Patents

Literature

39results about How to "Smooth fiber surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

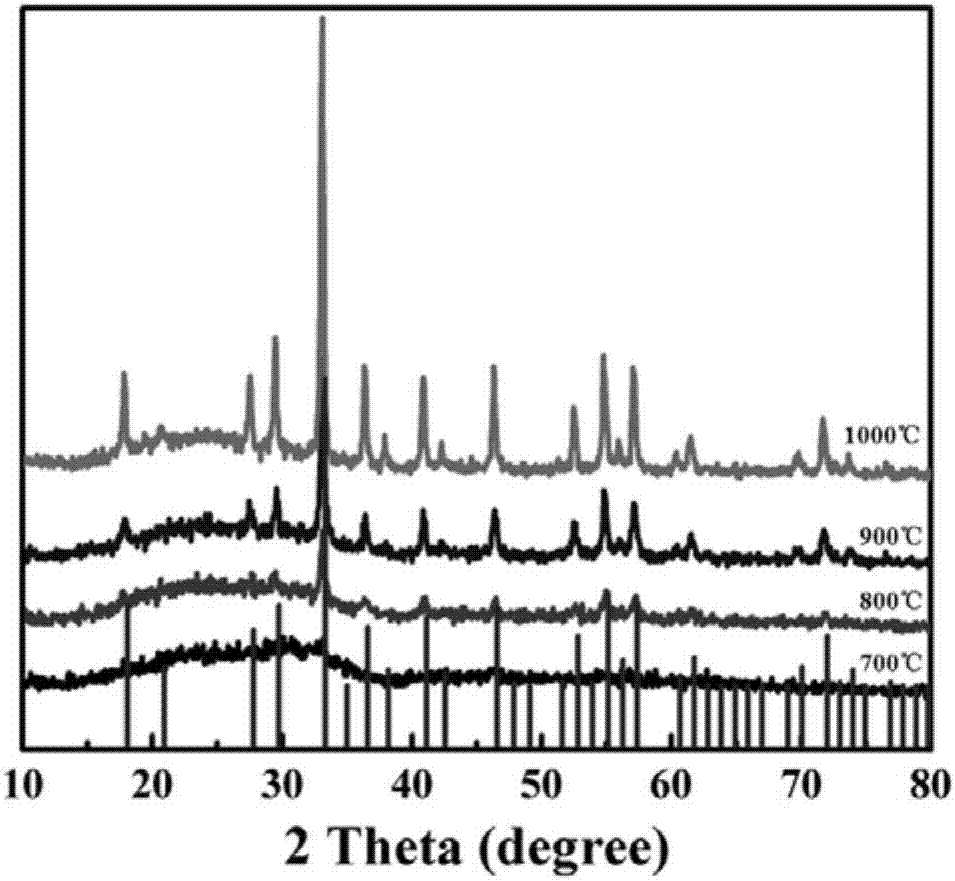

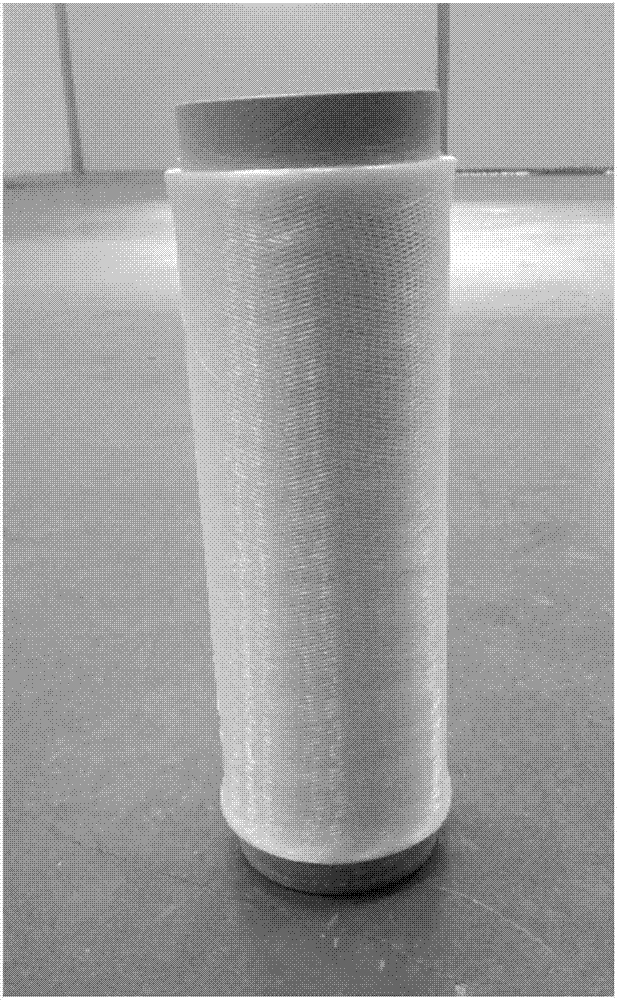

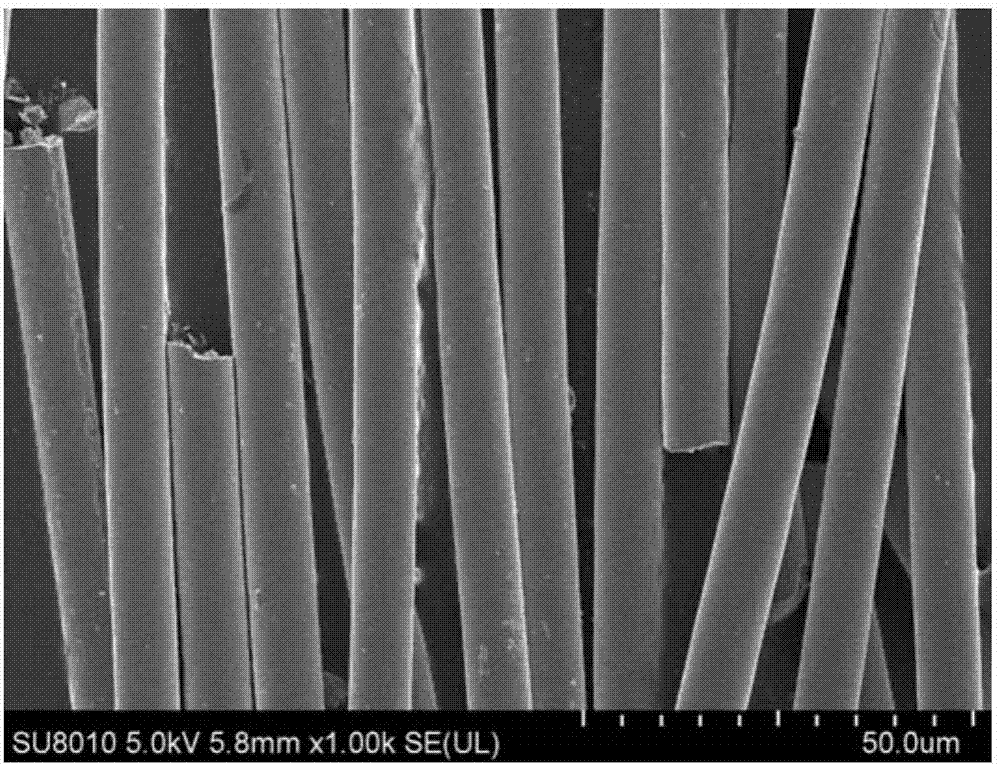

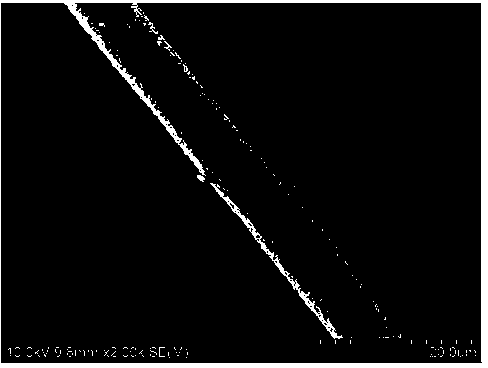

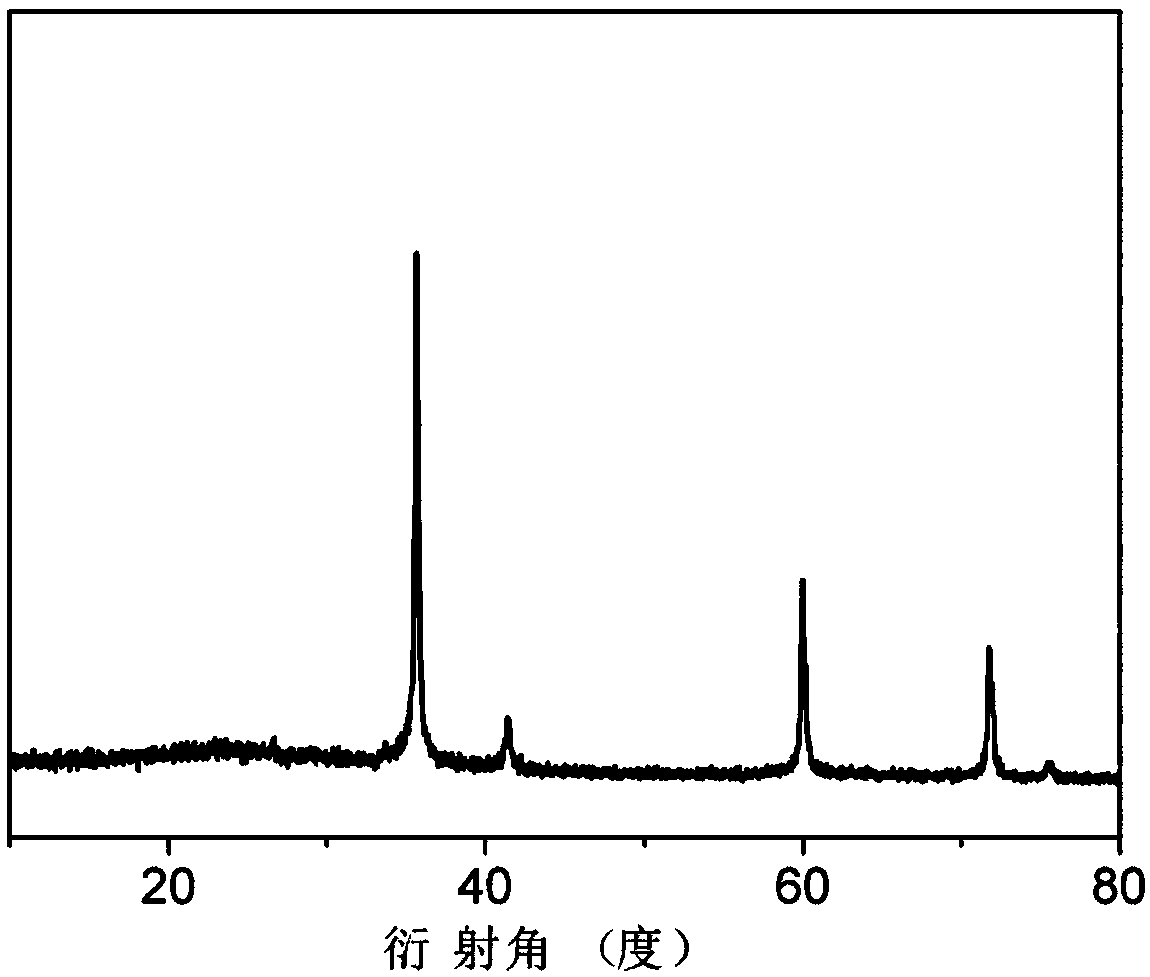

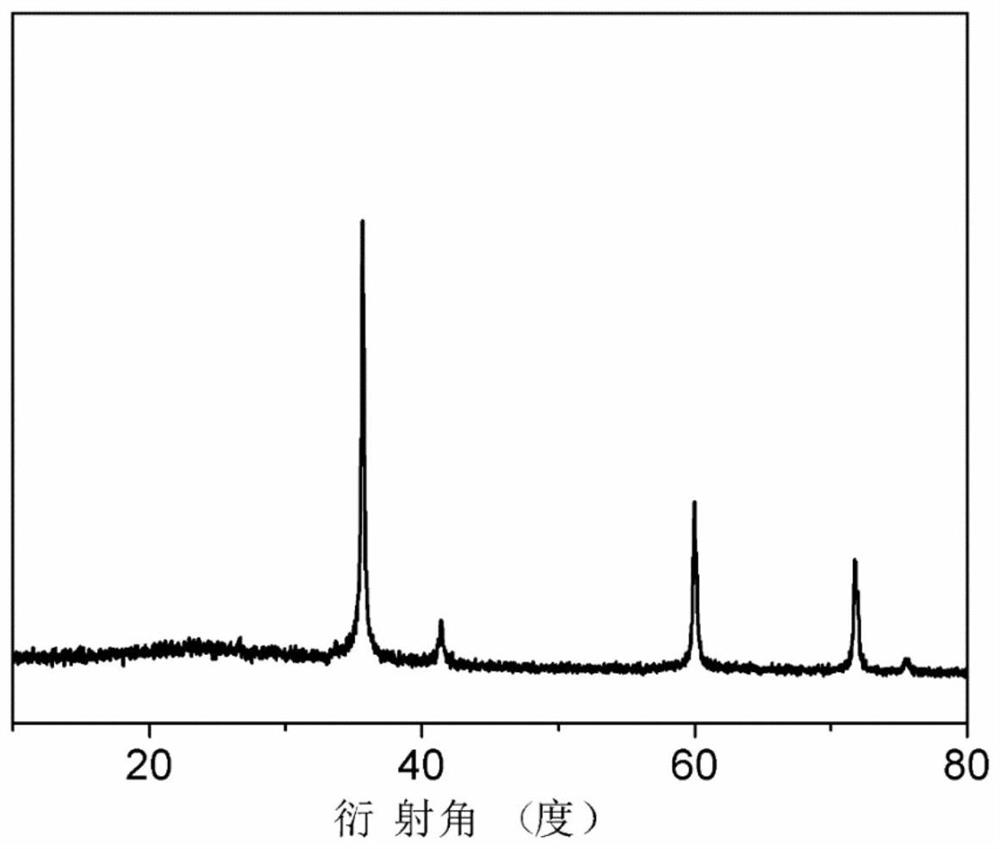

Preparation method of continuous fiber of yttrium aluminum garnet

ActiveCN106927808AGood effectUniform diameterInorganic material artificial filamentsMonocomponent synthetic polymer artificial filamentFiberPolymer science

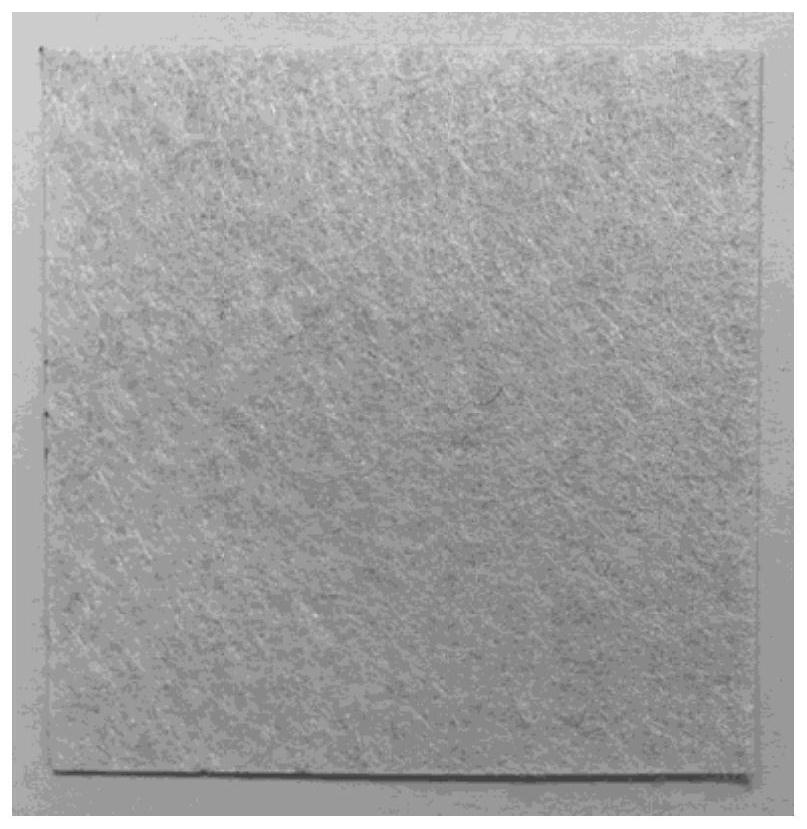

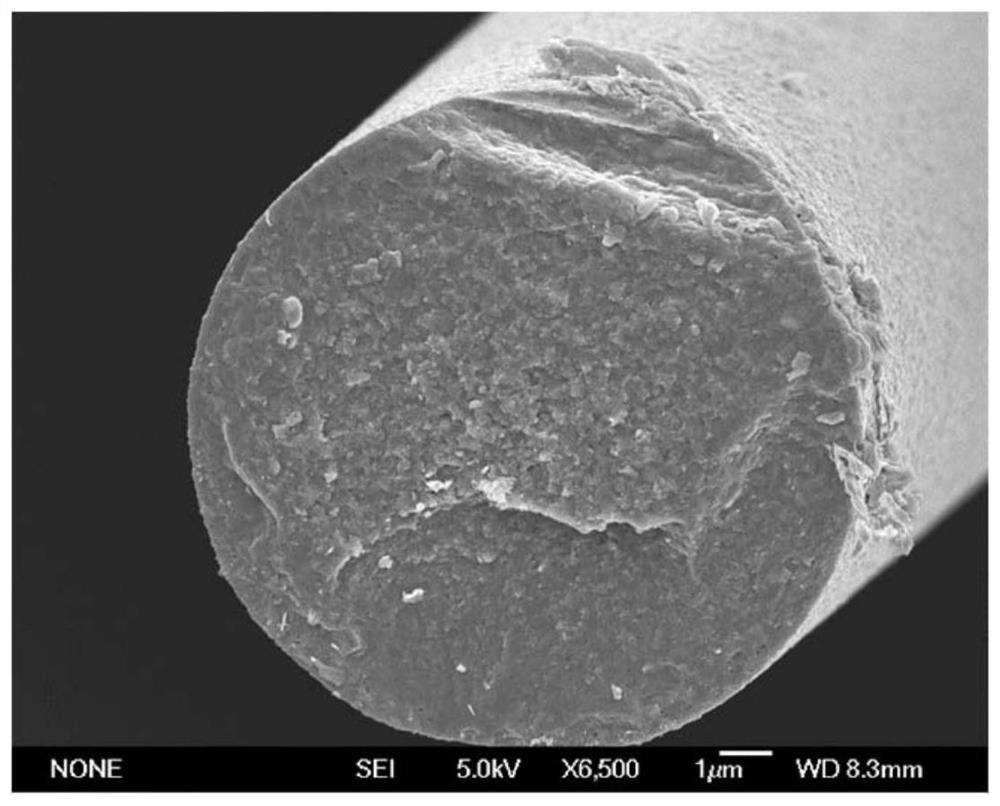

The invention relates to a preparation method of a continuous fiber of a yttrium aluminum garnet. The method comprises the steps of preparing a spinnable precursor sol from aluminum oxide sol containing Al13 colloidal particles, a gamma-AlOOH nano dispersion liquid, yttrium oxide sol, glacial acetic acid and polyvinylpyrrolidone (PVP), preparing a gel continuous fiber by adopting a dry spinning technology and carrying out thermal treatment to obtain the continuous fiber of yttrium aluminum garnet, which is 6-12 microns in diameter. The precursor sol prepared by adopting a sol-gel method is uniform and stable, and can be stored for a long period of time. The length of the gel continuous fiber prepared with dry spinning can reach 3,000m, the fiber subjected to thermal treatment is smooth in surface, the internal structure is compact, the strength is high, and the fiber has very good flexibility, is small in high-temperature creep in a high-temperature using process, and can be widely applied to a composite material and a thermal protection material in the industries such as aerospace. The method is simple in process and short in production period, and industrialization is easy to implement.

Owner:SHANDONG UNIV

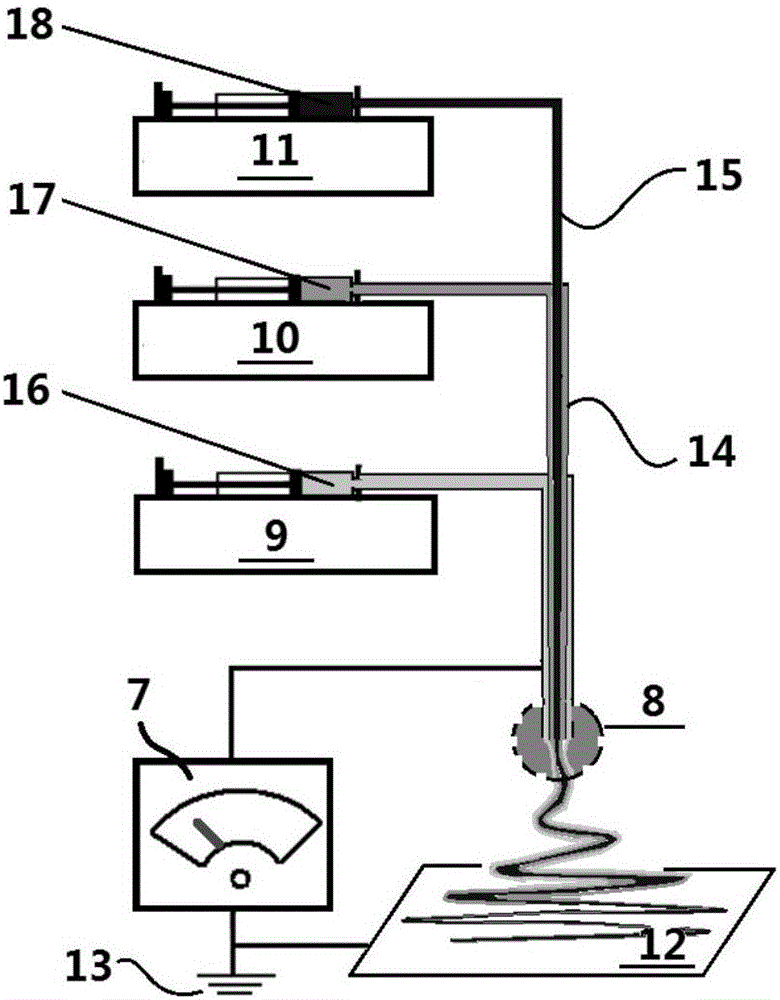

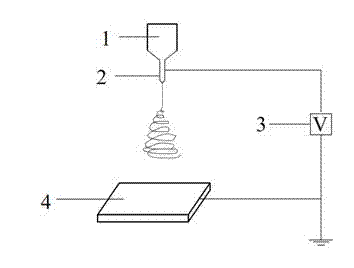

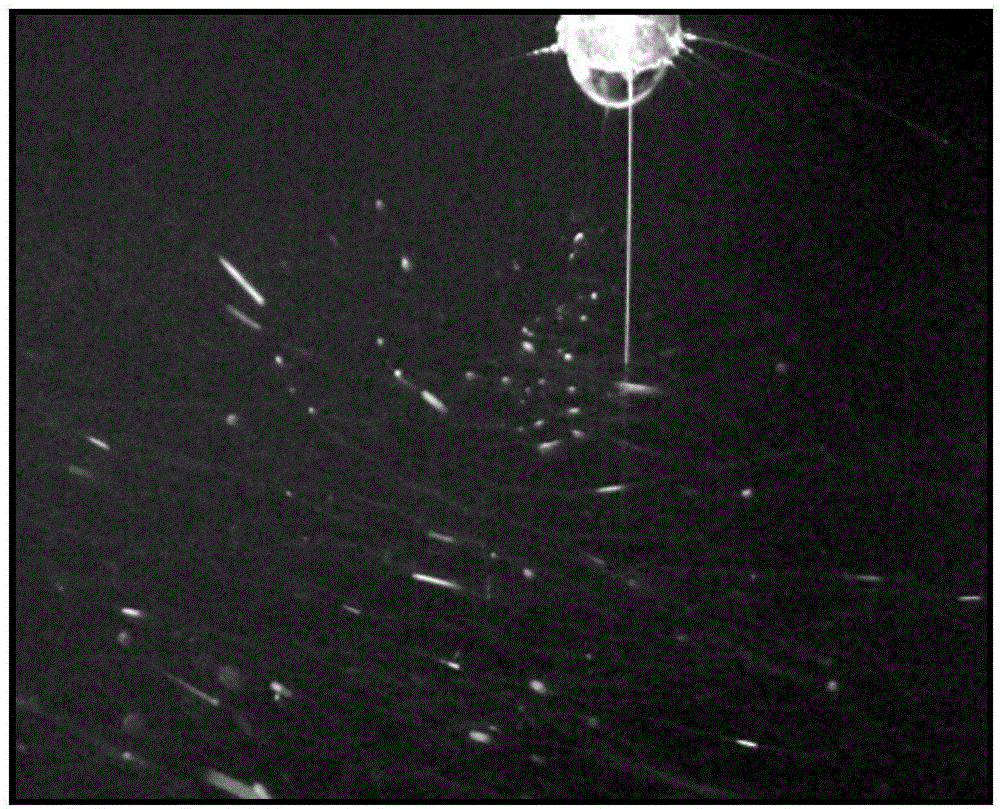

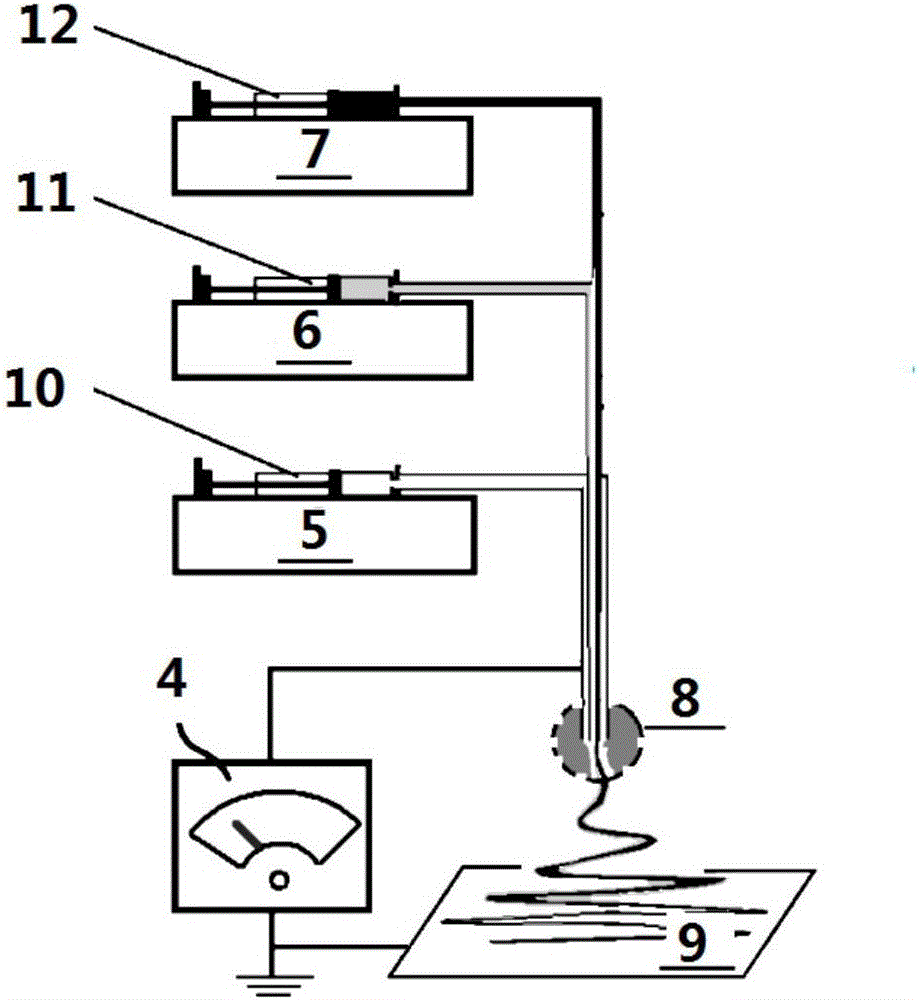

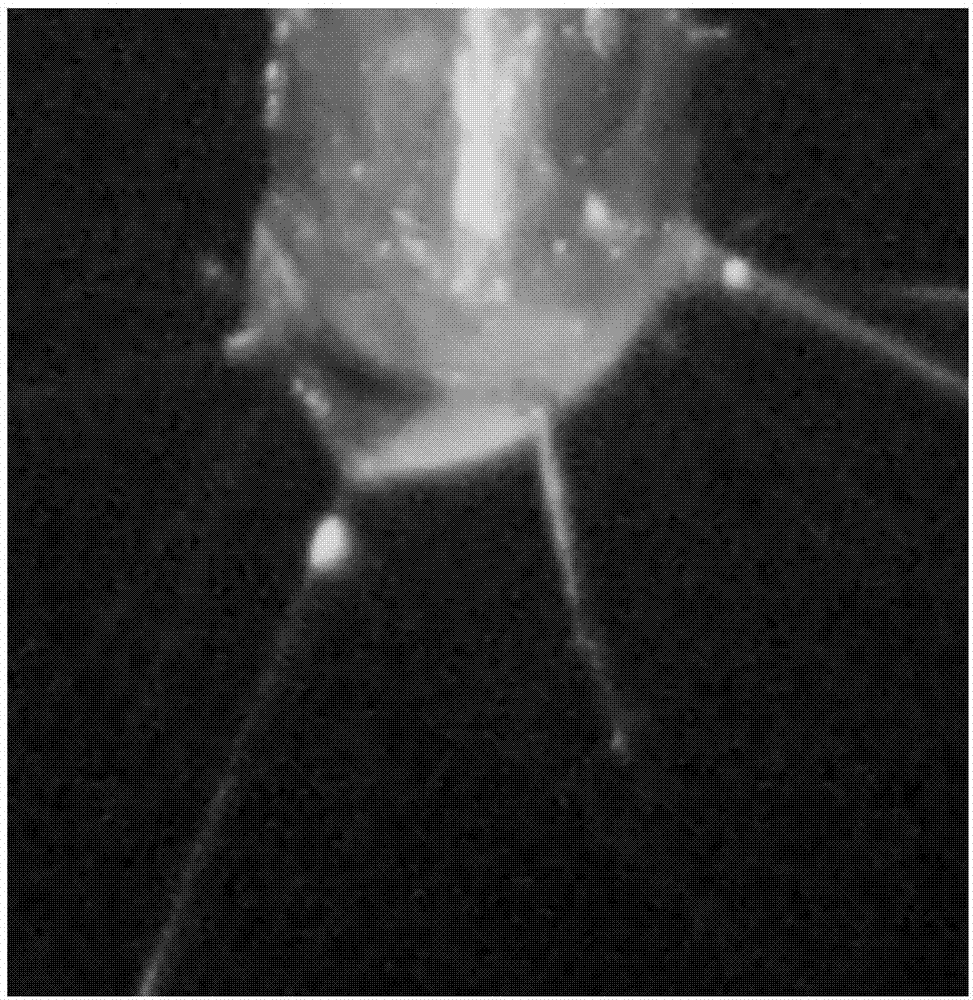

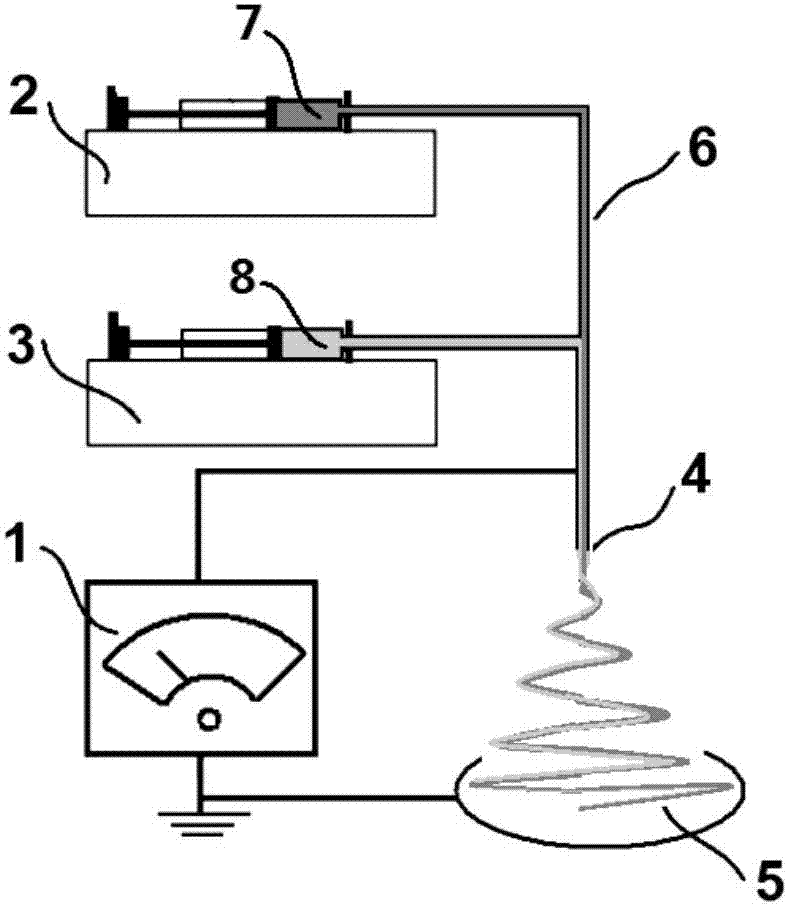

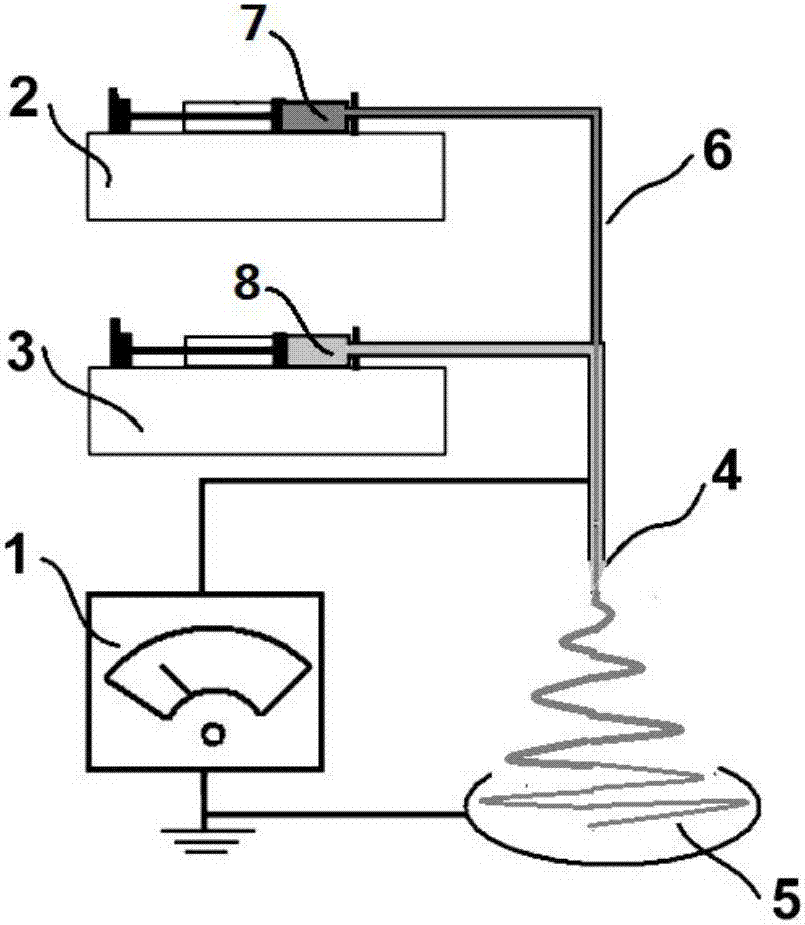

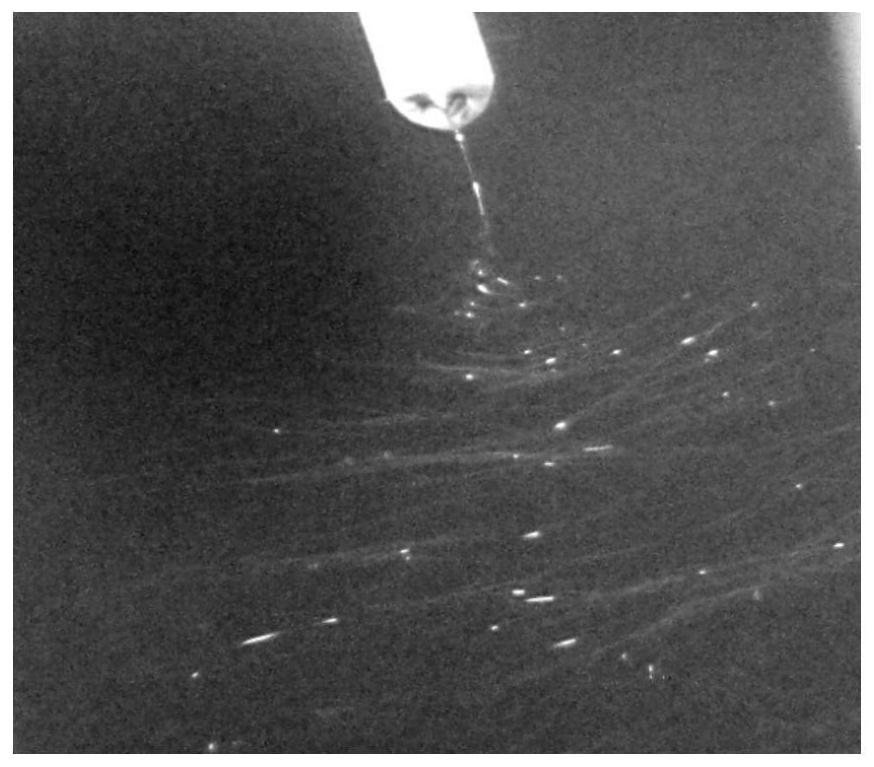

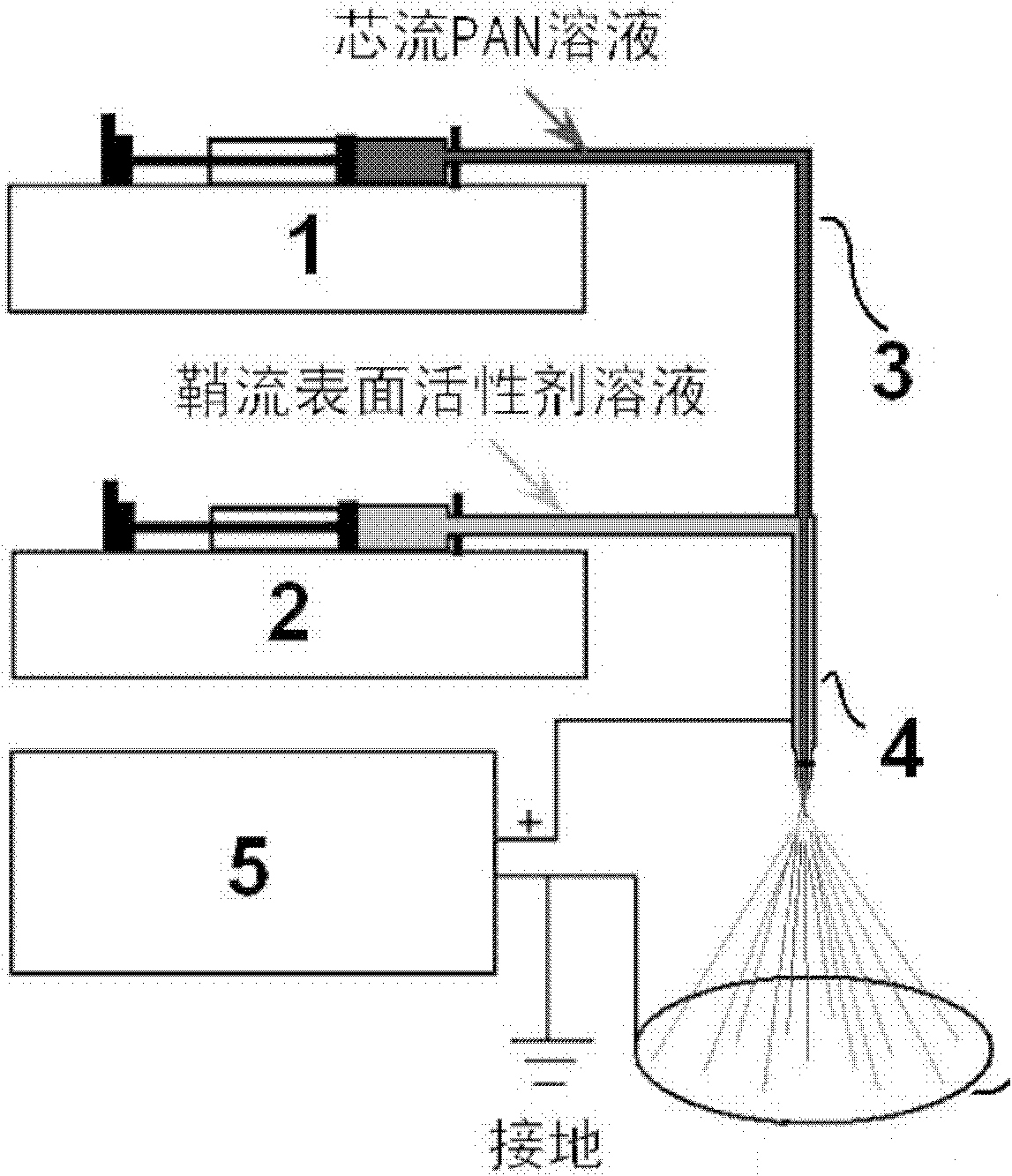

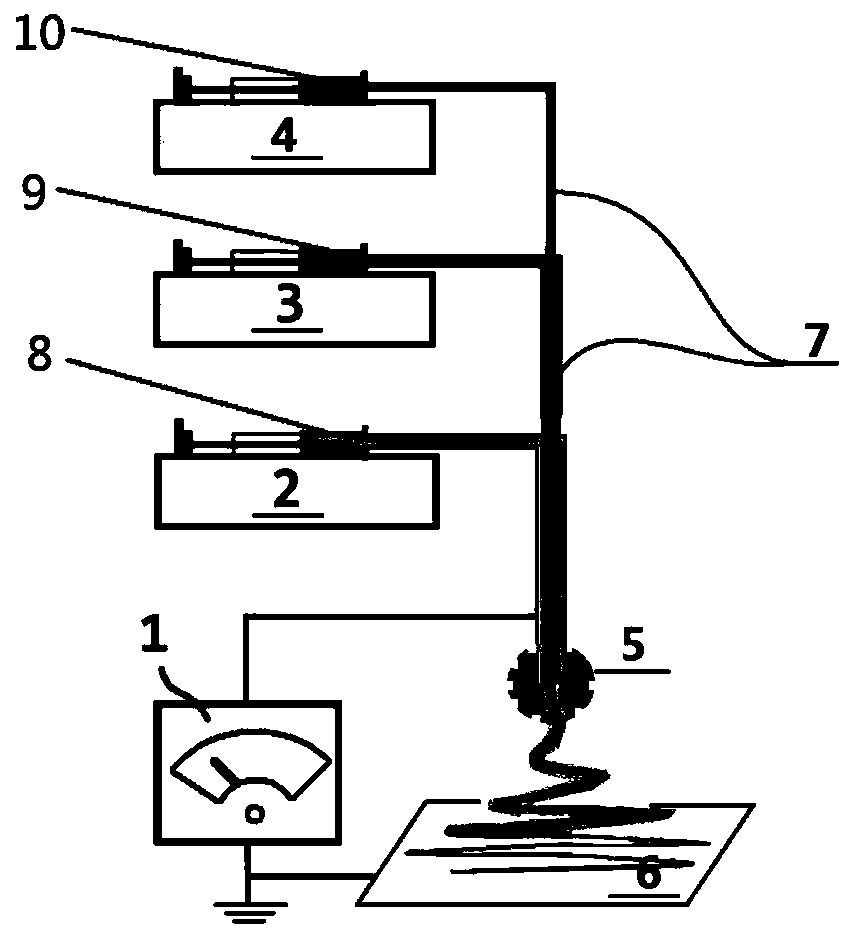

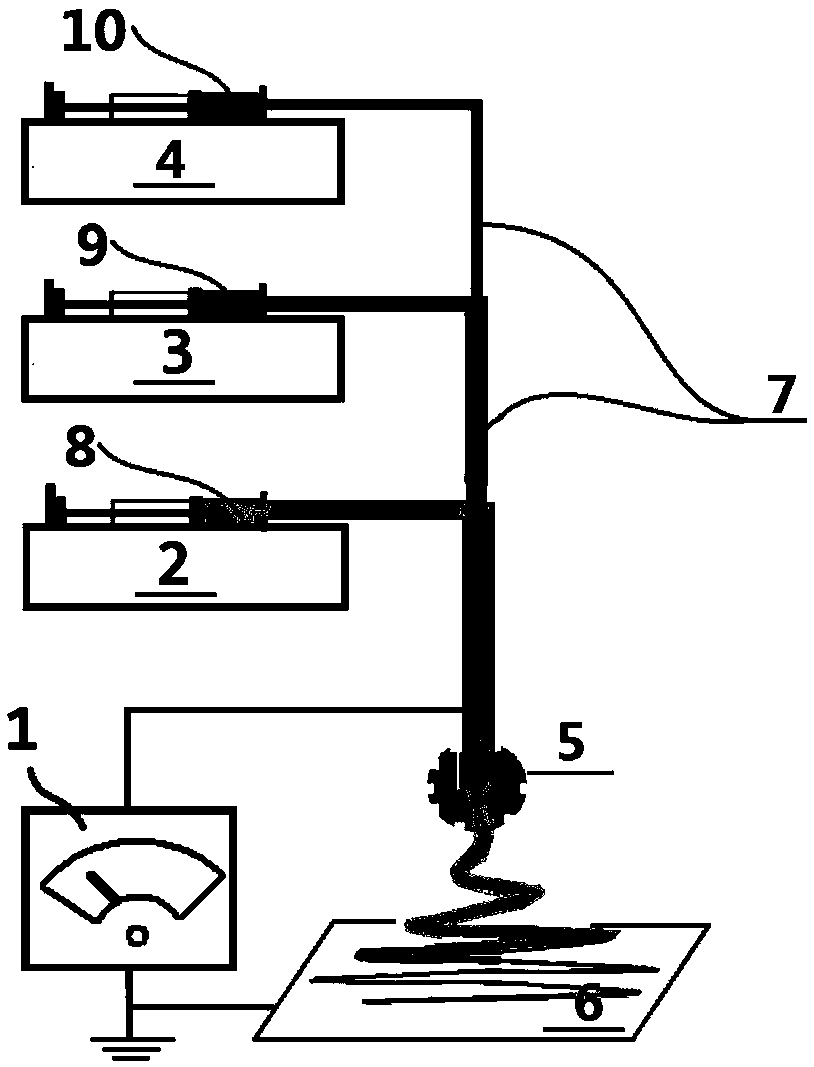

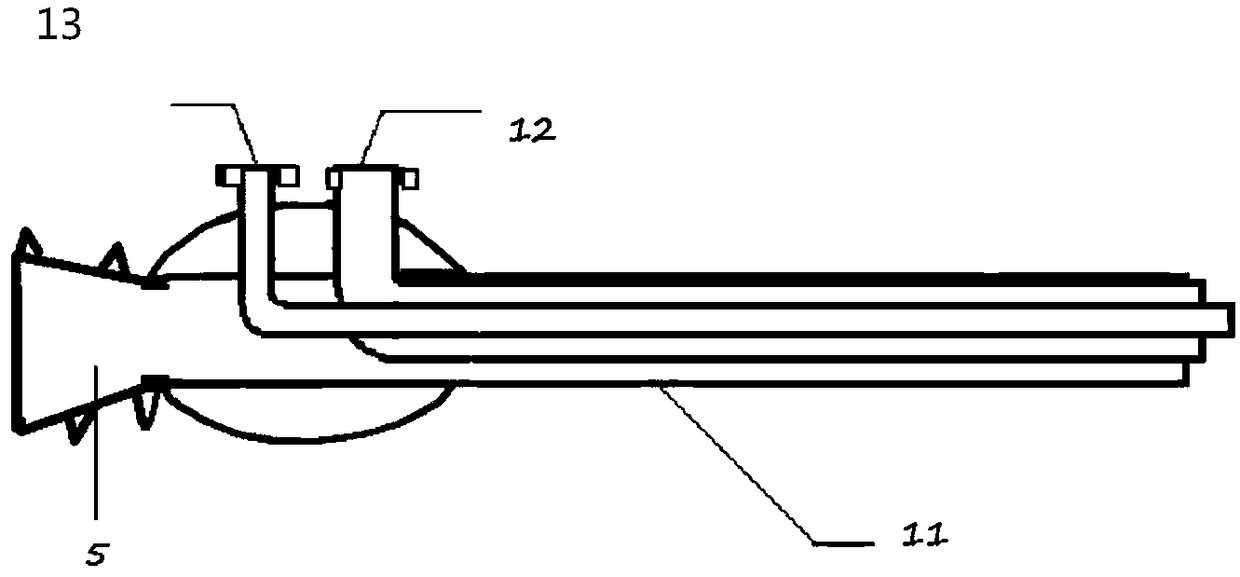

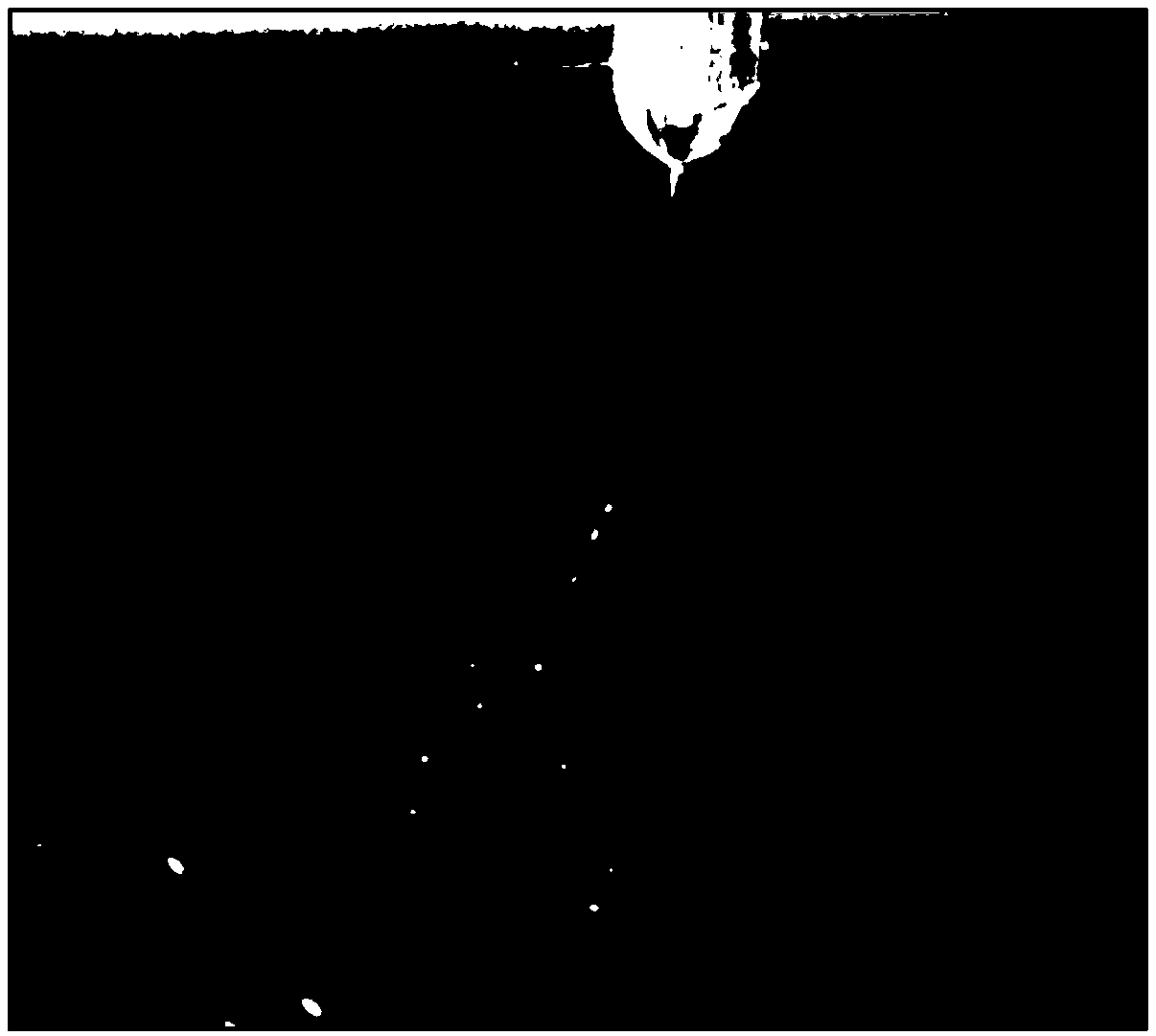

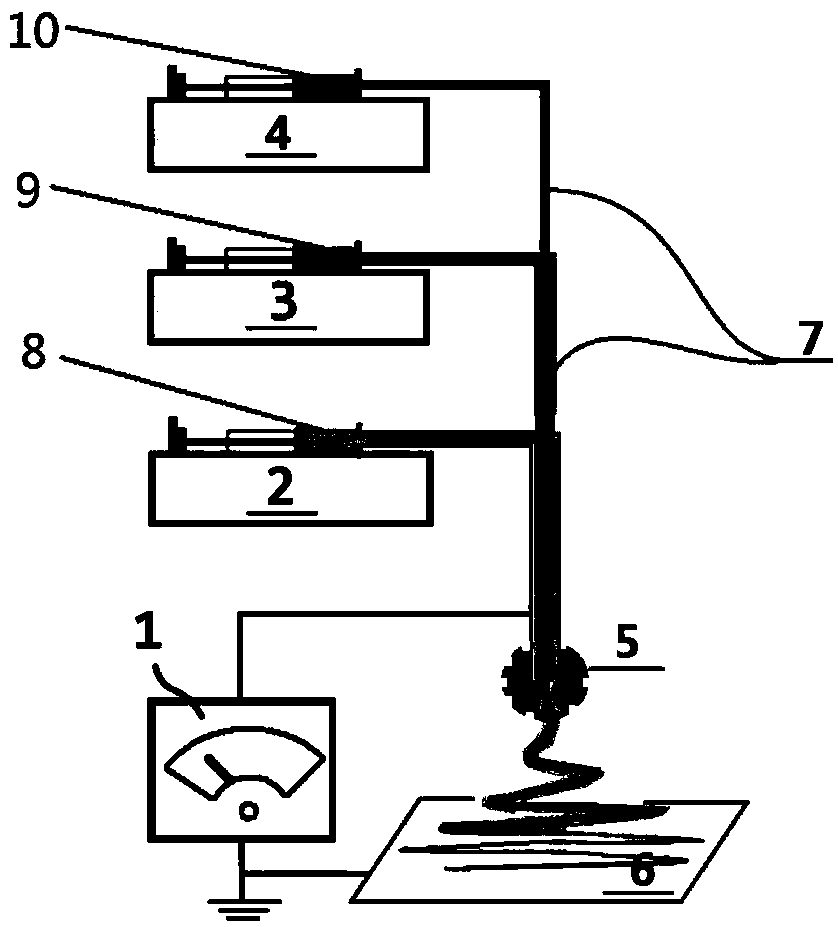

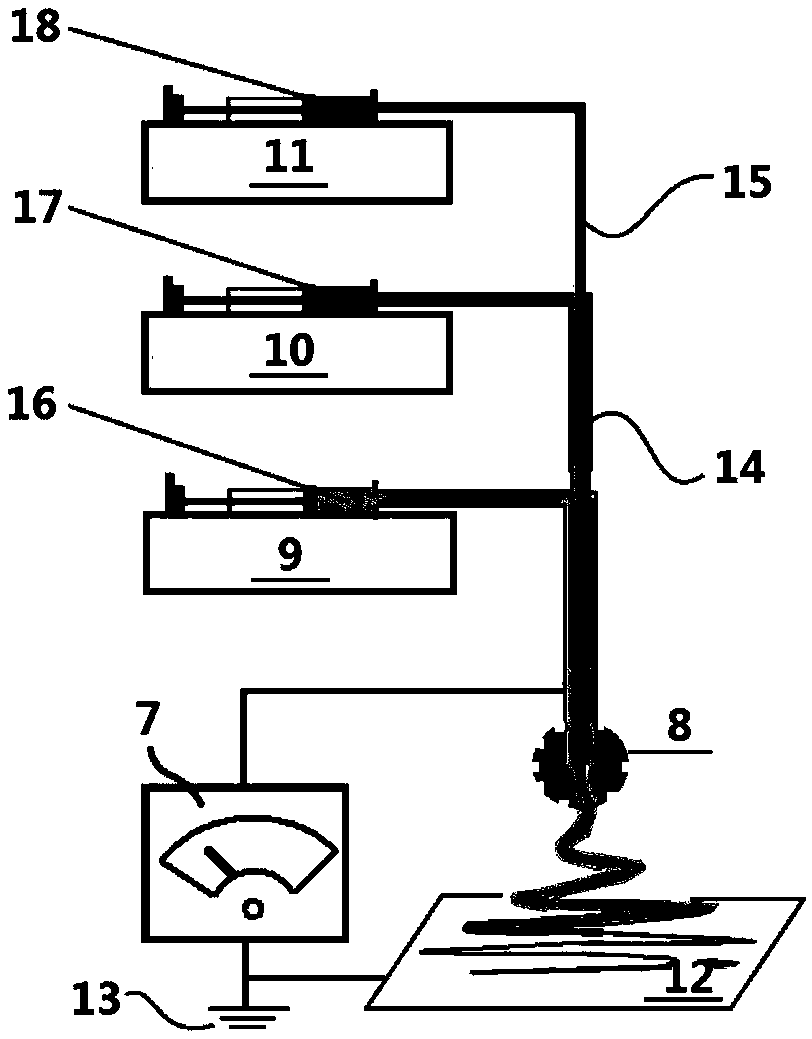

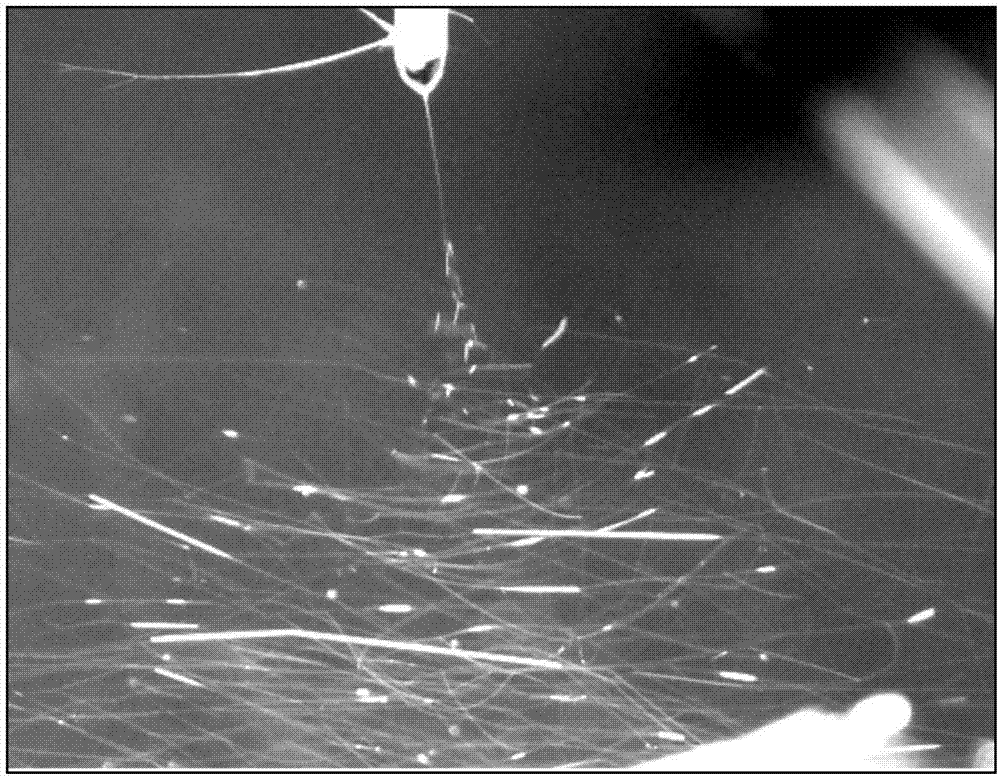

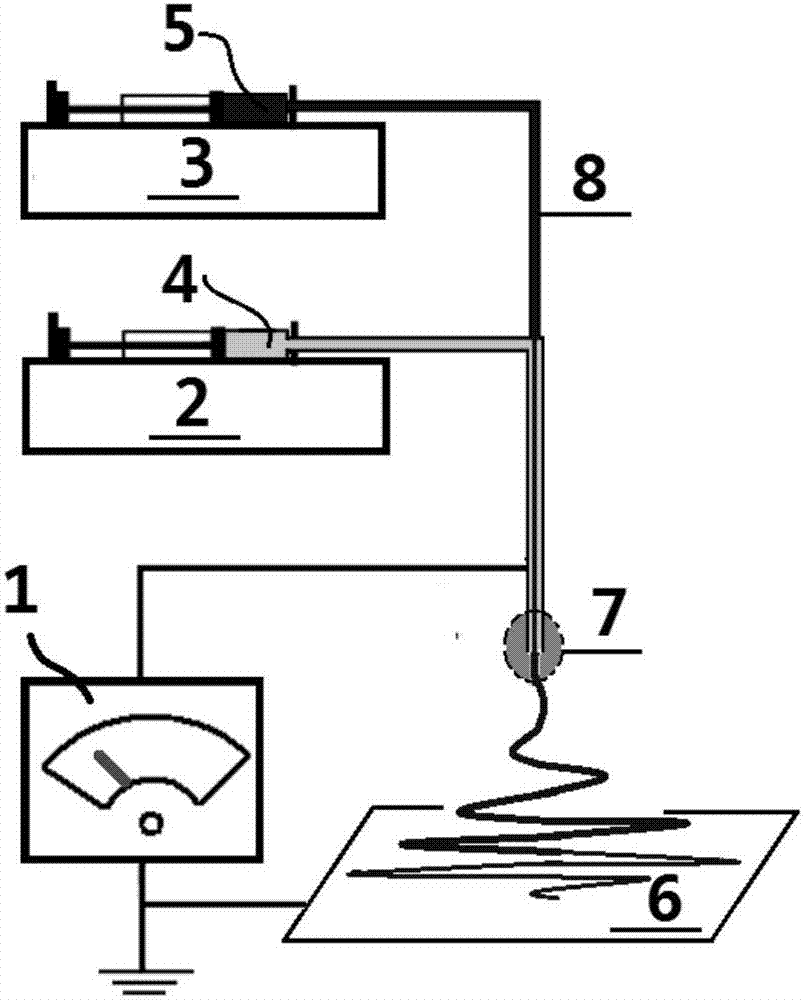

Three-level coaxial electro-spinning method for loading two sheath fluids without spinnability on core fluid

InactiveCN106676653AQuality improvementHigh quality core sheath structureConjugated cellulose/protein artificial filamentsFilament/thread formingThree levelNano structuring

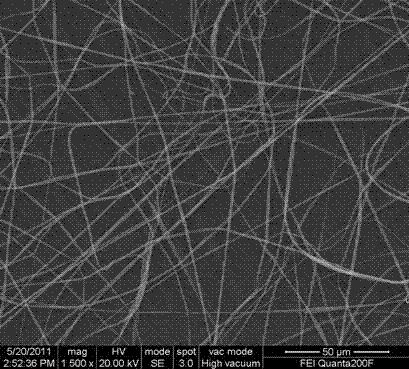

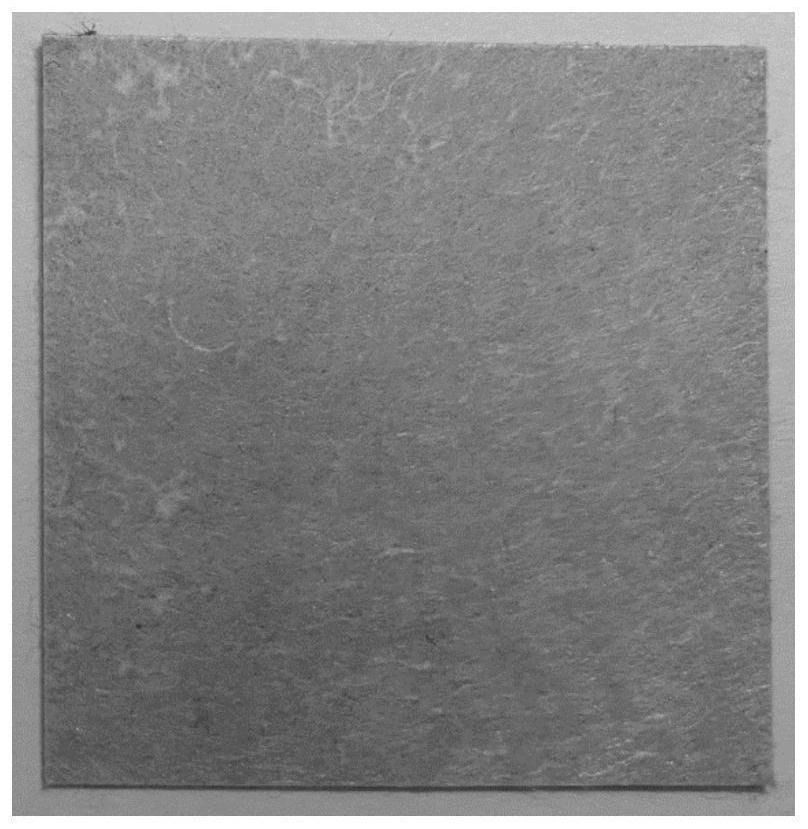

The invention relates to a three-level coaxial electro-spinning method for loading two sheath fluids without spinnability on a core fluid. According to the method, spinnability of the polymer core fluid is used as support, functional fluids without spinnability are loaded in an external sheath fluid surrounding manner to serve as an interlayer, pure organic solvents serve as outermost fluids, and a three-level coaxial high-voltage electrostatic spinning process is implemented. The outermost organic solvents can effectively ensure stability and continuous implementation of the three-level coaxial electro-spinning process, and high-quality core sheath structure nano-fiber products can be prepared. The functional fluids without spinnability are effectively led into the three-level coaxial electro-spinning process, and the nano-structure preparation capacity of the process is greatly extended. Besides, the method is effective in single step, prepared nano-fiber core sheath structures are clear, small in nano-fiber diameter, good in linearity and uniform in diameter distribution, and fiber surfaces are smooth. By the method, numerous functional components can be loaded on the polymer nano-fiber surfaces to obtain novel functional nano-fiber products.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

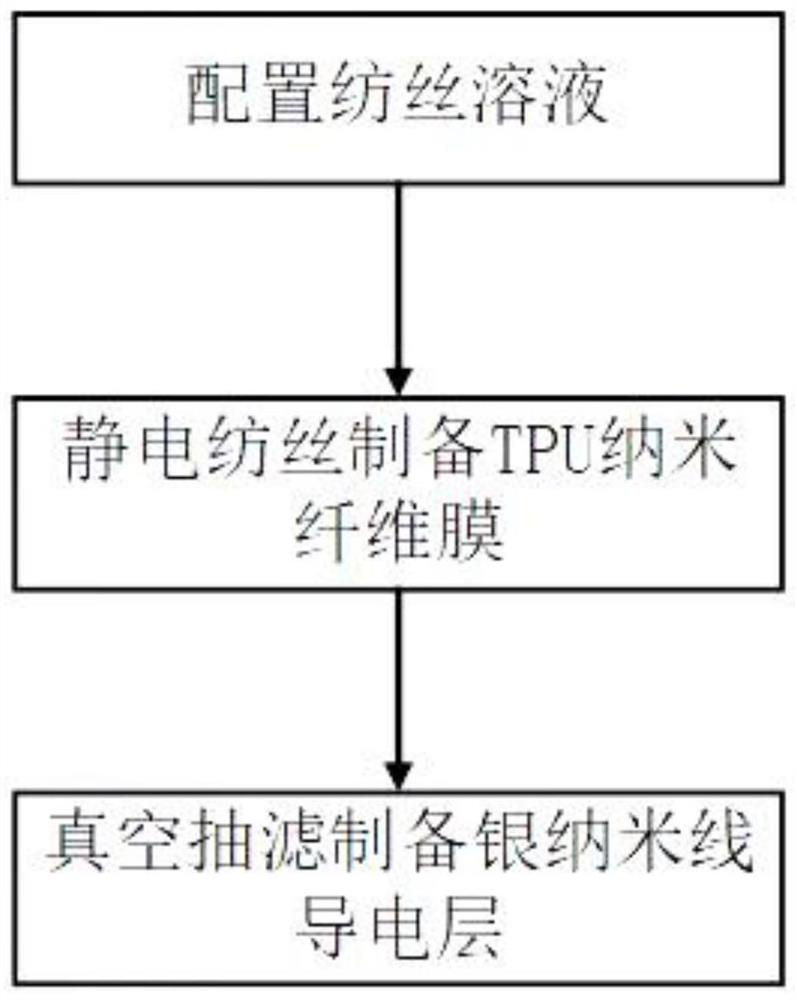

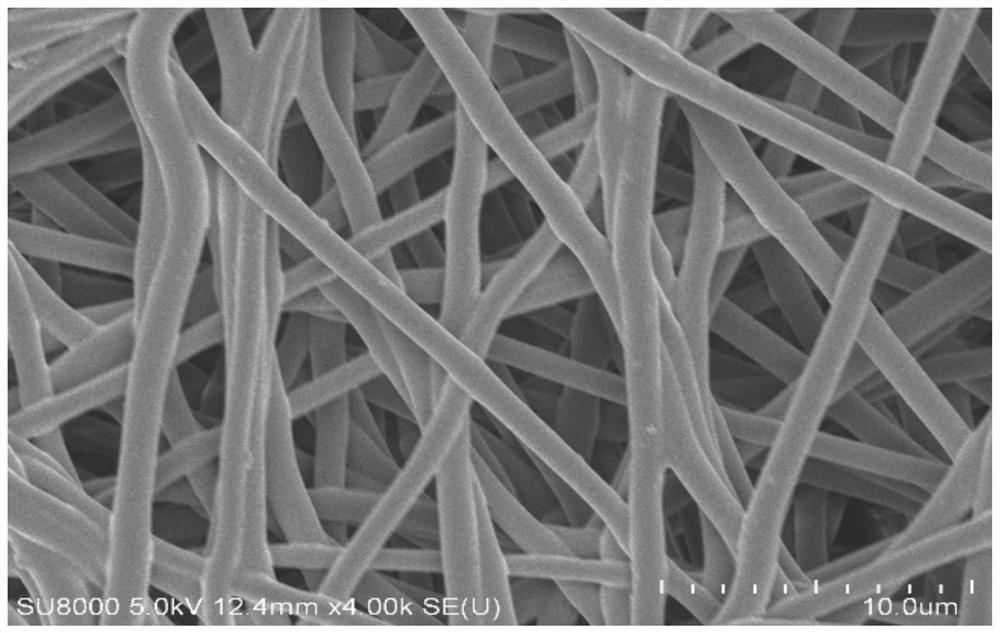

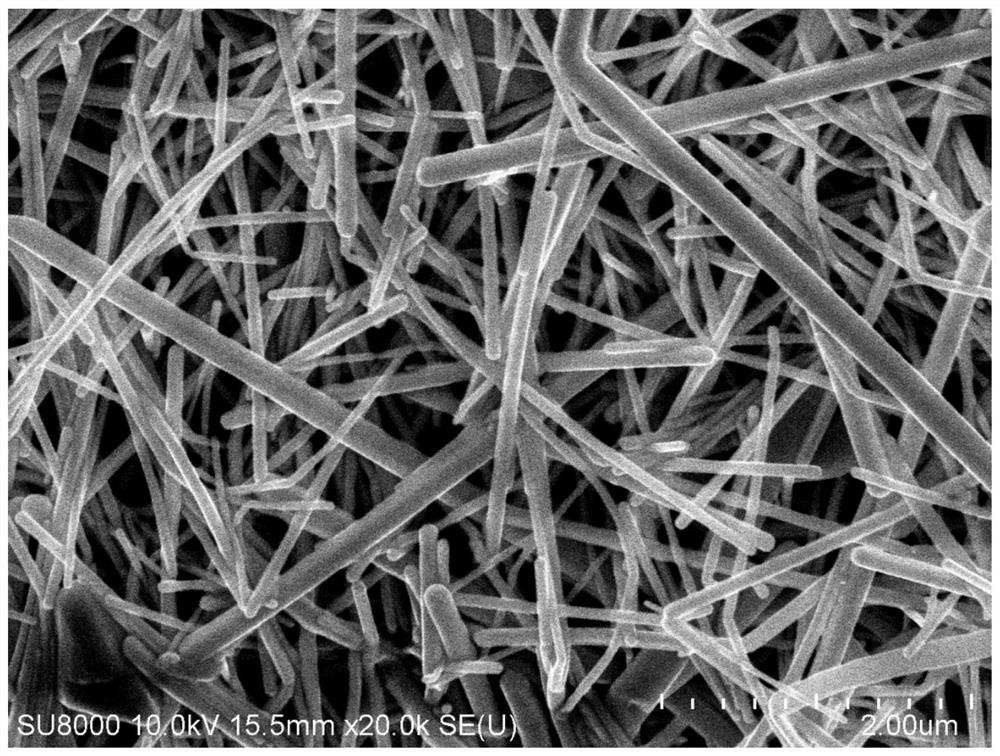

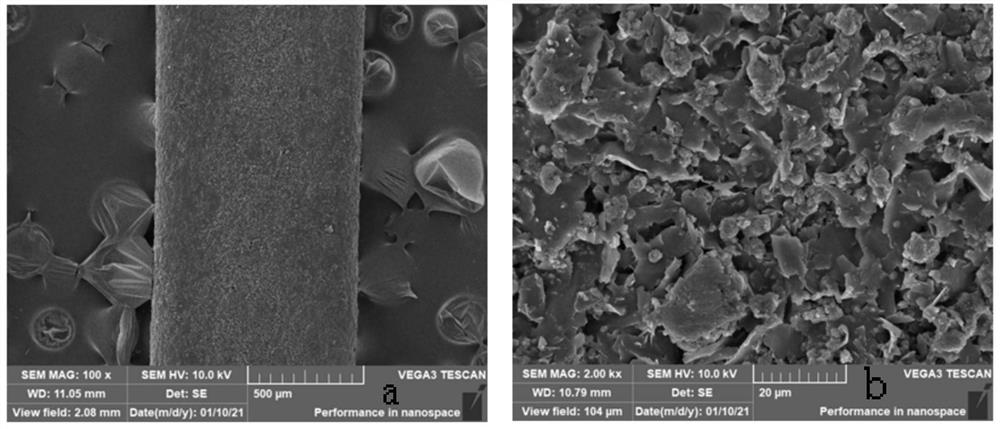

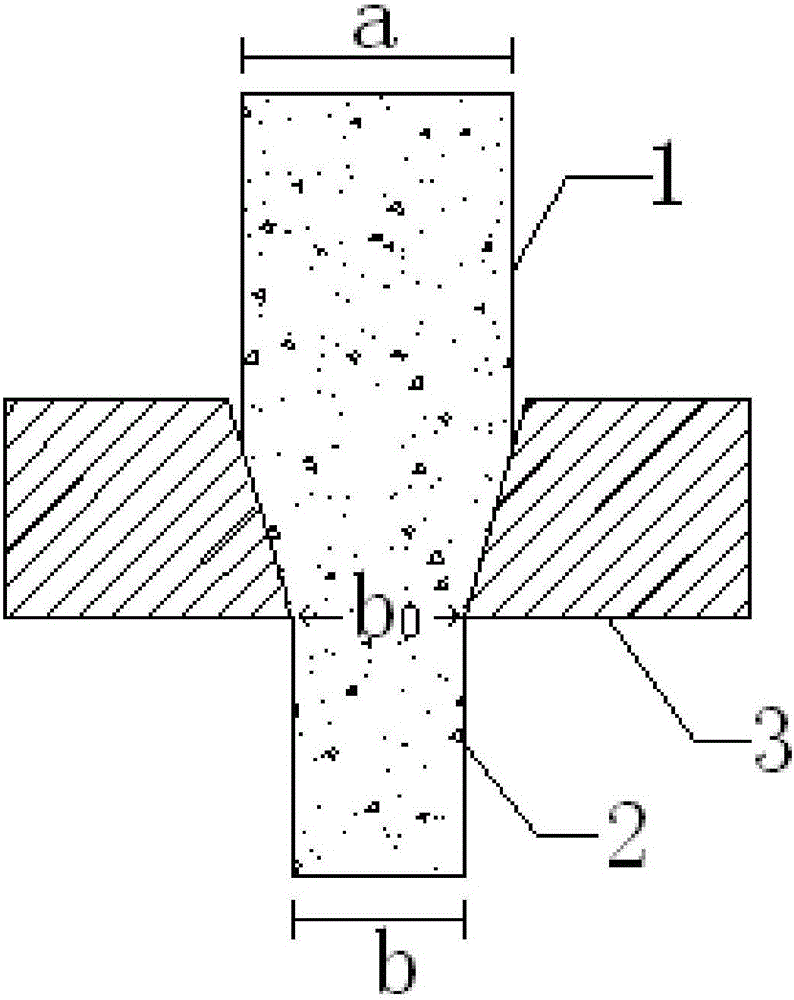

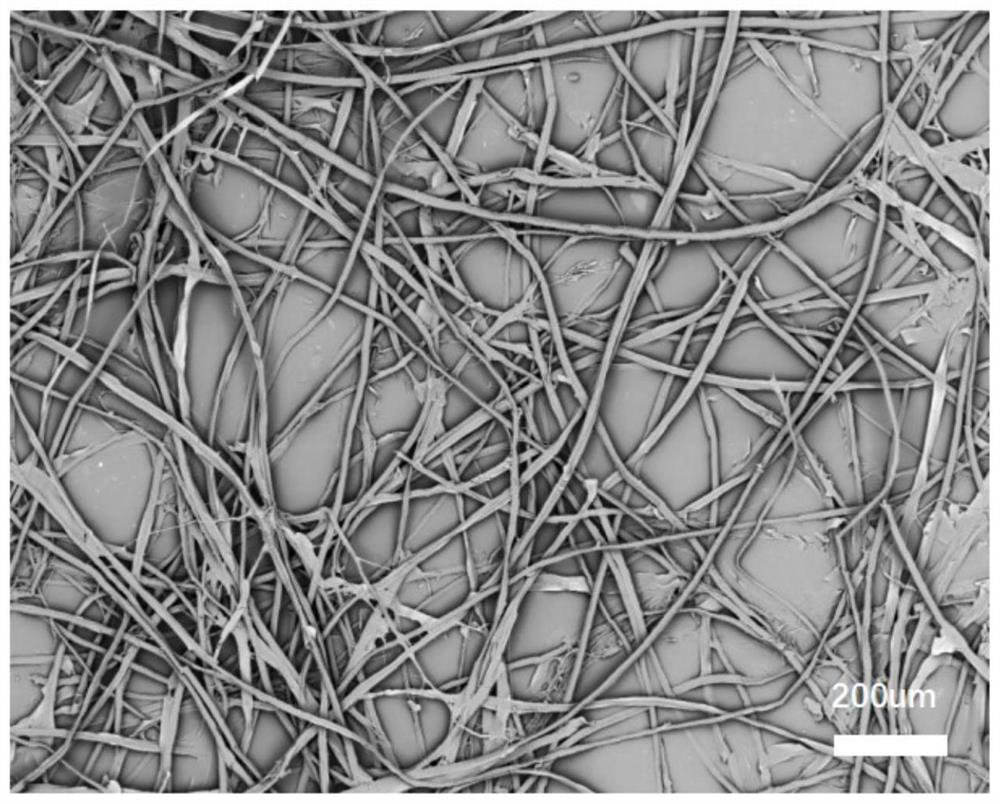

Preparation methods for composite nanofiber membrane and flexible strain sensor

ActiveCN112900080APromote formationAvoid damageMonocomponent polyurethanes artificial filamentFibre typesPolymer scienceSpinning

The invention discloses preparation methods for a composite nanofiber membrane and a flexible strain sensor. The preparation method for the composite nanofiber membrane comprises the following steps of firstly dissolving polymer particles in an organic solvent to prepare a spinning solution; transferring the spinning solution into an injector, extruding the spinning solution through the injector, and adjusting relevant parameters of electrostatic spinning to enable jet flow to be stable so as to collect a nanofiber membrane on a collecting plate; after silver nanowire dispersion liquid is diluted and subjected to water bath ultrasonic dispersion, depositing a metal nanowire layer on the pre-stretched nanofiber membrane through a vacuum-assisted suction filtration method; and increasing the binding force between nanowires and the binding force between the nanowires and an elastic substrate through high-temperature annealing. The prepared flexible strain sensor has a large sensing range and can be used for detecting deformation such as bending, stretching and twisting.

Owner:XI AN JIAOTONG UNIV

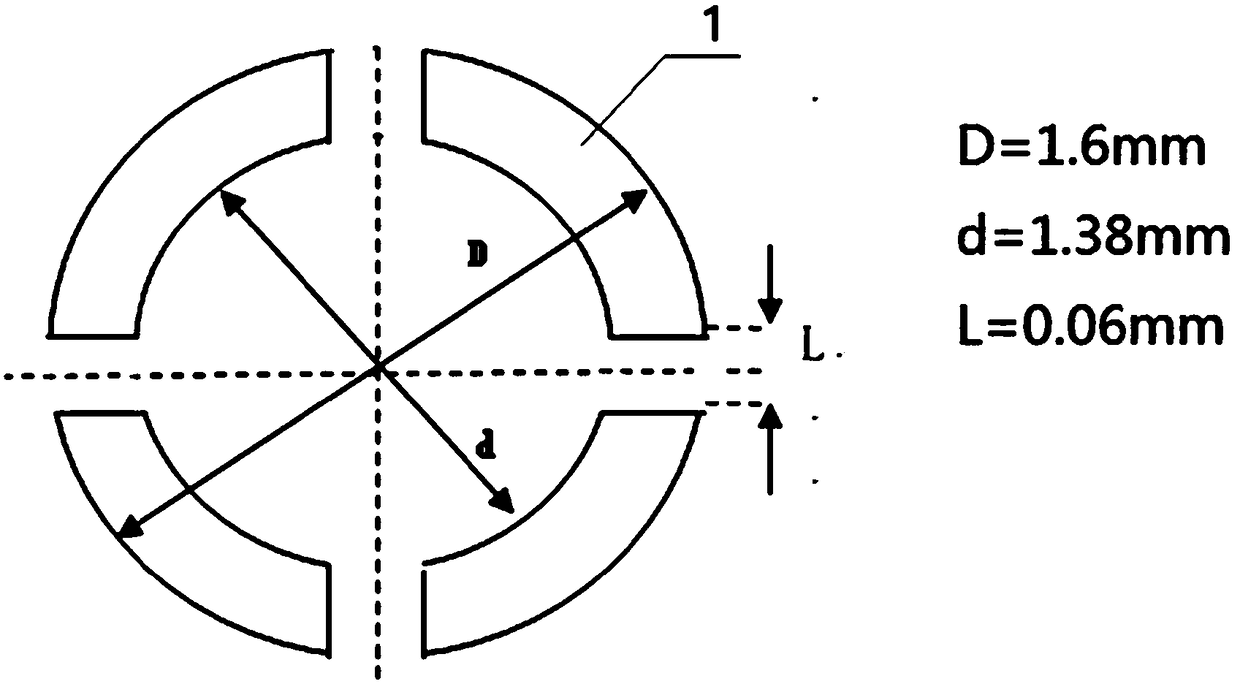

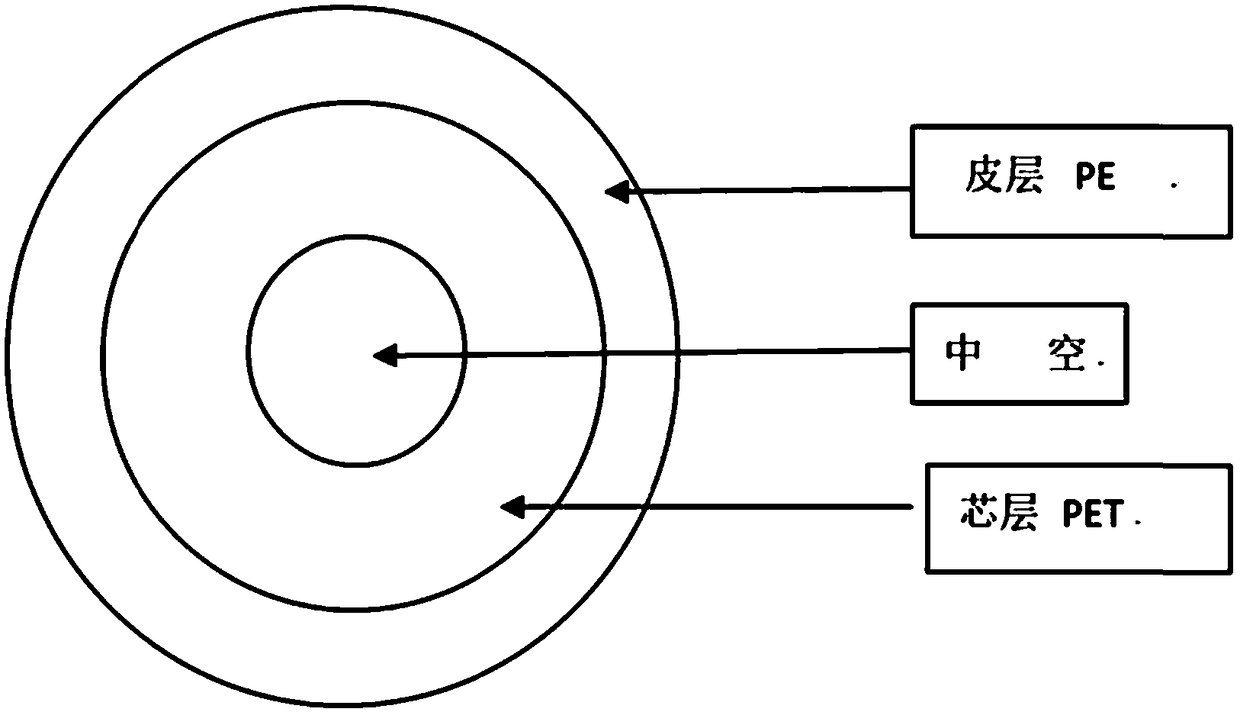

Preparation method of Kangshu (healthy and confortable) composite staple fiber

PendingCN109234846AImprove antibacterial propertiesRaise the stretching temperatureFilament forming substance formingHollow filament manufactureYarnFiber

The invention discloses a preparation method of Kangshu (healthy and confortable) composite staple fiber, comprising the steps: esterification reaction of PTA and EG is carried out; polycondensation reaction of the esterification product is carried out to obtain PET; polyethylene is melted into a PE melt by entering a screw extruder; the PET melt and the PE melt respectively enter a composite spinning manifold and are ejected from a composite hollow spinneret to obtain a hollow skin-core structure yarn; part of PE melt is taken out from the main pipe of the spinning manifold into which the PETmelt enters and a zinc-based ultrafine powder antibacterial agent and a dispersing agent potassium tripolyphosphate supported by zeolite are added to the part of the melt, and after uniformly mixing,the mixture returns to the main pipe; in the stretching process, secondary stretching is performed, and primary stretching is controlled in 1.88-2.14 times; the primary stretching adopts steam bath,and the temperature is controlled at 115 DEC C to 125 DECC. The first stage stretching of the invention is steam stretching. Stretching temperature can be improved to soften the PE, and the surface ofthe produced fiber is smooth with good bonding effect.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

Method for preparing forsterite porous superfine fibers by electrostatic spinning

ActiveCN105970357AUniform diameter distributionSimple preparation processInorganic material artificial filamentsFilament/thread formingElectrospinningDichloromethane

The invention relates to a method for preparing forsterite porous superfine fibers by electrostatic spinning, belonging to the technical field of material science. The fiber preparation method comprises the following steps: preparing a reaction liquid from anhydrous magnesium chloride, tetraethoxysilane and anhydrous dichloromethane according to a certain mole ratio, then carrying out gelation treatment on the reaction liquid by heating and triggering non-hydrolytic sol-gel reaction to synthesize forsterite gel; mixing absolute ethyl alcohol with a certain amount of polyvinylpyrrolidone (PVP) according to a certain proportion to obtain a PVP ethanol solution and dissolving the synthesized forsterite gel in the PVP ethanol solution to obtain a spinning precursor solution; preparing the spinning precursor solution into a forsterite xerogel / PVP complex fiber by adopting electrostatic spinning and then carrying out high-temperature calcination, thus obtaining the forsterite porous superfine fibers. The preparation method of the forsterite porous superfine fibers is simple to operate and easy to control, is low in preparation cost and can provide novel high-temperature thermal insulation materials for the fields, such as aviation and the military industry.

Owner:山西阿拉丁新材料有限公司

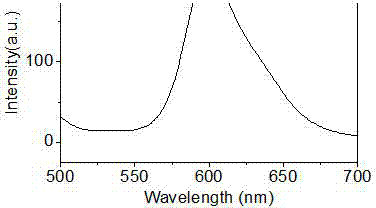

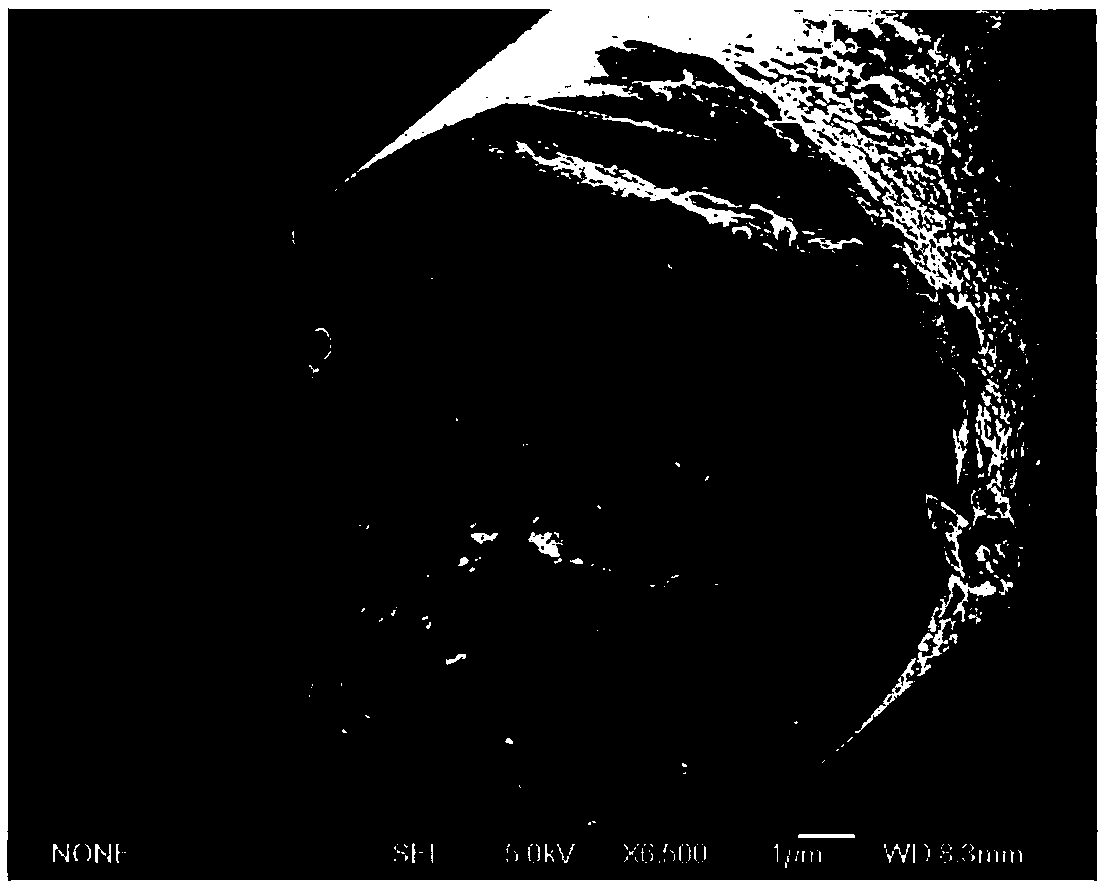

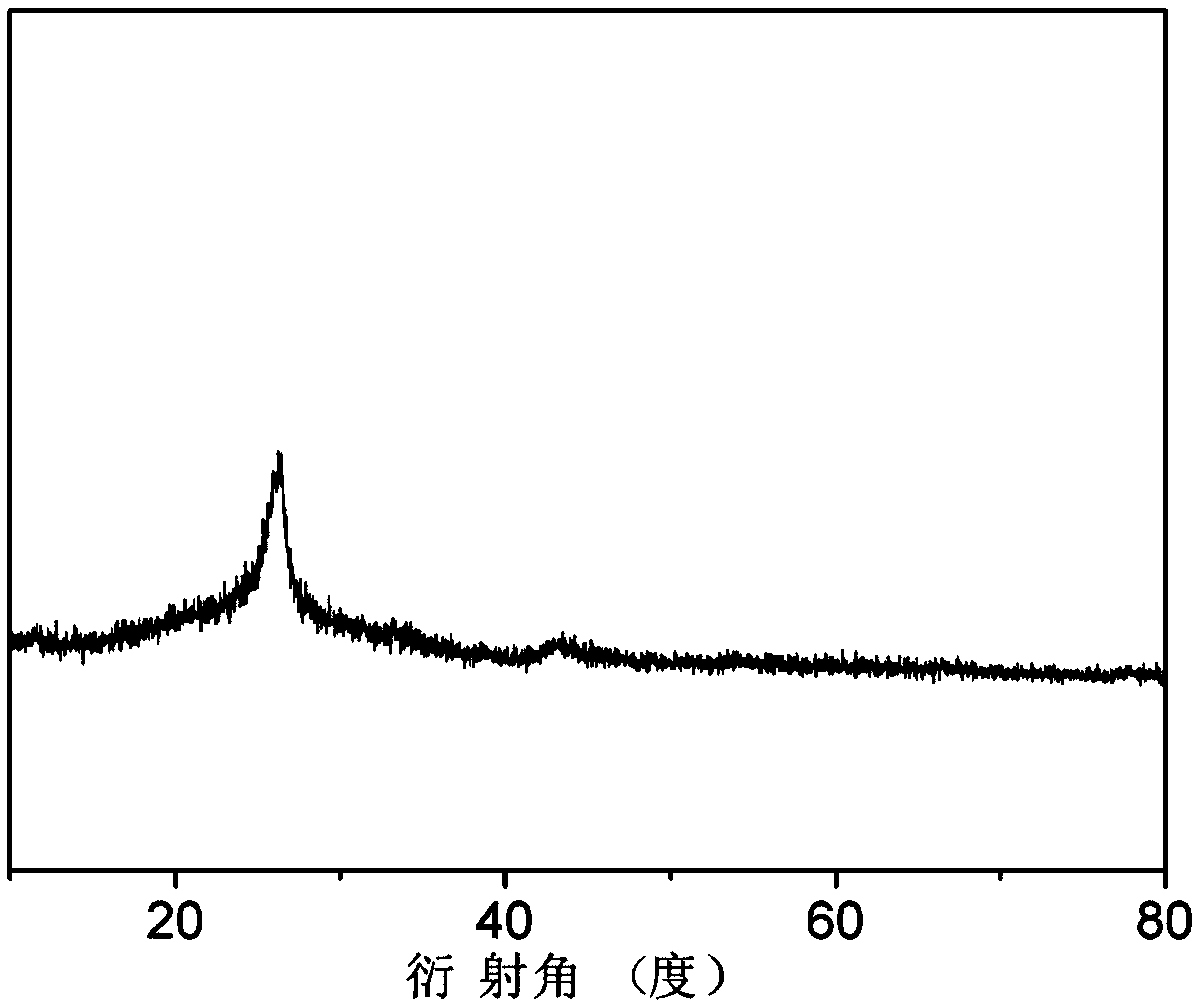

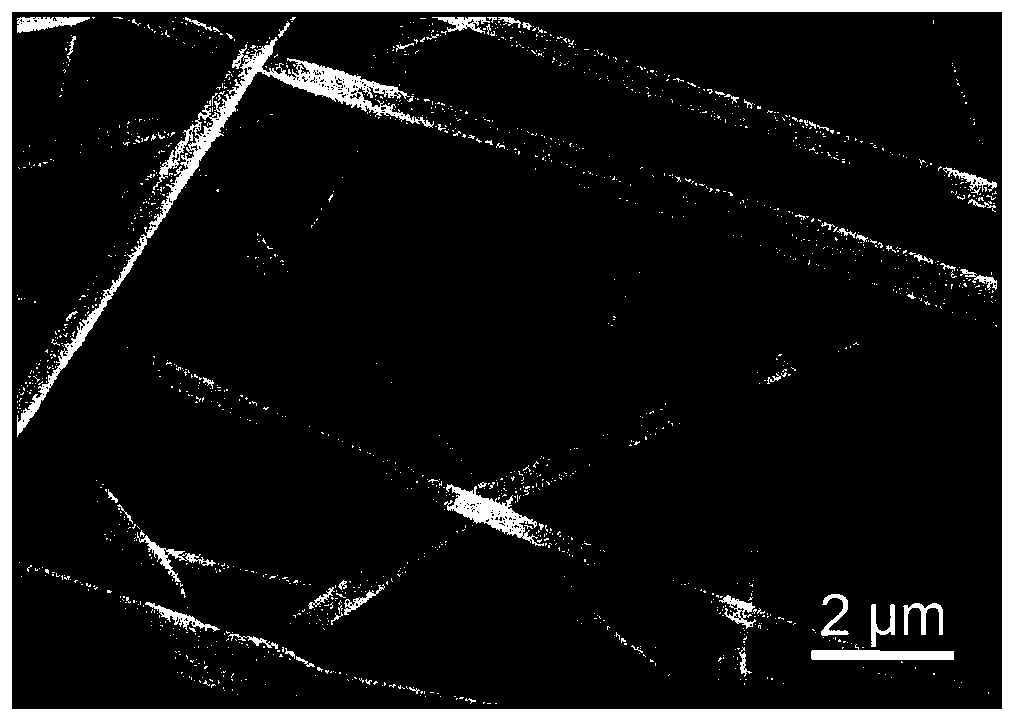

Preparation method of poly-p-phenylene ethylene derivative micro-nano fiber

InactiveCN102443858AGood mechanical propertiesSmooth fiber surfaceFilament/thread formingMonocomponent synthetic polymer artificial filamentElectrospinningBenzene

The invention discloses a preparation method of poly-p-phenylene ethylene derivative micro-nano fiber. The preparation method is characterized by comprising the following steps of: firstly preparing poly-p-phenylene ethylene derivative and tetrahydrofuran, chlorobenzene, methylbenzene, chloroform or dichloroethane into solution according to the concentration of 0.5-20wt%; then preparing the solution and normal hexane, normal heptane or cyclohexane and the like into solution according to the volume ratio of 1:4-20:1; and then carrying out electrostatic spinning. In the poly-p-phenylene ethylene derivative micro-nano fiber prepared by the invention, the diameter is 19nm-2mum, the surface of the fiber is smooth, the length is centimeter-level and the mechanical property is good; by measurement of a fluorescence spectrum, a photoluminescence spectrum of the fiber is consistent to that of a spinning-coating film; and by a simple orientation device, an emission spectrum shows very strong polarization.

Owner:NANCHANG UNIV

Modification method for leukocyte filtering membrane

InactiveCN106117590AAvoid deformation effectsAchieve filteringSemi-permeable membranesFilter effectChemistry

Owner:广州新克力生物科技有限公司

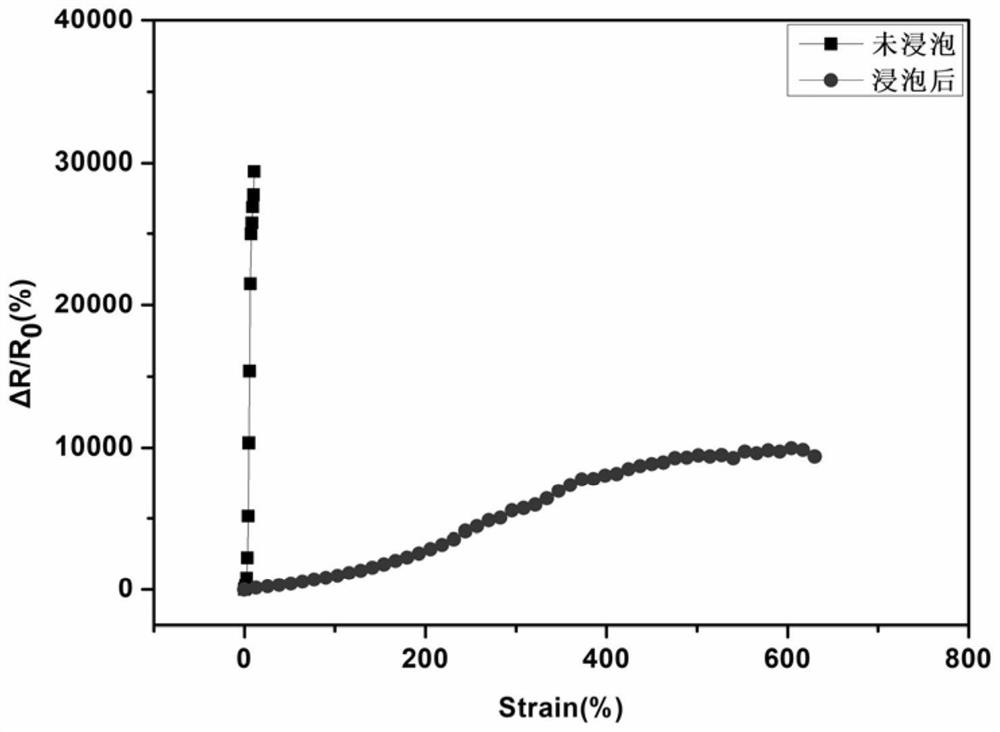

Conductive network remodeling method based on SBS conductive fibers, conductive composite fibers prepared by using method and preparation method thereof

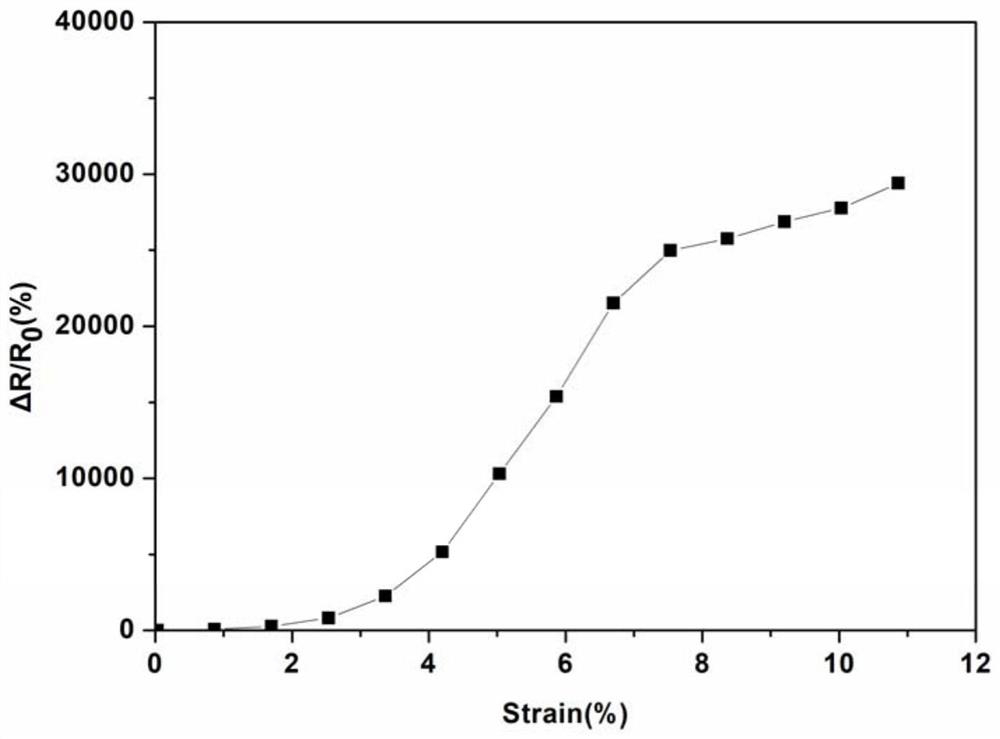

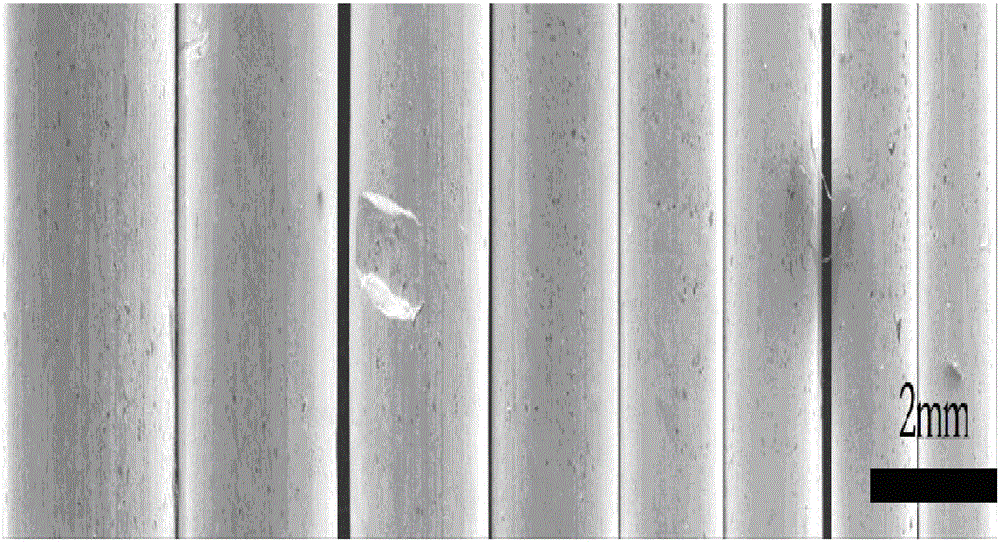

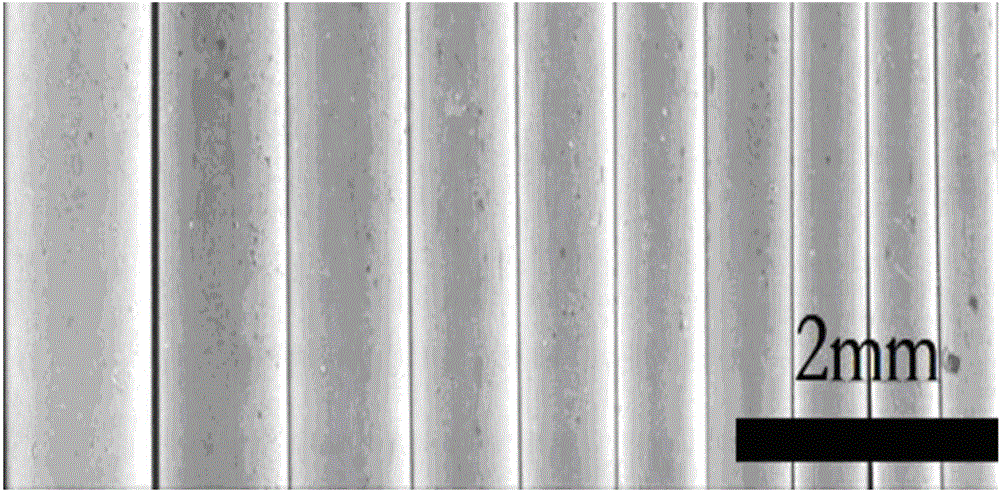

ActiveCN113089126AGuaranteed StrengthImprove electrical performanceElectroconductive/antistatic filament manufactureSynthetic fibresEthyl acetateElectric properties

The invention relates to the technical field of polymer conductive materials, in particular to a conductive network remodeling method based on SBS conductive fibers. The method comprises the following steps: (1) preparing an ethyl acetate mixed solution; and (2) soaking the SBS conductive fibers in the ethyl acetate mixed solution prepared in the step (1) for 5-15 s, taking out the SBS conductive fibers, and drying the SBS conductive fibers. According to the method, the conductive network in the conductive fibers is remodeled, the technical problem that the electrical property of the fibers is poor due to uneven distribution of conductive particles in the conductive fibers is solved, the surface of the fibers is smooth, the electrical property is effectively improved, and the strength of the fibers cannot be reduced. The invention also provides a conductive composite fiber prepared by using the conductive network remodeling method based on the SBS conductive fibers, and a preparation method of the conductive composite fiber. The preparation method is simple to operate, convenient and economical, the fibers cannot be damaged, and the prepared fibers have good spinnability, stretchability, conductivity, high strain range and stability.

Owner:QINGDAO UNIV

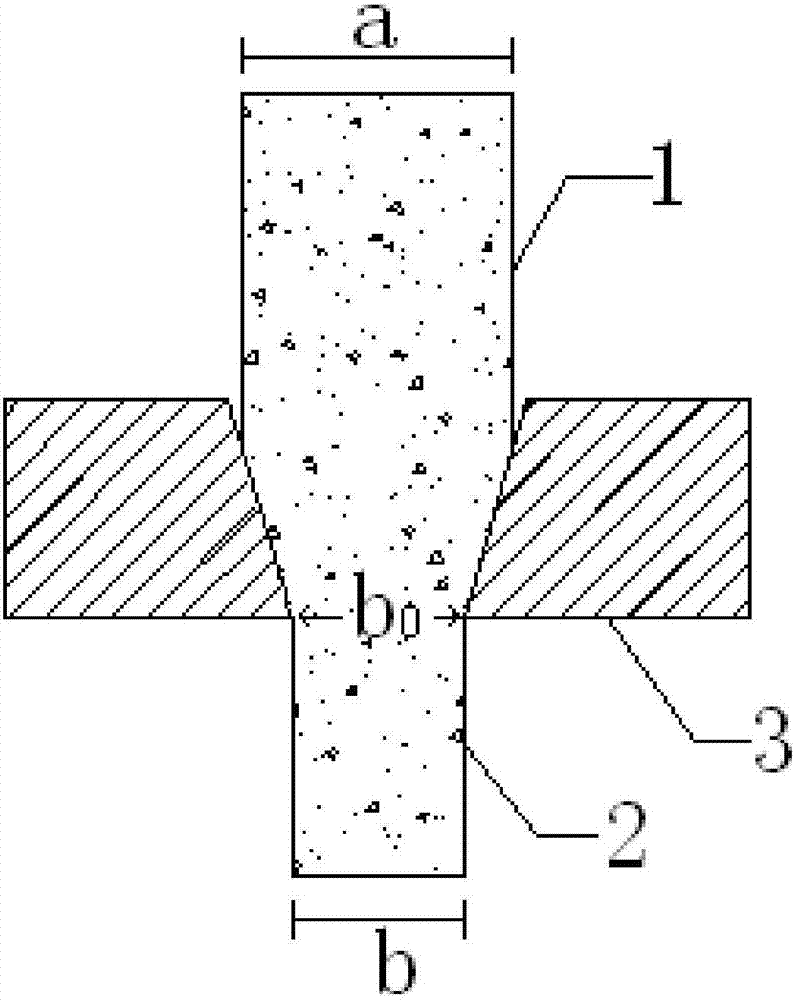

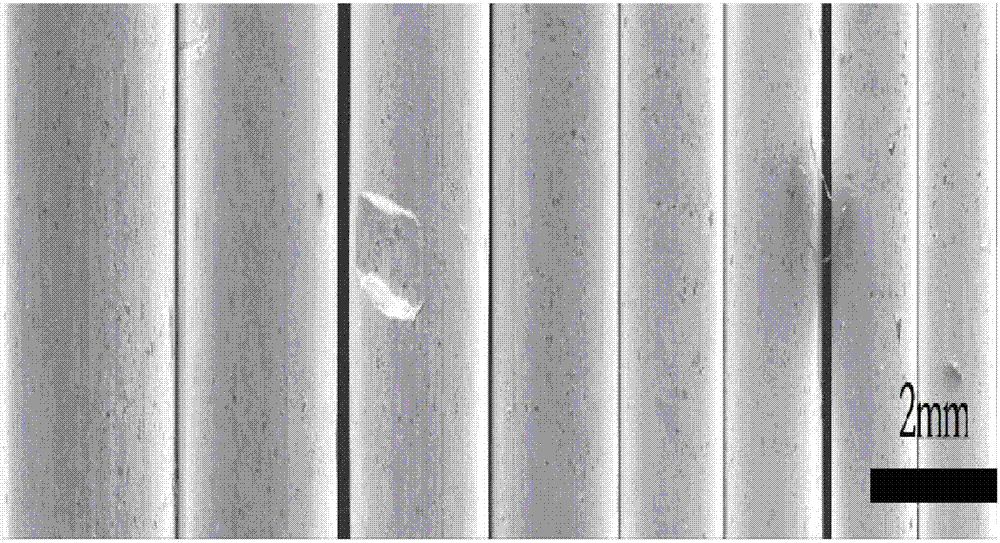

Method for manufacturing CuZnAl or CuZn alloy continuous fiber through cold drawing

The invention discloses a method for manufacturing CuZnAl or CuZn alloy continuous fiber through cold drawing and relates to a manufacturing method for alloy fiber. The method aims at solving the problems that a CuZnAl or CuZn alloy is low in yield strength, and the difficulty for manufacturing small fiber of the CuZnAl or CuZn alloy is high. The method includes the steps that firstly, an original cast ingot is manufactured; secondly, the original cast ingot is subjected to hot extrusion to form a bar; thirdly, the bar is corroded; fourthly, cold drawing is conducted; fifthly, the alloy fiber with the target diameter are manufactured; and sixthly, the alloy fiber is annealed after cold drawing. By means of the method, the problem that the CuZnAl or CuZn alloy continuous fiber is low in yield strength under the room temperature condition, and consequently, shape memory, superelasticity and the damping characteristic are affected are solved; in addition, a cold drawing method is utilized for enabling the thick bar to be subjected to cold drawing to become the CuZnAl or CuZn alloy continuous fiber with the diameter being dozens of microns to hundreds of micrometers, and the problem that the difficulty of manufacturing the CuZnAl or CuZn alloy continuous fiber even in diameter and small in fiber is high is solved; and the method is suitable for manufacturing the CuZnAl or CuZn alloy continuous fiber.

Owner:HARBIN INST OF TECH

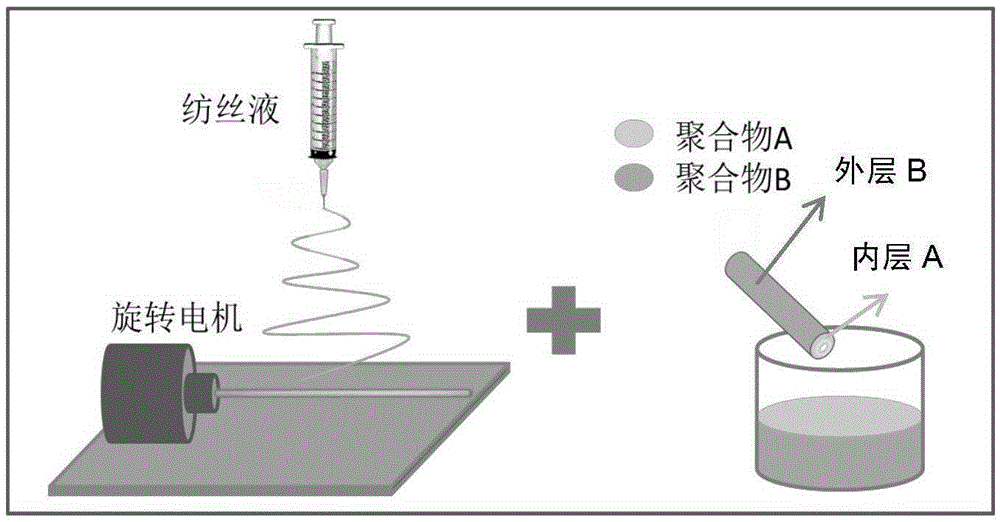

Drug-loading nano fiber having sheath and containing double-core structural feature and preparation method thereof

InactiveCN106821954AClear juxtapositionSmall diameterOrganic active ingredientsPharmaceutical non-active ingredientsFiberPolymer substrate

The invention provides a drug-loading nano fiber having a sheath and containing a double-core structural feature. The nano fiber comprises two inner core parts, wherein the periphery of the two inner core parts is provided with an outer sheath part; the outer sheath part and the inner core parts extend in the length direction; the outer sheath part is composed of a water-soluble polymer; one inner core part is composed of a stomach dissolving type polymer, and the other inner core part is composed of an intestine dissolving type polymer; and drugs are contained in the outer sheath part and the two inner core parts. The invention also provides a preparation method of the nano fiber. According to the invention, different polymer base materials are used for the sheath part and the core parts, and three-stage gradual release of loaded drugs can be regulated by the nano fiber under the structural support. The method provided by the invention is simple in preparation process and realizes single-step effectiveness; the parallel structure contained in the prepared nano fiber sheath is clean; and the nano fiber is small in diameter, favorable in linearity, uniform in diameter distribution and smooth in fiber surface.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Nanofiber capable of providing slow controlled release of medicines after pulse and preparation method of nanofiber

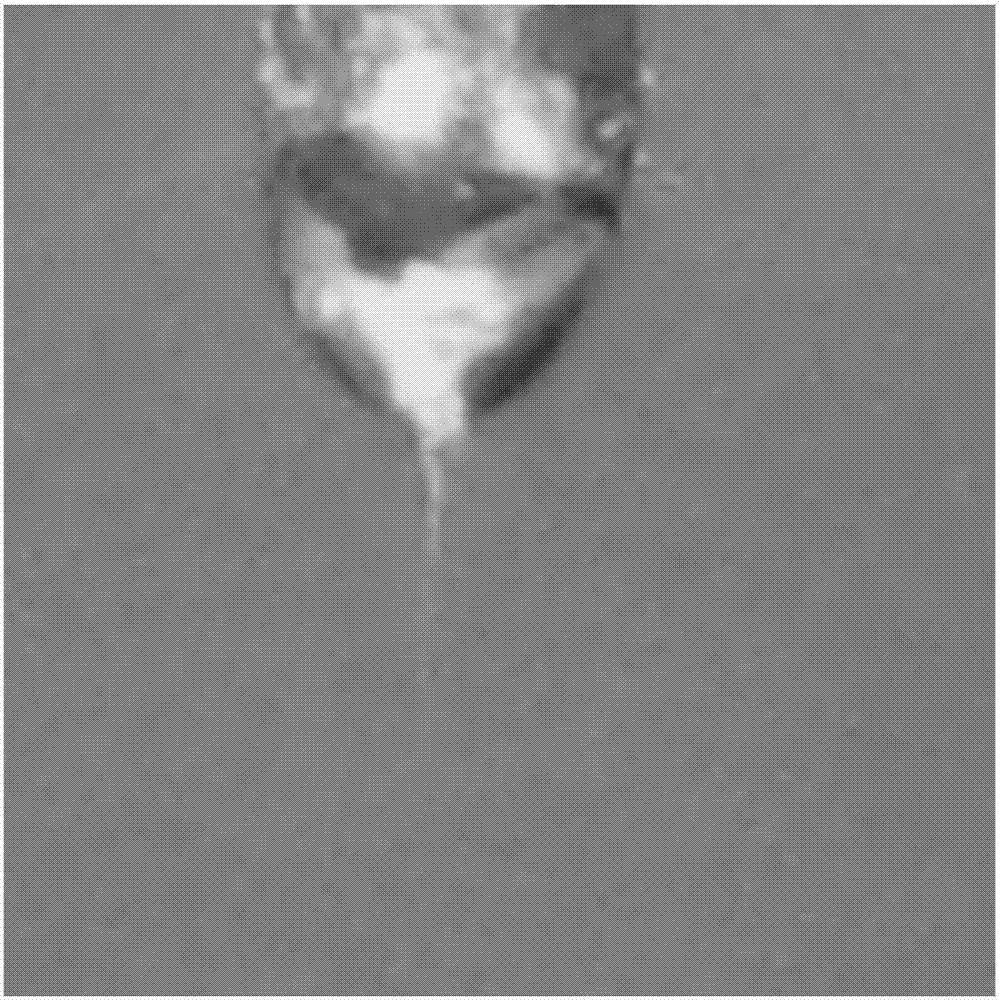

InactiveCN106880585AClear juxtapositionSmall nanometer diameterFilament/thread formingPharmaceutical delivery mechanismControlled releaseFiber bundle

The invention provides a nanofiber capable of providing slow controlled release of medicines after pulse. The nanofiber comprises a main fiber bundle, wherein a parallel fiber bundle is arranged at the outer side of the main fiber bundle, the main fiber bundle and the parallel fiber bundle extend in the length direction, in the radial cross section, the parallel fiber bundle covers the periphery of the main fiber bundle by 40-70 %, and the main fiber bundle is composed of a medicine and a polymer pharmaceutic adjuvant insoluble in water; the parallel fiber bundle is composed of a medicine and a pharmaceutical adjuvant easily soluble in water. The invention further provides a preparation method of the nanofiber. The preparation method comprises the following steps: blending the medicine and the polymer pharmaceutical adjuvant insoluble in water into a consolute solution, and blending the medicine and the pharmaceutical adjuvant easily soluble in water into a consolute solution; controlling the rate of being injected into parallel spinning heads of the two solutions by adopting two injection pumps, and under the effect of high-voltage static electricity, by taking the outlets of the parallel spinning heads as a template, collecting the nanofiber by adopting a grounded fiber receiving flat plate; and preparing the nanofiber capable of providing slow controlled release of medicines after pulse.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

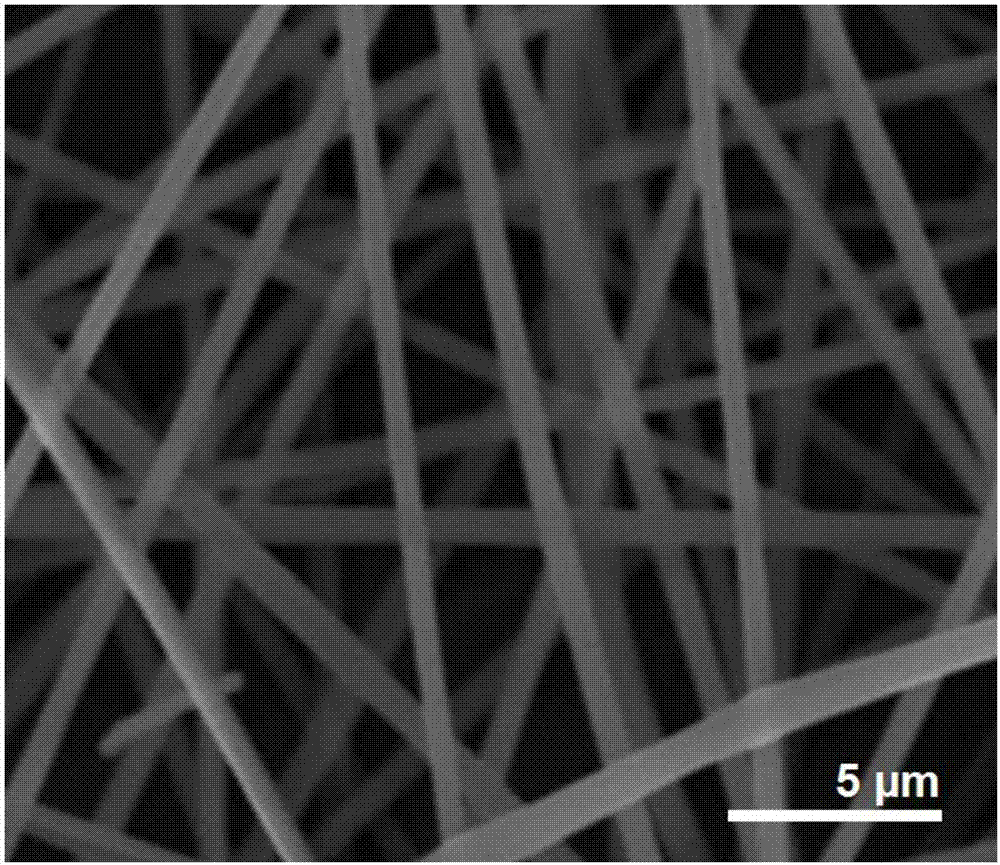

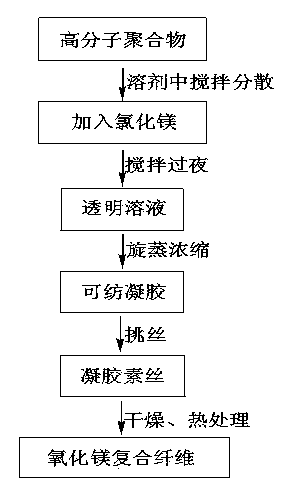

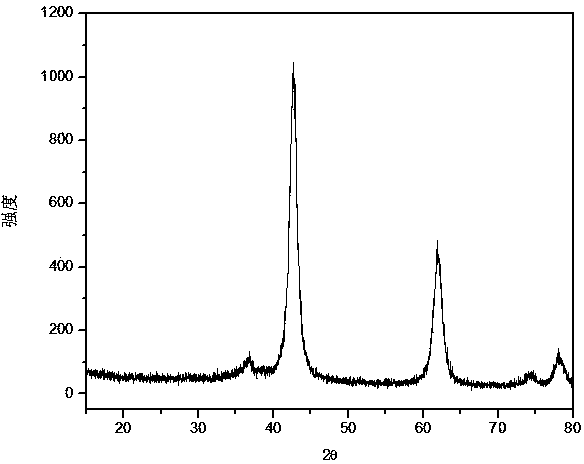

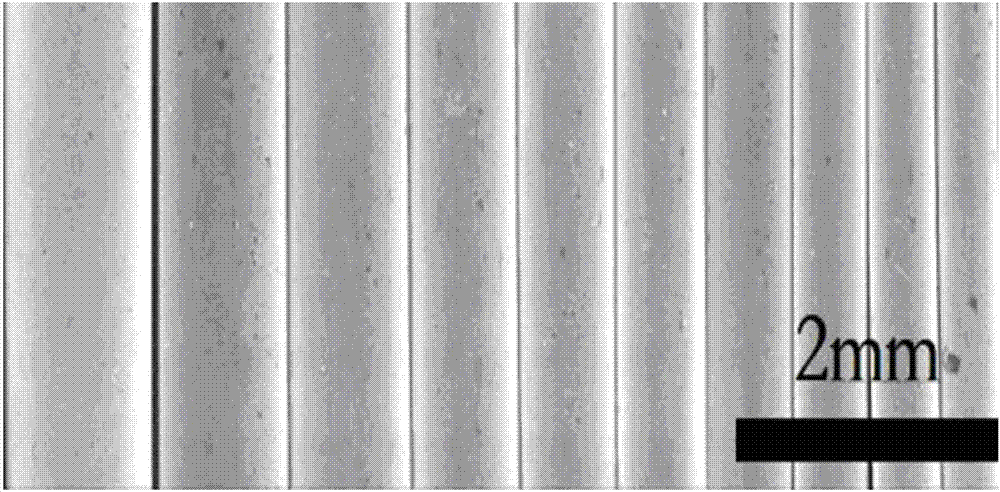

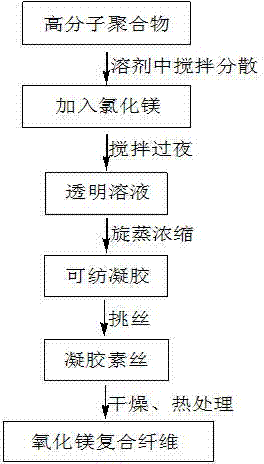

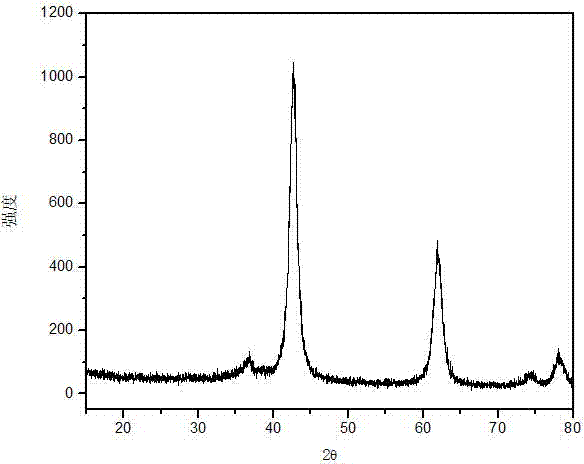

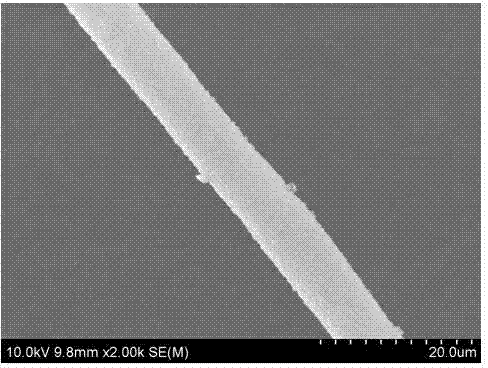

Method for preparing magnesium oxide composite fiber

The invention discloses a method for preparing a magnesium oxide composite fiber. The method is implemented by using a characteristic that a high-molecular polymer is easily formed into filaments and comprises the following steps: loading magnesium chloride on the high-molecular polymer so as to form a gel, and carrying out filament picking and calcining on the gel so as to obtain the magnesium oxide composite fiber. The obtained fiber is smooth in surface, has no significant defect, and has a relatively long length diameter, so that the fiber has good application prospect and good commercial value in the aspect of refractory and insulating materials.

Owner:EAST CHINA NORMAL UNIV

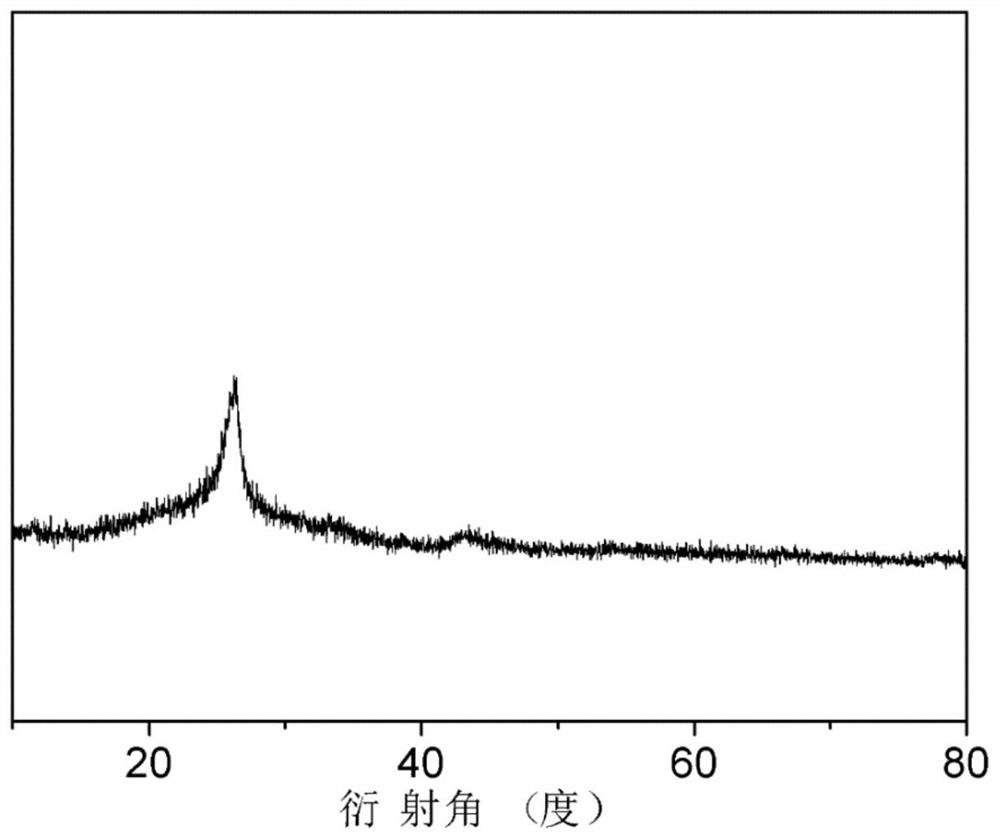

Preparation method of graphene fiber

The invention provides a preparation method of graphene fiber. The preparation method comprises the following steps that SiC fiber is heated in a vacuum environment and / or an inert gas environment, heating is conducted till the silicone element is degraded and effused, heat preservation is conducted, and the graphene fiber is obtained. the method takes SiC fiber as the raw material, and continuousindustrialized preparation of graphene fiber is achieved by adopting the simple technology.

Owner:NAT UNIV OF DEFENSE TECH

Flame-retardant fiber impregnating composition

The invention discloses a flame-retardant fiber impregnating composition. The flame-retardant fiber impregnating composition is characterized by being prepared from, by weight, 15-40 parts of liquid rubber, 10-25 parts of isocyanate, 5-15 parts of plasticizers, 5-12 parts of liquid petroleum tackifying resin, 3-6 parts of N-hydroxymethyl-3-(dimethoxyphosphonyl) propionamide and 5-10 parts of flame-retardant resin. According to the flame-retardant fiber impregnating composition, the advantages of resisting high temperature, being flame-retardant and high in bonding strength and the like are achieved, and due to the fact that the viscosity is small and the wettability is good, the good impregnating property on fibers is achieved; processed fiber yarn is smooth in surface and easy to weave and wind, the good bonding property with rubber and the smooth surface are achieved, no solvent is volatilized and energy consumption is low in the whole processing process, and the wide market value and the great market potential are achieved.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

Thermosetting internal combustion engine filter paper and preparation method thereof

PendingCN114687249AHigh strengthImprove breathabilityNatural cellulose pulp/paperPaper/cardboardPolyvinyl alcoholPlant fibre

The invention discloses thermosetting internal combustion engine filter paper and a preparation method thereof, and belongs to the technical field of papermaking. The thermosetting internal combustion engine filter paper is prepared from high-strength and high-modulus polyethylene fibers, plant fibers, aramid pulp and polyvinyl alcohol fibers through wet papermaking. Wherein the mass ratio of each fiber component is as follows: 30%-100% of the high-strength and high-modulus polyethylene fiber, 0%-50% of the plant fiber, 5%-20% of the aramid pulp and 1%-5% of the polyvinyl alcohol fiber. The preparation process of the thermosetting internal combustion engine filter paper comprises the following steps: (1) determining the ratio of fiber raw materials; (2) pulping plant fibers; (3) pretreating; (4) defibering the raw materials; the thermosetting internal combustion engine filter paper prepared by the preparation method disclosed by the invention has good hydrophobicity, excellent corrosion resistance, uniform pore size and excellent mechanical strength.

Owner:JIANGNAN UNIV

Environmentally-friendly wool and cotton blended fabric scale stripping treatment technology

InactiveCN105839390AActs as a lubricantEasy to handlePhysical treatmentBiochemical treatment with enzymes/microorganismsFiberUltrasound - action

The invention discloses an environment-friendly wool and cotton blended fabric descaling treatment process. Under the action of ultrasonic waves, the process includes double treatment of enzyme treatment and calcium carbonate grinding, which effectively improves the uniformity of descaling treatment on the wool surface, reduces the Cellular damage to the inner layer of the fiber improves the wearability and durability of wool blend fabrics. This process does not use heavy metals, halides and other substances harmful to the human body and the environment, and is an environmentally friendly fiber treatment process.

Owner:德清县新鑫达丝绸炼染有限公司

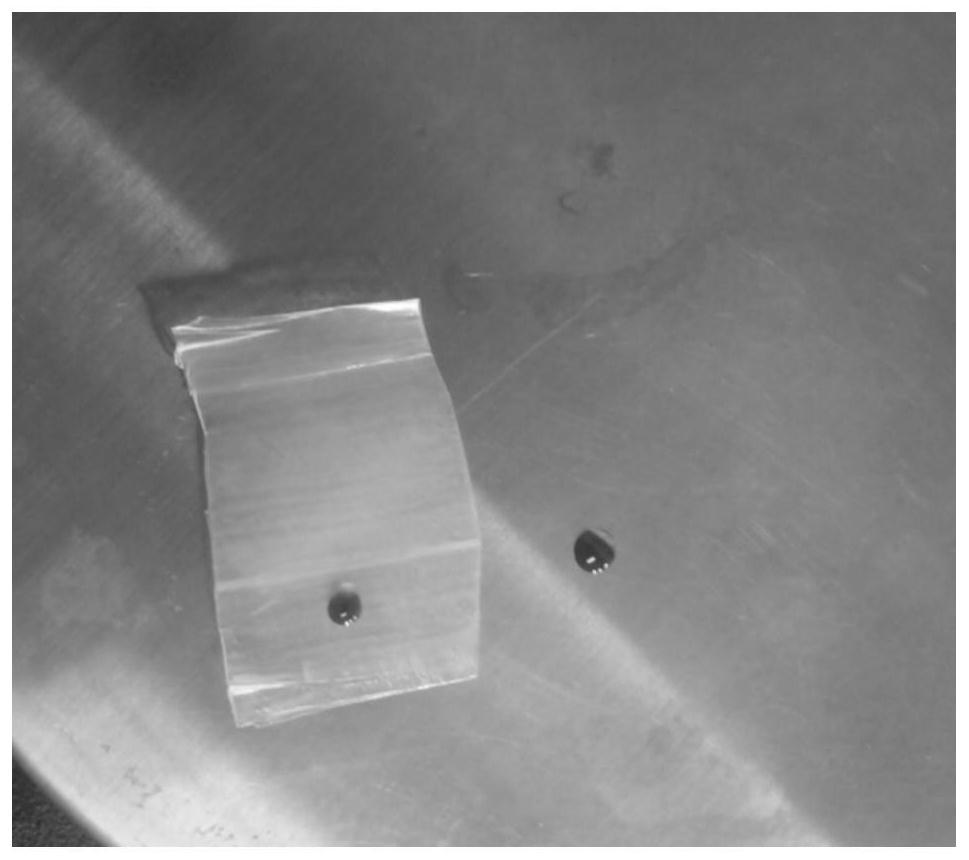

Nano-fibers with drug two-grade pulse releasing function and preparation method thereof

InactiveCN106860432AImplements secondary pulse release modeDissolve fastOrganic active ingredientsFilament/thread formingFiberWorking fluid

The invention provides nano-fibers with a drug two-grade pulse releasing function. Each nano-fiber comprises an inner core part and an sheath part, wherein the sheath part covers the inner core part; the inner core part and the sheath part extend along the length direction; the inner core part is composed of a drug and a polymer pharmaceutical excipient; the sheath part is composed of a drug and a pharmaceutical excipient which is easily dissolved into water. The invention further provides a preparation method of the nano-fibers; the preparation method comprises the following steps: blending the polymer pharmaceutical excipient and the drug of the inner core part to form a co-dissolved solution, and taking the blended solution as working fluid of the inner core part; blending the pharmaceutical excipient which is easily dissolved into the water and the drug of the sheath part to prepare a co-dissolved solution and taking the co-dissolved solution as working fluid of the sheath part; controlling speeds of injecting core and sheath solutions into a coaxial spinning head through two sets of injection pumps respectively; starting up a high-voltage generator and preparing the nano-fibers under the action of high voltage and static electricity. According to the nano-fibers provided by the invention, the sheath part and the inner core part of each nano-fiber adopt polymer matrixes with different dissolving performances, and the carried drugs can be regulated and controlled and be released in a two-grade pulse manner under the supporting of the structure.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

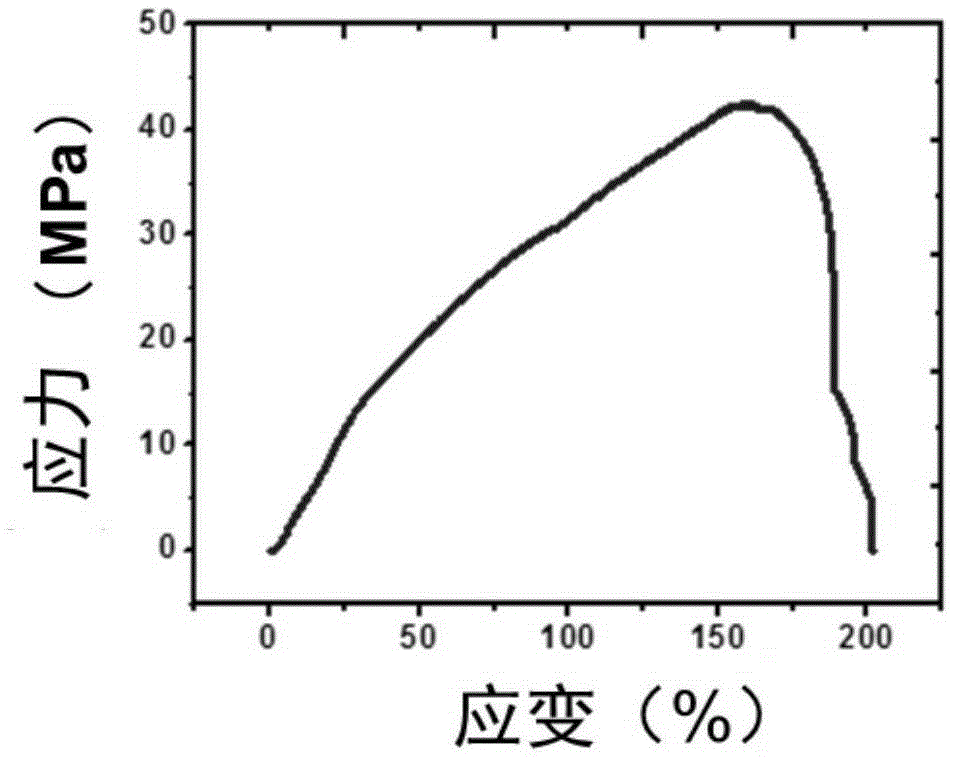

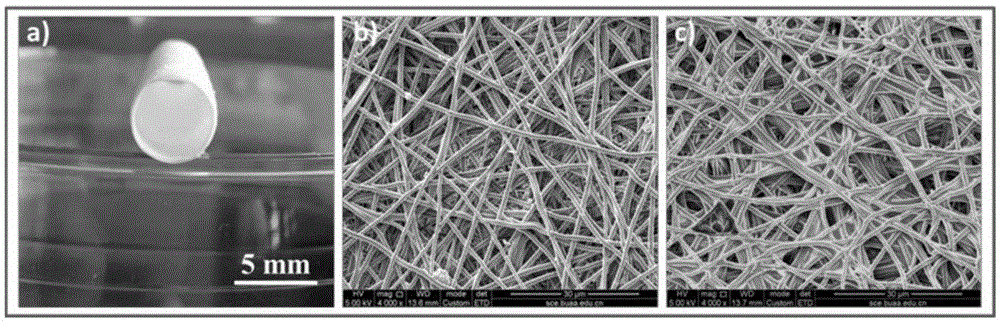

A kind of high-strength and high-elastic vascular stent and preparation method thereof

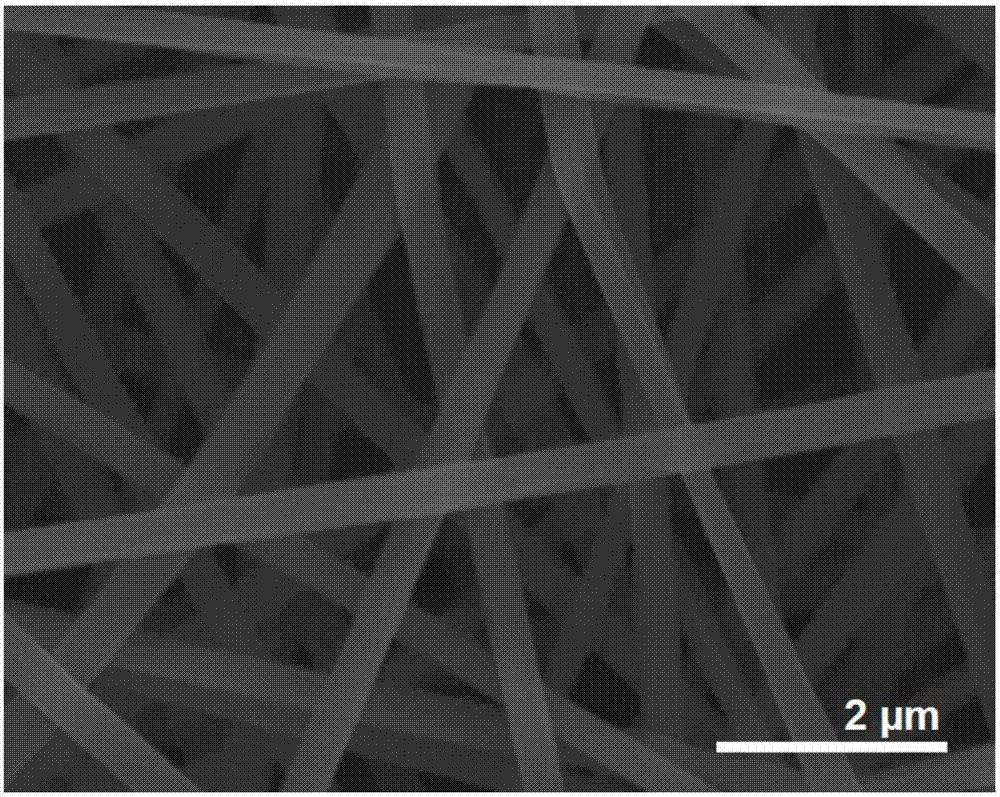

ActiveCN104383606BUniform shapeNarrow diameter distributionSurgeryFilament/thread formingHigh cellPorosity

The invention discloses a high-strength high-elasticity intravascular stent and a preparation method thereof and belongs to the field of chemical and ecological engineering. The high-strength high-elasticity intravascular stent has the advantages that a biocompatible polymer material is taken as a precursor; firstly, an electrostatic spinning method is adopted for preparing fibrous membranes with different mechanical properties; and on this basis, an electrospinning technology and a solution soaking and removing method are combined for preparing a high-strength, high-elasticity and high-porosity artificial intravascular stent, fibers used for forming the artificial intravascular stent are smooth in surface, uniform in morphology, narrow in fiber diameter distribution range, and excellent in vascular performance. The obtained artificial intravascular stent with high cell compatibility, strength, elasticity and porosity can be produced in a large scale and is expected to be applied to the actual clinical diagnosis.

Owner:BEIHANG UNIV

Preparation method of mulberry fibers

PendingCN114775067AAvoid damageHigh degumming rateVegetable materialBacteriological rettingBiotechnologyPectinase

The invention discloses a mulberry fiber preparation method which is simple and easy to operate, high in product economic benefit and suitable for large-scale production and processing. Before fiber extraction, mulberry bark is subjected to pretreatment such as beating and soaping, and the problem that microorganism-enzyme combined degumming is not thorough can be effectively solved. In the microbial fermentation process, bacteria take colloids as nutrient substances, macromolecular structures of the colloids in the mulberry bark are damaged, gaps among macromolecules are enlarged, fiber aggregates become loose, and enzyme secreted by microorganisms can conduct preliminary degumming on the mulberry bark. And performing biological enzyme degumming through combined treatment of cellulase, alkaline pectinase and neutral protease to obtain mulberry fibers. And further separating the fibers by using the vibration effect of an ultrasonic cell crusher to obtain micron-sized mulberry fibers. The prepared mulberry bark fiber is smooth in surface, high in degumming rate and small in fiber damage, chemical reagents are not used in the whole process, and the requirement for environmental protection is met.

Owner:SUZHOU UNIV

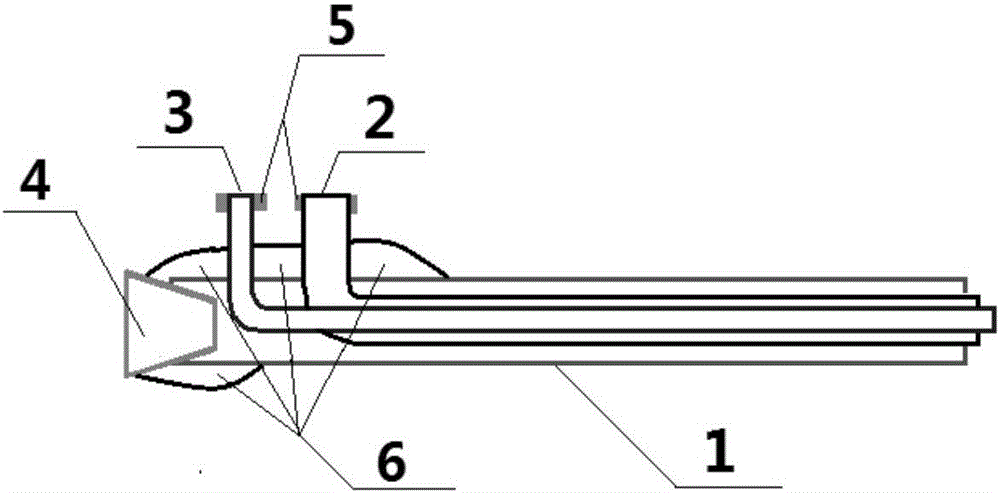

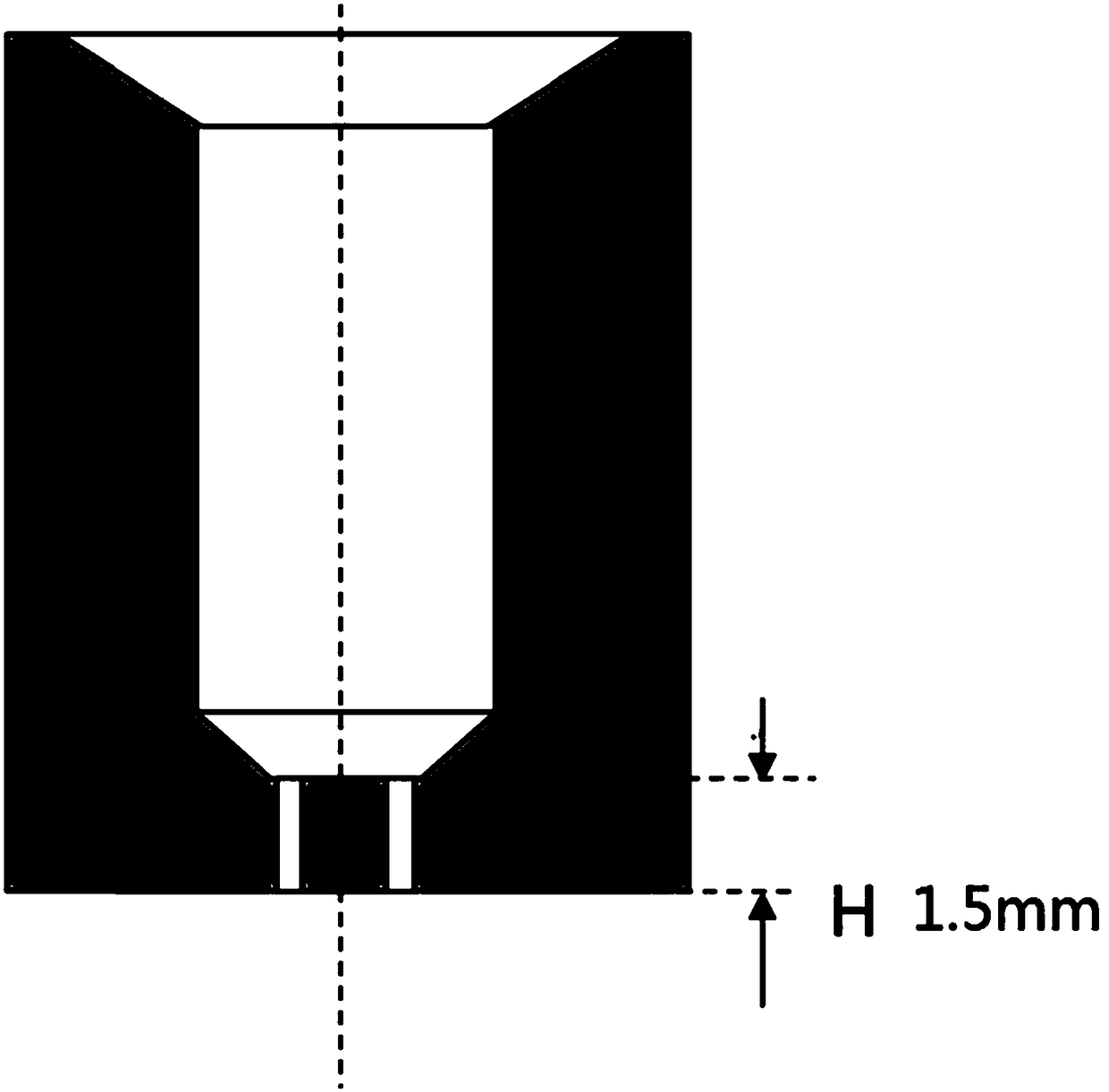

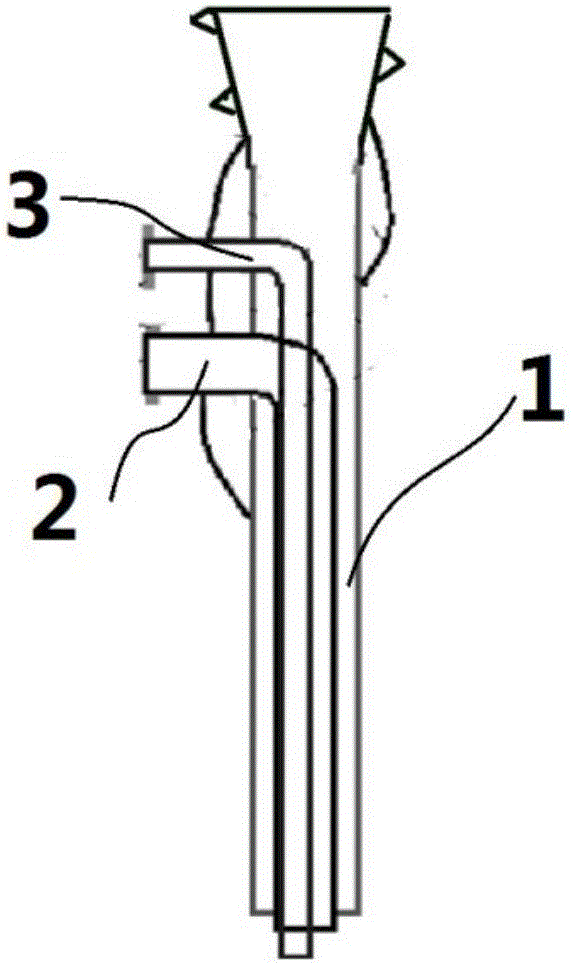

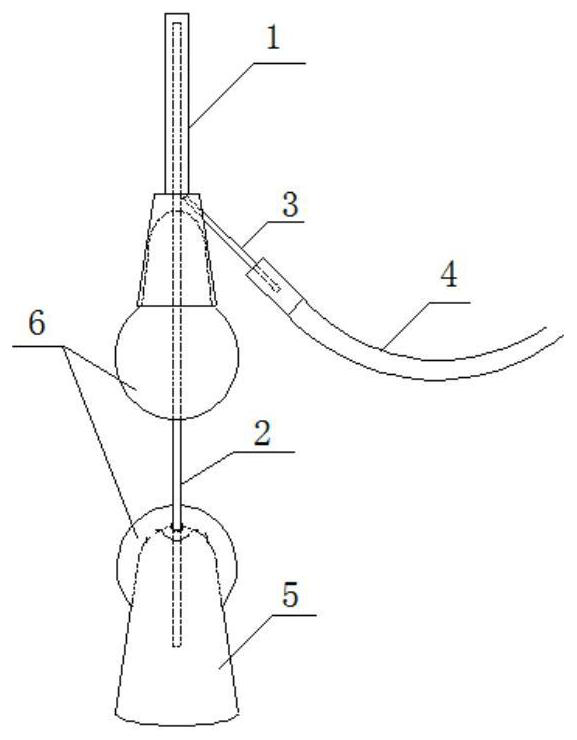

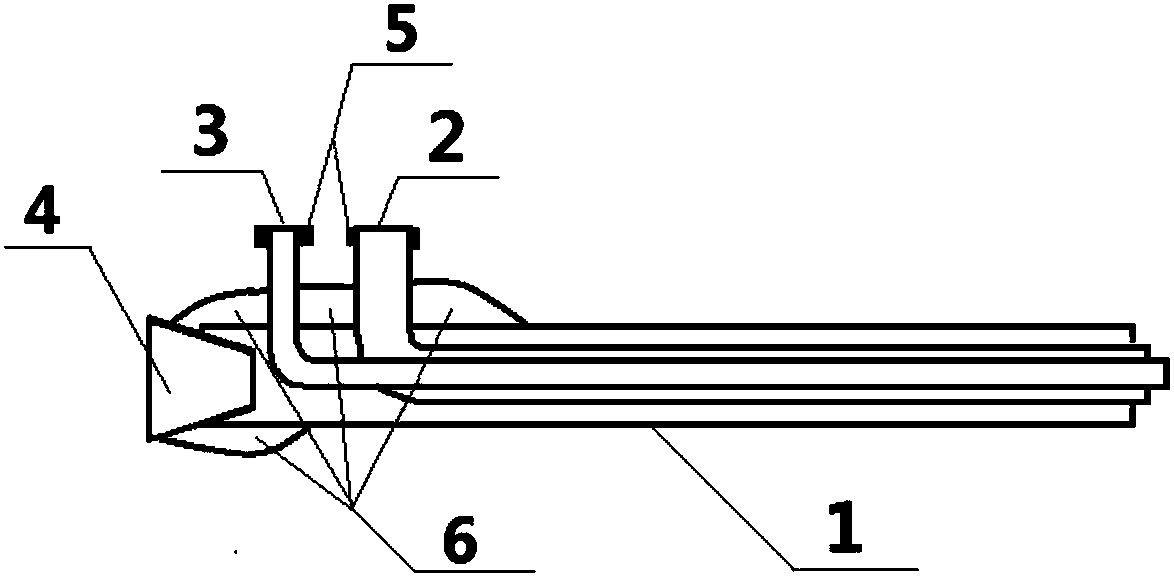

Detachable coaxial nozzle, electrospinning device and preparation method of core sheath nanofiber

ActiveCN109295511BReduce interactionAnti-lostFilament/thread formingTextile/flexible product manufactureNanofiberCapillary Tubing

The invention provides a detachable coaxial nozzle, an electrospinning device and a preparation method of core-sheath nanofibers. The detachable coaxial nozzle includes an insulating polymer tube, a core liquid guiding metal capillary and a sheath liquid injection needle. The back end of the material tube is detachably connected with the core fluid guiding metal capillary, and one end of the sheath fluid injection needle communicates with the insulating polymer tube. The invention has a series of advantages, such as: 1) the operation of coaxial electrospinning is convenient and the process is smooth; 2) the nozzle is easy to clean after electrospinning; 3) the design of the nozzle conforms to the basic principle of electro-fluid interaction, which is highly efficient and energy-saving Effect; 4) The axis of the nozzle is precise, and high-quality core-sheath nanofibers can be prepared. The invention has the advantages of simple process, single-step feasible, energy-saving and high-efficiency in the preparation of high-quality core-sheath nanofibers with complete structure.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

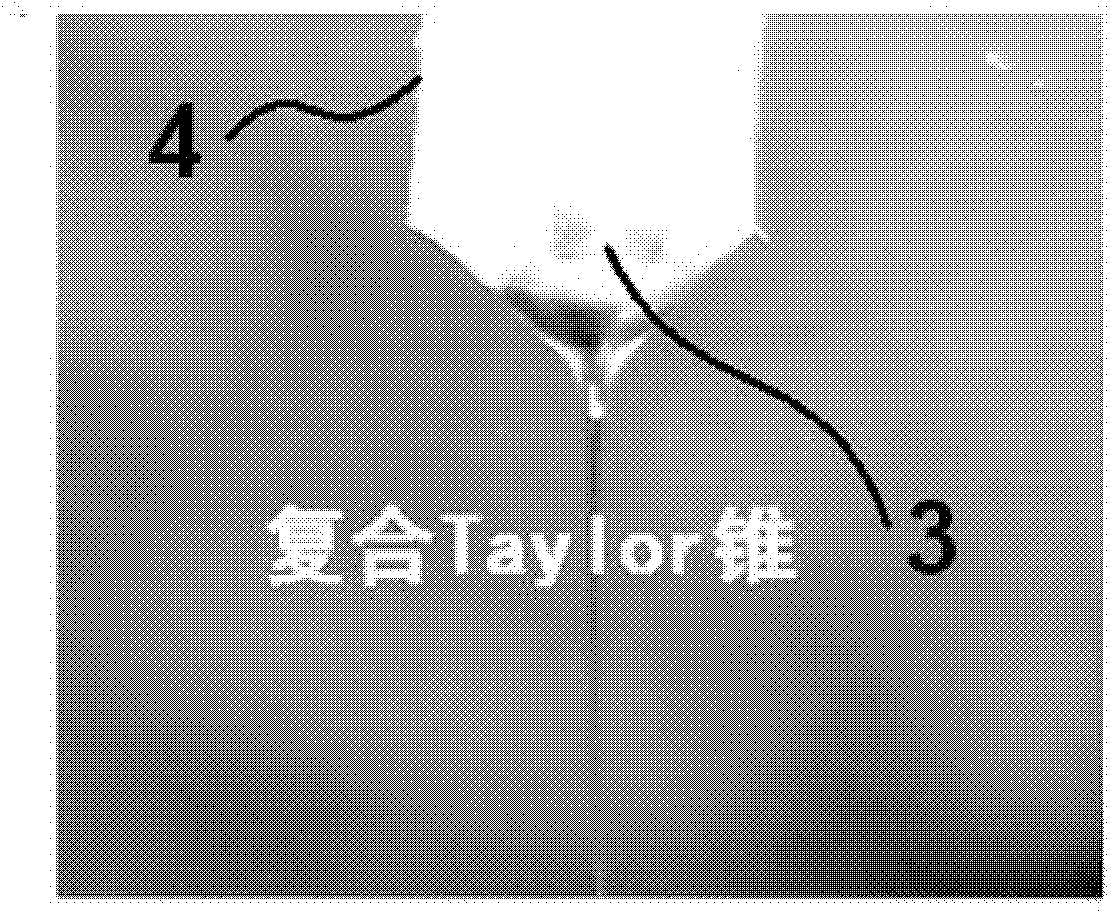

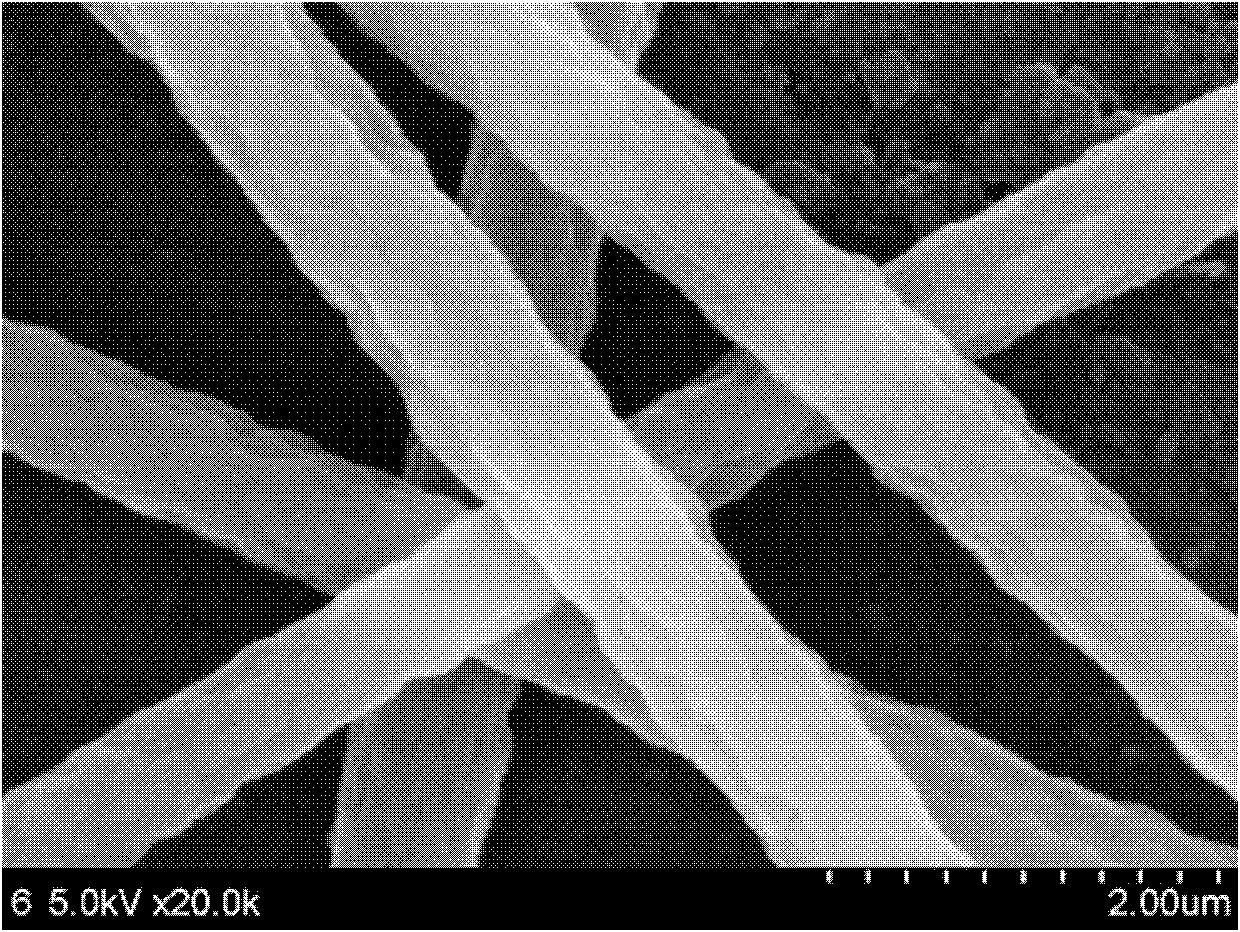

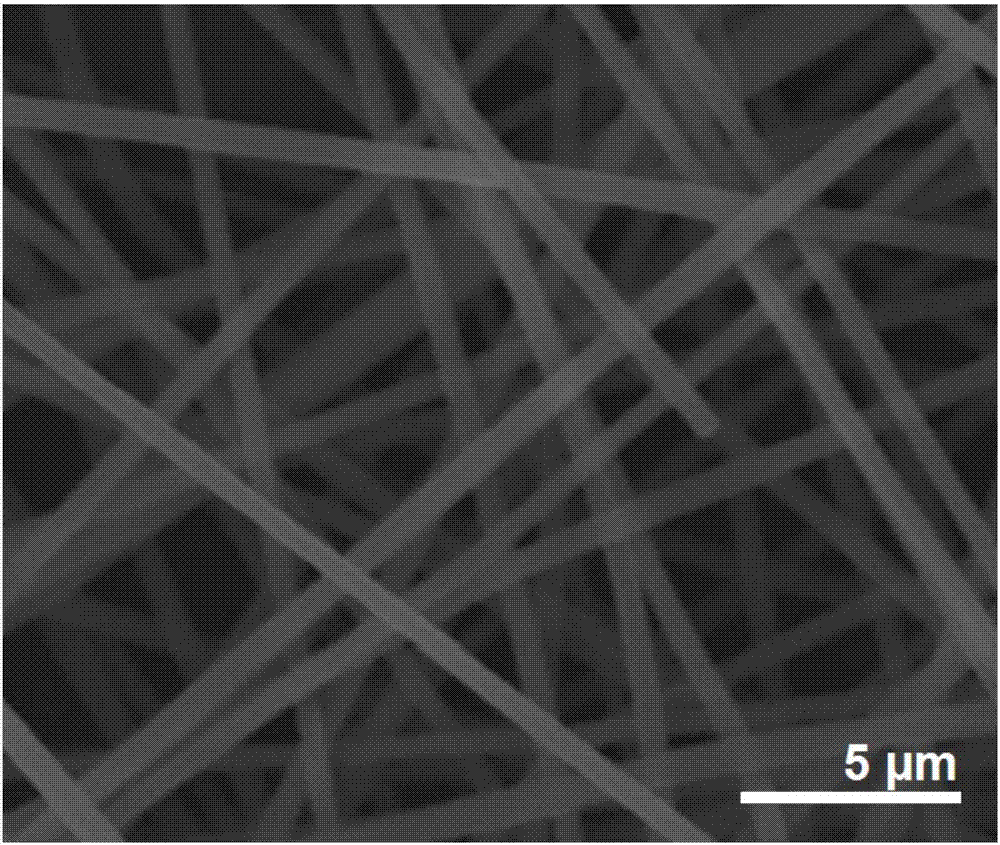

Method for preparing polyacrylonitrile nano-fibers by circulation and coaxial electrospinning of surface active agent solution

InactiveCN102517670BSmall diameterEvenly distributedFilament/thread formingMonocomponent synthetic polymer artificial filamentN dimethylformamideNanofiber

The invention discloses a method for preparing polyacrylonitrile nano-fibers by circulation and coaxial electrospinning of a surface active agent solution. Self-assembly coaxial spinning heads are adopted for electrospinning. The method is characterized in that outer sheath fluid for coaxial electrospinning is the surface active agent solution. A surface active agent comprises cationic, anionic and nonionic surface active agents dissolved in N,N-dimethylformamide, N,N-dimethylacetylamide or dimethylsulfoxide. The concentration of the surface active agent is 1%-6% (w / v). According to the method, the preparation process is simple, the prepared polyacrylonitrile nano-fibers are not only small in diameter and uniform in distribution, but also low in diameter dispersion factor and smooth in surface, and the defects that the spinning process is interrupted due to the easy blockage of the spinning head, the produced polymer nano-fibers are poor in quality, and the like in the prior art can be overcome.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method of graphene fiber

The invention provides a method for preparing graphene fibers, which comprises the following steps: in a vacuum environment and / or an inert gas environment, the SiC fiber is subjected to a temperature-raising step, and the temperature is raised to the decomposition and escape temperature of silicon element, and then kept warm to obtain the graphene fiber. The method uses SiC fibers as raw materials, and adopts a simple process to realize the continuous industrial preparation of graphene fibers.

Owner:NAT UNIV OF DEFENSE TECH

A kind of cold drawing prepares the method for cuznal or cuzn alloy continuous fiber

The invention discloses a method for manufacturing CuZnAl or CuZn alloy continuous fiber through cold drawing and relates to a manufacturing method for alloy fiber. The method aims at solving the problems that a CuZnAl or CuZn alloy is low in yield strength, and the difficulty for manufacturing small fiber of the CuZnAl or CuZn alloy is high. The method includes the steps that firstly, an original cast ingot is manufactured; secondly, the original cast ingot is subjected to hot extrusion to form a bar; thirdly, the bar is corroded; fourthly, cold drawing is conducted; fifthly, the alloy fiber with the target diameter are manufactured; and sixthly, the alloy fiber is annealed after cold drawing. By means of the method, the problem that the CuZnAl or CuZn alloy continuous fiber is low in yield strength under the room temperature condition, and consequently, shape memory, superelasticity and the damping characteristic are affected are solved; in addition, a cold drawing method is utilized for enabling the thick bar to be subjected to cold drawing to become the CuZnAl or CuZn alloy continuous fiber with the diameter being dozens of microns to hundreds of micrometers, and the problem that the difficulty of manufacturing the CuZnAl or CuZn alloy continuous fiber even in diameter and small in fiber is high is solved; and the method is suitable for manufacturing the CuZnAl or CuZn alloy continuous fiber.

Owner:HARBIN INST OF TECH

A kind of preparation method of magnesium oxide composite fiber

The invention discloses a method for preparing a magnesium oxide composite fiber. The method is implemented by using a characteristic that a high-molecular polymer is easily formed into filaments and comprises the following steps: loading magnesium chloride on the high-molecular polymer so as to form a gel, and carrying out filament picking and calcining on the gel so as to obtain the magnesium oxide composite fiber. The obtained fiber is smooth in surface, has no significant defect, and has a relatively long length diameter, so that the fiber has good application prospect and good commercial value in the aspect of refractory and insulating materials.

Owner:EAST CHINA NORMAL UNIV

An electrospun nanofiber with drug radial isolation distribution characteristics and preparation method thereof

InactiveCN106757502BClear structureSmall nanometer diameterOrganic active ingredientsFilament/thread formingFiberElectrospun nanofiber

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Conductive blended textile

InactiveCN107687045ASmooth fiber surfaceImprove spinning efficiencyWeft knittingLayered productsYarnPolymer science

The invention discloses a conductive blended textile. The conductive blended textile comprises a fabric main body and a functional coating layer, the fabric main body is interwoven by yarns, and a plurality of breathable holes are formed in the surface of the functional coating; the yarns are made by blending of wool fibers, conductive fibers and jute fibers or other fibers, wherein the diameter of the wool fibers is 56.84 micrometers, the fineness of the wool fibers is 523 dtex, the density of the wool fibers is 28.6 strips / cm, the diameter of the conductive fibers is 9.07 micrometers, the fineness of the conductive fibers is 113 dtex, the density of the conductive fibers is 37.7 strips / cm, the diameter of the jute fibers is 70.33 micrometers, the fineness of the jute fibers is 657 dtex,the density of the jute fibers is 46.3 strips / cm, the diameter of the other fibers is 43.89 micrometers, the fineness of the other fibers is 411 dtex, and the density of the other fibers is 53.2 strips / cm. The conductive blended textile has the advantages that solvent does not evaporate in the spinning process, the surface of the fibers is smooth, the spinning efficiency is greatly improved, and energy and the cost are saved.

Owner:太仓市明烨化纤有限公司

An electrospun nanofiber with discrete and uneven drug distribution characteristics and its preparation method

InactiveCN106835300BSimple structureClear structureConjugated cellulose/protein artificial filamentsElectro-spinningFiberMedicine

The invention provides an electro-spinning nano fiber with discrete uneven distribution characteristics of drugs. The fiber comprises a core part. A sheath part is arranged at the outer circle of the core part. The core part and the sheath part extend coaxially. The inside of the core part is loaded with drugs. One side of the sheath part is provided with a parallel outer surface layer. The parallel outer surface layer extends in the length direction, and covers 40-60% of the outer circle of the sheath part. The inside of the parallel outer surface layer is loaded with drugs. The invention further provides a preparation method of the nano fiber, and a device for achieving the preparation method. The electro-spinning nano fiber with discrete uneven distribution characteristics of drugs has the advantages of being simple in preparation process, effective in a single step, clear in the structure of the prepared nano fiber, small in nano-particle diameter, good in linearity, uniform in diameter distribution and smooth in fiber surface. The uneven distribution characteristics of drugs provides an effective implementation method for the design of a plurality of new drug slow release materials.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

An electrospun nanofiber with drug gradient distribution characteristics and its preparation method

InactiveCN106801261BClear structureSmall nanometer diameterFilament/thread formingArtificial filaments from cellulose derivativesFiberElectrospun nanofibers

The invention provides a drug-loaded nanofiber with drug gradient distribution characteristics. The nanofiber comprises an inner core layer, the periphery of the inner core layer is provided with an interlayer, the periphery of the interlayer is provided with an outer surface layer, the inner score layer, the interlayer and the outer surface layer extend coaxially, the inner core layer, the interlayer and the outer surface layer all contain drugs, and drug concentration increases in sequence from outside to inside in gradient distribution. The invention further provides a preparation method of the nanofiber with the drug gradient distribution characteristics and provides a device for achieving the method. According to the preparation method of the nanofiber with the drug gradient distribution characteristics, the preparation process is simple, and effective with single step, the prepared nanofiber inner core layer, interlayer and outer layer are clear in structure, and the nano is small in diameter, good in linearity, even in diameter distribution and smooth in fiber surface. The drug gradient distribution method is capable of providing an effective implementation method for the design and preparation of a great number of drug slow and controlled materials.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Electrospinning preparation method of nanofibers with material gradient distribution characteristics

InactiveCN106381532BClear structureSimple preparation processMonocomponent cellulose artificial filamentElectro-spinningFiberWorking fluid

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Nanofiber with medicine material radial and reverse distribution characteristics and preparation method thereof

InactiveCN106929928AFacilitated releaseClear structureMaterial nanotechnologyConjugated cellulose/protein artificial filamentsControl releaseMaterial Design

The invention provides a nanofiber with medicine material radial and reverse distribution characteristics. The nanofiber comprises an inner core part, wherein an outer sheath part is arranged at the periphery of the inner core part; the inner core part and the outer sheath part coaxially extend; medicine and polymer materials are contained in the inner core part and the outer sheath part; the concentration of the medicine is in progressive increase distribution along the fiber diameter direction from outside to inside; the concentration of the polymer materials is in progressive decrease distribution along the fiber diameter direction from outside to inside. An effective implementation method can be provided for slow controlled release material design and preparation of various kinds of novel medicine through the medicine material radial and reverse distribution structure characteristics of the nanofiber. The nanofiber has the advantages that the preparation process is simple; the single step is effective; the core sheath structure of the prepared nanofiber is clear; the nanometer diameter is small; the linearity is good; the diameter distribution is uniform; the fiber surface is smooth.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com