An electrospun nanofiber with discrete and uneven drug distribution characteristics and its preparation method

A technology of electrospinning nanofibers and uniform distribution, which is applied in the field of materials science, can solve the problems of poor slow-release effect of nanofibers, and achieve remarkable technological progress, smooth fiber surface, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

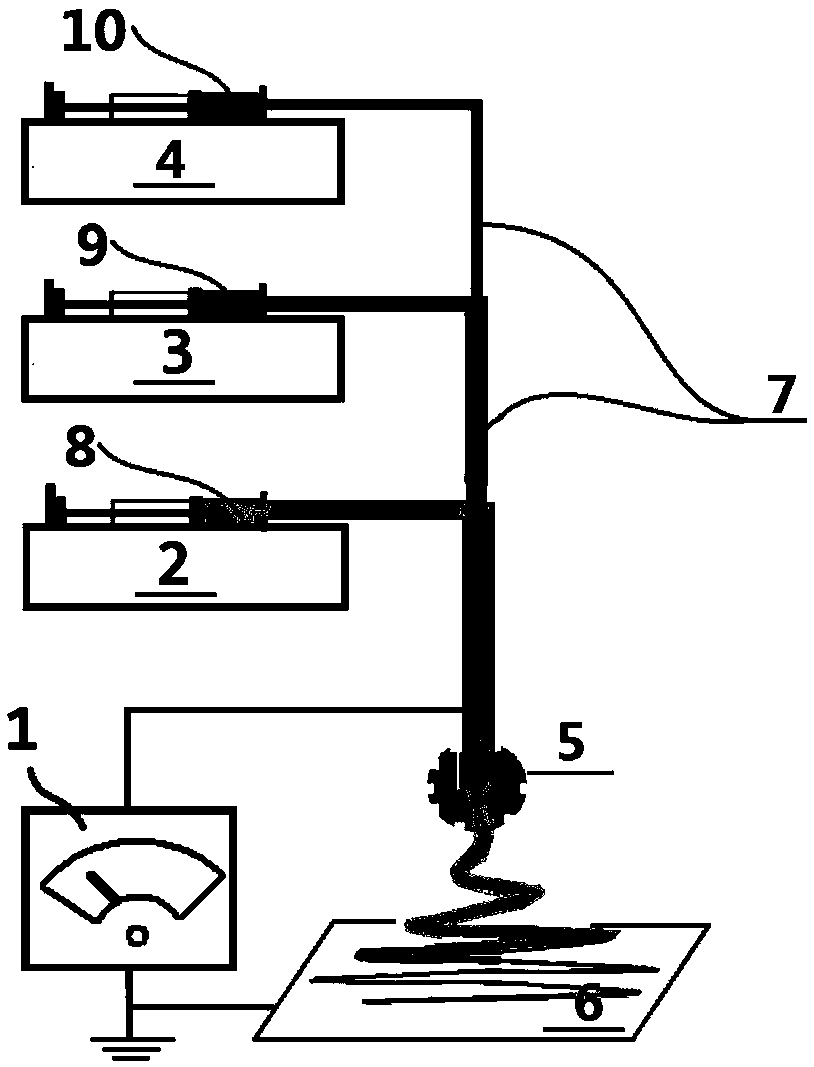

[0027] Example 1: Implementation of coaxial electrospinning process on one side in parallel

[0028] 8 grams of polyvinylpyrrolidone and 2 grams of ketoprofen were co-dissolved in 100 grams of ethanol to prepare the working fluid for the outer layer. Put 44 grams of ethyl cellulose into 200 grams of ethanol to make a mother liquor with good spinning properties. The above mother liquor was equally divided into two parts. A part of them directly uses the sheath liquid of the parallel coaxial side, and the other part is added with 8 grams of ketoprofen, and after co-dissolving into a uniform solution, it is used as the core liquid of the parallel coaxial side. Fill the above three working fluids into syringes and install them on the corresponding syringe pumps, connect the fluids of each layer to each inlet of the three-stage combined spinning head, and connect the high-voltage spinning head and the high-voltage electrostatic generator.

[0029] According to the following proce...

Embodiment 2

[0033] Example 2: Characterization analysis of the morphology and structure of nanofibers with discrete and uneven distribution of drugs

[0034] Field emission scanning electron microscopy (FESEM) was used to observe the surface of the fiber prepared in Example 1 after spraying gold, and the results were as follows Figure 4 shown. The prepared fiber exhibits a good linear state, no beading structure occurs, the fiber surface is smooth, and the fiber accumulation is uniform. The diameter is 710 ± 140 nm, the distribution is relatively uniform, and the diameter distribution is relatively concentrated.

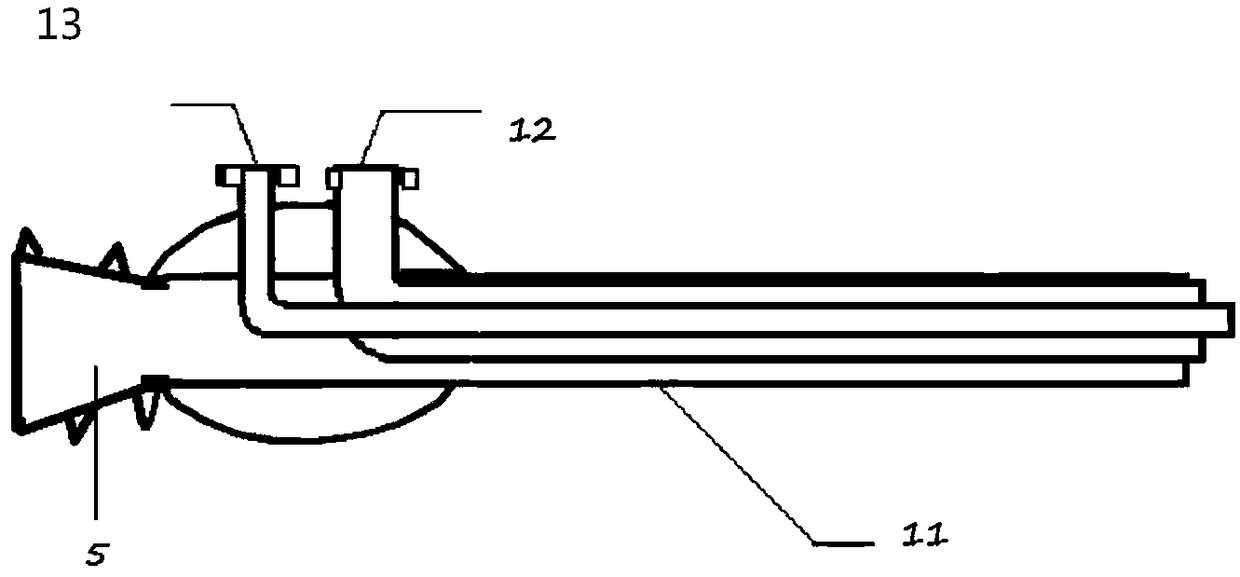

[0035] The internal structure of the prepared fiber was observed by high-resolution transmission electron microscope (TEM), and the results were as follows: Figure 5 As shown, the juxtaposed side of the nanofibers contains a clear coaxial structure, and the sheath of the coaxial side shows a lower gray feature because the blank does not contain drugs.

[0036] Schematic dia...

Embodiment 3

[0039] The sustained and controlled release performance of ketoprofen provided by nanofibers with discrete and uneven drug distribution characteristics:

[0040] According to the 2015 edition of Chinese Pharmacopoeia Appendix ⅩD Release Test Method 2, the RCZ-8A intelligent dissolution tester was used to conduct the in vitro dissolution test on the drug-loaded nanofibers obtained above. The speed was controlled at 50rpm, the temperature was 37±0.1°C, and the dissolution medium was 900mL of pH7.2 phosphate buffer solution to investigate the in vitro drug release performance of nanofibers with discrete and uneven drug distribution characteristics. Sampling 5mL at the scheduled time to obtain a sample of the dissolution solution, and immediately replenish the same volume of isothermal fresh medium. After appropriate dilution of the sample, at λ max = 257 nm place, adopt ultraviolet-visible spectrophotometer to carry out ultraviolet measurement, calculate drug ketoprofen dissolu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com