Barium titanate ceramic dielectric material and capacitor prepared using barium titanate ceramic dielectric material

A technology of ceramic dielectric and barium titanate, which is applied in the direction of laminated capacitors, fixed capacitor dielectrics, fixed capacitor parts, etc., can solve the problem of high-efficiency automation in the production and assembly of light and small modules, and the large volume of wafer ceramic high-voltage capacitors , not suitable for high-voltage circuit applications, etc., to achieve the effect of good molding process, uniform material, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

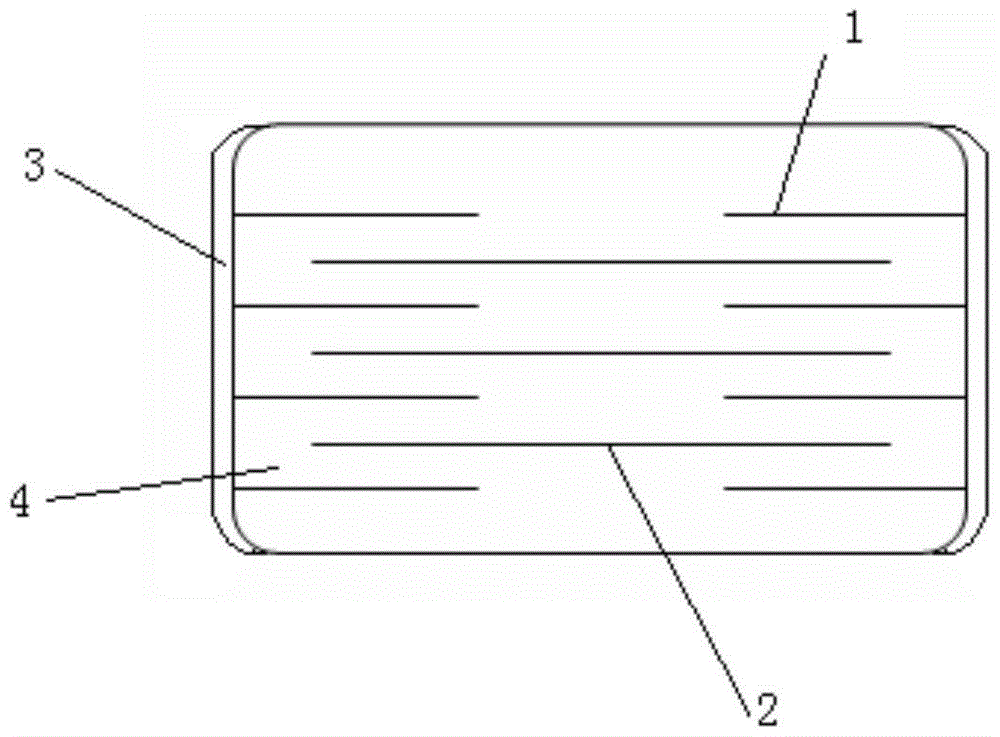

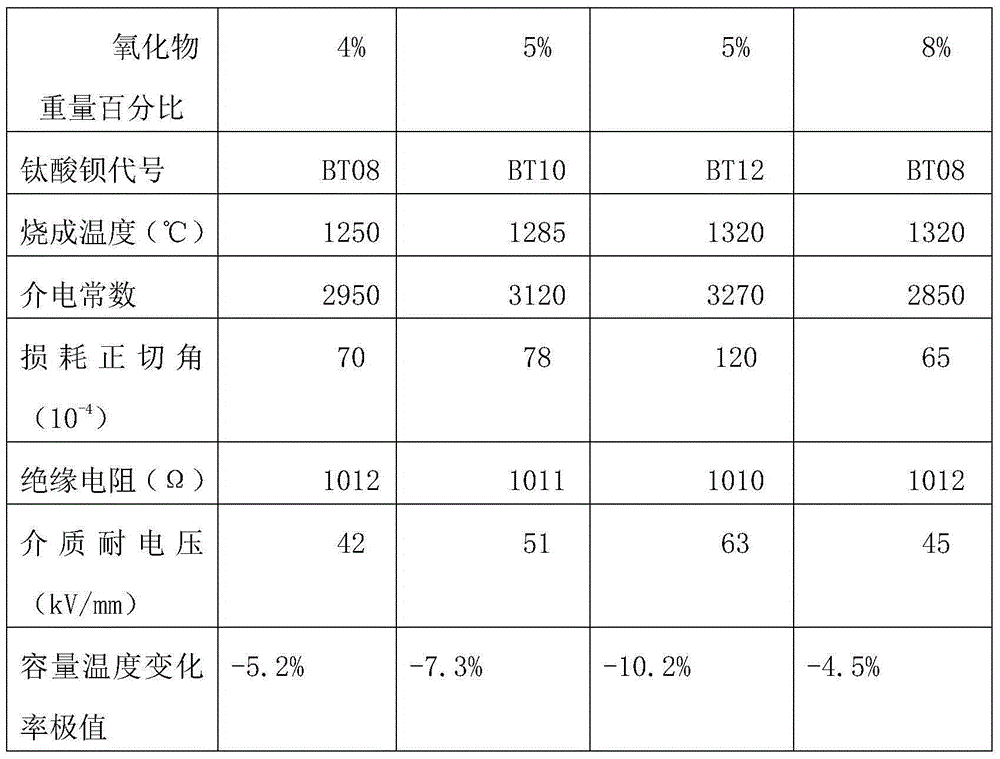

[0013] A barium titanate ceramic dielectric material is prepared by the following method steps: calcining according to the method step conditions in Table 1, and then doping according to the method step conditions in Table 2 to obtain an anti-reduction barium titanate ceramic dielectric material; When these barium titanate ceramic dielectric materials are used to make MLCC products by conventional process methods, the firing temperature is shown in Table 2. The obtained MLCC products such as figure 1 As shown, the two ends are terminal electrodes, and the inner electrode is composed of alternately superimposed electric field shielding electrodes 1 and suspended inner electrodes 2. There is also a dielectric layer between the electrodes. This MLCC product has good dielectric withstand voltage, stable capacity, and good performance. The characteristics of the high-voltage MLCC product performance test parameters are shown in Table 2. The fabricated capacitor structure is as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com