Preparation method of BaTiO3 ceramic sheet

A technology for ceramic sheets and grinding sheets is applied in the field of preparation of electronic components, which can solve the problems of high power attenuation, poor temperature coefficient and pressure stability of devices, and achieve the effects of high heating efficiency, low temperature coefficient and improved convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

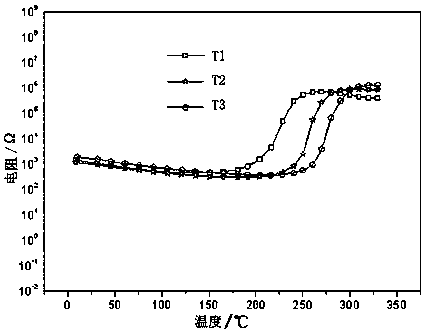

Image

Examples

Embodiment 1

[0034] (1) BaCO 3 , CaCO 3 、TiO 2 The first wet ball milling with PbO is evenly mixed, and the slurry is obtained by plate pressure filtration. The slurry is placed in an oven at 110-120°C for the first drying to form the first drying material, and the first drying material is in an oven at 1000-1100°C Medium heat preservation for 2 to 3 hours and pre-sintering to form a pre-synthesized material;

[0035] (2) Add graphene, Y 2 o 3 , Nb 2 o 5 and sintering agent, carry out the second wet ball milling, and after stirring and plate pressure filtration, carry out the second drying in an oven at 110-120°C to form the secondary drying material, and add equivalent The granulated material is obtained by granulating 0.1mol / L polyvinyl alcohol aqueous solution binder with 2 to 7% of the mass of the secondary drying material. The granulated material is selected from the blank screened by a 60-mesh screen, and then formed, Fired, lapped, and coated with electrodes.

[0036] Among ...

Embodiment 2

[0051] (1) BaCO 3 , CaCO 3 、TiO 2 The first wet ball milling with PbO is evenly mixed, and the slurry is obtained by plate pressure filtration. The slurry is placed in an oven at 110-120°C for the first drying to form the first drying material, and the first drying material is in an oven at 1000-1100°C Medium heat preservation for 2 to 3 hours and pre-sintering to form a pre-synthesized material;

[0052] (2) Add graphene, Y 2 o 3 , Nb 2 o 5 and sintering agent, carry out the second wet ball milling, and after stirring and plate pressure filtration, carry out the second drying in an oven at 110-120°C to form the secondary drying material, and add equivalent The granulated material is obtained by granulating 2-7% of the 0.5mol / L polyvinyl alcohol aqueous solution binder of the mass of the secondary drying material. The granulated material is selected from the blank screened by a 60-mesh screen, and then formed, Fired, lapped, and coated with electrodes.

[0053] Among t...

Embodiment 3

[0068] (1) BaCO 3 , CaCO 3 、TiO 2 The first wet ball milling with PbO is evenly mixed, and the slurry is obtained by plate pressure filtration. The slurry is placed in an oven at 110-120°C for the first drying to form the first drying material, and the first drying material is in an oven at 1000-1100°C Medium heat preservation for 2 to 3 hours and pre-sintering to form a pre-synthesized material;

[0069] (2) Add graphene, Y 2 o 3 , Nb 2 o 5 and sintering agent, carry out the second wet ball milling, and after stirring and plate pressure filtration, carry out the second drying in an oven at 110-120°C to form the secondary drying material, and add equivalent The granulated material is obtained by granulating 2-7% of the 1mol / L polyvinyl alcohol aqueous solution binder of the mass of the secondary drying material. The granulated material is selected from the blank screened by a 60-mesh screen, and then formed and fired. into, through the grinding process, and then coated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com