Ceramic ultrafine powder tape casting ultrathin dielectric paste and ceramic film formed by ceramic ultrafine powder tape casting ultrathin dielectric paste

A technology of ultra-fine powder and dielectric slurry, which is applied in the fields of fixed capacitor dielectric, fixed capacitor parts, and capacitor manufacturing. , to achieve the effect of good peeling degree, smooth surface and stable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

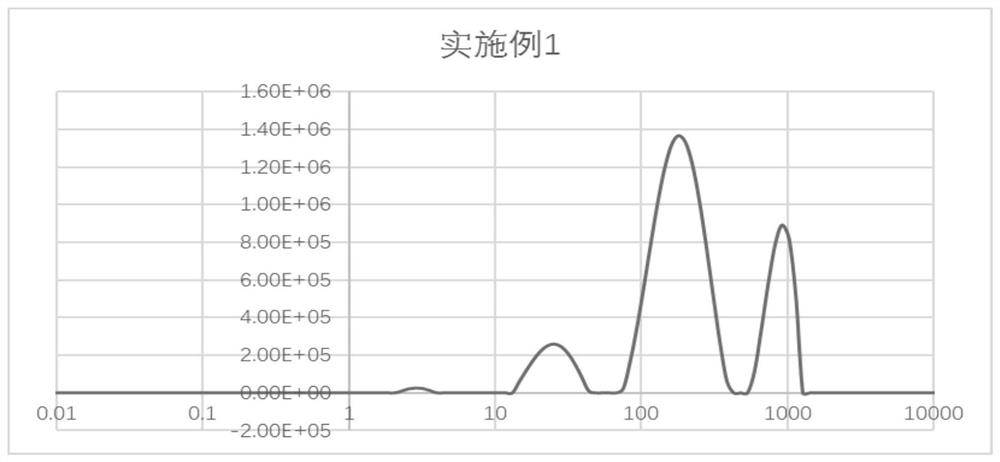

Embodiment 1

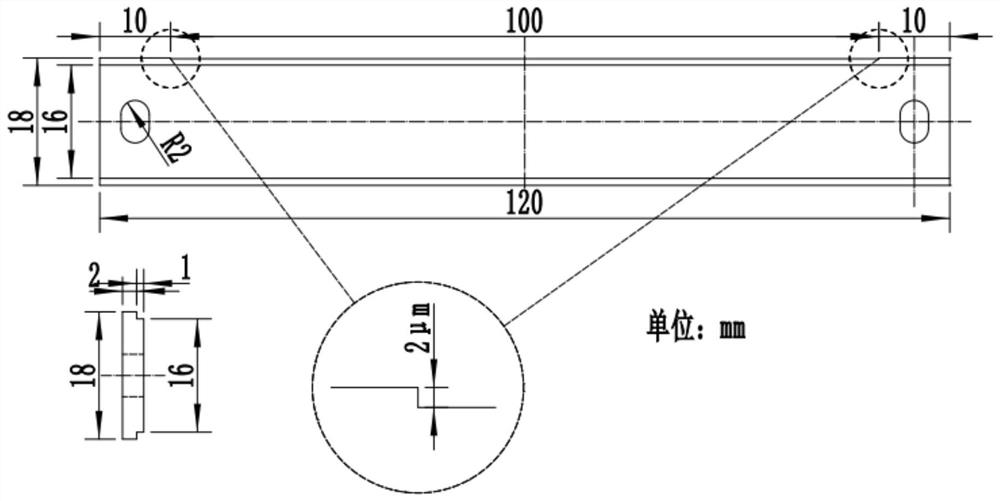

[0046] The ceramic ultrafine powder casting ultra-thin medium slurry described in this embodiment, based on 100 parts of the total weight of the slurry, includes the following components:

[0047]

[0048]

[0049] The preparation method of ceramic ultrafine powder casting ultrathin medium slurry described in this embodiment includes the following steps:

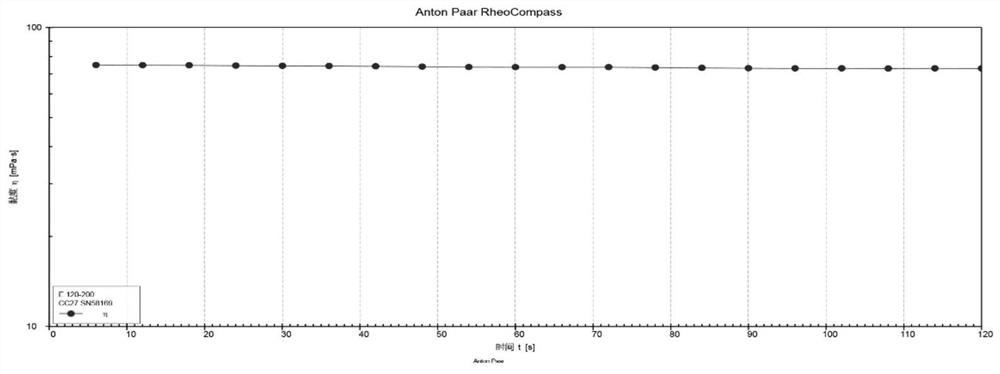

[0050] (1) Take the above-mentioned selected amount of porcelain powder, ethanol, ethyl acetate, oleic acid, and dispersant (AKM-0531) to mix, put the mixed slurry into a 10L nylon tank for tank grinding, nylon tank Put 3mm zirconia balls in advance, the volume filling rate of zirconia balls reaches 45%, the pot milling speed is 60Hz, and the pot milling time is 6H;

[0051] (2) Continue to add the selected plasticizer (DOP), defoamer (DC-350CS), binder (BH-3 and BM-2) to the above slurry, and disperse the mixed slurry in this step for 6 hours After sealing the tank body, continue to put the nylon tank on the tank mil...

Embodiment 2-11

[0066] The slurry system of the following examples 2-11 of the present invention is the same as that of example 1, the only difference is that the added content of each functional auxiliary agent is slightly different, and the specific auxiliary agent added amount is shown in the following table 1 respectively. The preparation process of the slurry is the same as in Example 1.

[0067] Table 1 embodiment 2-11 slurry (based on slurry 100g total amount)

[0068]

[0069]

experiment example

[0077] According to the test method of the obtained slurry and the obtained membrane performance (based on the same casting method) in the foregoing embodiment 1, the obtained slurry in the above-mentioned examples 2-11 and comparative examples 1-3 and based on the slurry flow The performance of the stretched diaphragm is detected, the test method and equipment are the same as in Example 1, and the test results are shown in Table 2 below.

[0078] Table 2 performance test results of slurry and diaphragm

[0079]

[0080]

[0081] Visible, the present invention is based on the slurry that barium titanate ultrafine powder forms, and its viscosity performance is very stable, has effectively ensured that the casting performance of slurry makes, and, the ceramic diaphragm obtained through scraper casting process, not only can A thin film with a thickness of less than 2 μm is obtained, and the thickness uniformity and quality of the diaphragm are good, which can meet the perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com