Ceramic dielectric material as well as preparation method and application thereof

A technology of ceramic dielectric and doped materials, which is applied in the direction of fixed capacitor dielectric, fixed capacitor parts, fixed capacitors, etc., can solve the problems of large fluctuations in dielectric constant and limit the application range of barium titanate, and achieve a well-matched Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

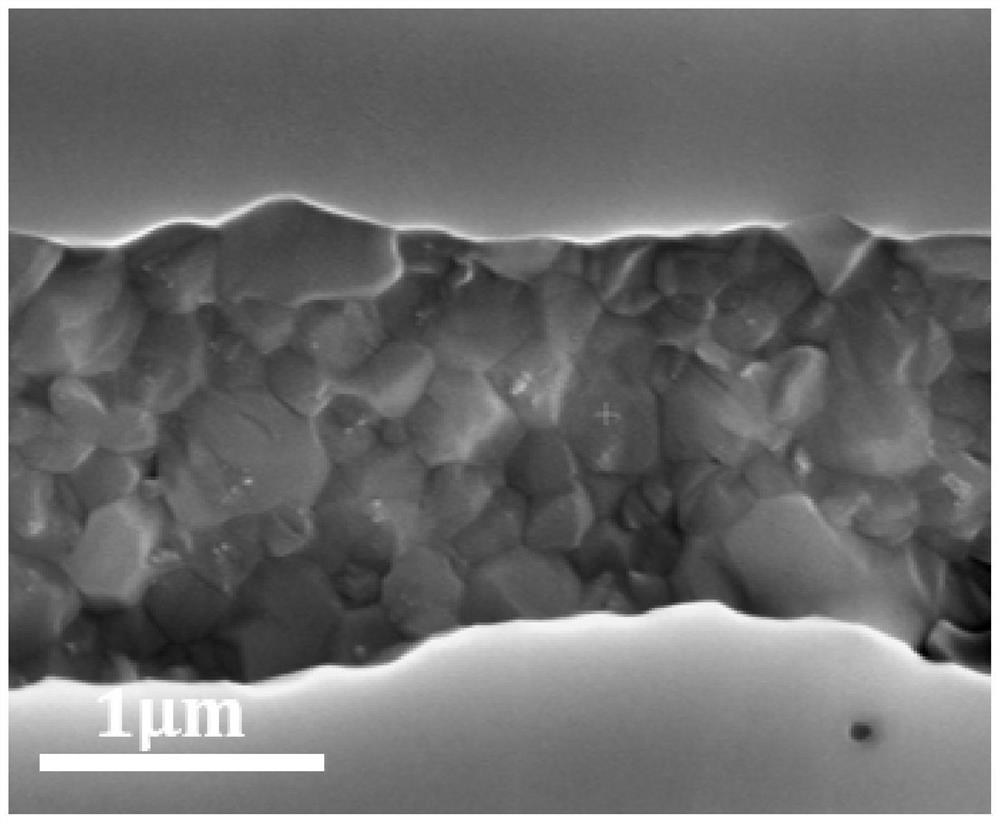

Embodiment 1

[0053] In this embodiment, the host material BaTiO 3 The particle size of the powder is 180 nm, and Table 1 is the formula table of each component in Example 1.

[0054] The formula table of table 1 embodiment 1

[0055]

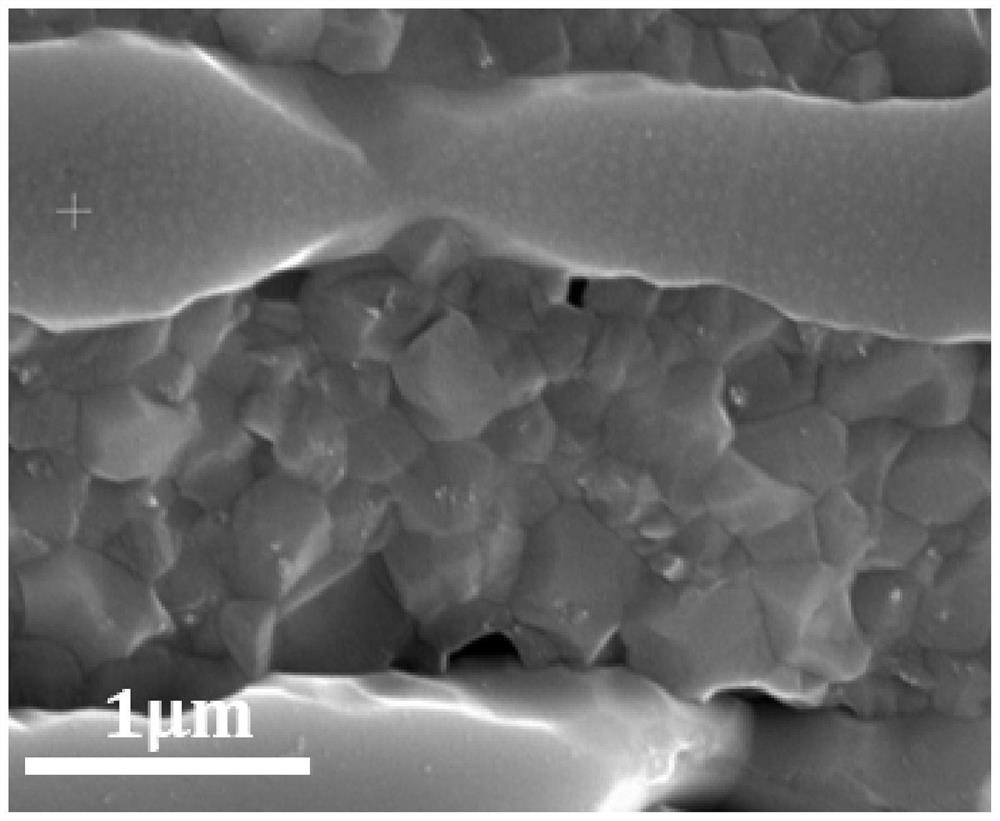

Embodiment 2

[0057] In this embodiment, the host material BaTiO 3 The particle size of the powder is 240 nm, and Table 2 is the formula table of each component in Example 2.

[0058] The formula table of table 2 embodiment 2

[0059]

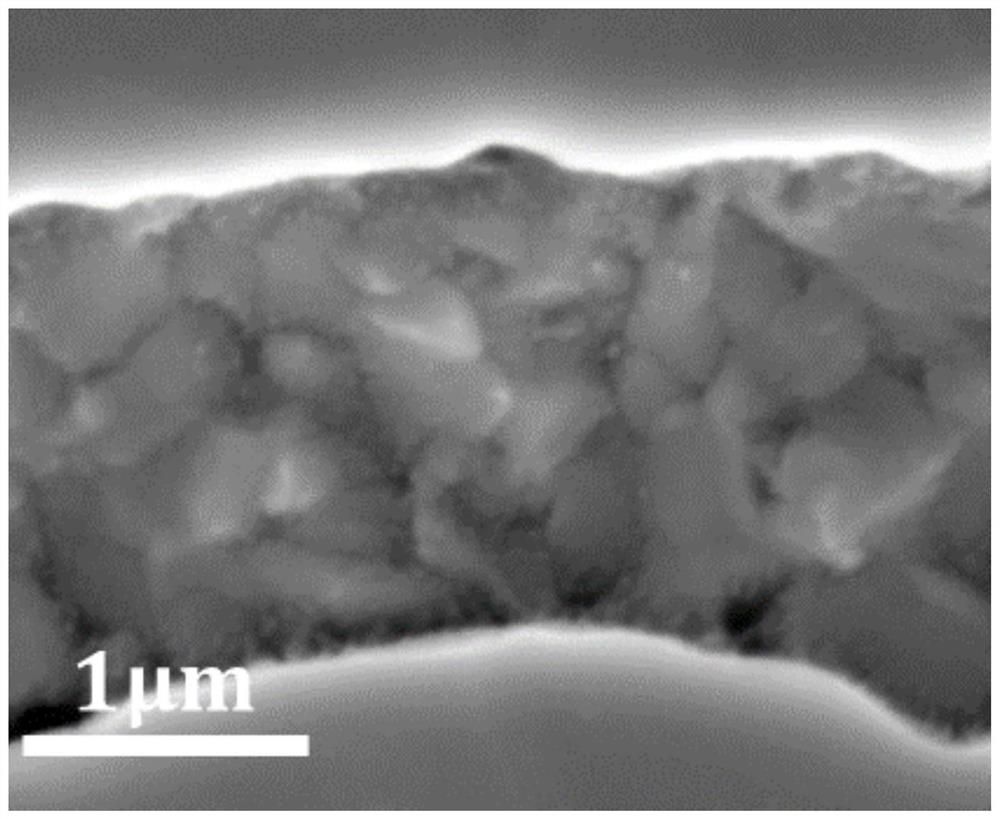

Embodiment 3

[0061] In this embodiment, the host material BaTiO 3 The particle size of the powder is 240 nm, and Table 3 is the formula table of each component of Example 3.

[0062] The formula table of table 3 embodiment 3

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com