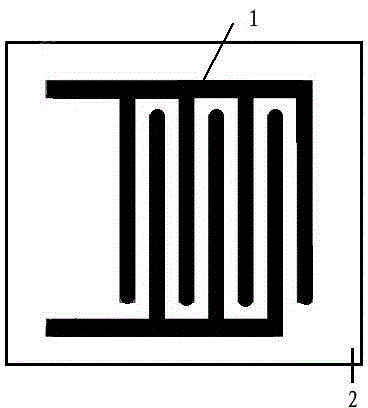

Surface acoustic wave (SAW) transducer

A surface acoustic wave and transducer technology, applied to electrical components, impedance networks, etc., can solve problems such as unstable performance, atomic migration, and high finger-breaking rate of electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

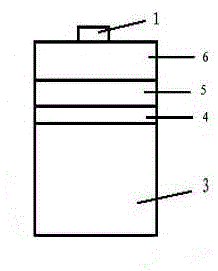

[0025] A surface acoustic wave (SAW) transducer, as shown in the figure, first prepares a diamond film 3 on a silicon substrate by microwave plasma CVD method, and the thickness of the diamond film is 20 μm. The grains are required to be fine, uniform, and dense; the volume ratio of argon, hydrogen, and methane in the CVD method is about 15:4:1, and the flow rate is 600 sccm.

[0026] To polish the surface of the diamond film 3, rough polishing is first performed with diamond micropowder, and then the surface is finely repaired with silicon dioxide as an abrasive, so that the surface roughness of the diamond film 3 is less than 3nm.

[0027] In a high-vacuum sputtering chamber, an Al target is used as a target material to perform high-vacuum magnetron sputtering on the surface of the diamond film 3 to deposit a thin layer of ALN film 4 with a film thickness of 0.3 μm. N high vacuum magnetron sputtering 2 The :Ar volume ratio flow ratio is 9:13, the flow rate is 20 sccm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com