Nanocrystalline barium titanate ceramic and preparation method thereof

A technology of crystalline barium titanate and ceramics, which is applied in the field of nanocrystalline barium titanate ceramics and its preparation, can solve the problems of poor performance and wide particle size distribution, and achieve the effects of uniform distribution, uniform components and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

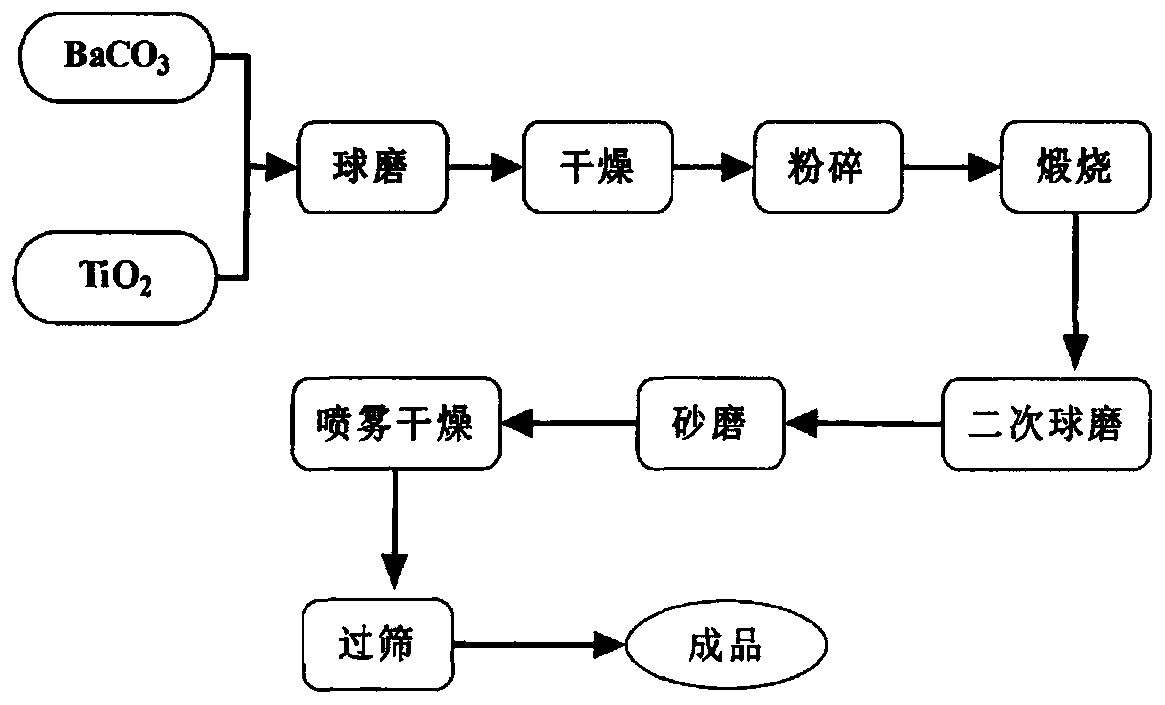

[0059] The embodiment of the present invention provides a preparation method of nanocrystalline barium titanate ceramics, comprising the following steps:

[0060] S1, mixing barium carbonate and titanium dioxide by ball milling to obtain slurry A;

[0061] S2. Slurry A is sanded to obtain slurry B;

[0062] S3. The slurry B is dried, sieved, and calcined to obtain nanocrystalline barium titanate ceramics.

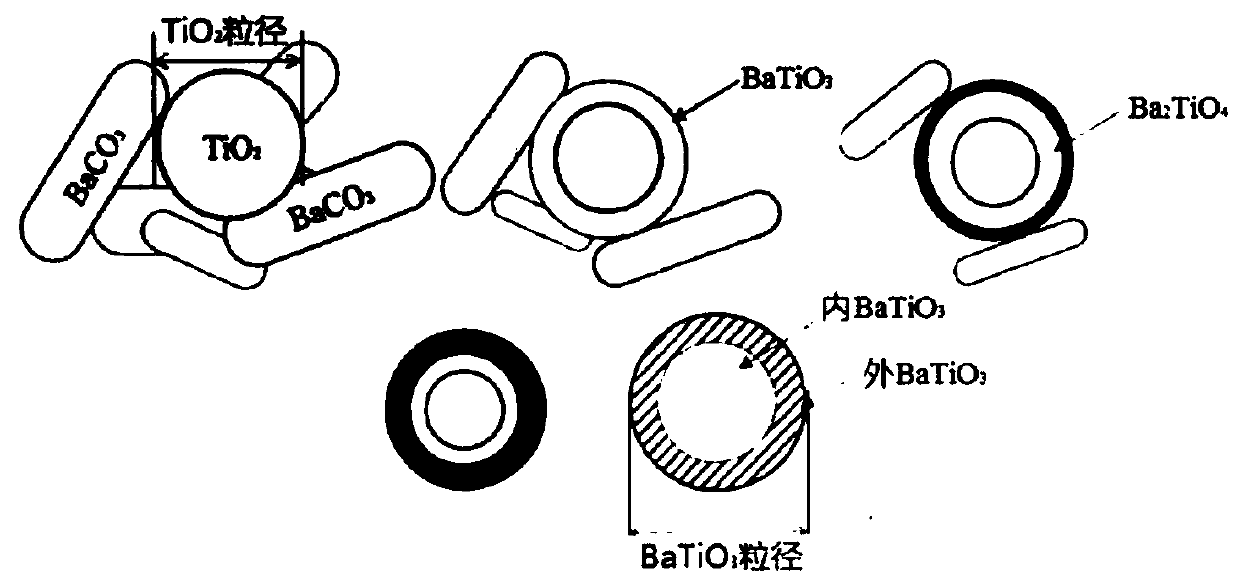

[0063] In order to obtain nanocrystalline barium titanate ceramics with no agglomeration, uniform components and high purity, the present invention increases its sintering activity by first mixing barium carbonate and titanium dioxide with ball milling, and then increases the sintering activity on the basis of the traditional solid-phase synthesis method. The sanding step of the raw material powder is to obtain powder particles with uniform size and good mixing degree, and then calcined to obtain nanocrystalline barium titanate nano-ceramics with small particle size, unifo...

Embodiment 1

[0086] A preparation method of nanocrystalline barium titanate ceramics, comprising the steps of:

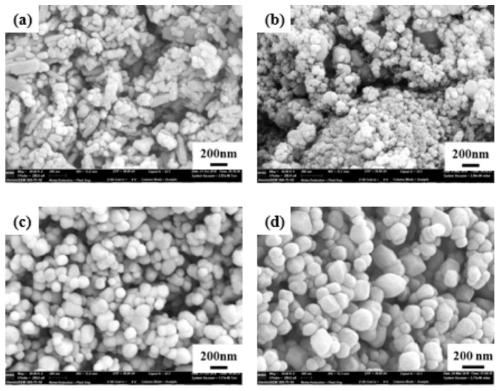

[0087] (1) KS BaCO 3 (BET is 12m 2 / g) and TA60 TiO 2 (D 50 60nm, BET 83.8m 2 / g, the manufacturer is Aladdin) puts into the nylon ball mill jar after weighing according to the ratio of Ba / Ti of 1, adds the zirconium beads that diameter is 5mm as the ball mill material, wherein, material: ball: water=1:2.5: 2.5; add 1% triethanolamine, which is the sum of the mass of barium carbonate and titanium dioxide, as a dispersant, and perform ball milling for 4 hours, and set the rotation speed at 280rpm to obtain slurry A;

[0088] (2) Slurry A is poured into a horizontal sand mill for sand milling, using zirconium beads with a diameter of 0.1mm as the ball milling material, adding 2% triethanolamine of the sum of barium carbonate and titanium dioxide mass as a dispersant for sand milling 2h, the speed of the sand mill is set to 2800rpm, the pump speed is set to 100L / h, and the slu...

Embodiment 2

[0091] This embodiment is basically the same as Embodiment 1, except that the sintering temperature is 1000°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com