Barium titanate/polyvinylidene fluoride composite dielectric film and preparation method thereof

A technology of composite dielectric film and polyvinylidene fluoride, which is applied in the field of barium titanate/polyvinylidene fluoride composite dielectric film and its preparation, can solve rare and other problems, achieve smooth surface, improve film-forming performance, and film layer uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

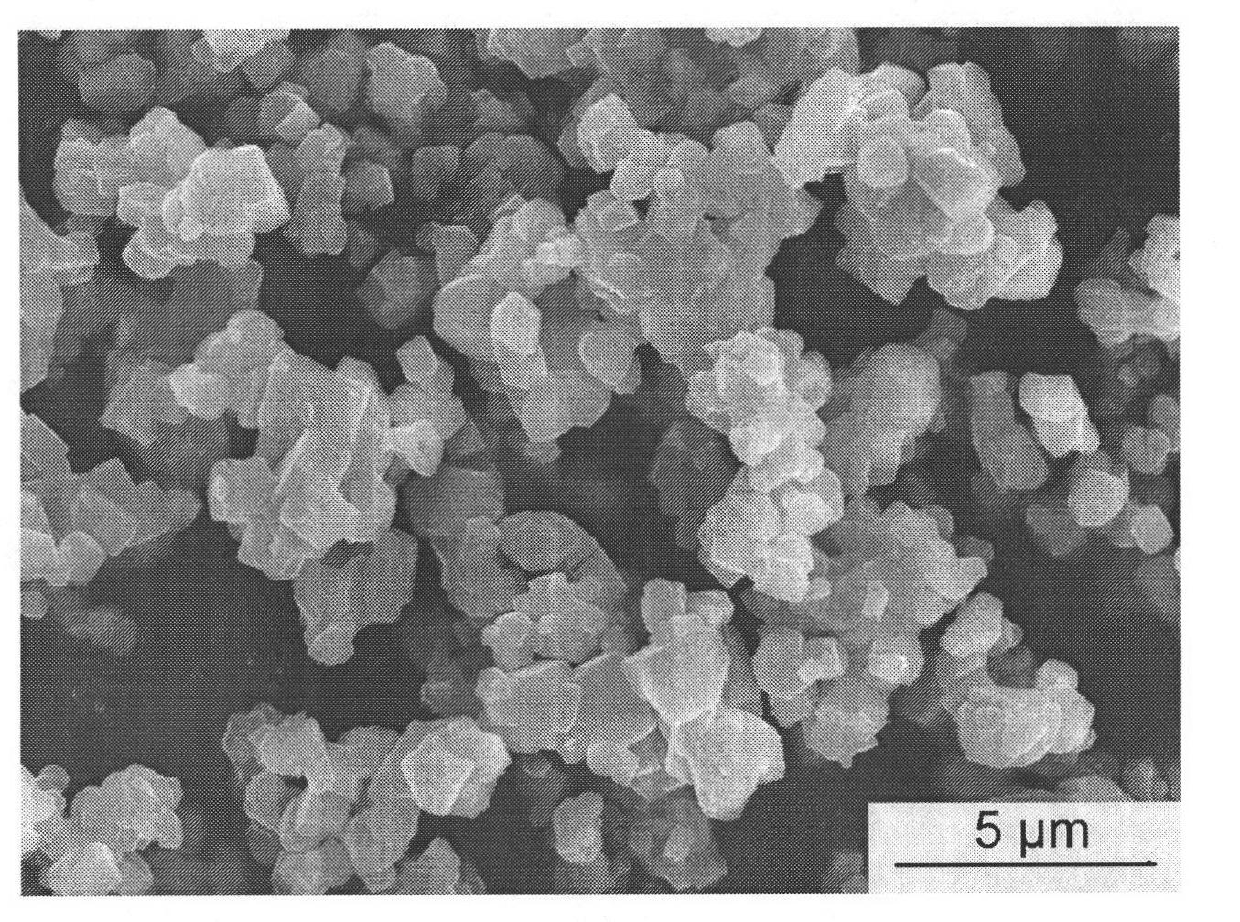

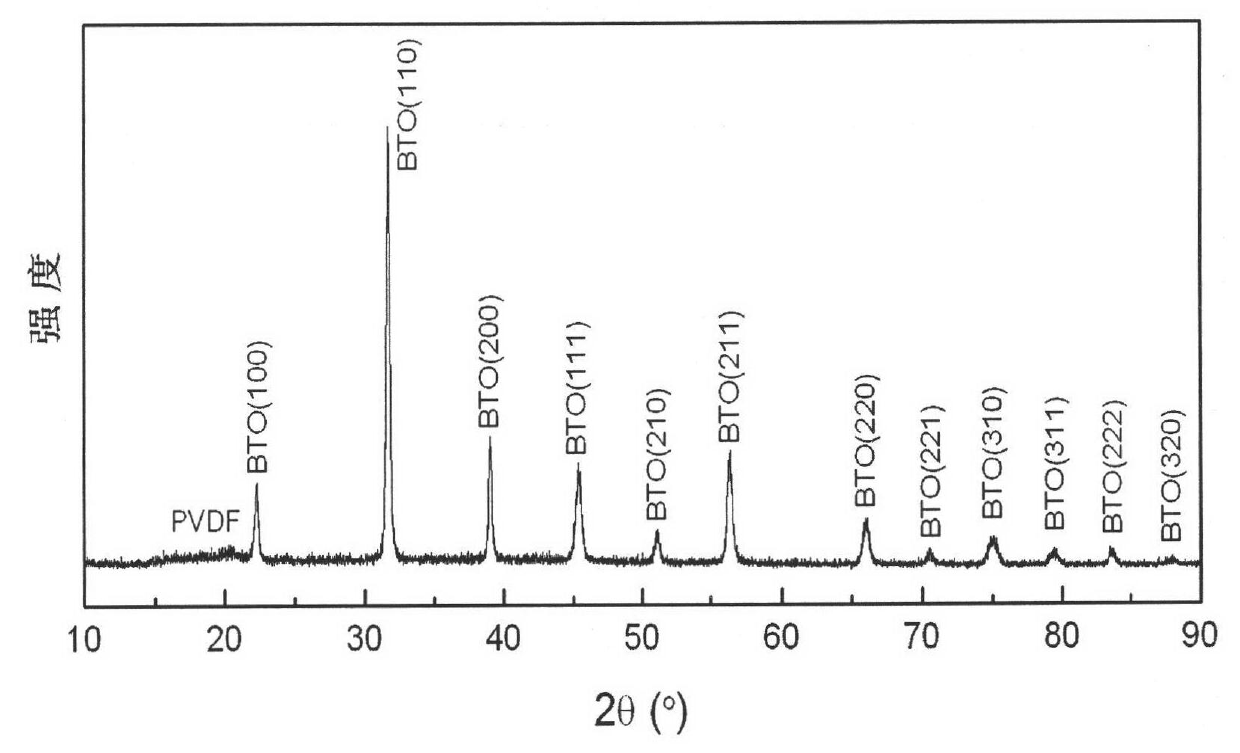

[0037] By BaTiO 3 Stoichiometric Dosage Ratio Weighing BaCO 3 and TiO 2 , put into the agate mixing tank, add agate balls and alcohol, the volume ratio of agate balls, alcohol and powder is 6:2:1, mix on a planetary ball mill or a three-roll mixer for 24h; in an oven at 100 After drying at ℃~120℃, calcining in air at 1100℃ for 4h to obtain BaTiO 3 Ceramic powder; the SEM photo of the powder is as follows figure 1 As shown, the particle size distribution of the powder is uniform, and the average particle size is less than 500nm.

[0038] Measure a certain amount of NMP with a graduated cylinder and add PAA with a dropper, mix well, wherein the volume fraction of PAA is 3%. Add PVDF powder to the mixed solvent of NMP and PAA at a mass percentage concentration of 25%, stir well and place it in an oven, and heat at 80°C for 1 hour to fully dissolve the PVDF polymer powder. Configure to obtain PVDF solution.

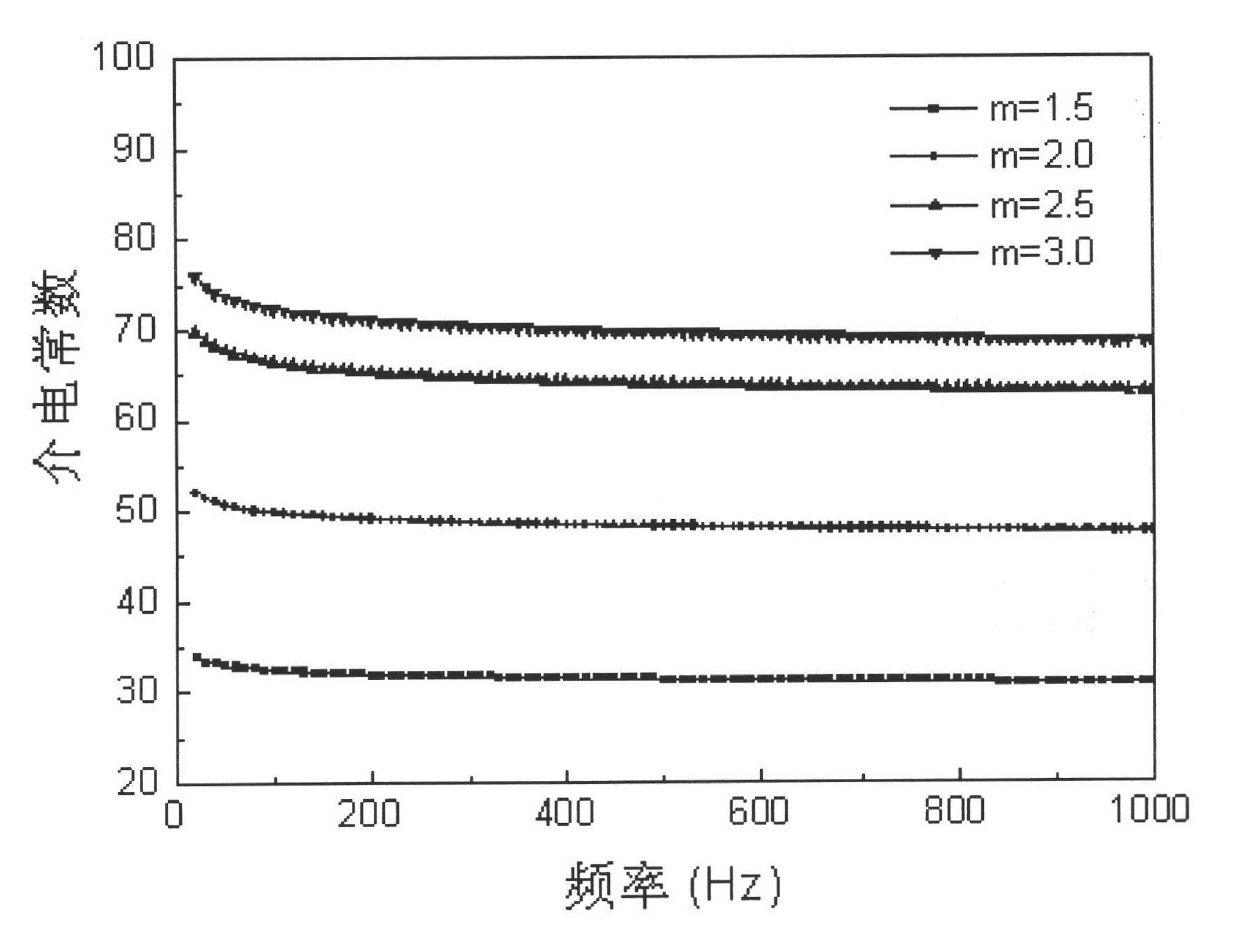

[0039] By BaTiO 3 The mass ratio of BaTiO to PVDF is m: 1 3 The ...

Embodiment 2

[0045] Using BaTiO purchased from the market 3 Ceramic powder (the average particle size of the powder is less than 500nm, the SEM photo is as follows Figure 6 Shown) is raw material, and the mass ratio that adopts and embodiment 1 to prepare BTO and PVDF is the BTO / PVDF colloid of m=3.0 and m=4.0, and carry out thin film spinning on the homogenizer, then thin film is placed in ion Soak in water for 20s, extract the NMP / PAA composite liquid solvent in the film colloid to obtain a gel-state BTO / PVDF composite film, and finally dry it in an oven at a temperature of 80°C to finally obtain a BTO / PVDF composite dielectric film. The throwing process parameters of the film are shown in Table 2.

[0046] Table 2

[0047]

[0048] The same method as in Example 1 was used to test the dielectric constant and dielectric loss of the film in the frequency range of 20 Hz to 1 MHz. Test results such as Figure 7 and Figure 8 shown. The test results show that in the frequency range...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com