Barium hafnium titanate leadless piezoelectric ceramic with high piezoelectric coefficient and preparation method of leadless piezoelectric ceramic

A barium titanium hafnium oxide and lead-free piezoelectric technology, applied in the field of piezoelectric ceramics, can solve the problems of difficult industrialized production, serious environmental pollution, and performance that has not been reported in literature, and achieves the effects of saving production costs and a simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

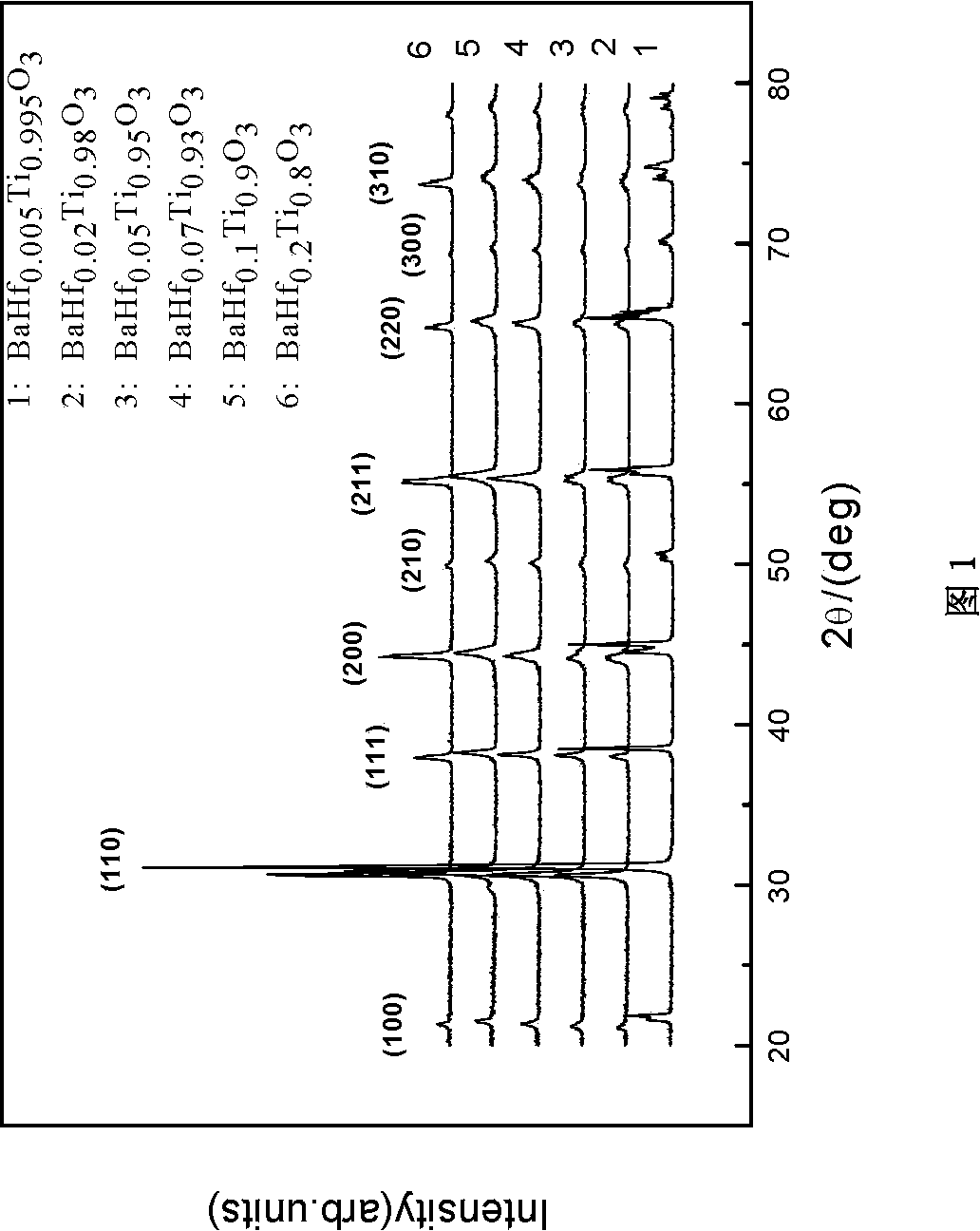

[0023] Example 1, the high piezoelectric coefficient barium hafnate titanium lead-free piezoelectric ceramics are obtained according to the following preparation method: the first step, the BaCO 3、 TiO 2 and HfO 2 According to the ratio of the amount of substance 1: (1-x): x mixed into the mixed material, where x=0.005 or x=0.02 or x=0.05 or x=0.07 or x=0.1 or x=0.2; the second step, Put the mixed material and deionized water into the ball mill and mill for 15 h to 18 h to obtain a slurry. The amount of deionized water added is 1 to 1.5 times the volume of the mixed material, and then the slurry is placed at a temperature of 80 ° C to After drying at 100°C for 3 hours to 5 hours, keep the temperature in a high-temperature resistance furnace at 1100°C for 2 hours to 4 hours to obtain powder; the third step is to mix polyvinyl alcohol with a mass percentage concentration of 2.5% per 4 grams of powder The solution is 0.3ml to 0.4ml, and polyvinyl alcohol solution ...

Embodiment 2

[0024] Example 2, the high piezoelectric coefficient barium hafnate titanium lead-free piezoelectric ceramics are obtained according to the following preparation method: in the first step, BaCO 3、 TiO 2 and HfO 2 According to the ratio of the amount of substance 1: (1-x): x mixed into the mixed material, where x=0.005 or x=0.02 or x=0.05 or x=0.07 or x=0.1 or x=0.2; the second step, Add the mixed material and deionized water into the ball mill and mill for 15 h or 18 h to obtain a slurry. The amount of deionized water added is 1 or 1.5 times the volume of the mixed material, and then the slurry is placed at a temperature of 80 ° C or After drying at 100°C for 3 hours or 5 hours, keep the temperature in a high-temperature resistance furnace at 1100°C for 2 hours or 4 hours to obtain powder; in the third step, mix polyvinyl alcohol with a mass percentage concentration of 2.5% per 4 grams of powder The solution is 0.3 ml or 0.4 ml, and polyvinyl alcohol solution i...

Embodiment 3

[0025] Example 3, as an optimization of the above example, in the second step of Example 3, the temperature rise rate of the high temperature resistance furnace is 2°C / min to 4°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com