Bismuth ferrite-barium titanate binary high-temperature piezoelectric ceramic material as well as preparation method and application thereof

A high-temperature piezoelectric and ceramic material technology, applied in the field of high-temperature piezoelectric materials, can solve problems such as low piezoelectric performance, large dielectric loss, and limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing a bismuth ferrite-barium titanate binary high-temperature piezoelectric ceramic material, comprising the following steps:

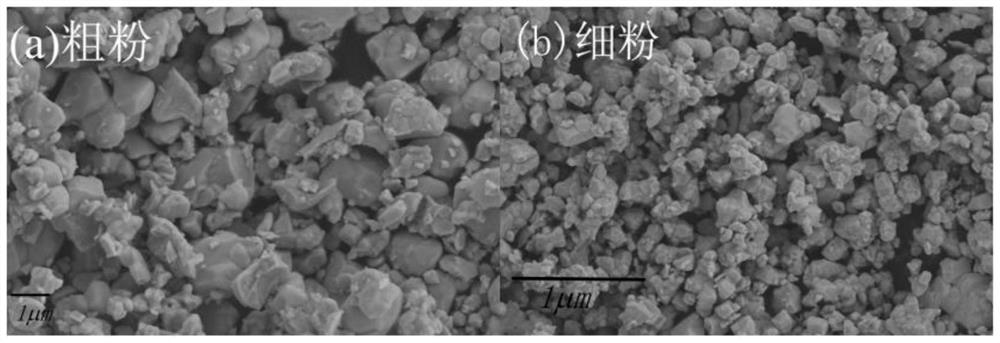

[0023] Mix the bismuth ferrite-barium titanate powder with the first ball milling medium, and perform the first ball milling to obtain bismuth ferrite-barium titanate coarse powder, the particle size of the bismuth ferrite-barium titanate coarse powder is 800nm~ 1.5μm;

[0024] Mix the bismuth ferrite-barium titanate powder with the second ball milling medium, and perform the second ball milling to obtain bismuth ferrite-barium titanate fine powder, the particle size of the bismuth ferrite-barium titanate fine powder is 100~ 800nm;

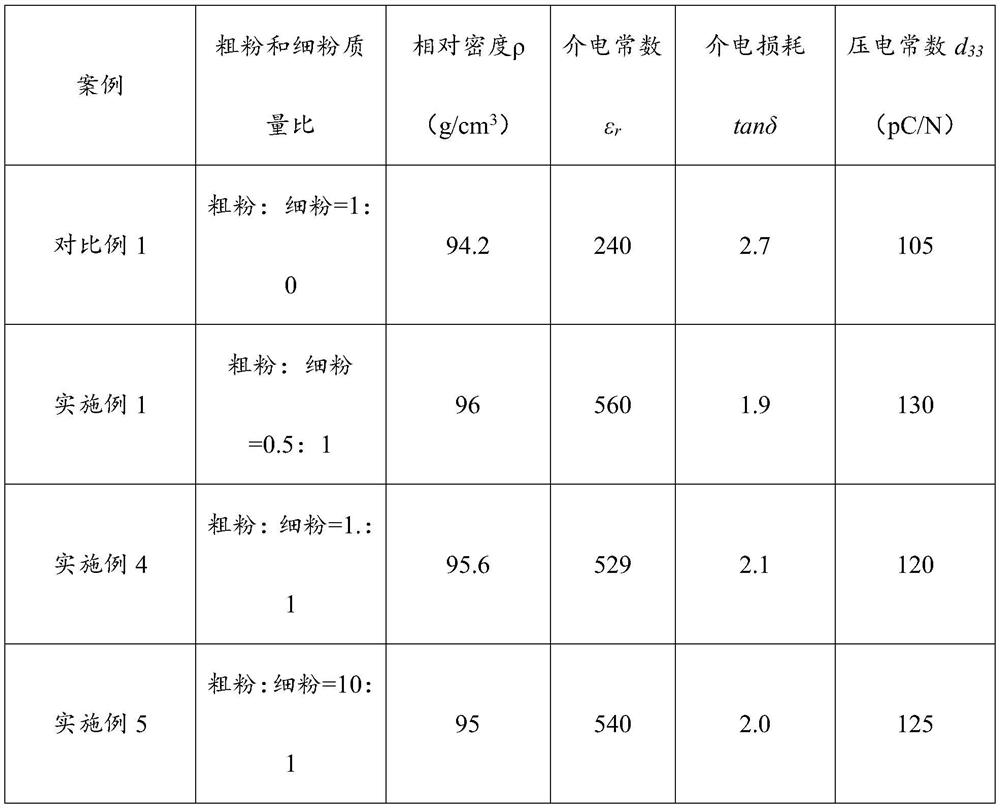

[0025] Mixing the bismuth ferrite-barium titanate coarse powder and bismuth ferrite-barium titanate fine powder to obtain a mixed powder; mixing the mixed powder with a binder, followed by granulation and isostatic pressing , debinding and sintering to obtain bismuth ferr...

Embodiment 1

[0055] According to chemical composition (1-x)BiFeO 3 -xBaTiO 3 , x=0.25, the analytically pure Bi 2 o 3 , Fe 2 o 3 、TiO 2 、BaCO 3 and MnO 2 According to the required stoichiometric ratio, 30 g of the above-mentioned raw materials were weighed and put into a ball mill jar. Under the condition of the ball milling speed of 250 r / min, 30 mL of deionized water and 90 g of zirconia balls with a diameter of 5 mm were added for ball milling for 6 hours. The final slurry was poured into a ceramic bowl for drying, passed through a 120-mesh screen, put it into a crucible, raised the temperature to 750 °C at a heating rate of 5 °C / min, and calcined for 4 hours. The obtained material was passed through a 120-mesh screen, and the obtained The material repeats the above steps to perform ball milling, calcination and ball milling in turn to obtain 0.75BiFeO 3 -0.25BaTiO 3 Synthetic powder;

[0056] Add 15mL of absolute ethanol, 15g of the 0.75BiFeO 3 -0.25BaTiO 3 The synthetic po...

Embodiment 2

[0061] The difference from Example 1 is only: x=0.30, and the others are the same as Example 1, which is recorded as 0.70BF-0.30BT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com