Lanthanum oxide doped and modified potassium-sodium niobate-based transparent ceramic and preparation method thereof

A potassium-sodium niobate-based, transparent ceramic technology, applied in the field of functional ceramic materials, to achieve the effects of strong practicability, easy production, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

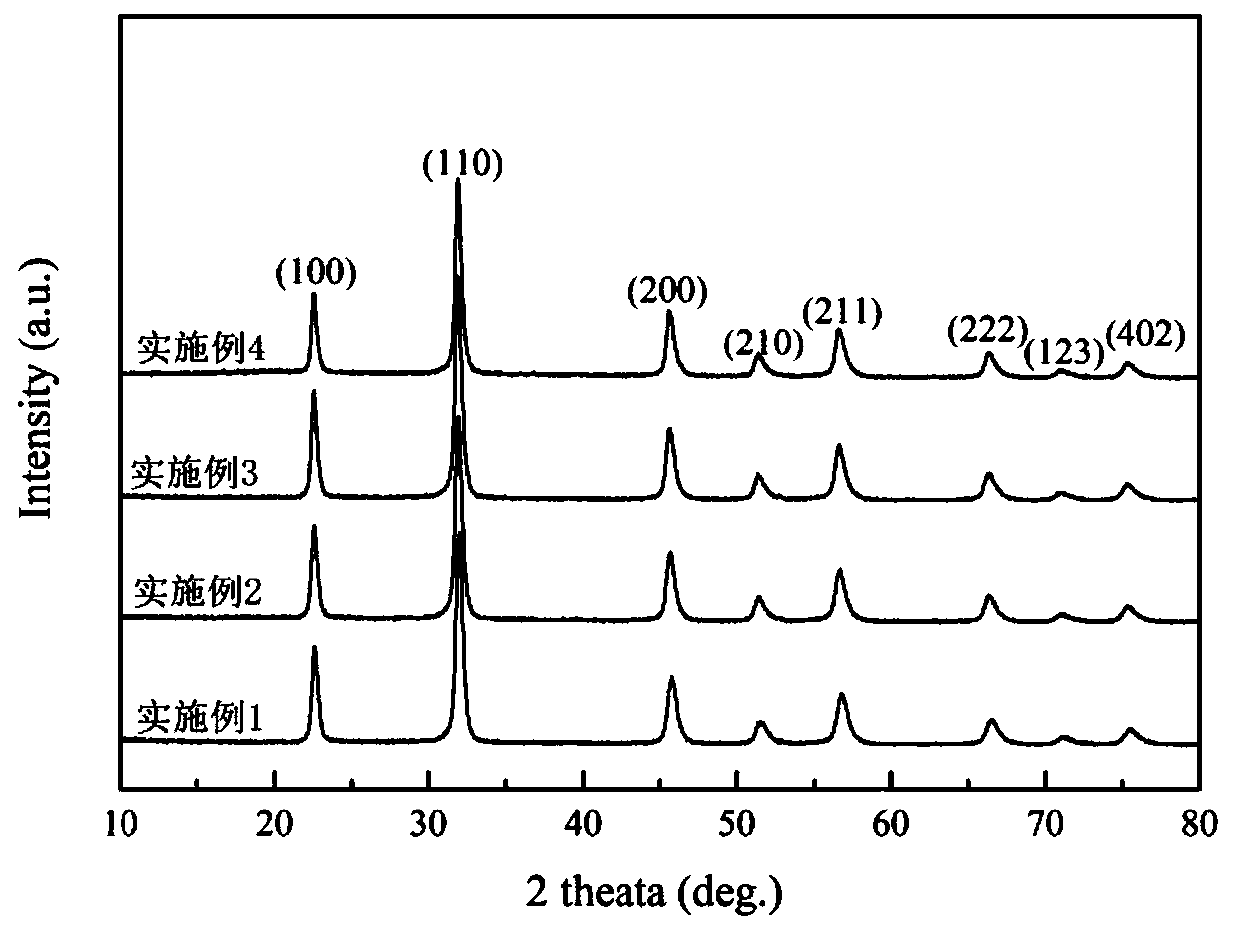

[0034] The chemical formula of the ceramic material in this example is 0.825 (K 0.5 Na 0.5 )NbO 3 -0.175Sr 1-3x / 2 Lax (Sc 0.5 Nb 0.5 )O 3 , where x=0. The steps of its preparation method include:

[0035] (1) Ingredients

[0036] According to 0.825(K 0.5 Na 0.5 )NbO 3 -0.175Sr 1-3x / 2 La x (Sc 0.5 Nb 0.5 )O 3 , the stoichiometric ratio of x=0 weighs the raw material K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 , SrCO 3 、Sc 2 o 3 , La 2 o 3 Mix evenly, put the raw material mixture into a ball mill jar, use zirconium balls as the balls and absolute ethanol as the ball milling medium, fully mix and mill for 18 hours, and the ball milling speed is 350r / min. Dry the raw material mixture at 80°C for 1 to 2 hours, and pass through a 60-mesh sieve to obtain a mixed powder;

[0037] (2) pre-burning

[0038] The raw material mixture passed through a 60-mesh sieve in step (1) was placed in an alumina crucible, compacted with an agate rod, raised to 950°C at a heating rate of...

Embodiment 2

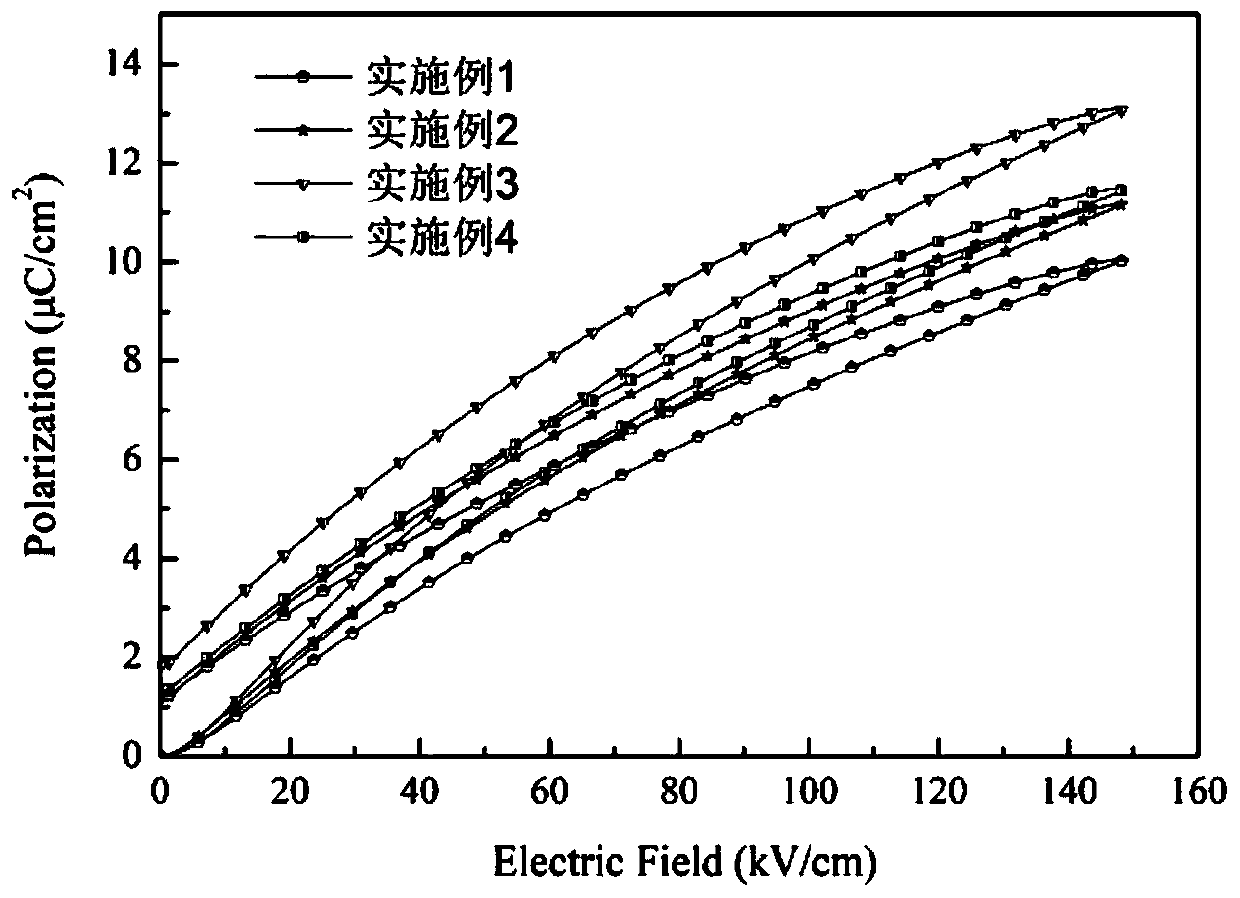

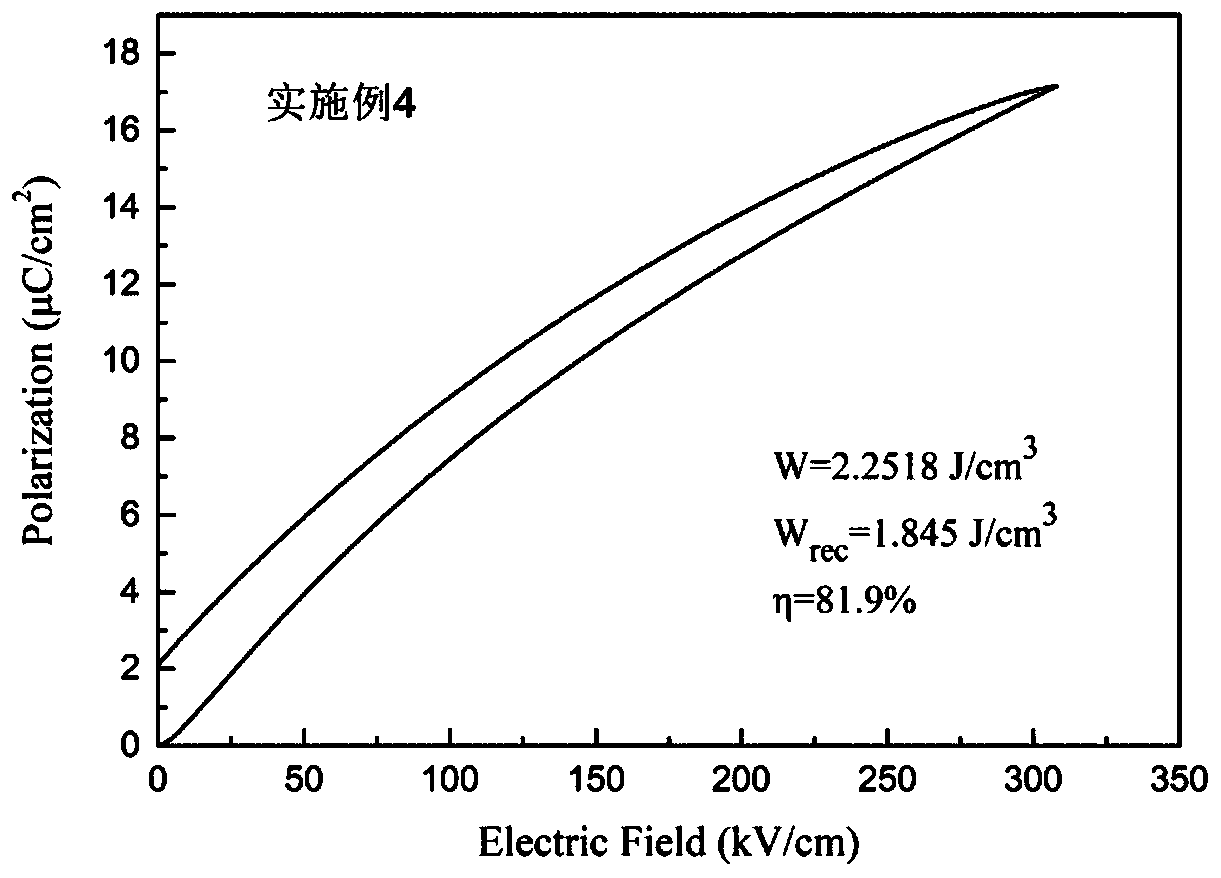

[0051] The chemical formula of the ceramic material in this example is 0.825 (K 0.5 Na 0.5 )NbO 3 -0.175Sr 1-3x / 2 La x (Sc 0.5 Nb 0.5 )O 3 , where x=0.01. Its preparation method repeats the preparation method of Example 1 according to the above formula to obtain the lanthanum oxide-doped potassium sodium niobate-based transparent ceramic material. The unipolar hysteresis loop diagram of the ceramic material of this embodiment measured under the electric field condition of room temperature and 150kV / cm is as follows figure 2 . The dielectric properties of the transparent ceramic material in this embodiment at room temperature are shown in Table 1.

Embodiment 3

[0053] The chemical formula of the ceramic material in this example is 0.825 (K 0.5 Na 0.5 )NbO 3 -0.175Sr 1-3x / 2 La x (Sc 0.5 Nb 0.5 )O 3 , where x=0.02. Its preparation method repeats the preparation method of Example 1 according to the above formula to obtain the lanthanum oxide-doped potassium sodium niobate-based transparent ceramic material. The unipolar hysteresis loop diagram of the ceramic material of this embodiment measured under the electric field condition of room temperature and 150kV / cm is as follows figure 2 . The dielectric properties of the transparent ceramic material in this embodiment at room temperature are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com