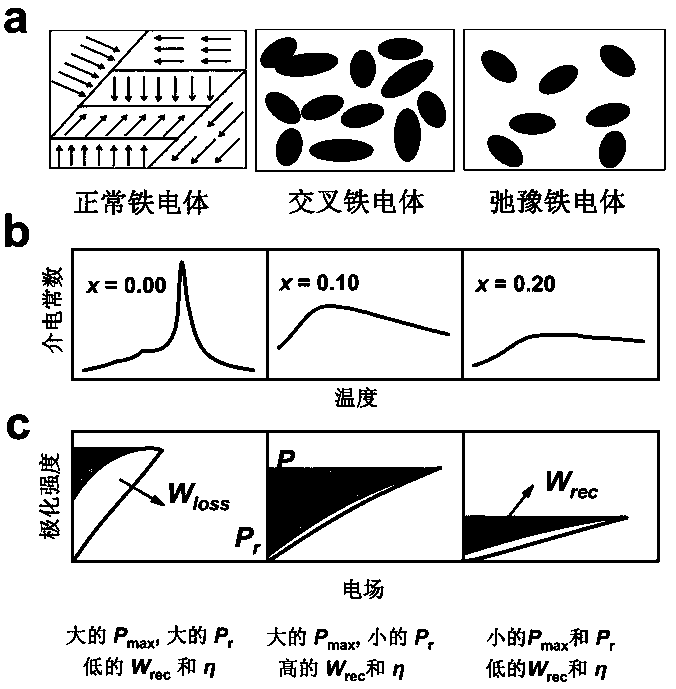

Barium titanate-based high-energy-storage-density electronic ceramic and preparation method thereof

InactiveCN111018516AImprove energy storage capacityUniform grain sizeChemical compositionFree energies

The invention relates to barium titanate-based high-energy-storage-density electronic ceramic and a preparation method thereof. The preparation method comprises the following steps: doping Sr<2+>, Bi<3+>, Mg<2+> and Nb<5+> ions into barium titanate ceramic to form a chemical composition of (1-x)Ba(1-y)SryTiO3-xBi(Mg2 / 3Nb1 / 3)03, and enabling the chemical composition to be in a crossed region; and 2, calculating the chemical proportion of the formula components obtained in the step 1, weighing high-purity BaCO3, SrCO3, Bi2O3, MgO, TiO2 and Nb2O5 powder, and carrying out ball-milling drying, presintering, tabletting and sintering to obtain the barium titanate-based high-energy-storage-density electronic ceramic. According to the method, electric domain engineering, Rankine free energy calculation and the like are introduced in the component design process; compared with an existing product, the energy storage performance of the ceramic prepared through a solid-phase method is greatly improved, the technological process is simple, prepared samples are uniform in grain size and high in chemical uniformity and electrical uniformity, and high energy storage density and efficiency are shown.

Owner:XIAN TECHNOLOGICAL UNIV

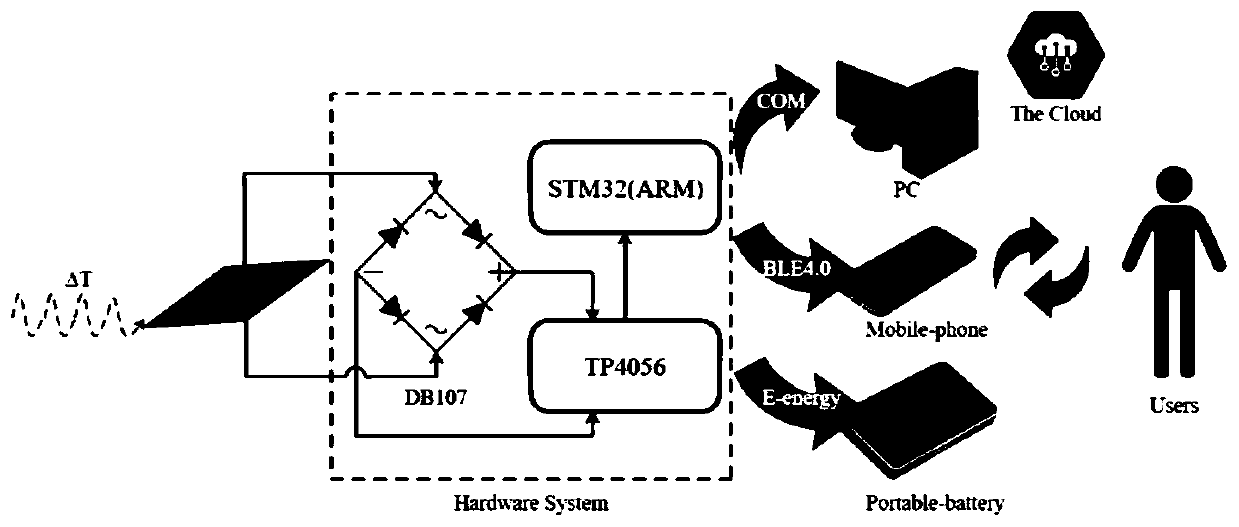

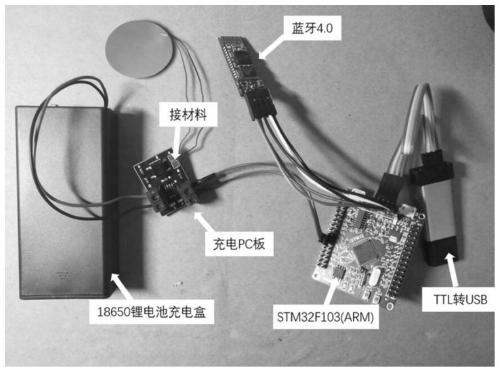

Application of pyroelectric material

ActiveCN111592351AImprove collection efficiencyCeramic shaping apparatusGenerators/motorsThermoelectric materialsPorosity

The invention discloses application of a pyroelectric material. The pyroelectric material is used for collecting heat energy, the heat energy is converted into electric energy by utilizing temperaturechange, and the pyroelectric material is a porous zirconium calcium barium titanate ceramic material; the temperature change is greater than or equal to 1 DEG C; and the porosity of the porous bariumcalcium zirconate titanate ceramic material is 10-60%. The porous zirconium-calcium-barium titanate ceramic material is applied to heat energy collection for the first time, the inventor finds that the porous barium calcium zirconate titanate can be used as the pyroelectric material, and the working principle is as follows: when the environment temperature changes, the pyroelectric material has apyroelectric effect and generates voltage on the upper and lower surfaces of the material, and the heat energy is converted into the electric energy. The porous barium calcium zirconate titanate serves as the pyroelectric material to be used for heat energy collection, the condition for converting the heat energy into the electric energy is that the temperature fluctuation is larger than or equalto 1 DEG C, that is, heat energy collection can be achieved only through temperature fluctuation of 1 DEG C, and the heat energy collection efficiency is greatly improved compared with a thermoelectric material in the prior art.

Owner:CENT SOUTH UNIV

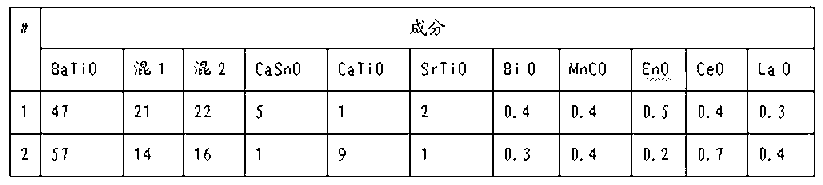

Ceramic capacitor medium and preparation method thereof

The invention discloses a ceramic capacitor medium. The ceramic capacitor medium comprises BaTiO3, and is characterized by also comprising a BaTiO3 and BaSnO3 synthetic material, a Bi2O3 and TiO2 synthetic material, a displacement modified material and a doped modified material. A method for preparing the ceramic capacitor medium is characterized by comprising the following steps of: grinding and uniformly mixing BaTiO3 ceramic, the displacement modified material and the doped modified material; and then putting the mixture into an alumina crucible, and preserving heat for 2.3 to 2.7 hours at the temperature of 1,300 to 1,350 DEG C. The ceramic capacitor medium has the beneficial effects that the dielectric-temperature characteristic of a new material accords with technical indexes of a microwave oven double-hole capacitor; the dielectric loss of the material is reduced; and the voltage resistance, particularly the alternating voltage resistance, of the medium is improved.

Owner:CHANGZHOU JIAGUAN ELECTRONICS

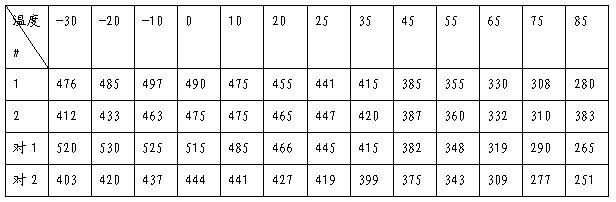

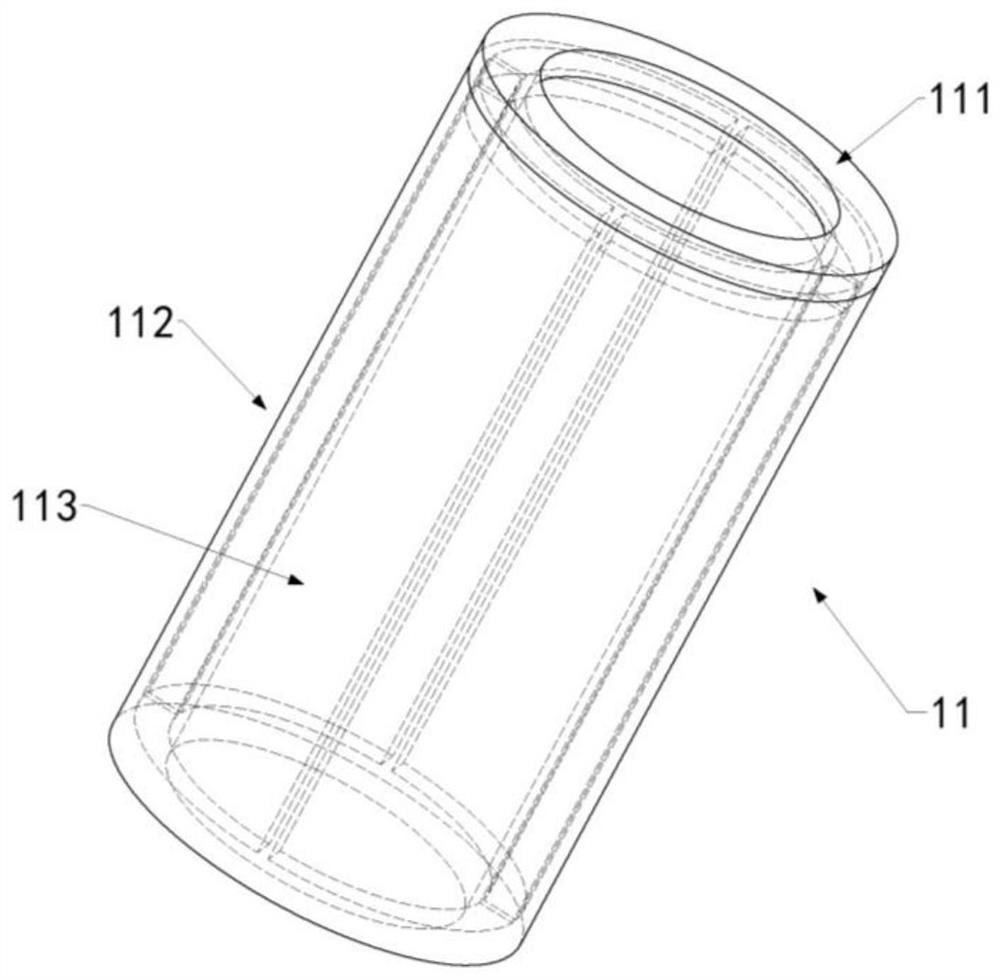

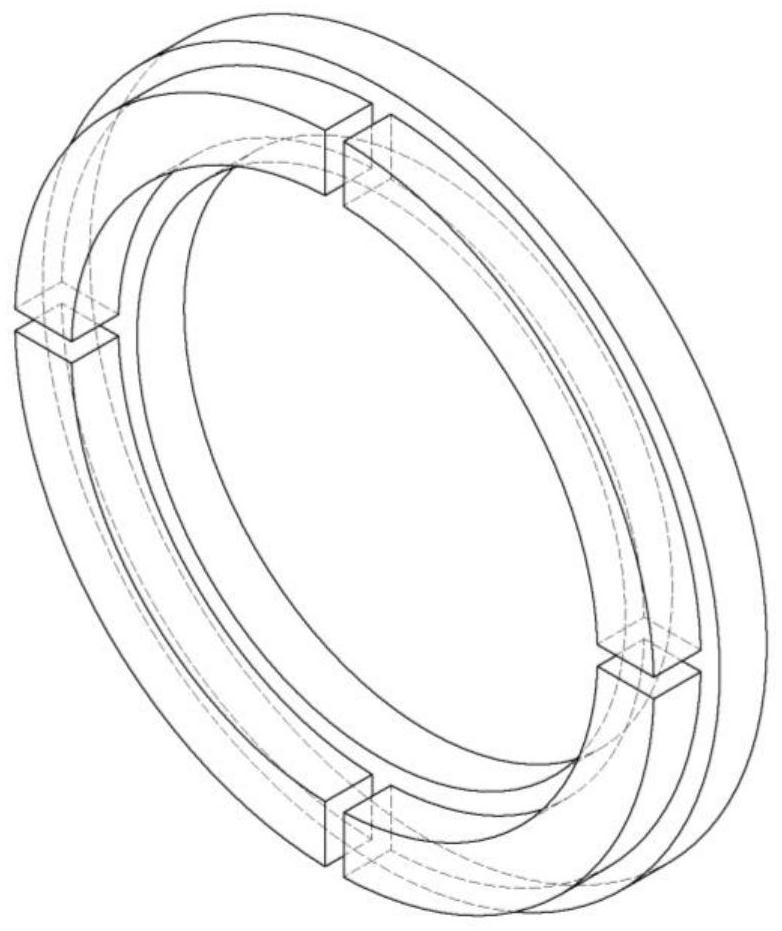

Ultrahigh-field animal magnetic resonance radio frequency probe with high dielectric constant

ActiveCN112162224AHigh sensitivityFlexible assemblyMeasurements using magnetic resonanceBarium titanateHemt circuits

The invention relates to a high-dielectric-constant ultrahigh-field animal magnetic resonance radio frequency probe which comprises a coil unit, the coil unit comprises a cylindrical coil circuit substrate and a cylindrical inner wall substrate, and the inner wall substrate is arranged in the coil circuit substrate. The two ends of a high-dielectric-constant ceramic unit are fixed between the coilcircuit substrate and the coil inner wall substrate through a ceramic unit support. All the units are independent of one another, assembling is flexible, and the sensitivity of the radio frequency probe can be effectively improved. The plurality of high-dielectric-constant ceramic blocks can greatly improve the B1 field emission efficiency in the central region, and avoids the adverse effects ofcoil mode increase and disorder caused by complete cylindrical barium titanate ceramic.

Owner:INNOVATION ACAD FOR PRECISION MEASUREMENT SCI & TECH CAS

Preparation method of BaTiO3 ceramic sheet

The invention discloses a preparation method of a BaTiO3 ceramic sheet, and belongs to electronic component preparation technologies. Components prepared by means of an existing BaTiO3-grouped ceramicsheet preparation method is higher in power attenuation and poorer in temperature coefficient and pressure resistance stability. Barium titanate ceramic is taken as a main body, complementary dopingof Nb5+ in lead titanate and barium titanate groups is achieved through multi-donor doping of Y3+ and Nb5+, and the total amount of doping is certain; the multi-donor doping of Y3+ and Nb5+ in the barium titanate group is achieved, and graphene is added to improve the heating uniformity and the heating rate of the ceramic sheet. The BaTiO3 ceramic sheet prepared by means of the method has the advantages that the heating efficiency is high, and higher voltage and temperature coefficient and lower power attenuation can be withstood under a static state. The convenience of BaTiO3 ceramic sheet production can be improved, and a prepared PTC ceramic sheet is more suitable for using in residential heating equipment.

Owner:AUPU HOME STYLE CORP LTD

Ceramic dielectric material as well as preparation method and application thereof

PendingCN114566382AMeet X5R requirementsRich varietyFixed capacitor dielectricStacked capacitorsCapacitanceRare-earth element

The invention provides a ceramic dielectric material as well as a preparation method and application thereof. A main body material of the material is BaTiO3, and doping materials comprise SiO2, CaO, V2O5, ZrO2 and oxides of rare earth elements; the oxides of the rare earth elements comprise at least two of Sc2O3, Sm2O3, Dy2O3 and Ho2O3; the addition amount of the BaTiO3 is 93.5 to 95 mol% in terms of molar percentage; the total addition amount of the doping material is 4.6-7 mol%. BaTiO3 is used as a main body material, a sintering aid, a metal oxide and a rare earth element are used as a composite doping agent, a barium titanate ceramic matrix is modified, the sintering aid and the doping material are added to refine particles, defects are controlled, and the grain size uniformity is improved, so that the high-reliability and high-performance barium titanate ceramic is prepared. The invention relates to a fine-grain ceramic and multilayer ceramic capacitor which has stable capacitance characteristics and is easier to stack.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com