Barium titanate-based high-energy-storage-density electronic ceramic and preparation method thereof

A high energy storage density, electronic ceramic technology, applied in the field of electronic components, can solve the problems of large electrostrictive effect of antiferroelectric materials, narrow sintering window, low energy storage efficiency, etc., and achieve chemical uniformity and electrical uniformity. High, high energy storage density and efficiency, the effect of energy storage performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention relates to a preparation method of barium titanate-based electronic ceramics with high energy storage density. Taking barium titanate ceramics as the object, the composition is designed according to electric domain engineering, and the barium titanate-based electronic energy storage ceramics is prepared by a solid phase method. . The prepared sample has high energy storage density and efficiency, and good temperature stability. Described method specifically comprises the following steps:

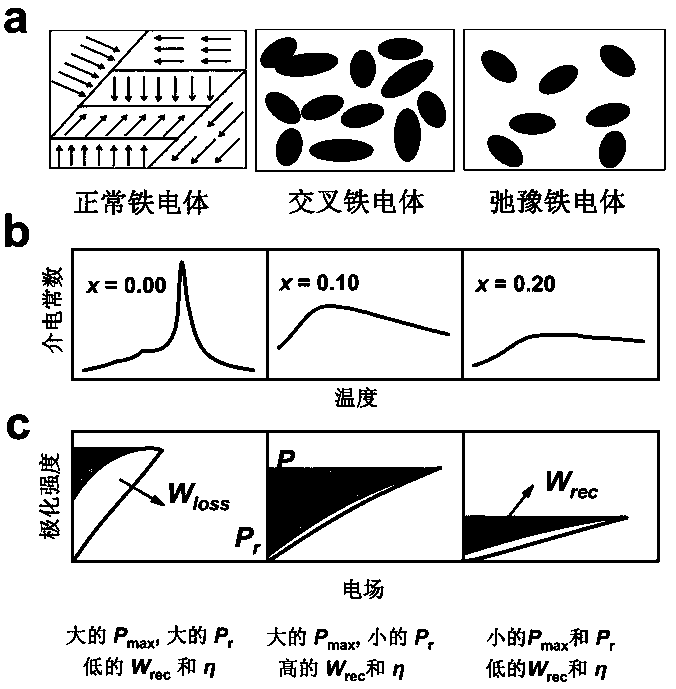

[0033] Step 1: Put Sr 2 +, Bi 3+ ,Mg 2+ ,Nb 5+ Ion doping into barium titanate ceramics to form (1-x)Ba (1-y) Sr y TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )0 3 chemical composition, so that it is in the intersection region;

[0034] Step 2: Calculate the chemical ratio of the formula components obtained in Step 1, and weigh the high-purity BaCO 3 , SrCO 3 、 Bi 2 o 3 , MgO, TiO 2 and Nb 2 o 5 The powder is dried by ball milling, pre-sintered, pressed into tablets, and ...

Embodiment 1

[0052] Change the chemical composition to Ba 0.65 Sr 0.35 TiO 3 -0.10Bi(Mg 2 / 3 Nb 1 / 3 )O 3 According to the formula, the raw materials are weighed according to the chemical ratio, after ball milling for 24 hours, dried and pressed into tablets, the pressed columnar block is placed in a sintering furnace for sintering, pre-sintered at 1100°C for 2 hours, and cooled naturally; the pre-sintered ceramic powder After the second ball milling into powder, it is pressed into tablets, and the pressed disc is sintered in a sintering furnace, held at 600°C for two hours to remove the glue, and then the heating rate is 3°C / min, raised to 1320°C for 5 hours, Sintering is complete. Then cool naturally to room temperature to obtain barium titanate-based energy storage ceramics.

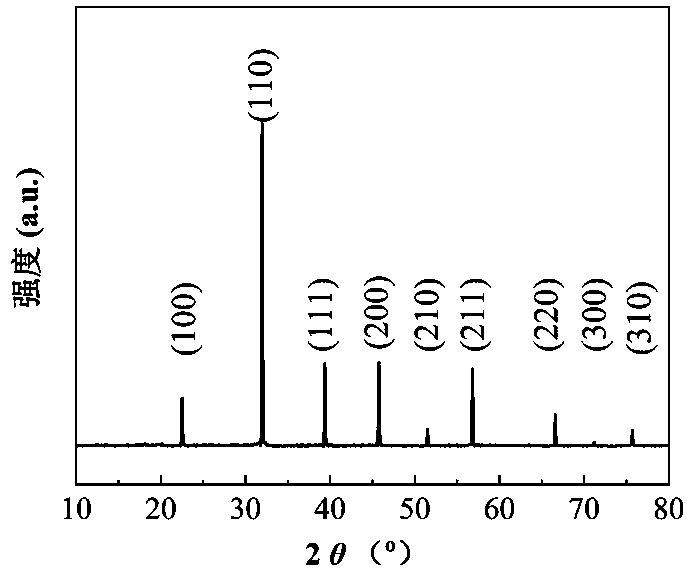

[0053] X-ray diffractometer (RINT 2000, Rigaku) was used to detect the phase composition of the sample during pre-calcination, as figure 2 As shown, it is a typical pseudo-cubic structure without diffracti...

Embodiment 2

[0055] Change the chemical composition to Ba 0.65 Sr 0.35 TiO 3 According to the formula, the raw materials are weighed according to the chemical ratio, after ball milling for 24 hours, dried and pressed into tablets, the pressed columnar block is placed in a sintering furnace for sintering, pre-sintered at 1050°C for 2 hours, and cooled naturally; the pre-sintered ceramic powder After secondary ball milling into powder, press into tablets, place the pressed discs in a sintering furnace for sintering, hold at 600°C for 2 hours to remove glue, then heat up at a rate of 3°C / min, raise to 1280°C for 5 hours, and sintering is complete . Then cool naturally to room temperature to obtain barium titanate-based energy storage ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Breakdown electric field strength | aaaaa | aaaaa |

| Energy storage efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com