Samarium-doped bismuth ferrite-barium titanate ceramic film as well as preparation method and application thereof

A technology of ceramic film and bismuth ferrite, applied in the field of dielectric materials, to achieve the effects of high breakdown field strength, excellent energy storage performance, and high energy storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned a kind of samarium-doped bismuth ferrite-barium titanate ceramic thin film that the present invention proposes, described method specifically comprises the following steps:

[0030] Step 1): The raw materials are mixed and batched, ball milled, dried and sieved to obtain the raw material powder;

[0031] In this step, the Bi 2 o 3 , Fe 2 o 3 、BaCO 3 、TiO 2 and Sm 2 o 3The raw materials are mixed and proportioned according to the selected stoichiometric ratio, the raw materials are mixed with the organic solvent, and ball milling, drying and sieving are performed successively to obtain uniformly mixed raw material powders; according to the embodiments of the present invention, the chemical composition of the raw materials Composition is not particularly limited, and those skilled in the art can select according to actual needs, and according to a specific embodiment of the present invention, the composition of raw mate...

Embodiment 1

[0052] Raw material Bi 2 o 3 , Fe 2 o 3 、BaCO 3 、TiO 2 and Sm 2 o 3 Press x(Bi 1-y SM y )FeO 3 -(1-x)(Ba 1-y SM y )TiO 3 (x=0.30, y=0.15) carry out batching, wherein Bi 2 o 3Raw material excess 5%. The raw material is ball milled with absolute ethanol for 6 hours, dried and sieved, and the obtained powder is pre-fired at 700 degrees Celsius for 2 hours. After grinding the obtained powder, add polyvinyl alcohol solution with a concentration of 5% (mass percentage) to granulate, press it into a tablet under an 8MPa tablet press, and then use 25MPa cold isostatic pressing for 10 minutes to obtain a diameter of about 1 Inch, about 5mm thick wafer green body. After heat preservation and removal of polyvinyl alcohol, the green wafer was buried and fired at 1050 degrees Celsius for 2 hours to obtain a high-quality samarium-doped bismuth ferrite-barium titanate solid solution ceramic target.

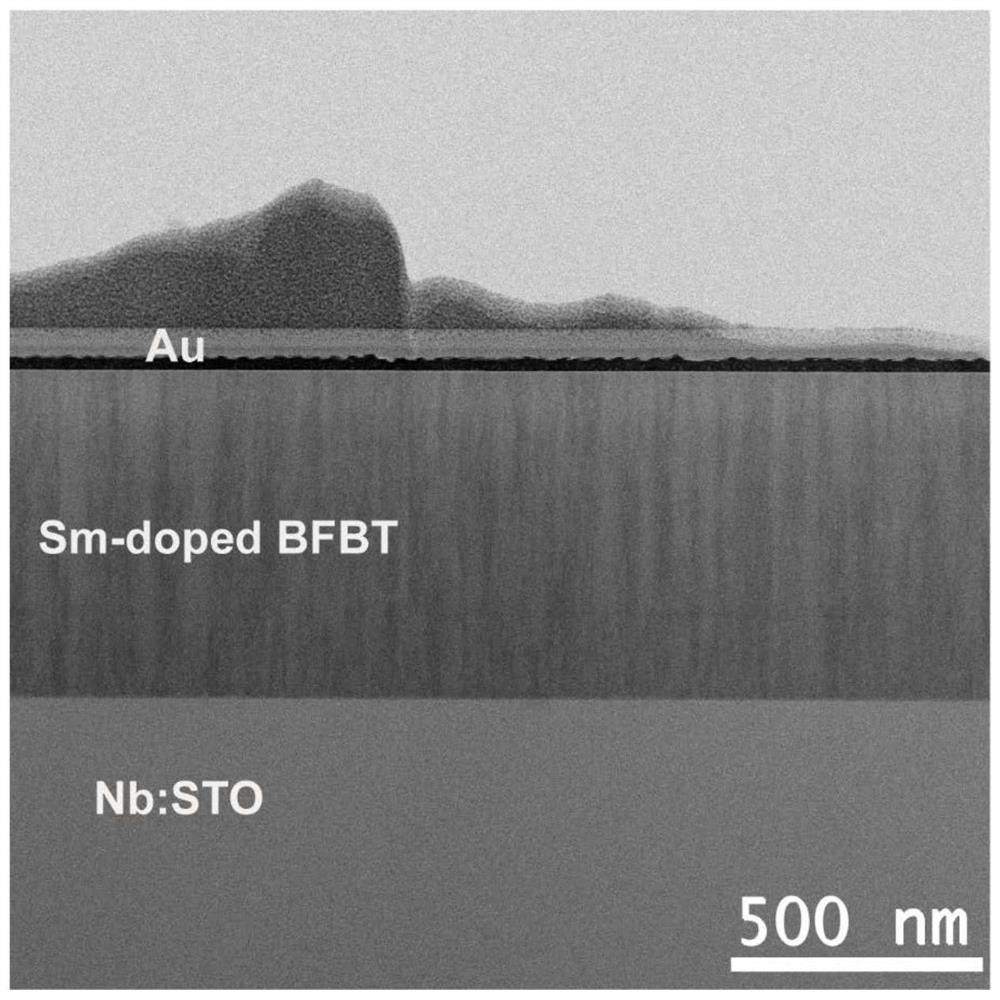

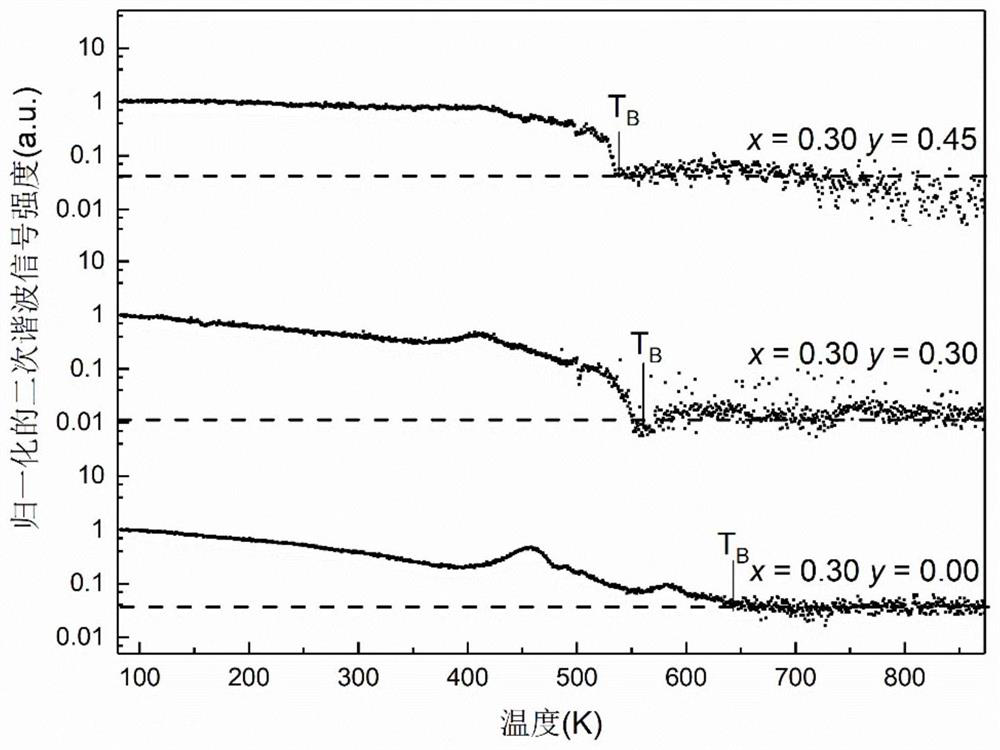

[0053] The solid solution ceramic target is bombarded with a pulsed laser t...

Embodiment 2

[0056] Raw material Bi 2 o 3 , Fe 2 o 3 、BaCO 3 、TiO 2 and Sm 2 o 3 Press x(Bi 1-y SM y )FeO 3 -(1-x)(Ba 1-y SM y )TiO 3 (x=0.30, y=0.30) carry out batching, wherein Bi 2 o 3 Raw material excess 10%. The raw material is ball milled with absolute ethanol for 6 hours, dried and sieved, and the obtained powder is pre-fired at 700 degrees Celsius for 2 hours. After grinding the obtained powder, add polyvinyl alcohol solution of 5% (mass percentage) concentration to granulate, press into tablets under a 6MPa tablet press, and then use 25MPa cold isostatic pressing for 10 minutes to obtain a diameter of about 1 inch, about 7mm thick. After heat preservation and removal of polyvinyl alcohol, the green wafer was buried and fired at 1150 degrees Celsius for 2 hours to obtain a high-quality samarium-doped bismuth ferrite-barium titanate solid solution ceramic target.

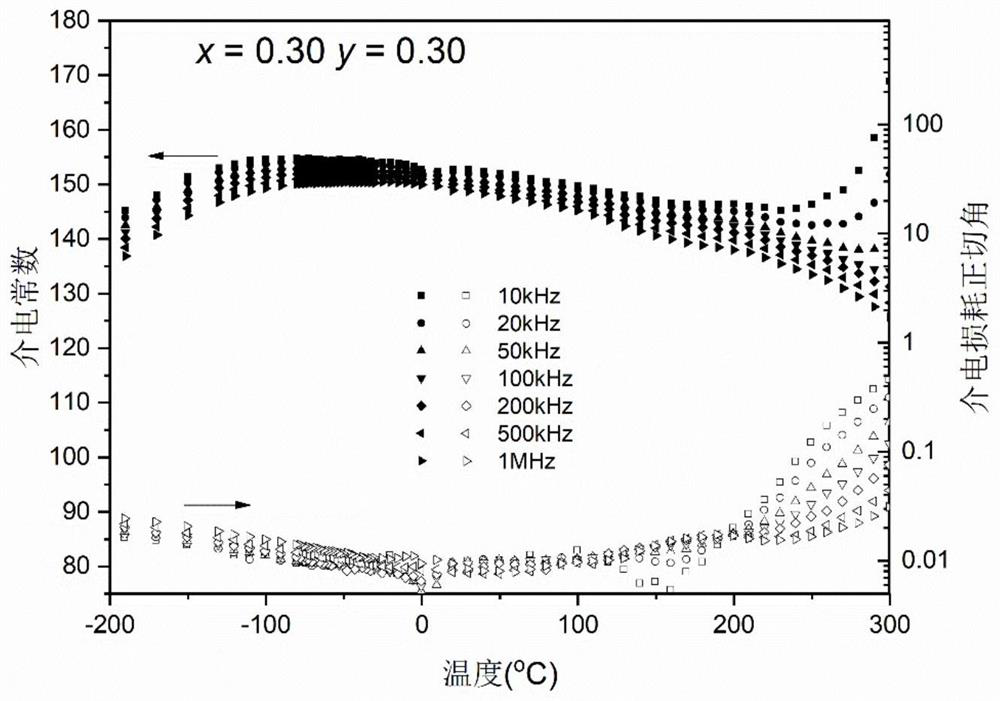

[0057] The solid solution ceramic target is bombarded with a pulsed laser to ablate and vaporize the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com